Drying method for panax notoginseng primary processing in drying room

A drying method and technology of notoginseng, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of drying chaos in the notoginseng drying room and confusion of notoginseng, and achieve the effect of preventing the confusion of notoginseng

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of notoginseng primary processing drying room drying method, comprises the following steps:

[0029] The first step is equipment inspection, check the working condition of the equipment in the drying room;

[0030] The second step is to put the Panax notoginseng on the baking tray evenly;

[0031] The third step is to install the rack, and place the plated Panax notoginseng on the grill;

[0032] The fourth step is to bake with the burner, start the burner to dry the grill in the drying room;

[0033] The fifth step is grinding, and the dried Panax notoginseng is used to treat the surface with a grinding machine;

[0034] The sixth step is to plate again, put the polished Panax notoginseng on the plate again and push it to the solar greenhouse for drying.

[0035] In use, the drying steps in the drying room are arranged reasonably in the drying room, and different batches of notoginseng in different production areas are dried in the drying room to prevent the ...

Embodiment 2

[0037] A kind of notoginseng primary processing drying room drying method, comprises the following steps:

[0038] The first step is equipment inspection, check the operation of the heating fan, circulation fan and dehumidification fan in the drying room, and check the water level of the water tank in the drying room;

[0039] The second step is to put the Panax notoginseng on the baking tray evenly, and the thickness of the Panax notoginseng after loading is 1cm lower than the upper edge of the baking tray;

[0040] The third step is to install racks, place the plated Panax notoginseng on the grill, and push it into the drying room, and place 10 grills in each drying room;

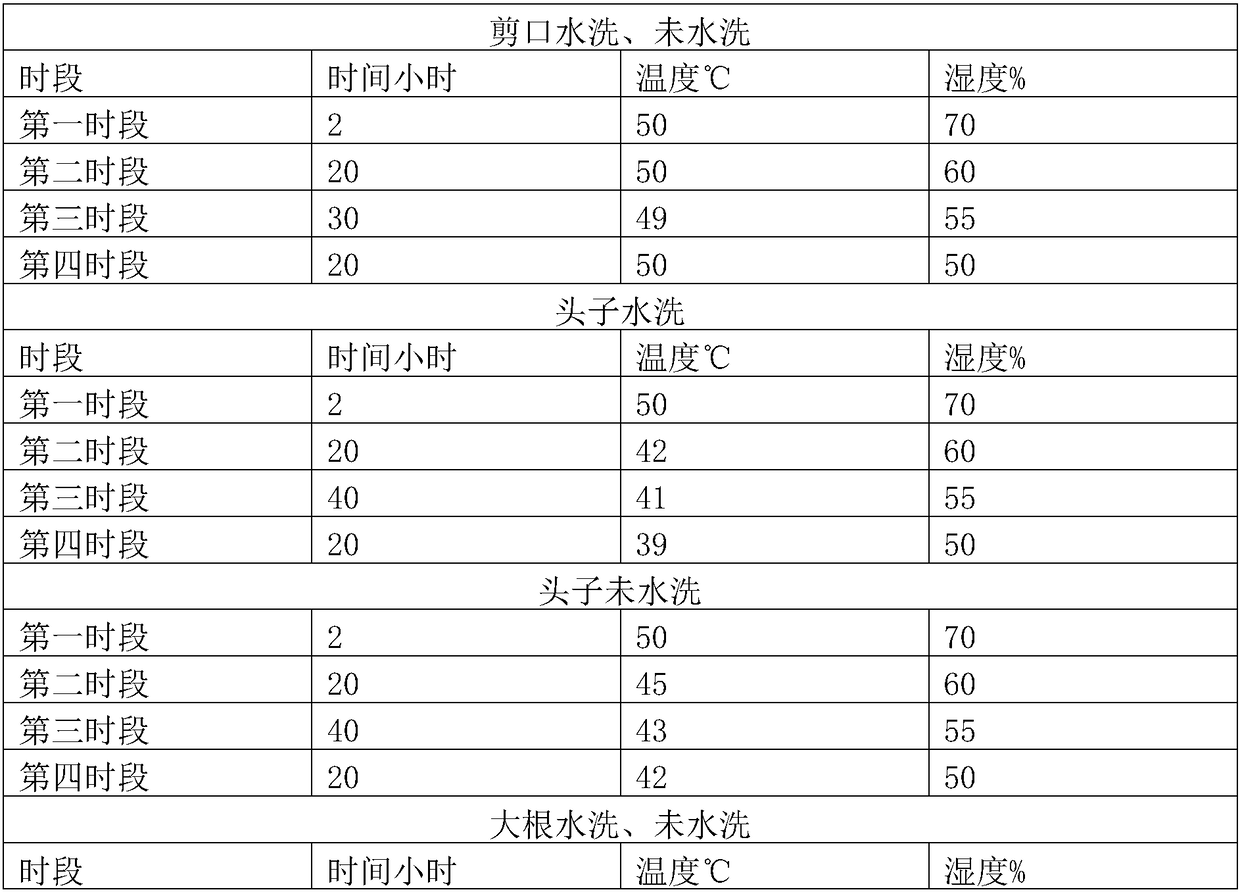

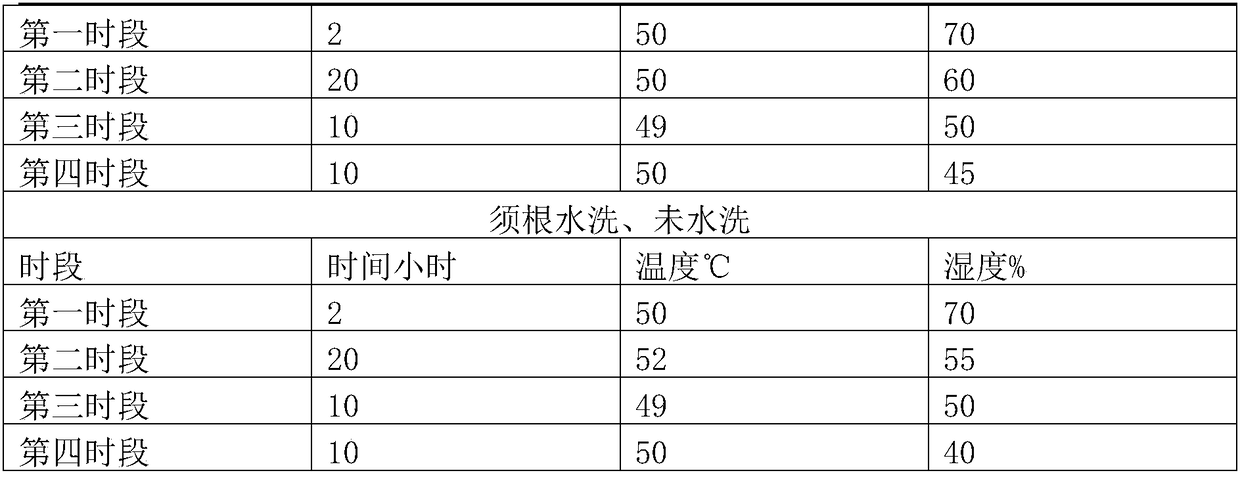

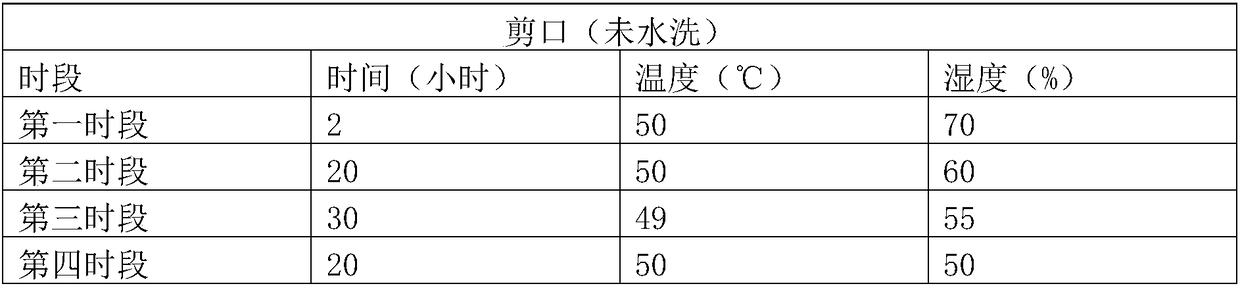

[0041] The fourth step is to bake the burner, start the burner to dry the grill in the drying room, press and hold the start button, the burner is in the working state, the ignition and feeding are automatically completed, and the gear of the burner is adjusted according to the heating situation of the dr...

Embodiment 3

[0047] A kind of notoginseng primary processing drying room drying method, comprises the following steps:

[0048] The first step is equipment inspection, check the operation of the heating fan, circulation fan and dehumidification fan in the drying room, and check the water level of the water tank in the drying room;

[0049] The second step is to put the Panax notoginseng on the baking tray evenly, and the thickness of the Panax notoginseng after loading is 1cm lower than the upper edge of the baking tray;

[0050] The third step is to install racks, place the plated Panax notoginseng on the grill, and push it into the drying room, with 14 baking racks placed in each drying room;

[0051] The fourth step is to bake the burner, start the burner to dry the grill in the drying room, press and hold the start button, the burner is in the working state, the ignition and feeding are automatically completed, and the gear of the burner is adjusted according to the heating condition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com