Patents

Literature

125results about How to "Stable and reliable feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

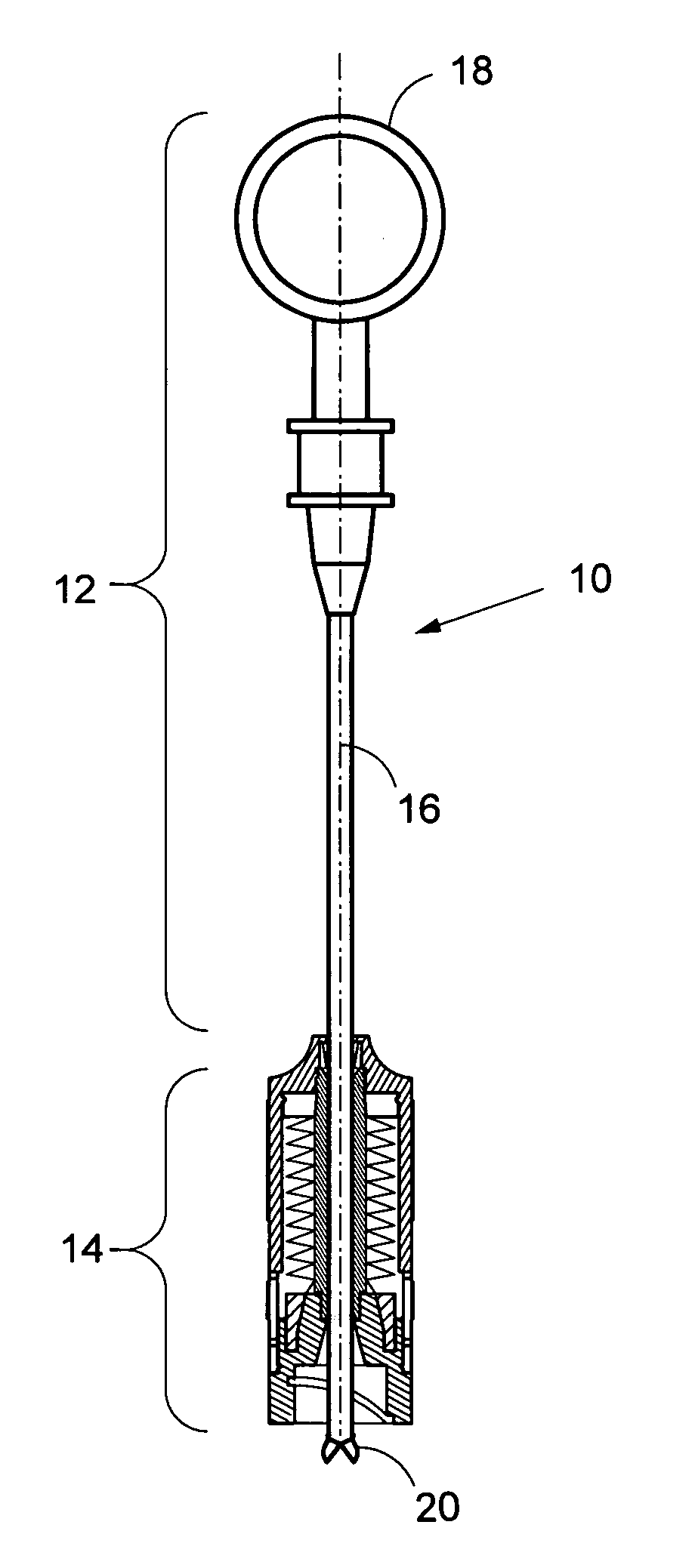

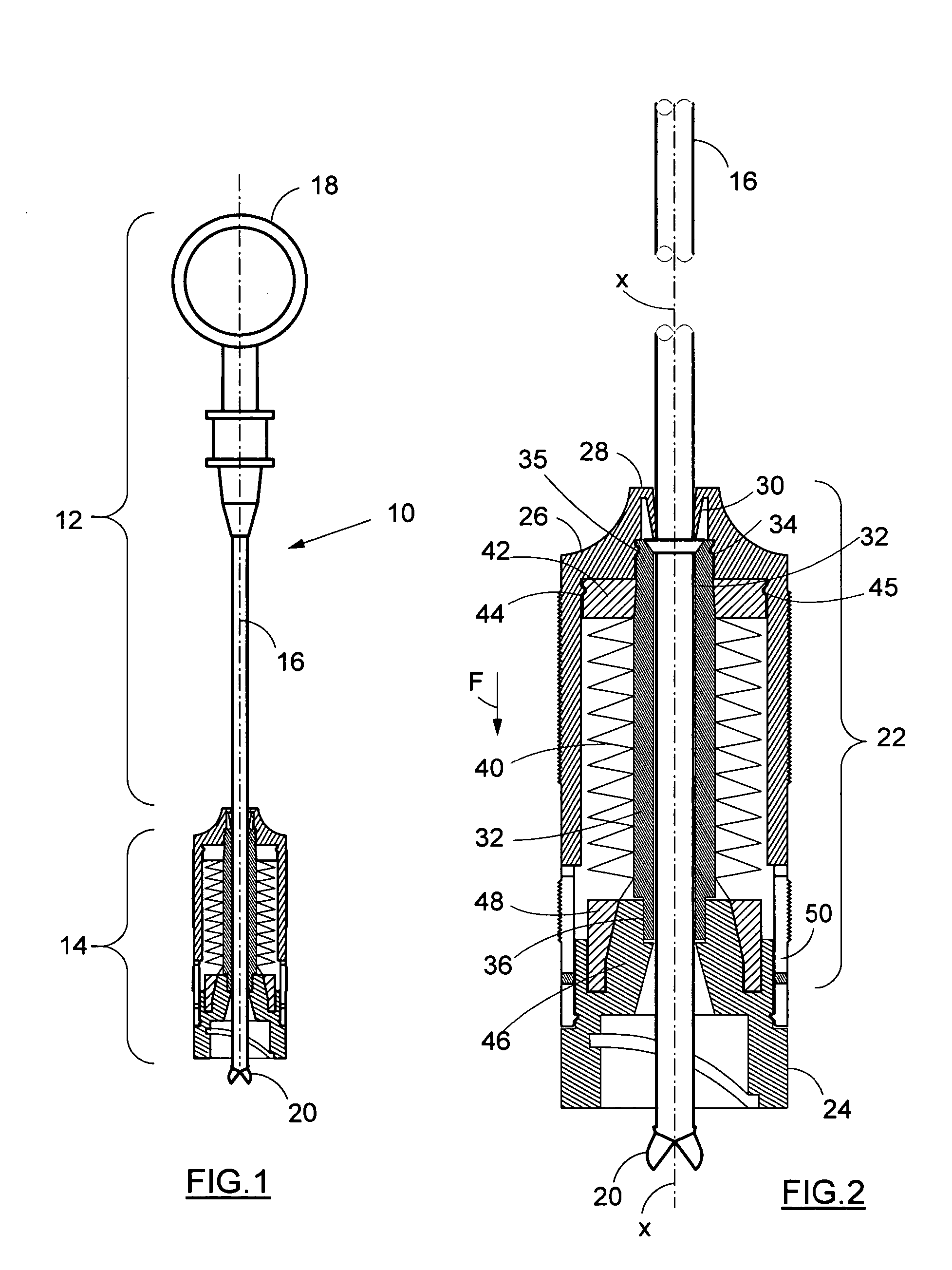

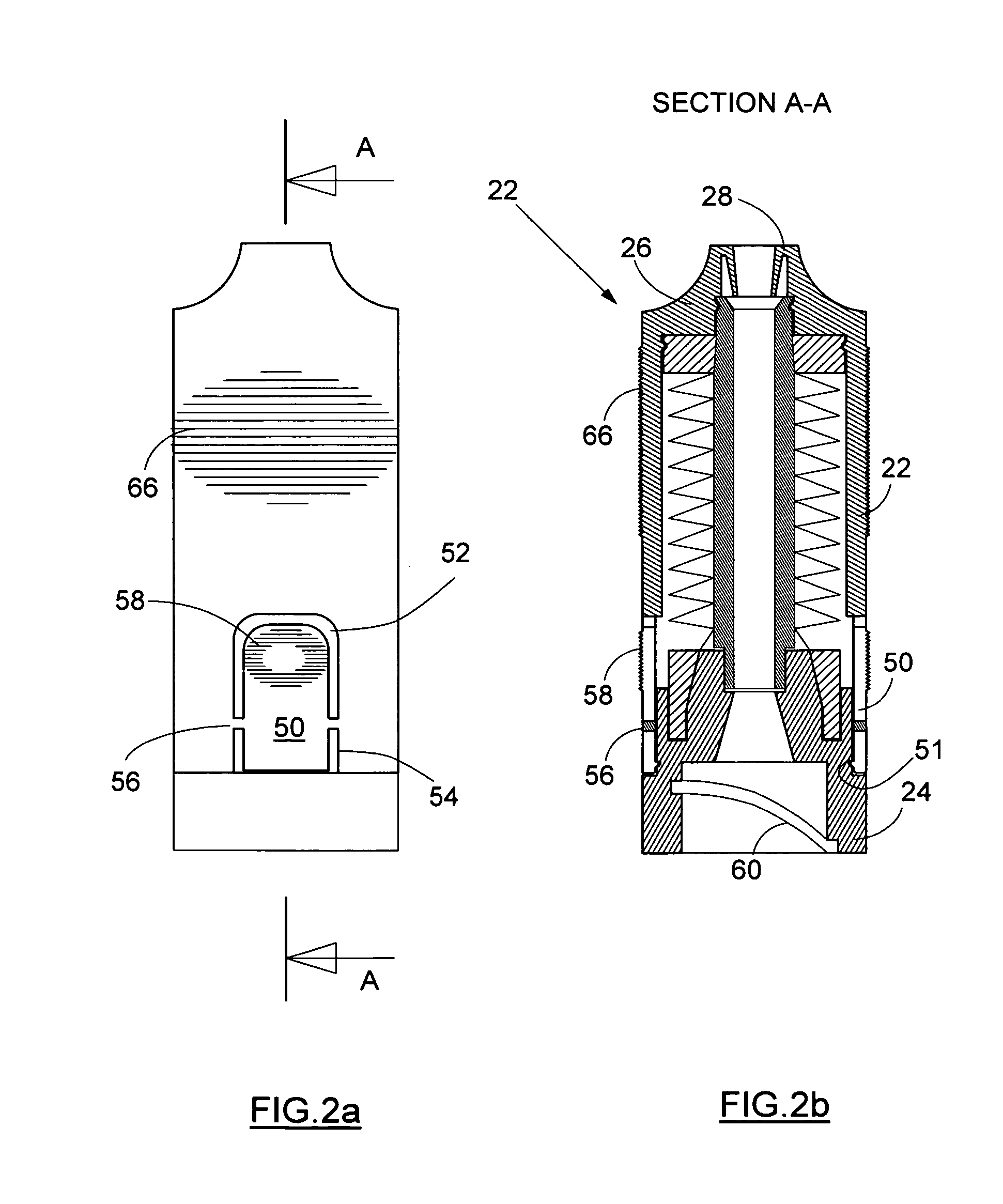

Surgical tool for endoscope

InactiveUS20060149131A1Clean handsReduce the possibilityGastroscopesVaccination/ovulation diagnosticsEngineeringEndoscope

Apparatus for sheathing an endoscopic tool is described. The apparatus is suitable for sheathing the tool when it is displaced in a proximal direction from a working channel of an endoscope. The apparatus comprises a sheathing assembly, which is attachable to a proximal port of the endoscope and to the endoscopic tool. Within the sheathing assembly is deployed a folded, flexible sleeve adapted to unfold from the assembly when the tool is retracted in the proximal direction from the working channel. The sheathing assembly is designed to allow displacement of the tool through the sheathing assembly in a distal direction and simultaneous retraction of the tool together with the sheathing assembly in the proximal direction.

Owner:STRYKER GI

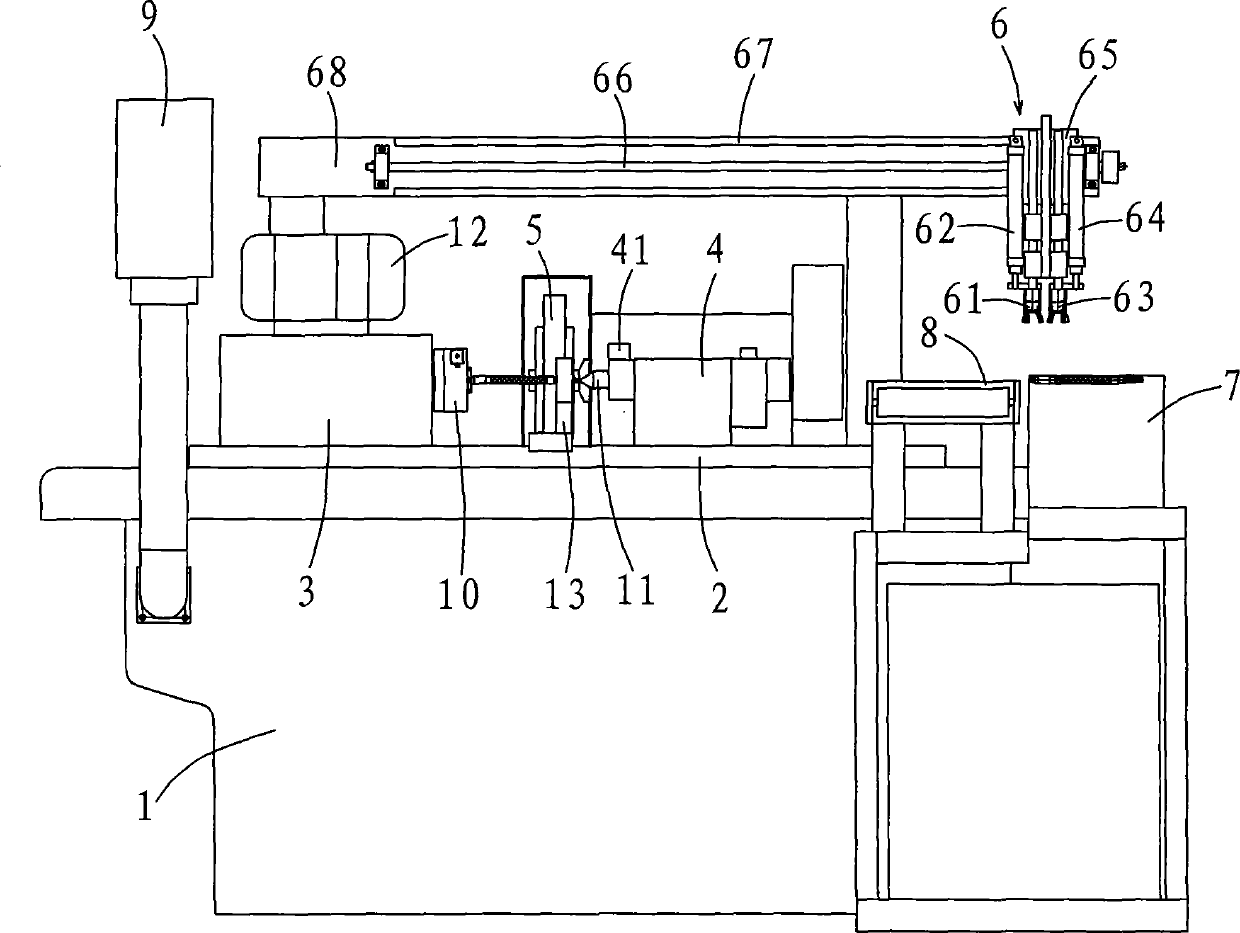

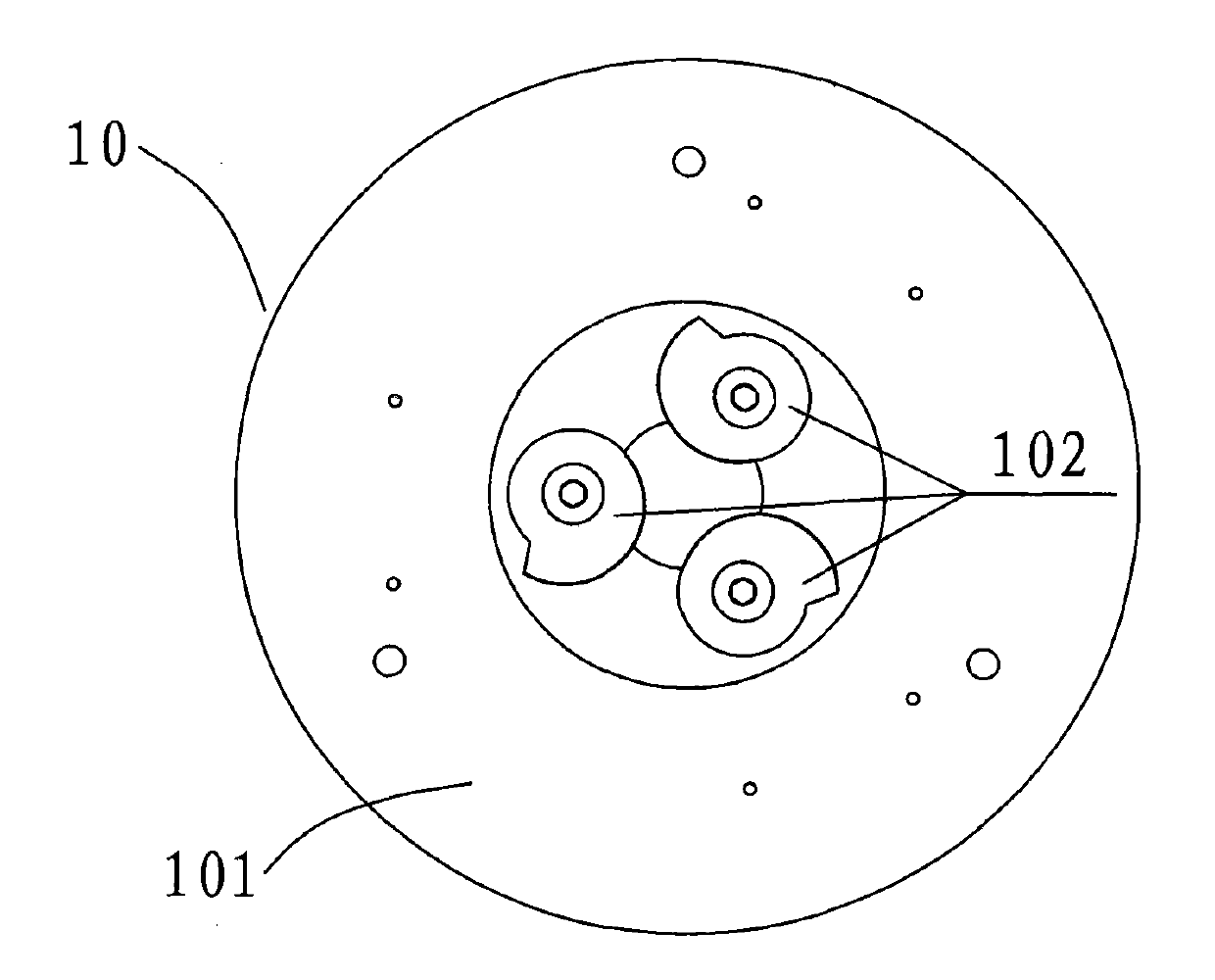

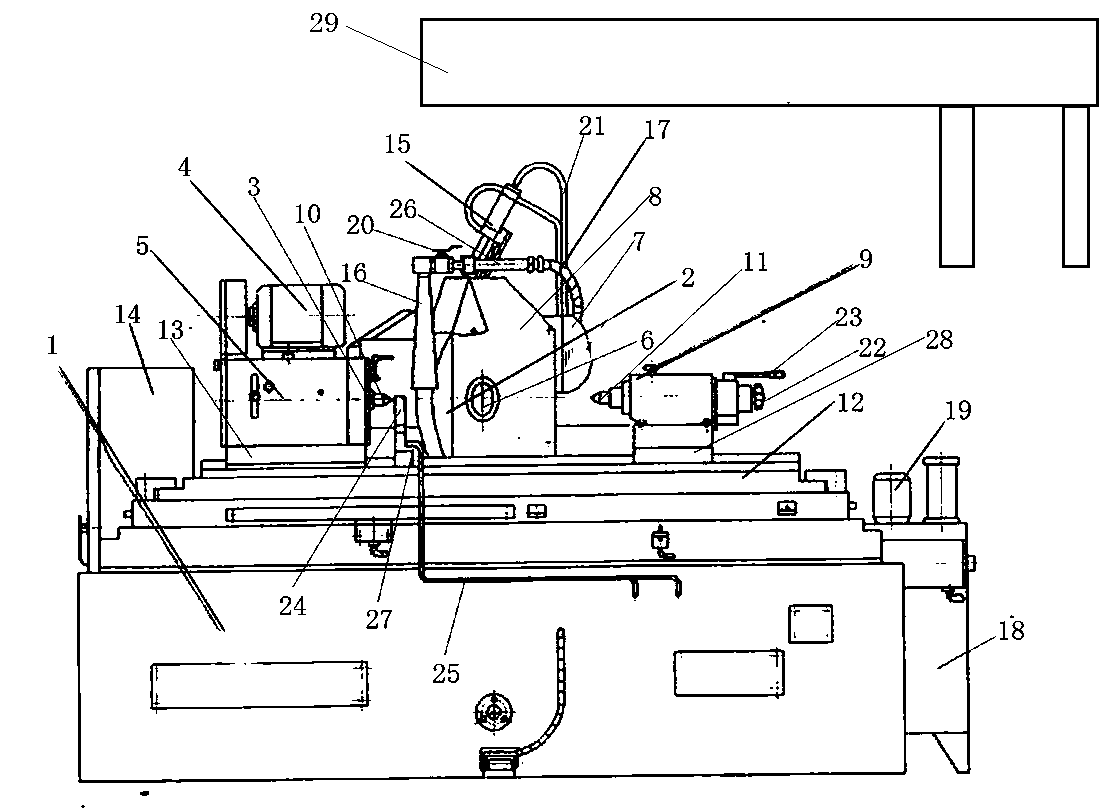

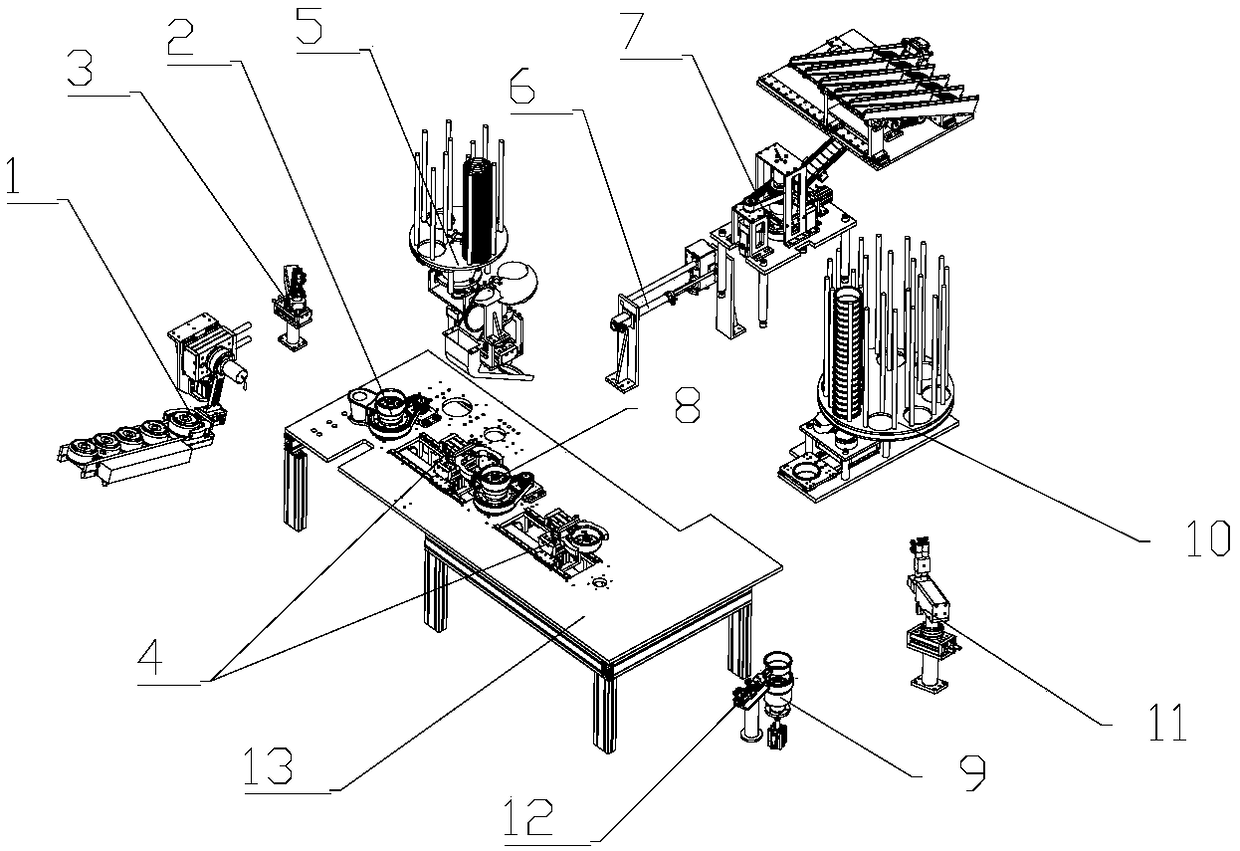

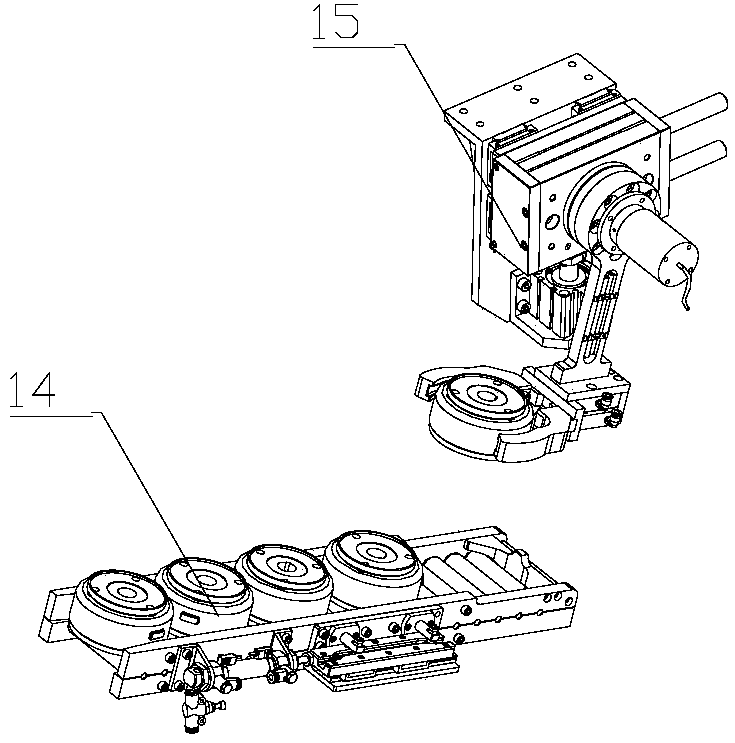

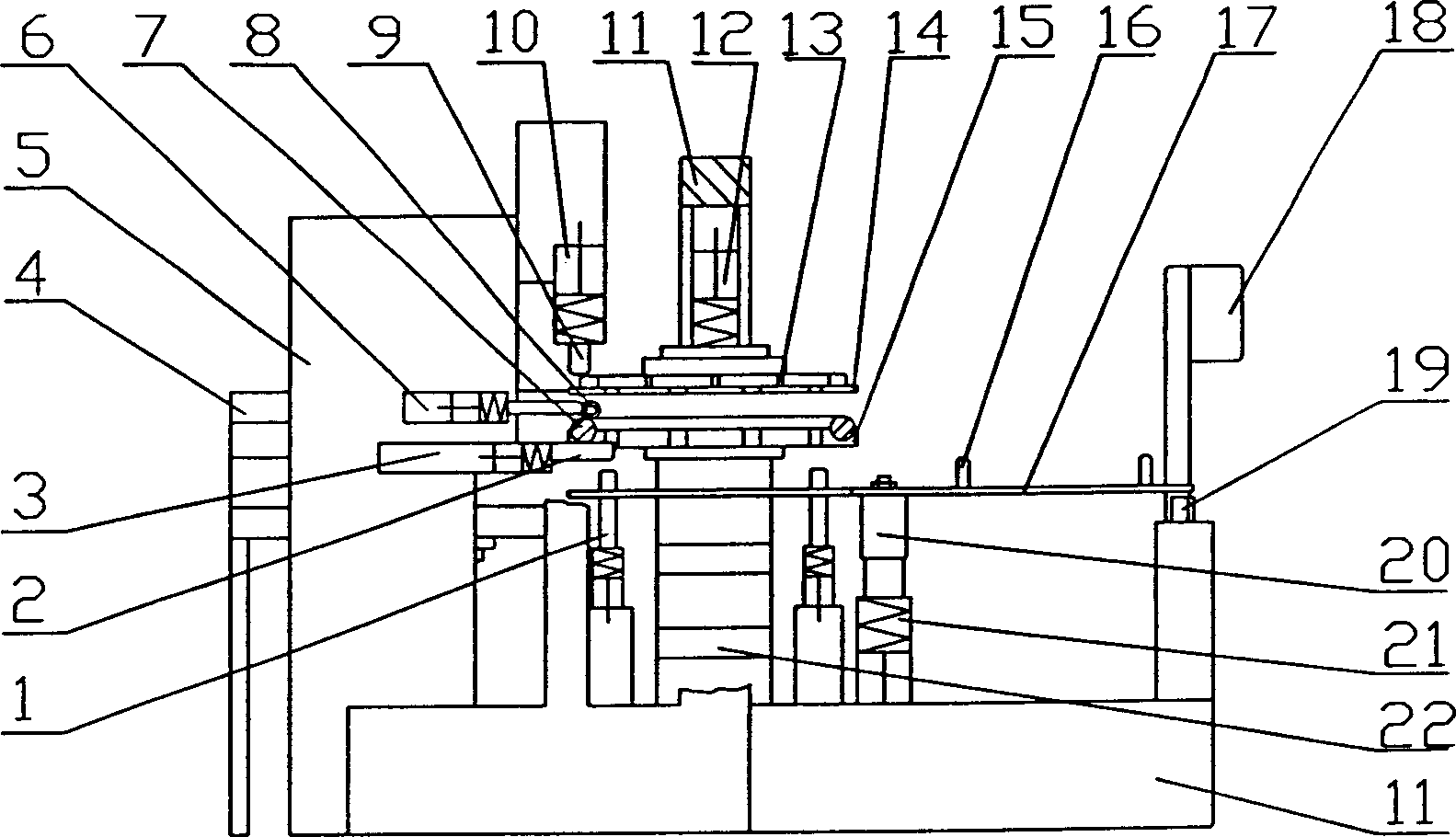

Fully-automatic grinder

InactiveCN103962901AHigh degree of automationReduce labor intensityRevolution surface grinding machinesGrinding feed controlNumerical controlMulti machine

The invention relates to a fully-automatic grinder comprising a base, a workbench, a headstock, a tailstock, a grinding wheel mechanism, a feeding and discharging manipulator, an automatic feeding mechanism, an automatic discharging mechanism and a numerical control device. A chuck and a centre are arranged on opposite faces of the headstock and the tailstock respectively and concentrically. The feeding and discharging manipulator comprises a taking pneumatic gripper, a taking cylinder, a putting pneumatic gripper, a putting cylinder, a guide slide fixing frame, a ball screw, a linear guide rail and a guide rail bracket, the taking pneumatic gripper, the taking cylinder, the putting pneumatic gripper and the putting cylinder are all mounted on the guide slide fixing frame, the taking pneumatic gripper and the putting pneumatic gripper are arranged at an included angle forward and backward and arranged parallelly leftward and rightward, and the guide slide fixing frame is in sliding fit with the ball screw and the linear guide rail. The grinder is high in automation degree, the whole process of feeding, discharging, clamping, machining, on-line measurement and the like of workpieces is completed automatically through the numerical control device, one-man multi-machine operation can be realized, production efficiency and production quality are improved, and labor intensity and production cost of workers are lowered.

Owner:JIAHE TOOLS

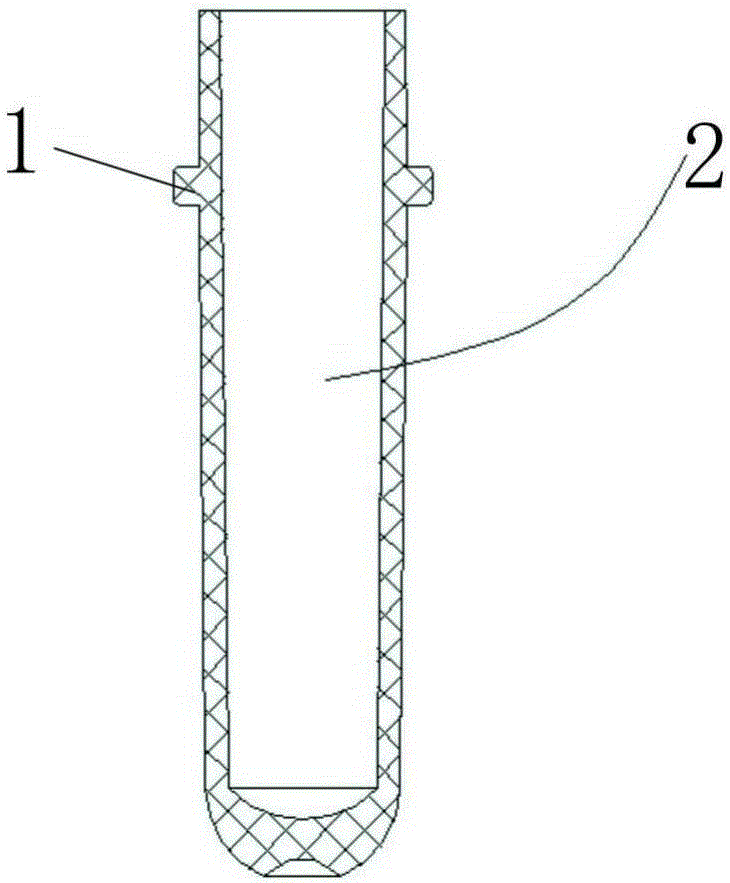

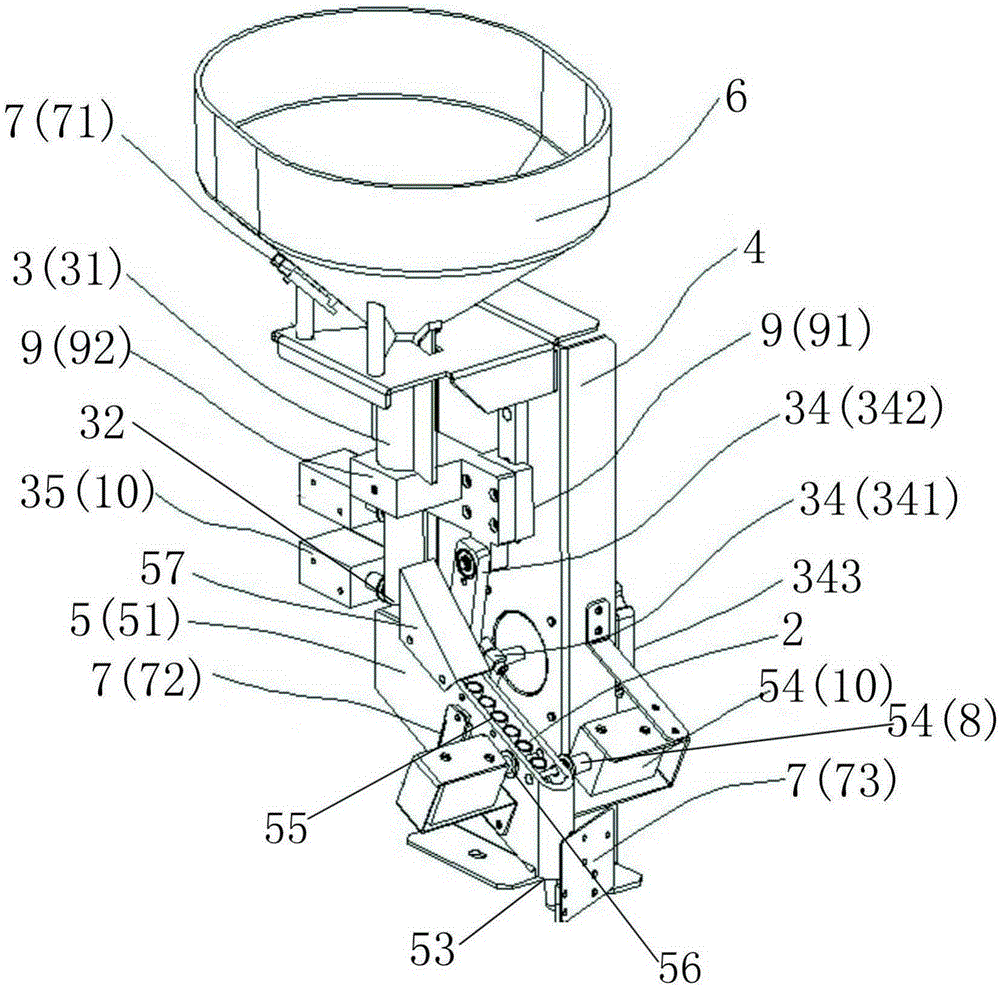

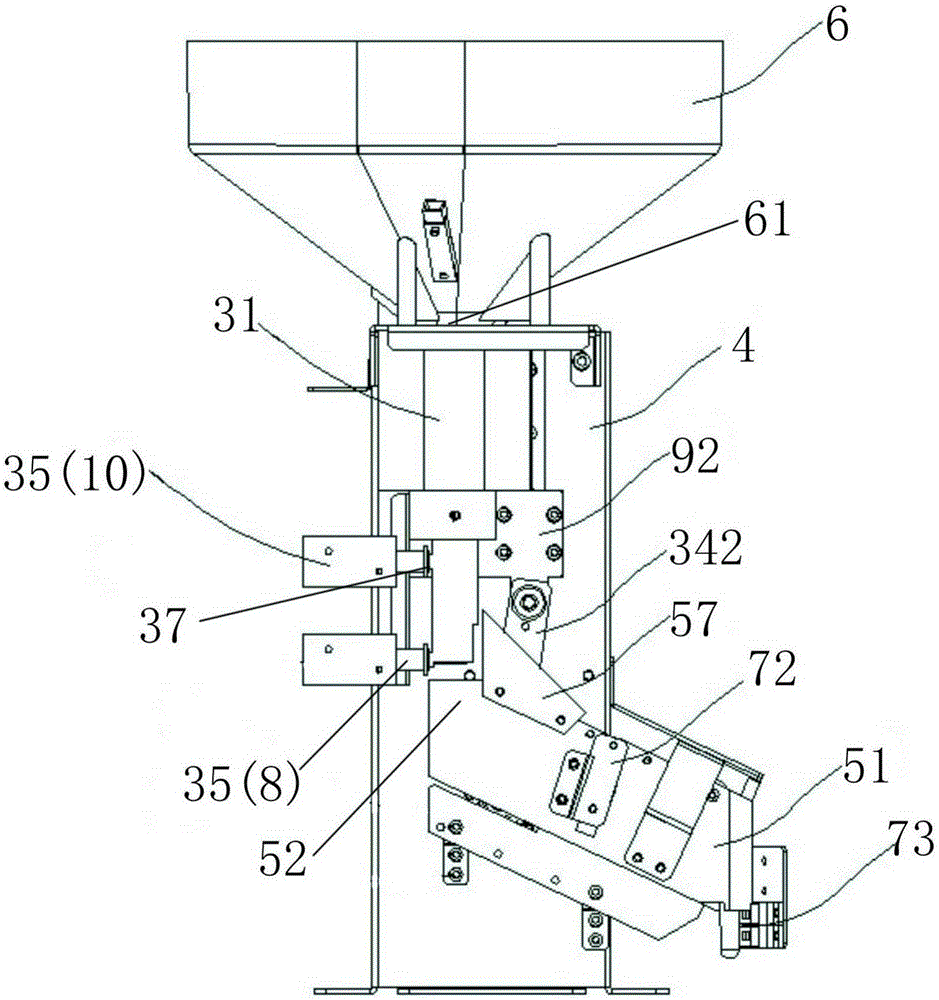

Reaction cup loading system for automatically conveying reaction cups to analysis device

InactiveCN105181985ACompact structureSimple operation and controlMaterial analysisEngineeringGuide tube

The invention provides a reaction cup loading system for automatically conveying reaction cups to an analysis device. The reaction cup loading system comprises a rack, as well as a cup storage cabin, a cup fetching mechanism and a cup conveying mechanism which are fixedly arranged on the rack and are arranged in sequence along a conveying direction of the reaction cups, wherein a cup outlet is formed in the bottom of the cup storage cabin; the cup fetching mechanism comprises a guide pipe, a driver for driving the guide pope to hoist to enable the guide pipe to stretch into the cup storage cabin from the cup outlet to take the cups, and a first mechanical switch for controlling the reaction cups in the guide pipe to fall off one by one from a first outlet; the cup conveying mechanism comprises a slide groove and a second mechanical switch for controlling the reaction cups in the slide groove to slide out one by one from a second outlet; the reaction cup loading system further comprises a cup detection mechanism arranged on the cup fetching mechanism and / or the cup conveying mechanism. A reaction cup automatic conveying device provides guarantees to full-automatic operation of a biological sample analysis system, has a compact whole structure, is simple to operate and control, has low operation fault rate and is accurate and reliable to convey; the device can be continuously operated for a long time with the matching of the detection mechanism, so that the conveying efficiency is improved and the operation cost is reduced.

Owner:SYSCAN MEDICAL TECH SUZHOU

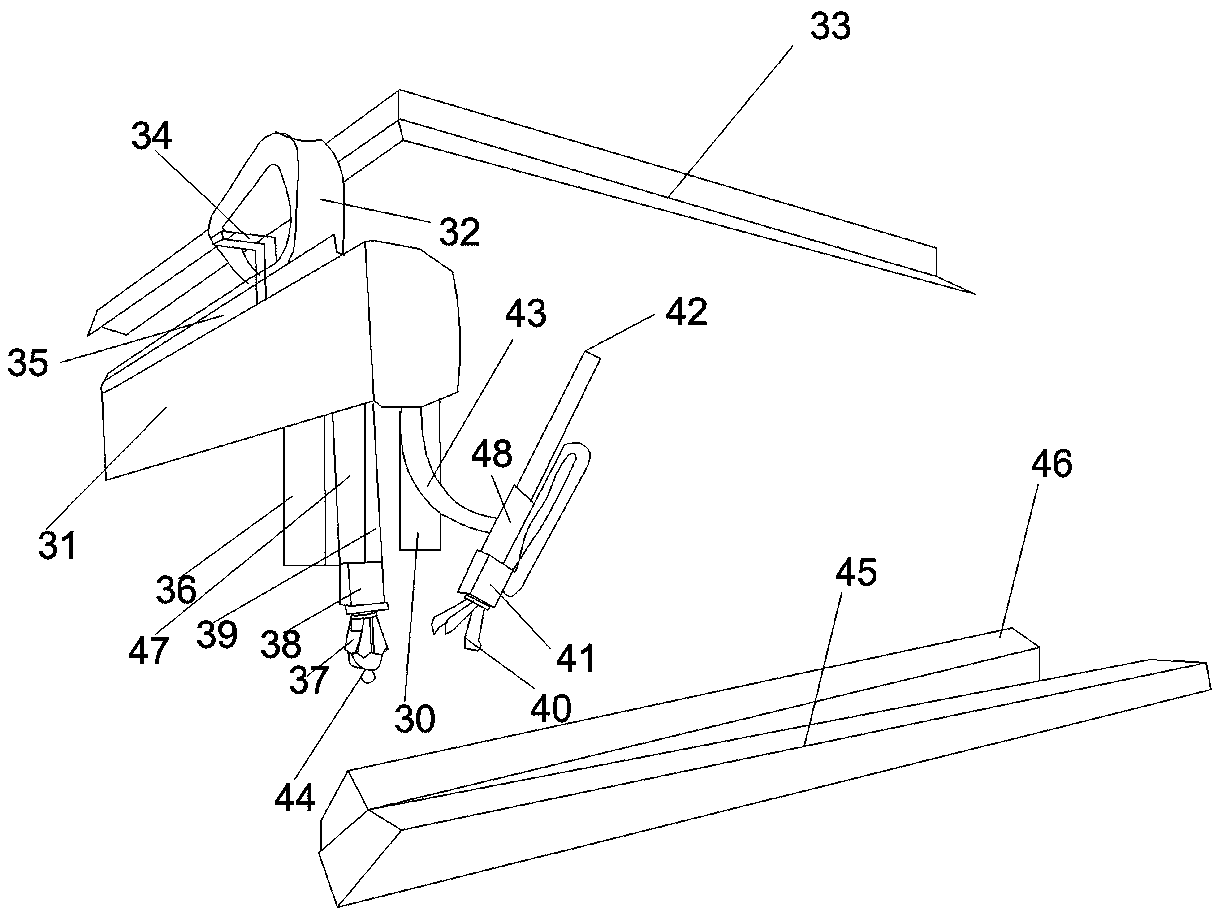

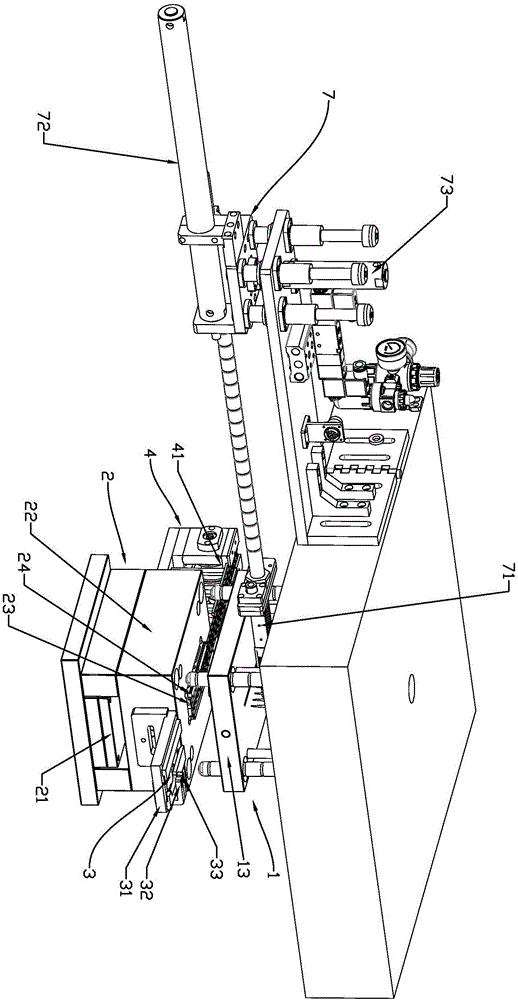

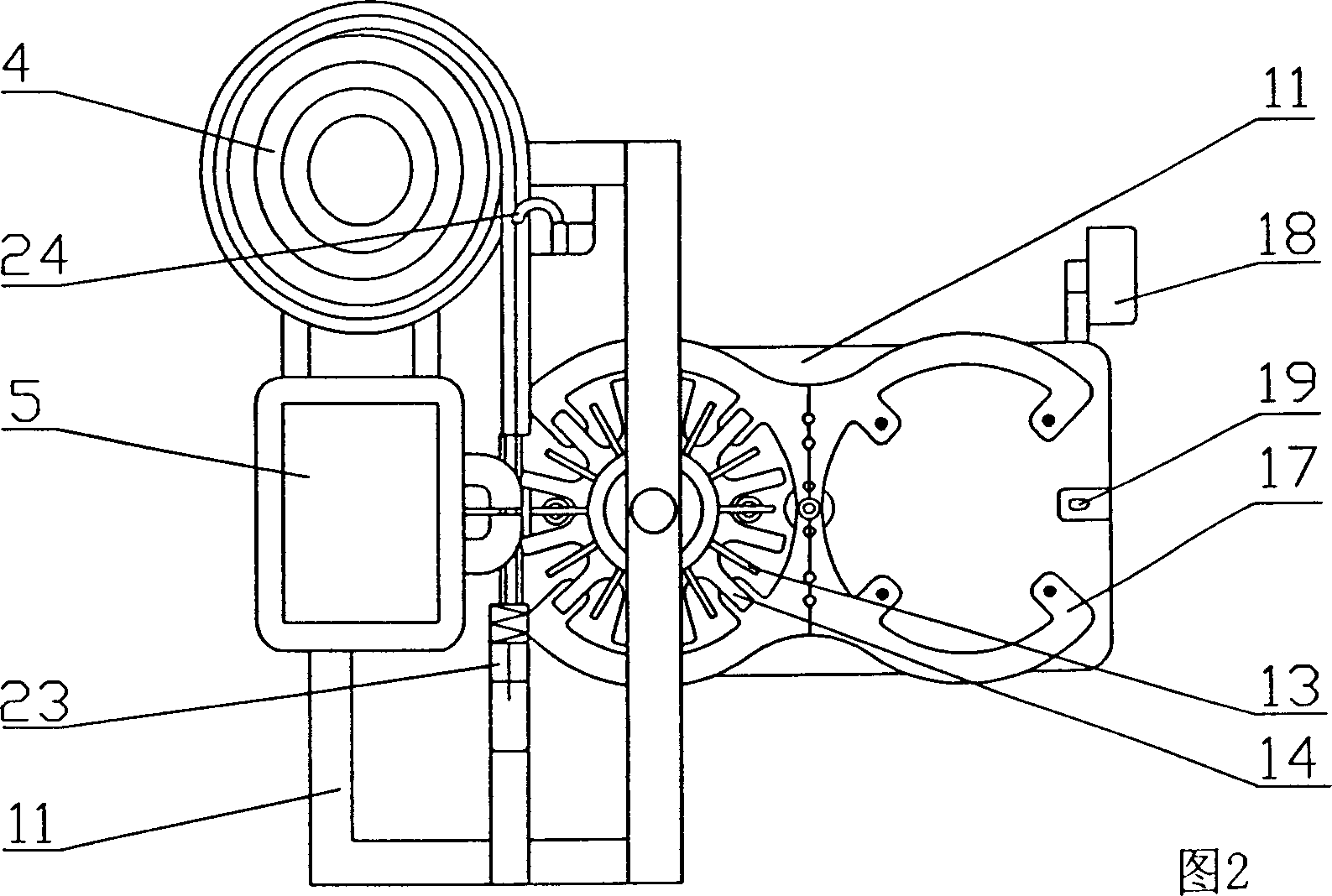

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

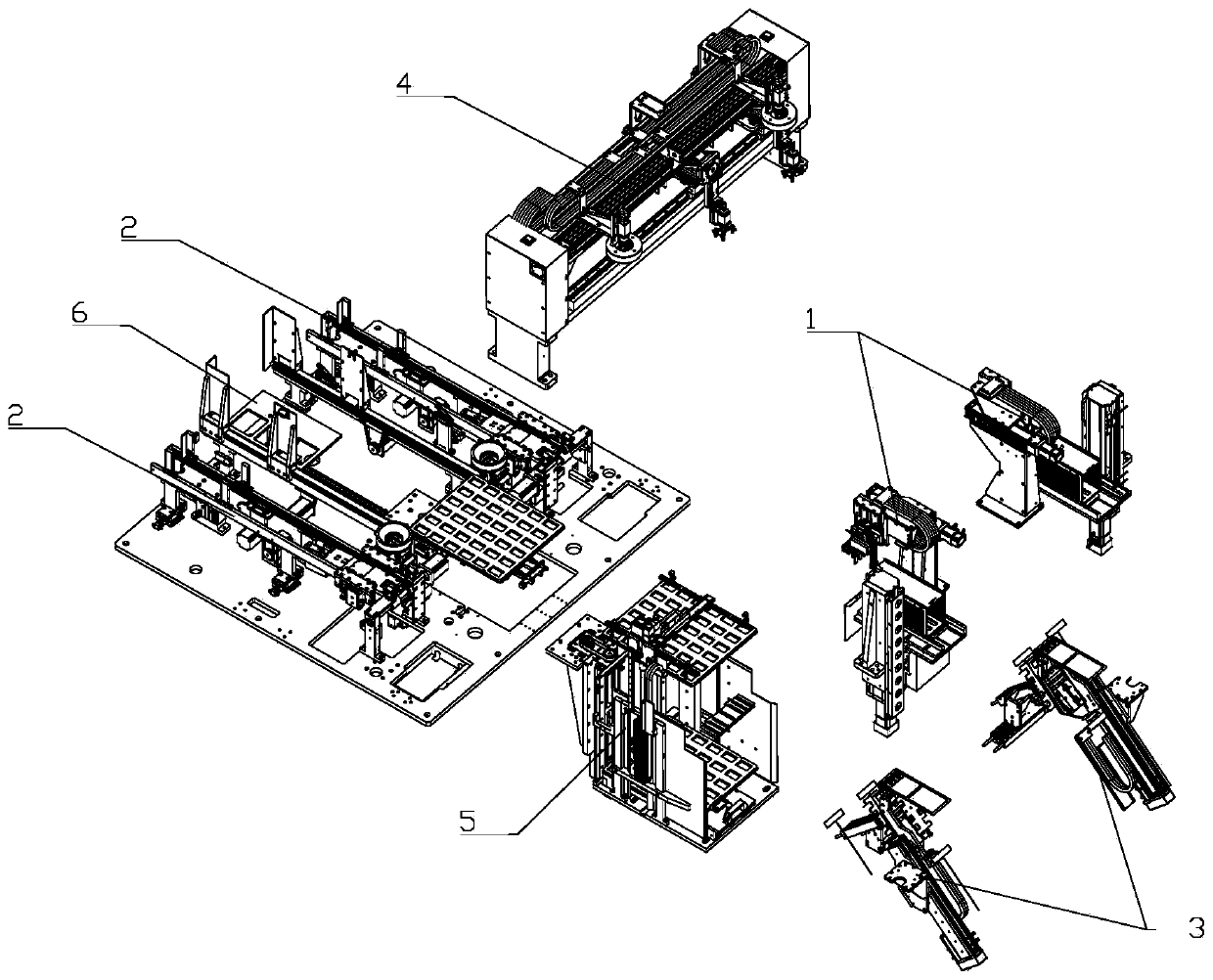

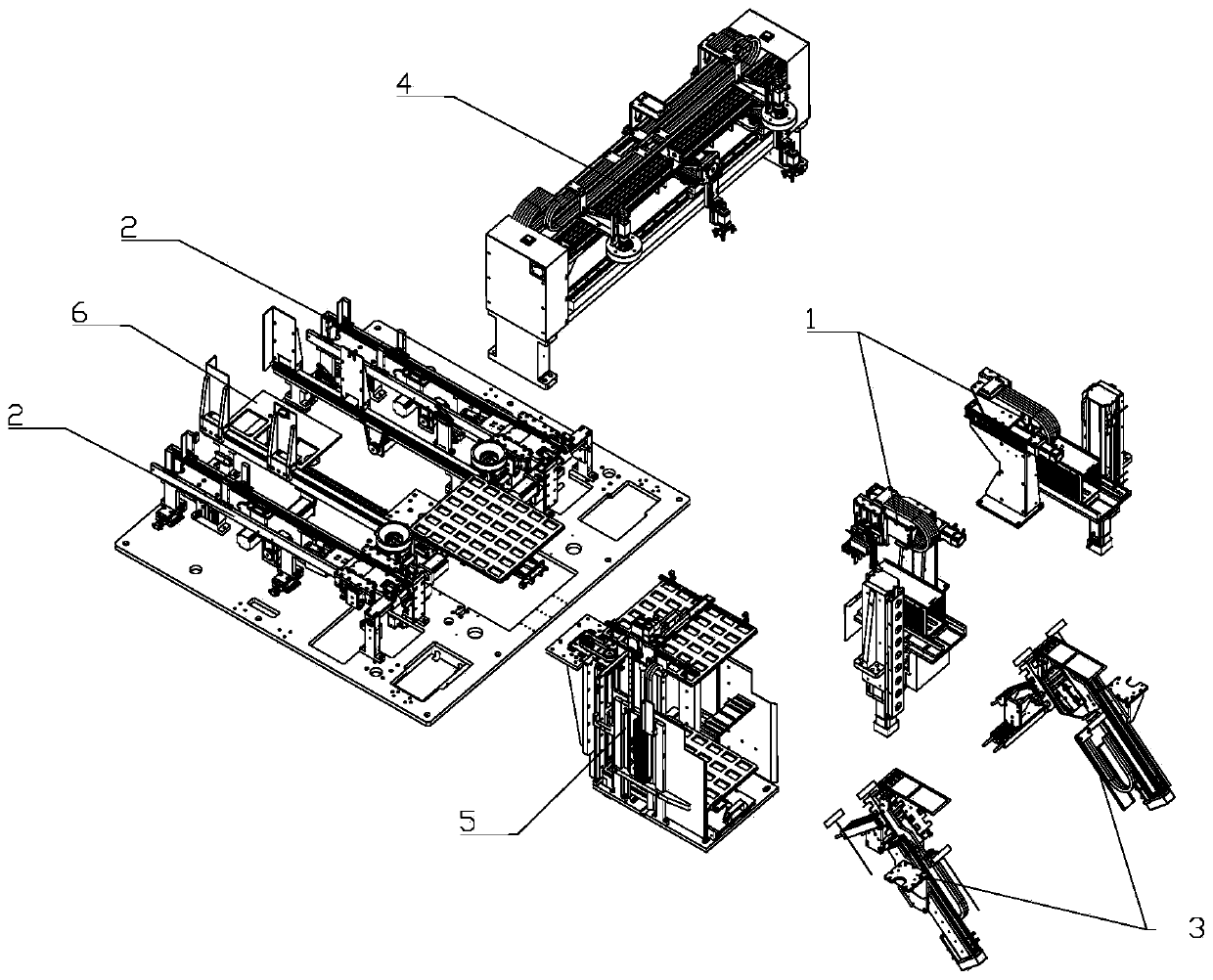

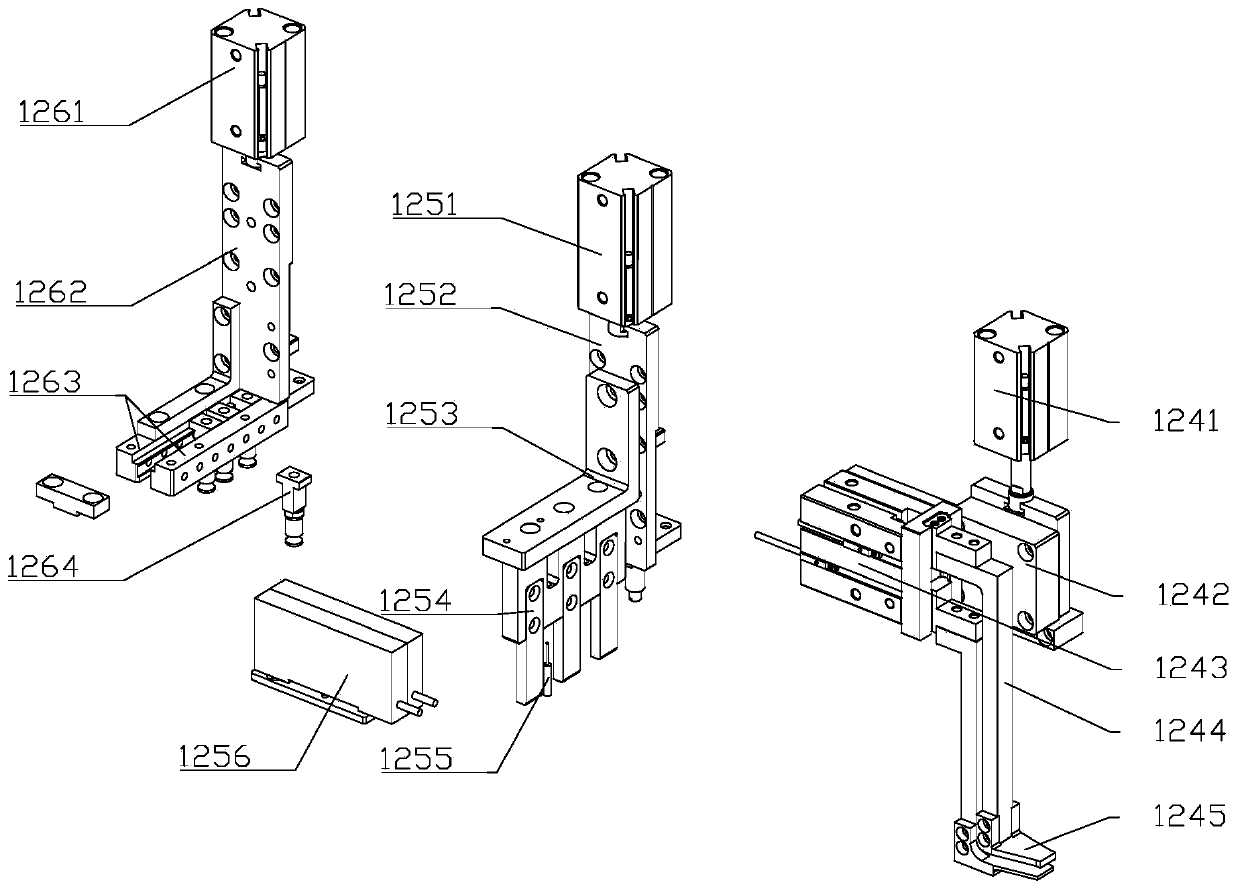

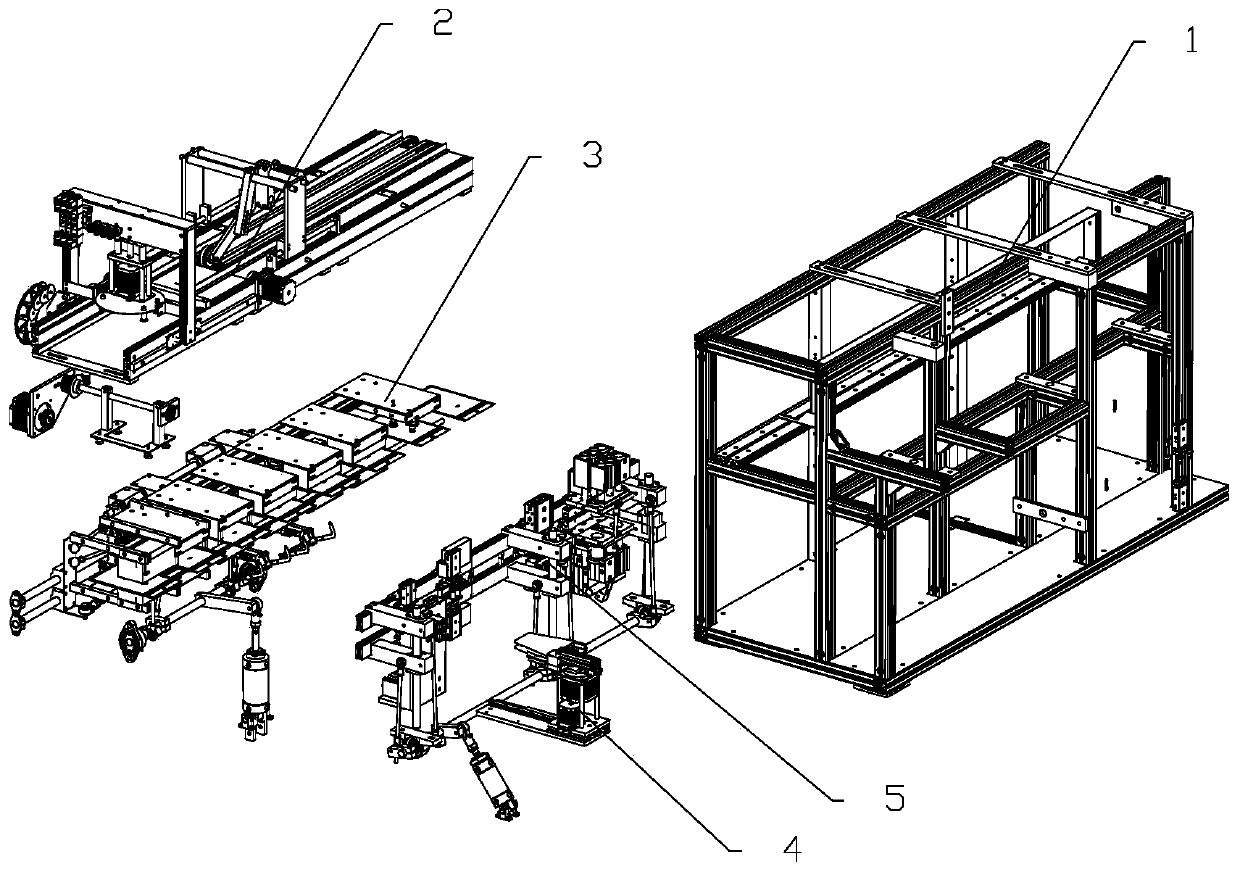

Integrated circuit, film removing method of integrated circuit and film removal arranging device of integrated circuit

InactiveCN110422416ASmooth peelingAvoid clutterSemiconductor/solid-state device manufacturingArticle unpackingIntegrated circuit manufacturingEngineering

The invention relates to the technical field of integrated circuit manufacturing, and discloses a film removal arranging device of an integrated circuit. The film removal arranging device comprises aframe, two symmetrically arranged carrier plate feeding devices, two symmetrically arranged carrier plate conveying line devices, two symmetrically arranged film removing devices, a carrying manipulator, a visual detection device, a tray feeding device and a tray conveying line device, wherein the carrier plate feeding devices, the carrier plate conveying line devices, the film removing devices, the carrying manipulator, the visual detection device, the tray feeding device and the tray conveying line device are arranged on the frame; the film removing devices are positioned below the carrier plate feeding devices; the carrier plate conveying line devices are connected with the carrier plate feeding devices; the tray feeding device is positioned between the two carrier plate feeding devices; the tray conveying line device is positioned between the two carrier plate conveying line devices and is connected with the tray feeding device; and the carrying manipulator and the visual detectiondevice are arranged on the frame and are positioned above the carrier plate conveying line devices and the tray conveying line device. The film removal arranging device has the advantages of being efficient and accurate in glue removing, automatic in feeding and discharging, high in processing efficiency and capable of collecting and arranging the integrated circuit.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

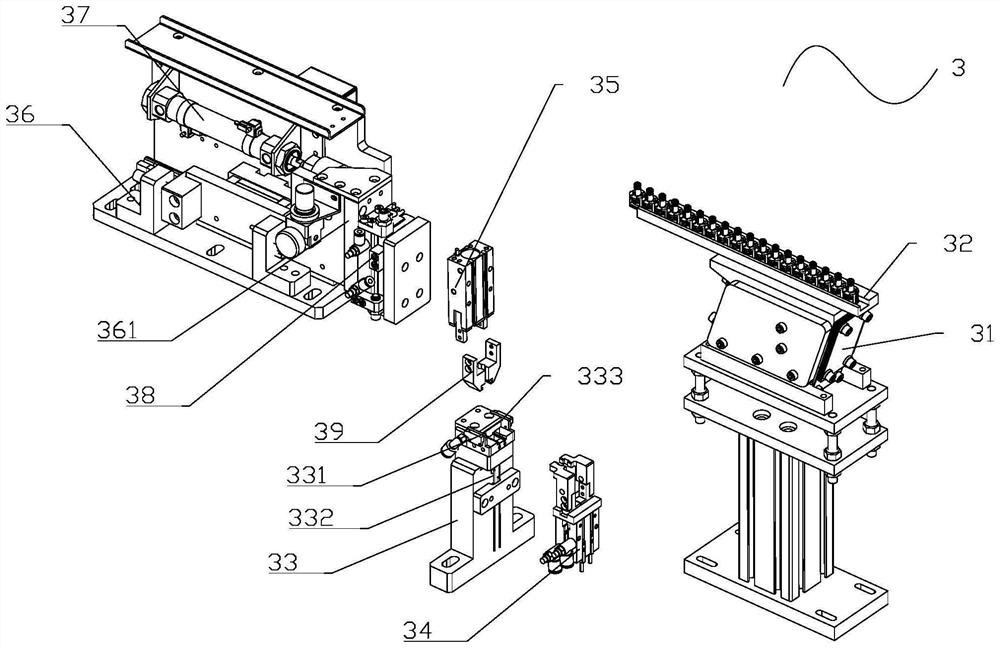

Tool plate jacking and positioning device

The invention discloses a tool plate jacking and positioning device which comprises a feeding carrier plate. A jacking module, a jacking blocking module and a non-return module are arranged on the feeding carrier plate, the jacking module comprises a jacking air cylinder and a jacking supporting plate, the jacking supporting plate is located in a jacking station, the jacking air cylinder drives the jacking supporting plate to ascend and descend, a tool bottom plate is supported on the jacking supporting plate and ascends and descends along the jacking supporting plate, the jacking blocking module comprises a jacking blocking air cylinder and a jacking blocking block, the jacking blocking air cylinder drives the jacking blocking block to do reciprocating motion, the jacking blocking block limits the front end of the tool bottom plate, the non-return module comprises a non-return elastic block doing elastic reset motion, and the non-return elastic block limits the rear end of the tool bottom plate. The structure is simple and reasonable, feeding operation is completed in a full-automatic mode, operation is convenient and fast, the labor intensity is greatly reduced, feeding work is stable and reliable, working efficiency is improved, feeding precision is effectively ensured, and safety coefficients are improved.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Vacuum absorption rubbing type separating and fetching mechanism and method

ActiveCN106218956APrevent wrong actionStable and reliable feedingPaper article packagingEngineeringRubbing

The invention discloses a vacuum absorption rubbing type separating and fetching mechanism and a vacuum absorption rubbing type separating and fetching method. The vacuum absorption rubbing type separating and fetching mechanism comprises an absorption rubbing mechanism, a lifting mechanism, a horizontal moving mechanism and a detection mechanism, and is characterized in that the absorption rubbing mechanism comprises a wide type finger cylinder clamping jaw, suction nozzle seats are respectively mounted on the left and right sides of the clamping jaw, four suction nozzles are respectively mounted on the suction nozzle seats, and an inclined suction nozzle is arranged in the middle of the right suction nozzles; the wide type finger cylinder clamping jaw is fixed below the lifting mechanism; the lifting mechanism comprises a lifting rack and is driven to lift by using a cylinder with a guide rod; the horizontal moving mechanism comprises a movable block provided with two sets of moving guide rods and guide sleeves, the lifting mechanism is driven to horizontally move by using a movable cylinder, and the detection mechanism gives signals to actuate actions of the parts. According to the invention, with the adoption of vacuum suction of eight suction nozzles and inclined suction nozzle and mask rubbing of driving the suction nozzles to suck by using the wide type finger cylinder clamping jaw, effective separation of masks is realized, and the problem that an automatic mask folding machine is not stable, reliable and durable in mask suction and separation is well solved.

Owner:珠海平川智达科技有限公司

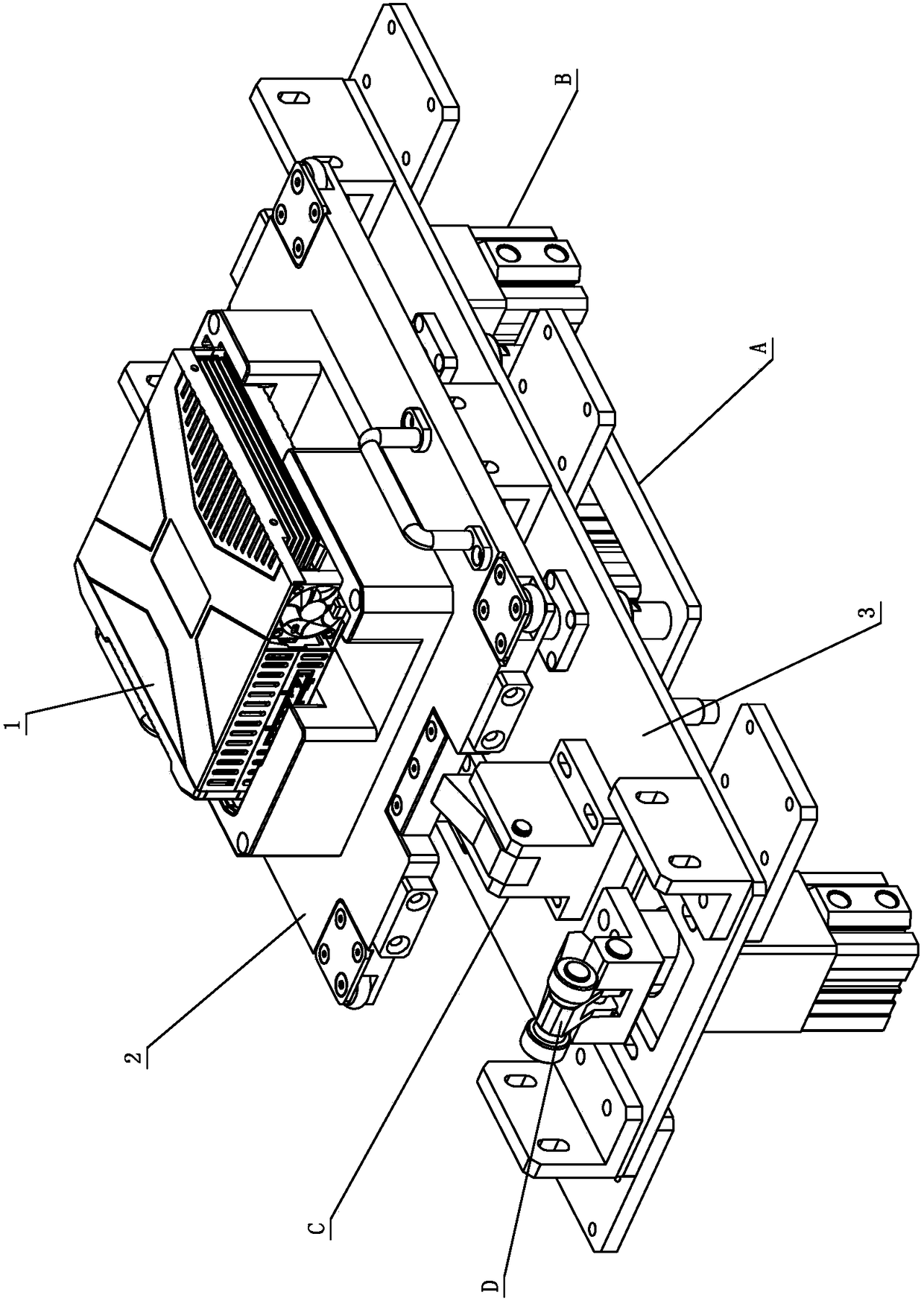

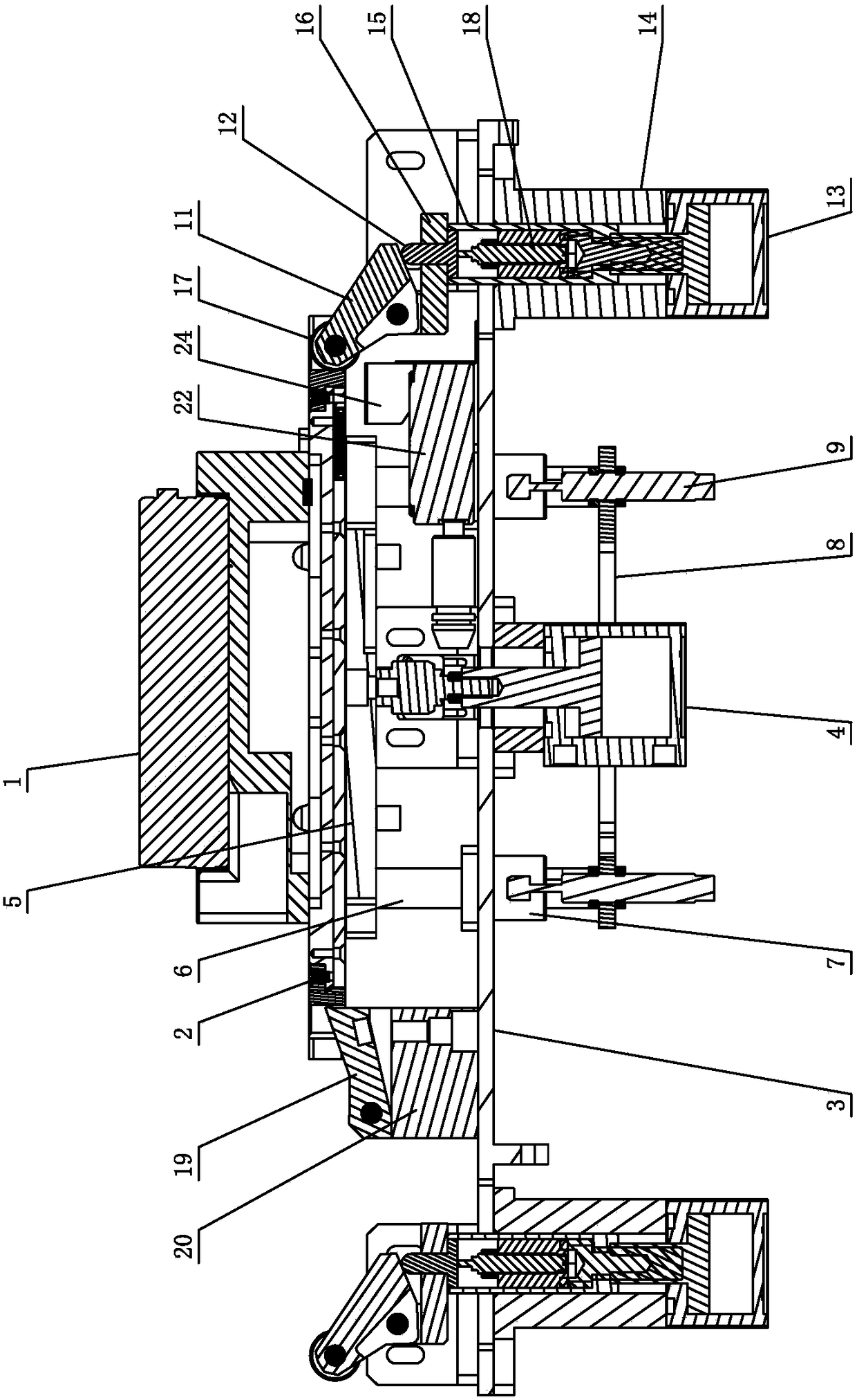

Full-automatic special riveting machine for motor cooling fins

ActiveCN106964744AImprove the efficiency of riveting processingStable riveting strengthPunch pressHeat sink

The invention discloses a full-automatic special riveting machine for motor cooling fins. The full-automatic special riveting machine for the motor cooling fins comprises a table board, an A workpiece feeding mechanism, a B workpiece feeding mechanism, an electric punch, a riveting mechanism and a discharging mechanism; the electric punch is fixed to the table board; the riveting mechanism is installed on the electric punch; the A workpiece feeding mechanism and the B workpiece feeding mechanism are arranged on the two sides of the riveting mechanism correspondingly and feed workpieces A and workpieces B to the riveting mechanism correspondingly; and the discharging mechanism is installed on the electric punch and pushes riveted cooling fins out of the riveting mechanism. The full-automatic special riveting machine for the motor cooling fins can greatly improve the riveting machining efficiency of the motor cooling fins, can stabilize the riveting force, improves the operation safety and has good market prospects.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Mobile phone polaroid laminating machine capable of reliably laminating polaroid

InactiveCN105242419AGood for extrusionEasy to operateNon-linear opticsEngineeringMechanical engineering

The invention relates to a mobile phone polaroid laminating machine capable of reliably laminating a polaroid. A polaroid loading mechanism comprises a loading platform longitudinally lifting mechanism, a loading platform station switching mechanism installed on the loading platform longitudinally lifting mechanism and a polaroid loading platform installed on the loading platform station switching mechanism; the polaroid loading platform comprises a laminated polaroid transferring substrate and a laminated polaroid transferring hinged side panel which is installed on the loading platform station switching mechanism, the laminated polaroid transferring substrate is hinged to the bottom end of the laminated polaroid transferring hinged side panel, the side, opposite to the hinged point, of the laminated polaroid transferring substrate can longitudinally rotate around the laminated polaroid transferring hinged side panel, the laminated polaroid transferring substrate is connected with a laminated polaroid transferring cylinder which drives one side edge of the laminated polaroid transferring substrate to rotate, a polaroid aligning mechanism is installed on the laminated polaroid transferring substrate, a vacuum adsorption plate which can absorb and fix the polaroid is installed at the bottom of the laminated polaroid transferring substrate in an attached mode, and a high-speed camera is arranged on the side edge of a vacuum adsorption seat which is fixed through a glass substrate. The mobile phone polaroid laminating machine capable of reliably laminating the polaroid has the advantages of being reasonable in polaroid laminating action and good in polaroid laminating quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

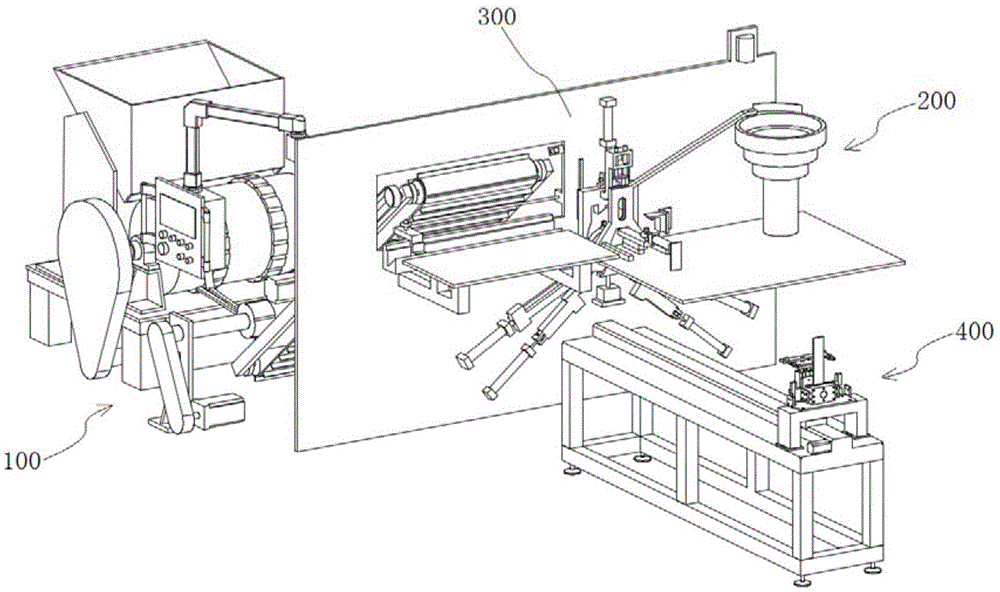

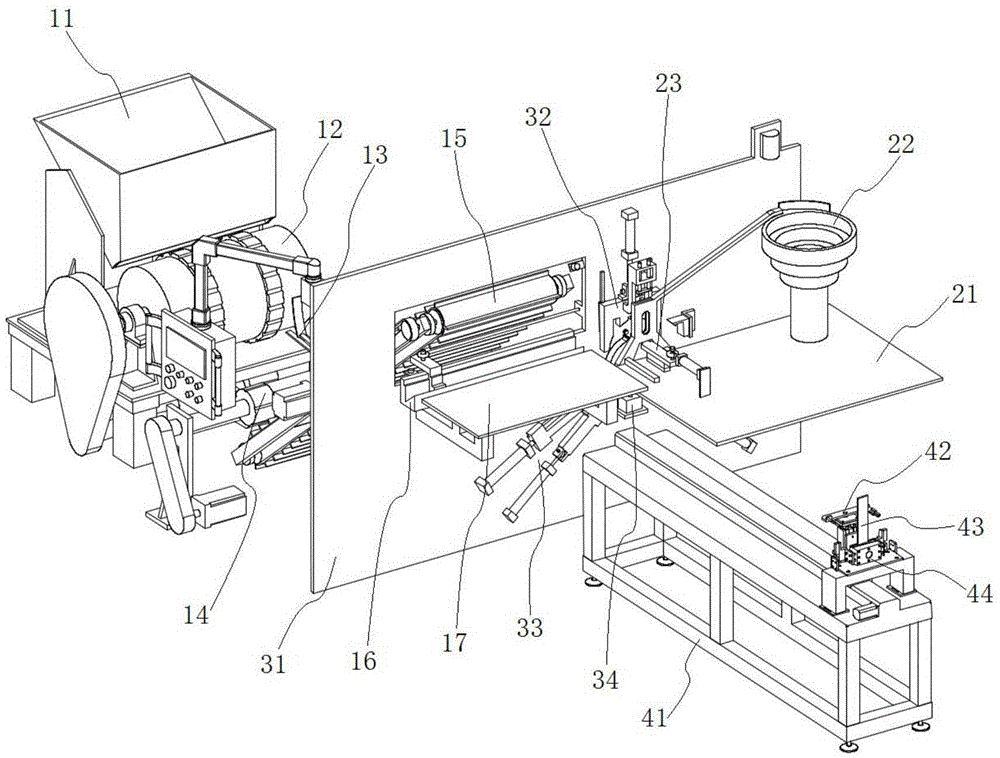

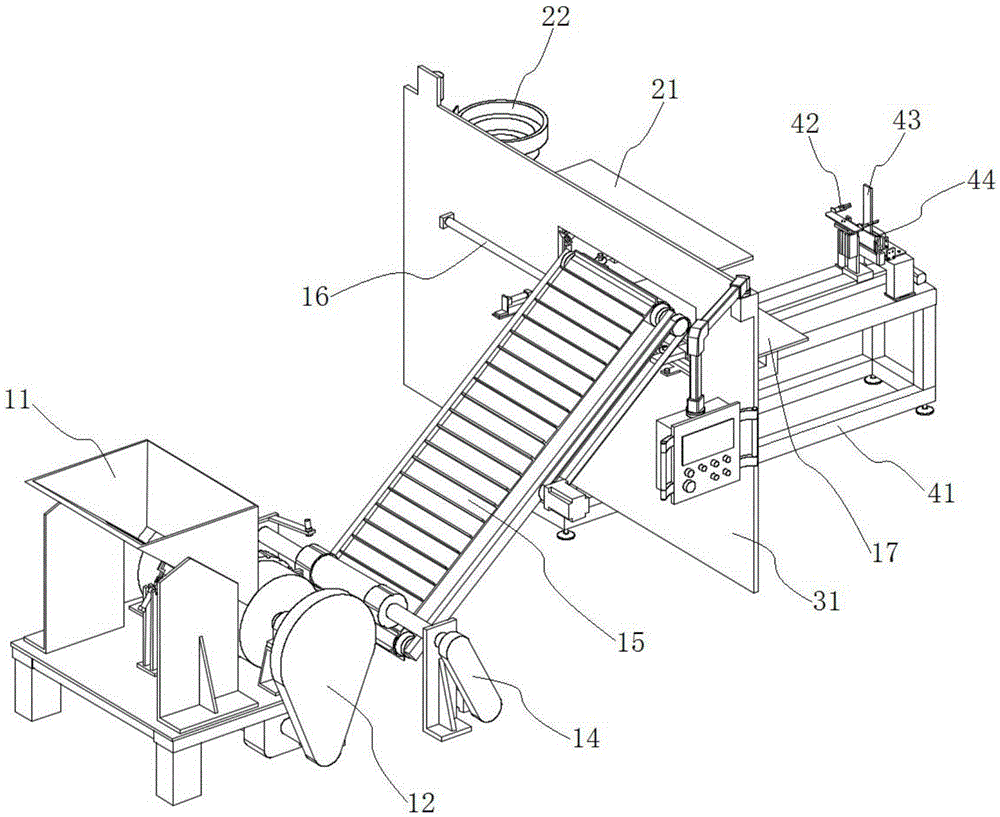

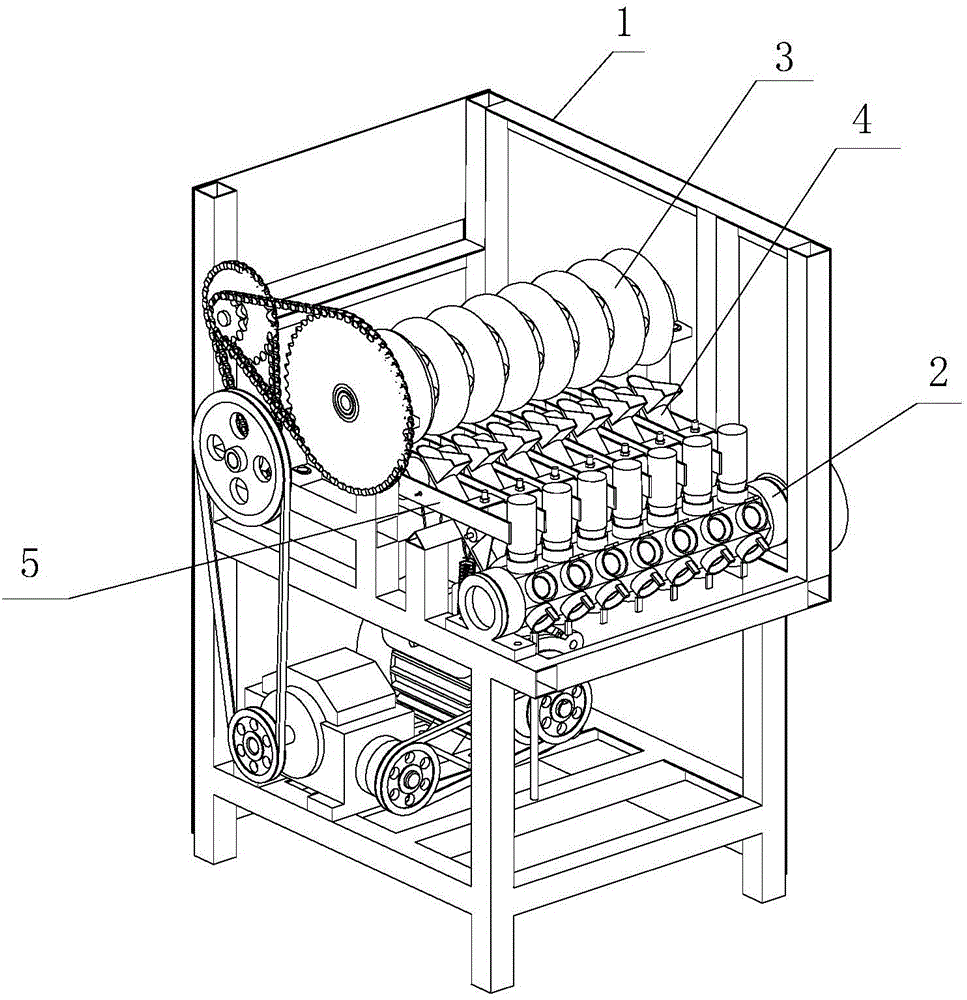

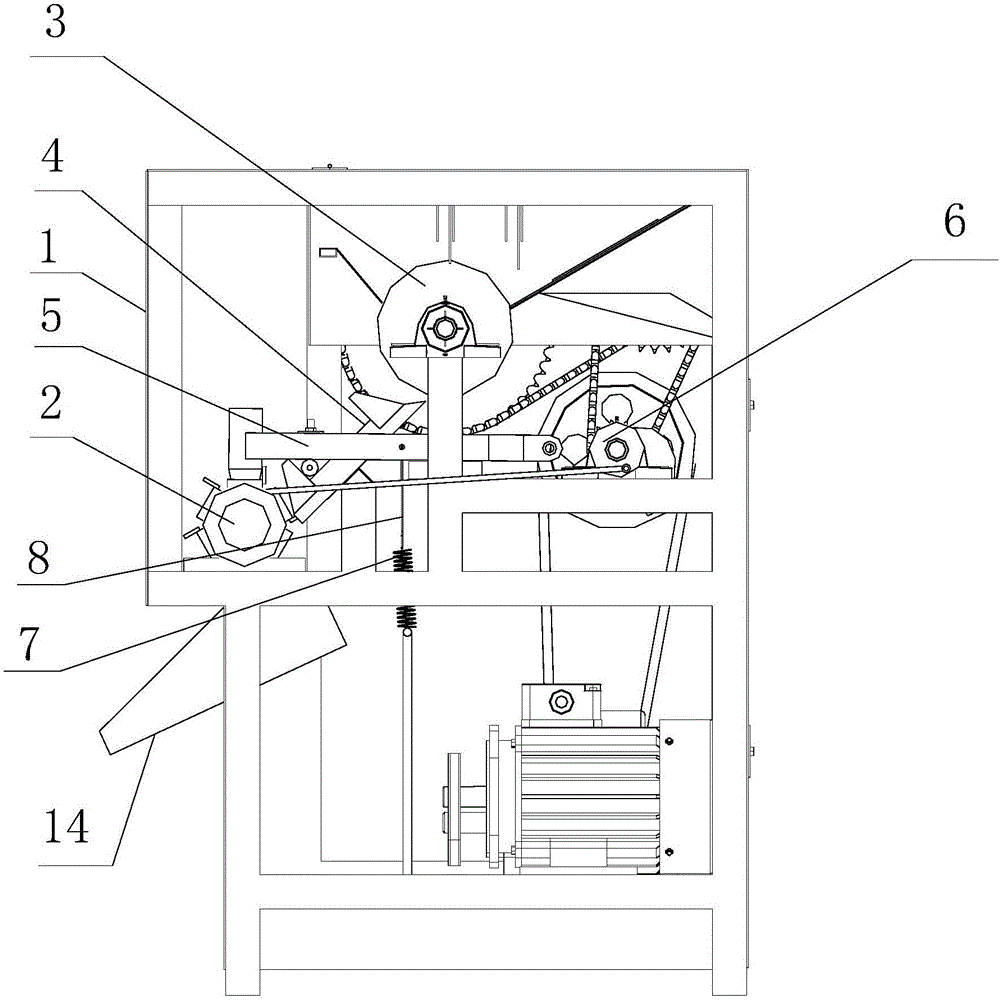

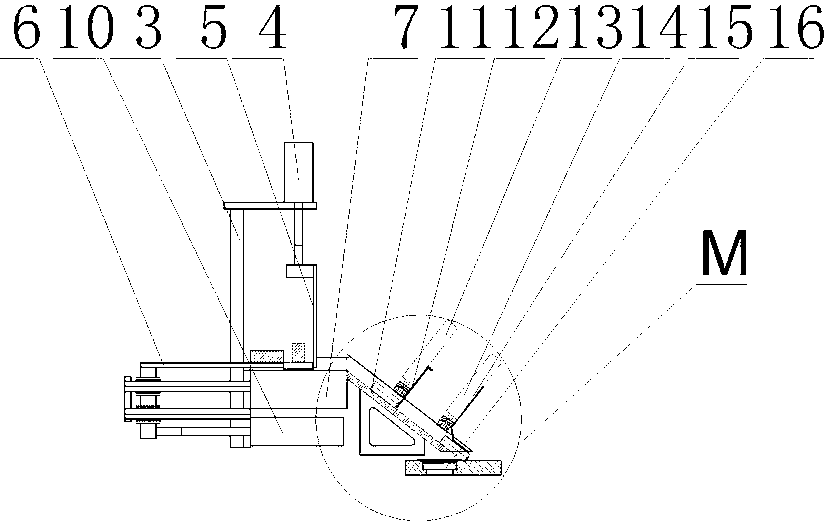

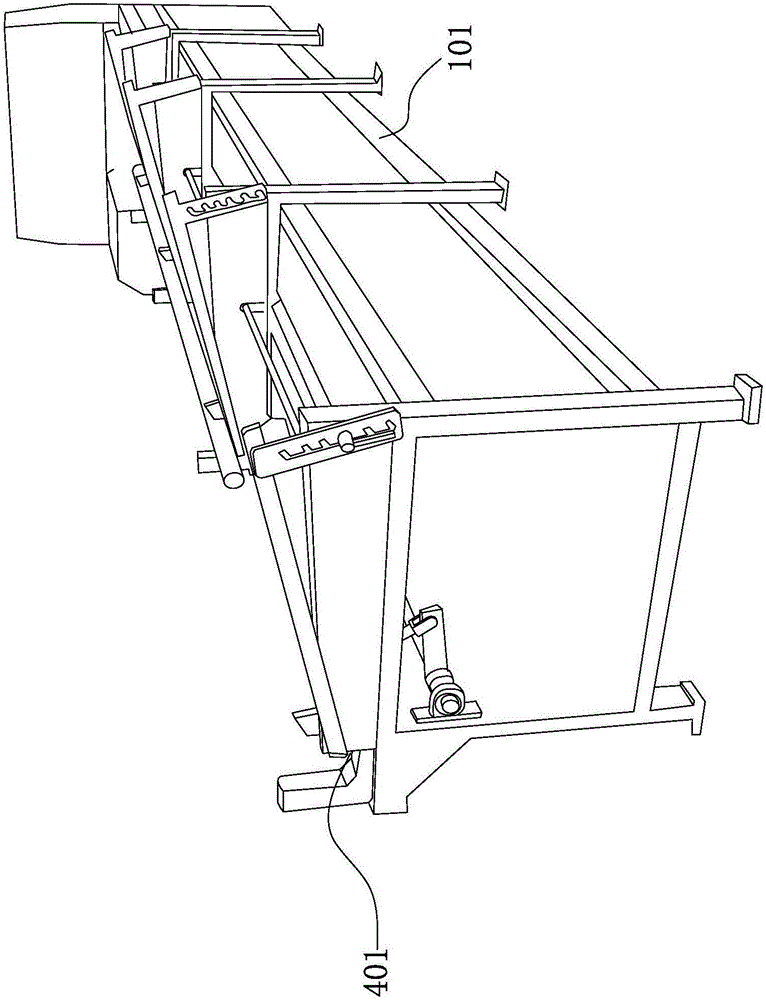

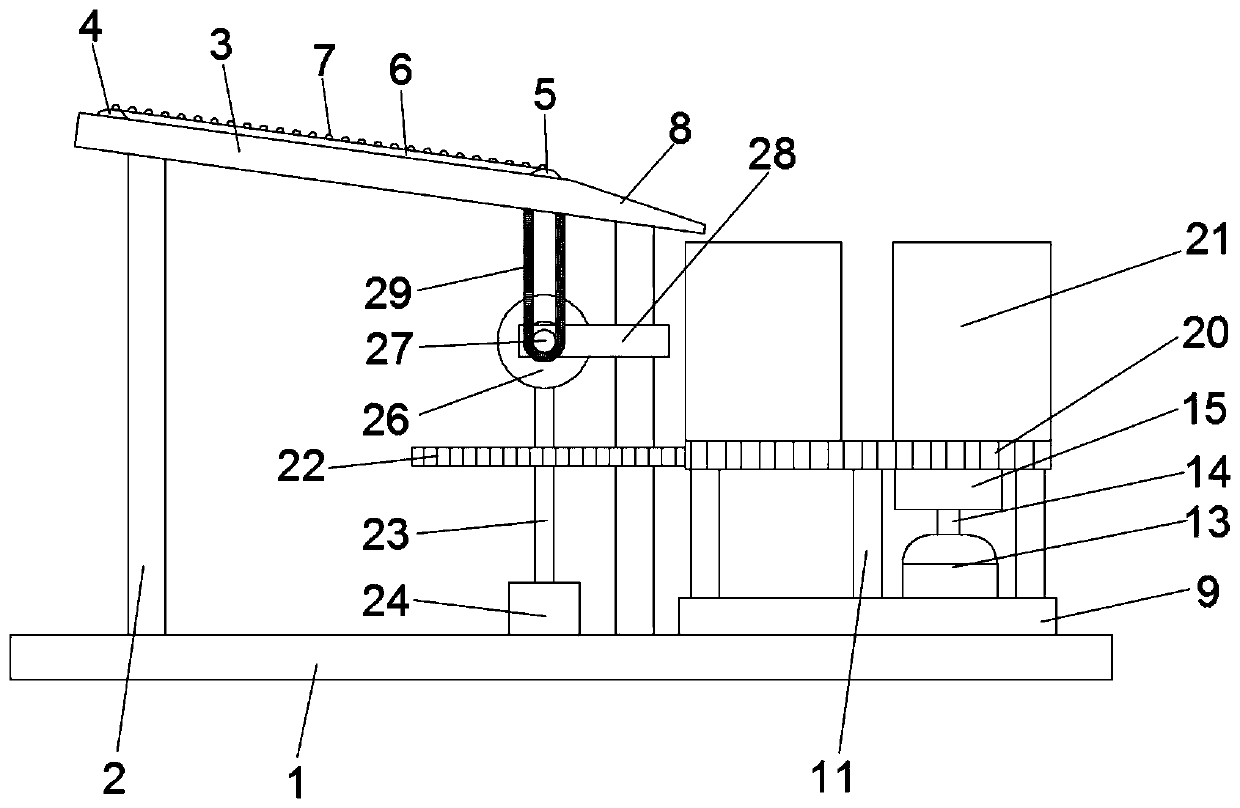

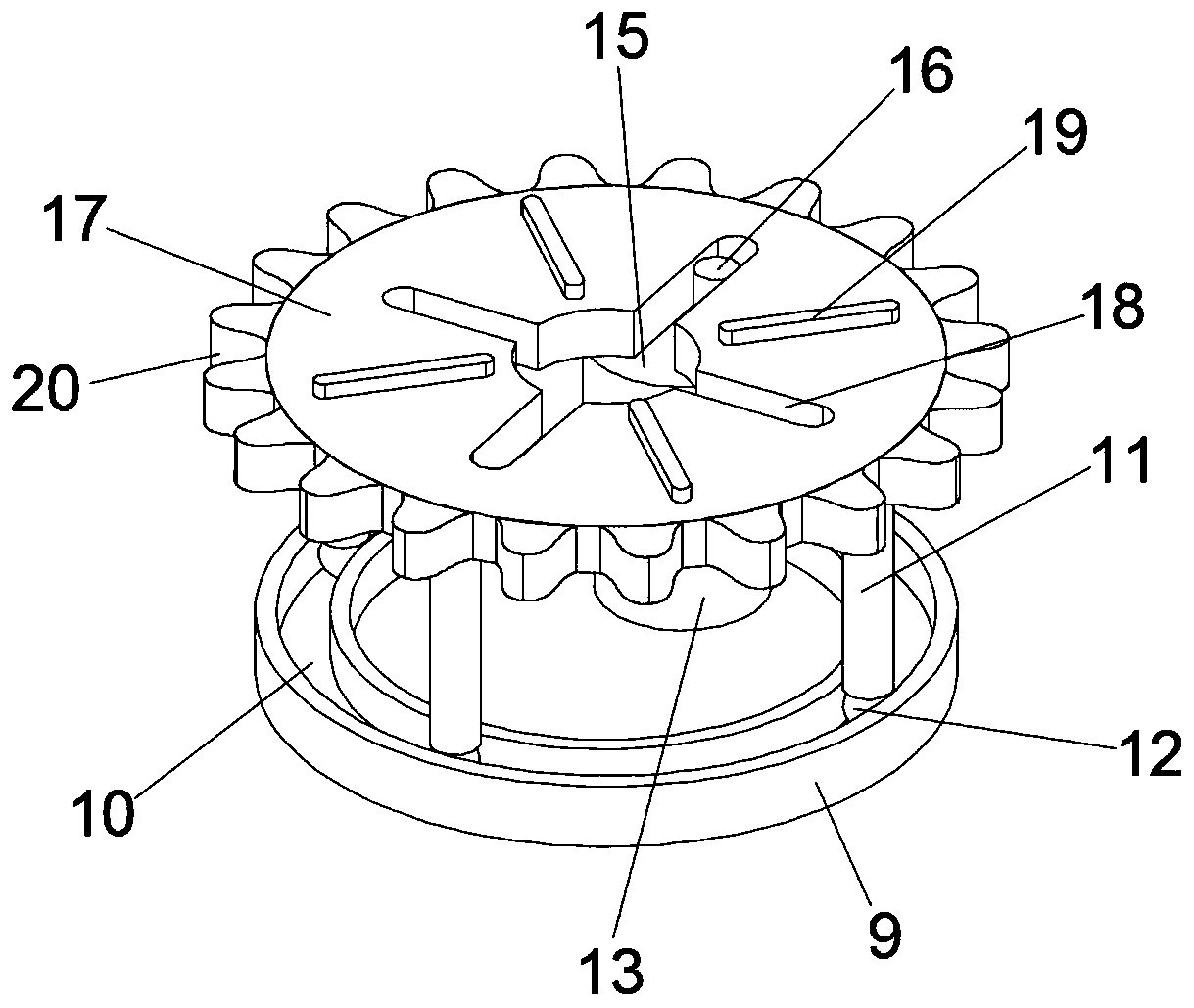

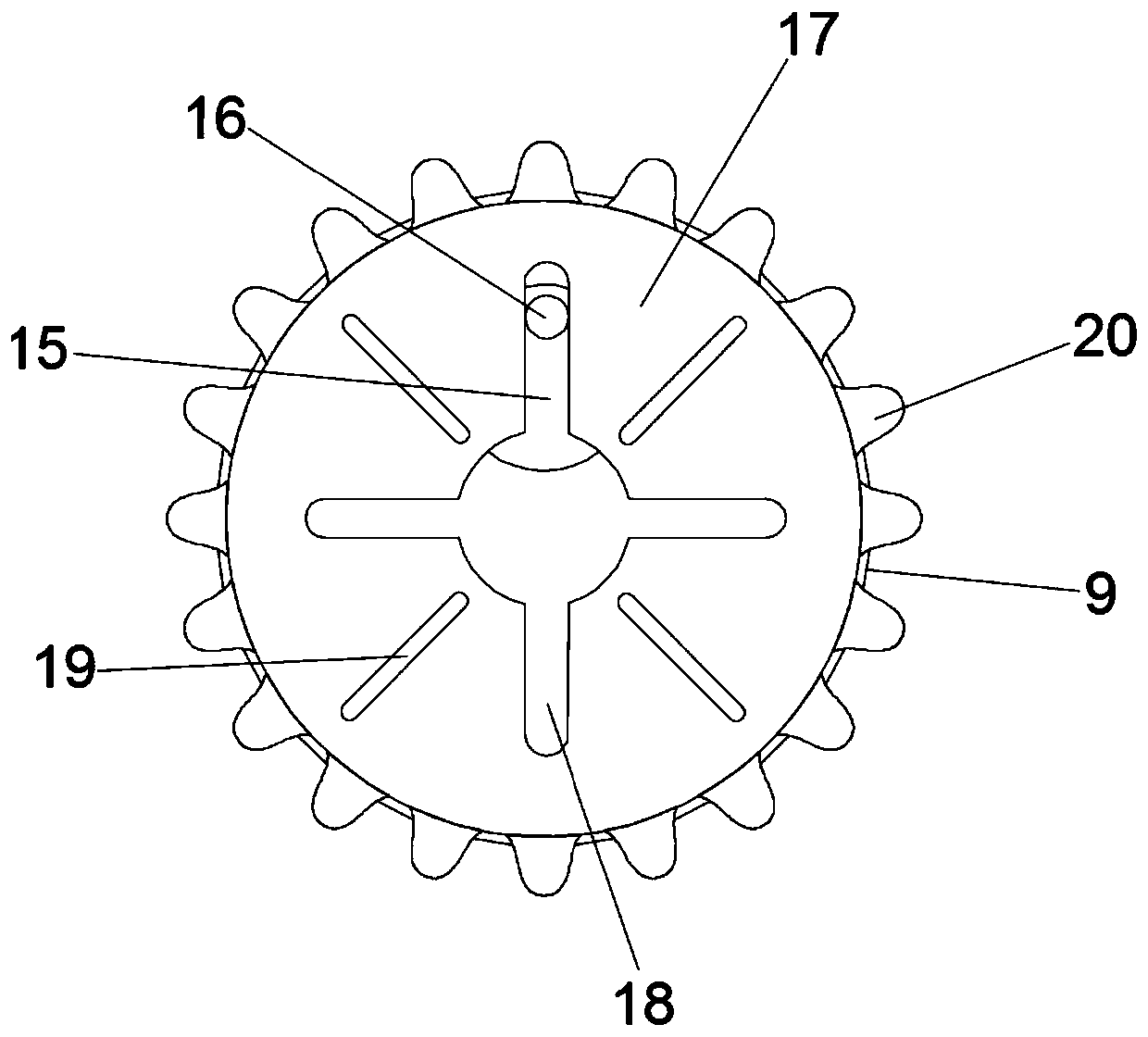

Bionic knocking arm type Chinese walnut shell crushing machine

The invention discloses a bionic knocking arm type Chinese walnut shell crushing machine. The bionic knocking arm type Chinese walnut shell crushing machine comprises: a rack, a shell crushing roller, a feeding mechanism, a shell crushing mechanism and a driving mechanism, wherein the rack is used for supporting each part; fruit grooves are formed in the shell crushing roller; the fruit grooves are used for storing materials; the feeding mechanism is used for conveying the materials into the fruit grooves; the shell crushing mechanism is used for simulating an artificial machining manner and knocking the materials in the fruit grooves so as to crush the materials; the driving mechanism is used for driving the feeding mechanism, the shell crushing mechanism and the shell crushing roller to act to ensure that the feeding mechanism can be kept feeding the materials into the fruit grooves continuously; the shell crushing mechanism can be kept knocking the materials in the fruit grooves continuously; the shell crushing roller can be kept rotating continuously and the crushed materials are poured and ventilated and newly added materials are transferred to a position under a knocking arm in the shell crushing mechanism and are knocked. The feeding mechanism of the bionic knocking arm type Chinese walnut shell crushing machine is simple, has good commonality and can be used for stably and reliably feeding; the shell crushing mechanism simulates the artificial machining manner, the shell crushing quality is good and the shell crushing efficiency is high; the whole machine has a compact structure.

Owner:宁国市昌水山核桃脱脯机械有限公司

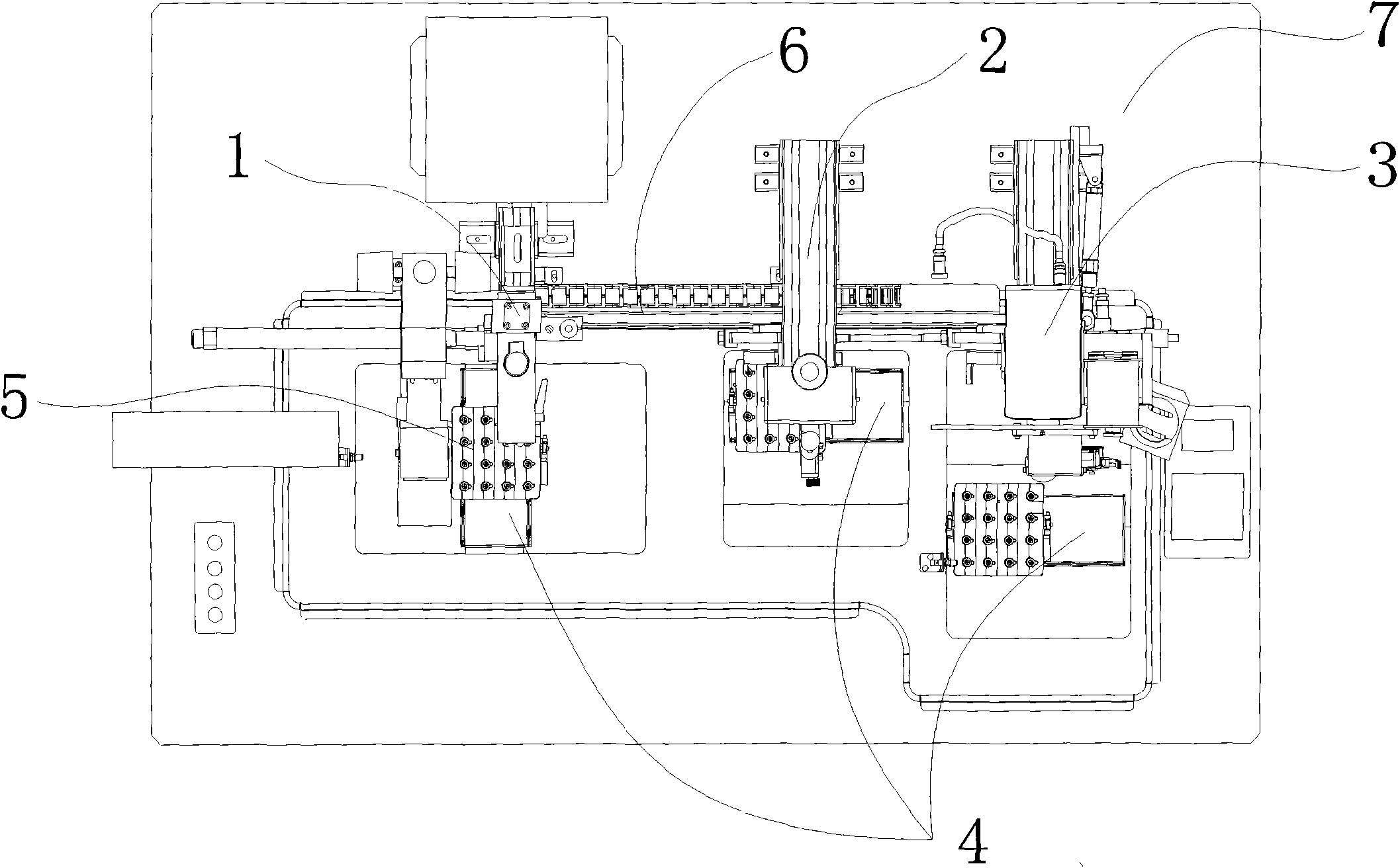

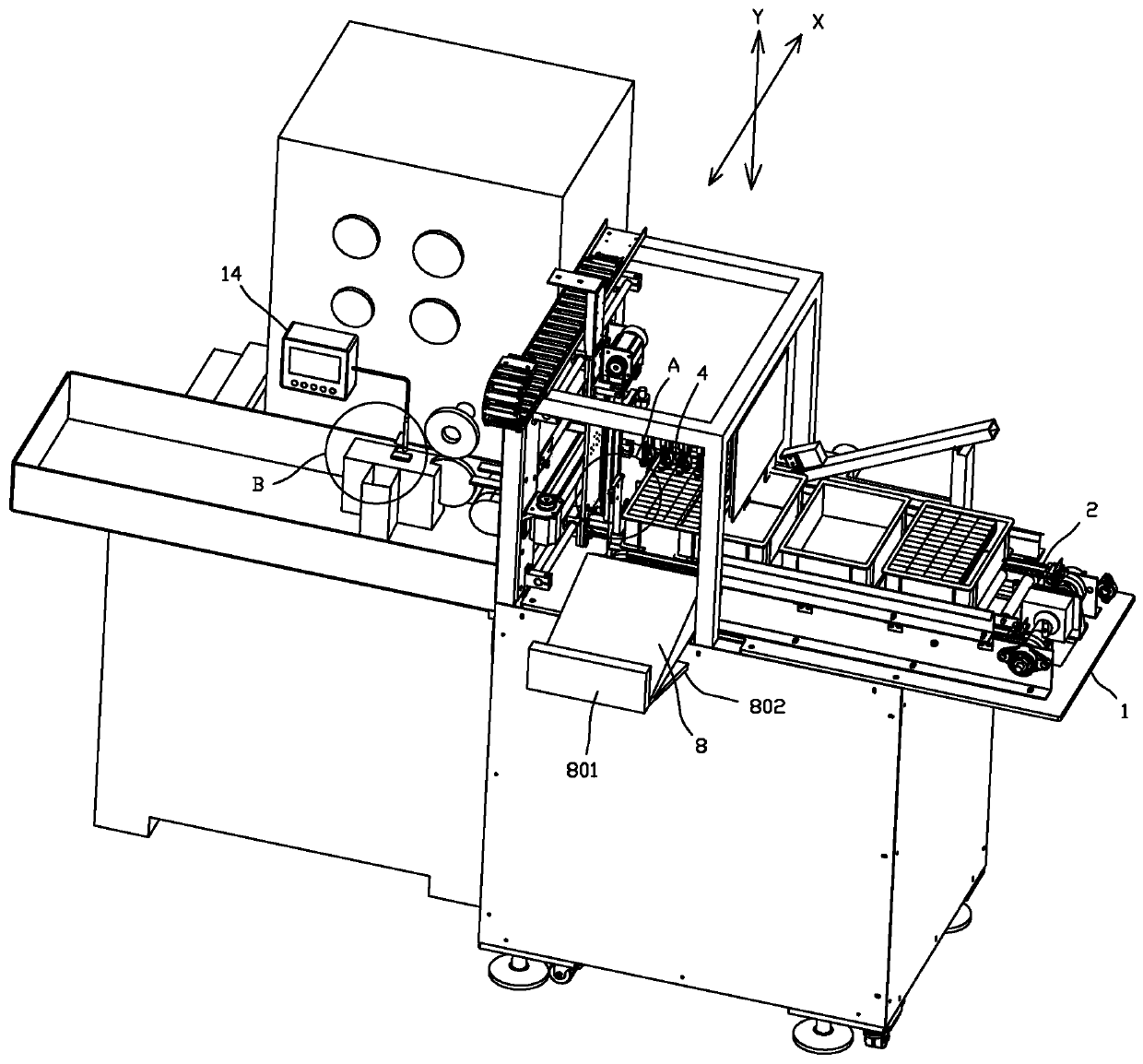

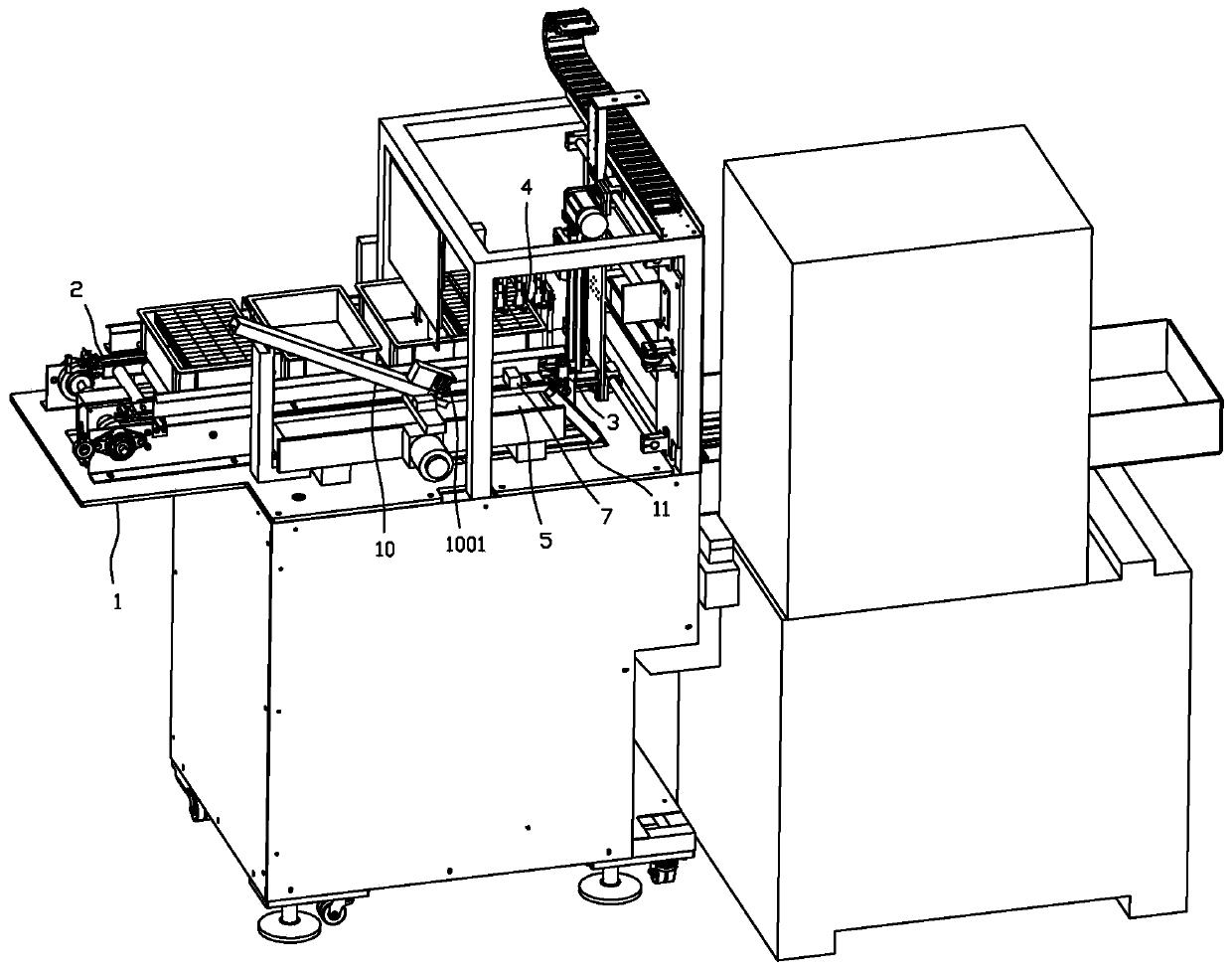

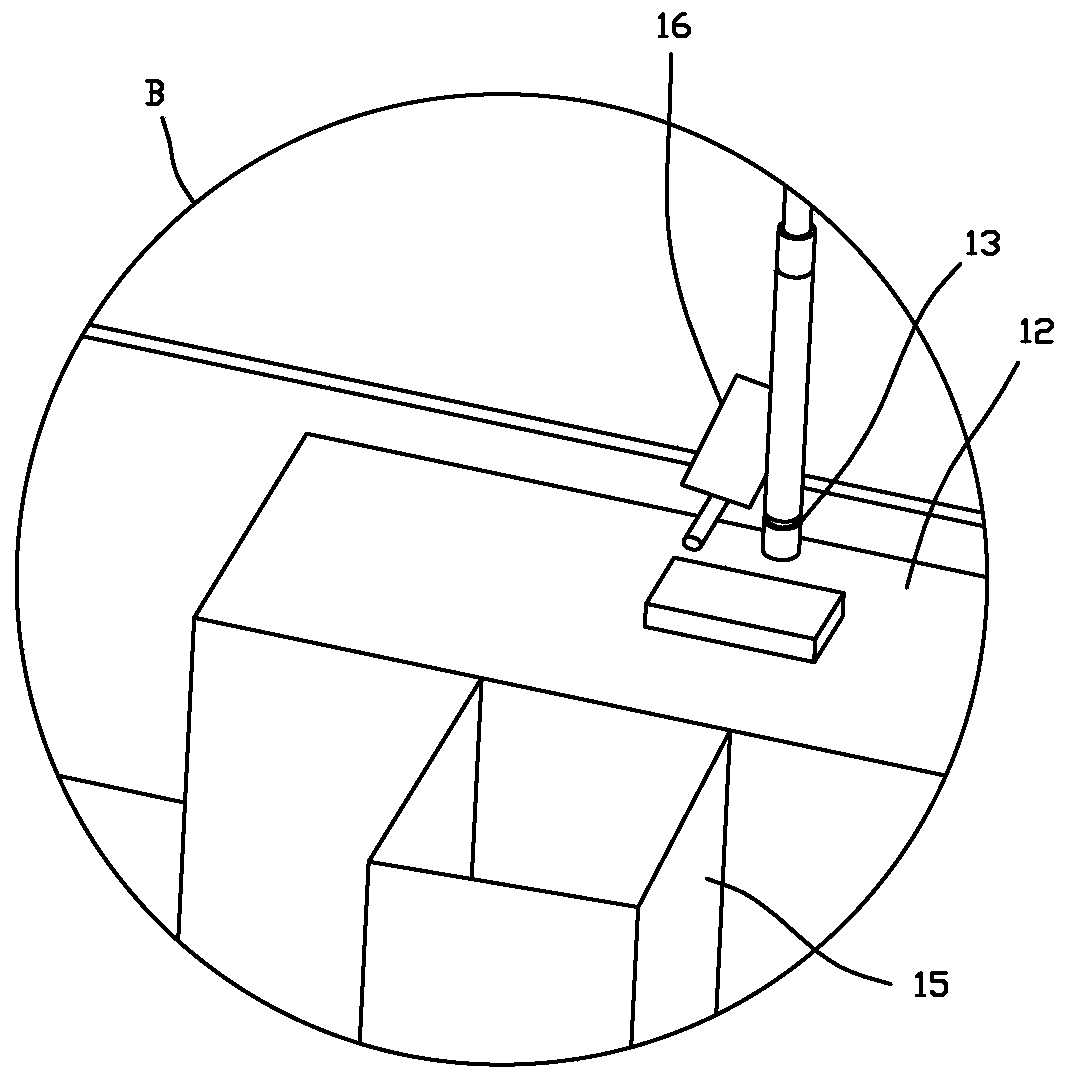

Visual micro spot welding and tin soldering automatic production line

ActiveCN102079024AAdaptableVisualWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to a visual micro spot welding and tin soldering automatic production line which comprises an automatic visual micro spot welding mechanism, an automatic detecting mechanism and an automatic tin soldering mechanism, wherein the automatic visual micro spot welding mechanism, the automatic detecting mechanism and the automatic tin soldering mechanism are arranged on a bottom plate mechanism; three two-dimensional movement platforms respectively corresponding to the automatic visual micro spot welding mechanism, the automatic detecting mechanism and the automatic tin soldering mechanism are installed on the bottom plate mechanism; tool plates for bearing workpieces are arranged on the movement modules of the two-dimensional movement platforms; the bottom plate mechanismis also provided with a carrying and positioning mechanism and a control circuit; the carrying and positioning mechanism is used for grasping and transferring the tool plates from one two-dimensionalmovement platform to another two-dimensional movement platform; and the control circuit is used for controlling the carrying and positioning mechanism. The visual micro spot welding and tin solderingautomatic production line provided by the invention can realize full-automatic operation of three working procedures of visual micro spot welding, detecting and tin soldering.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

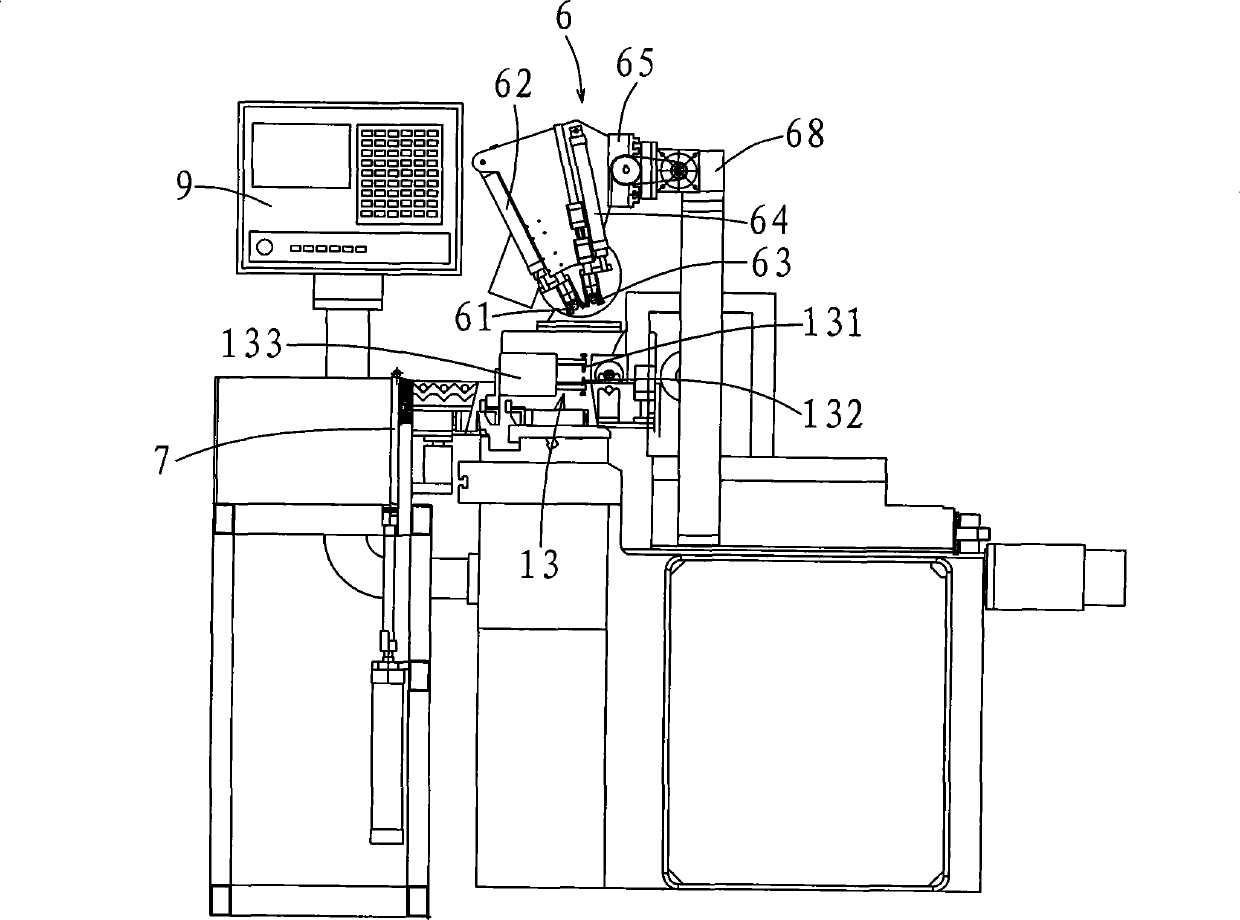

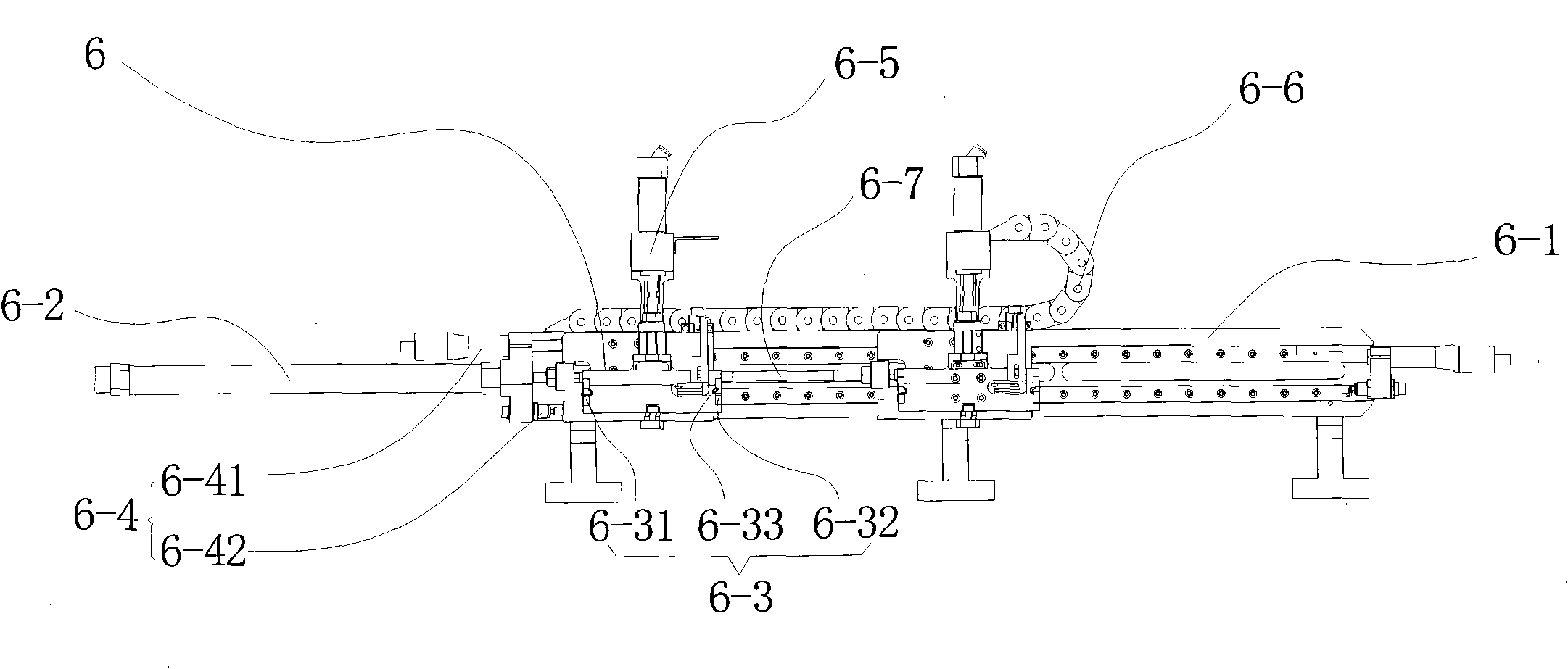

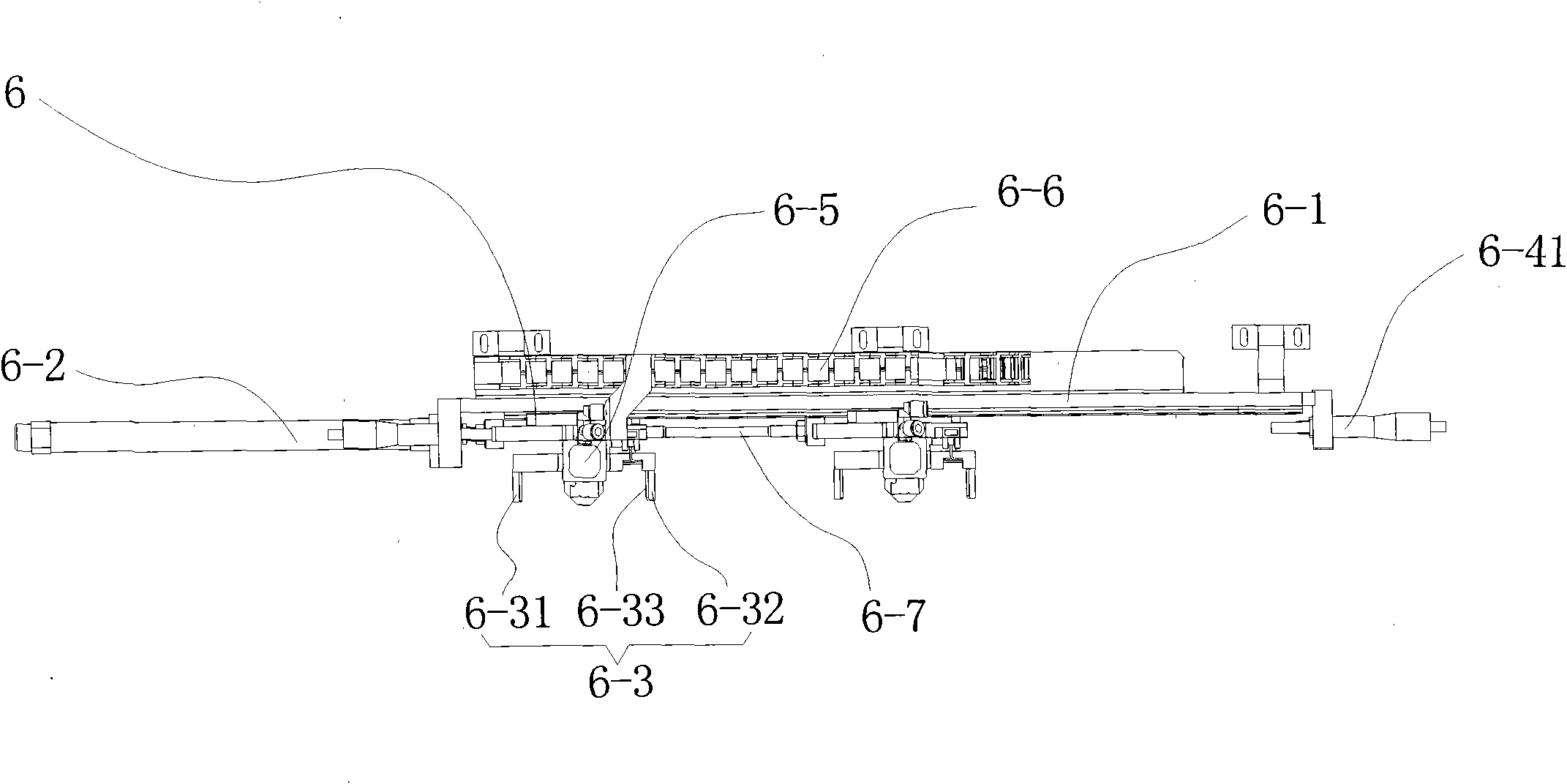

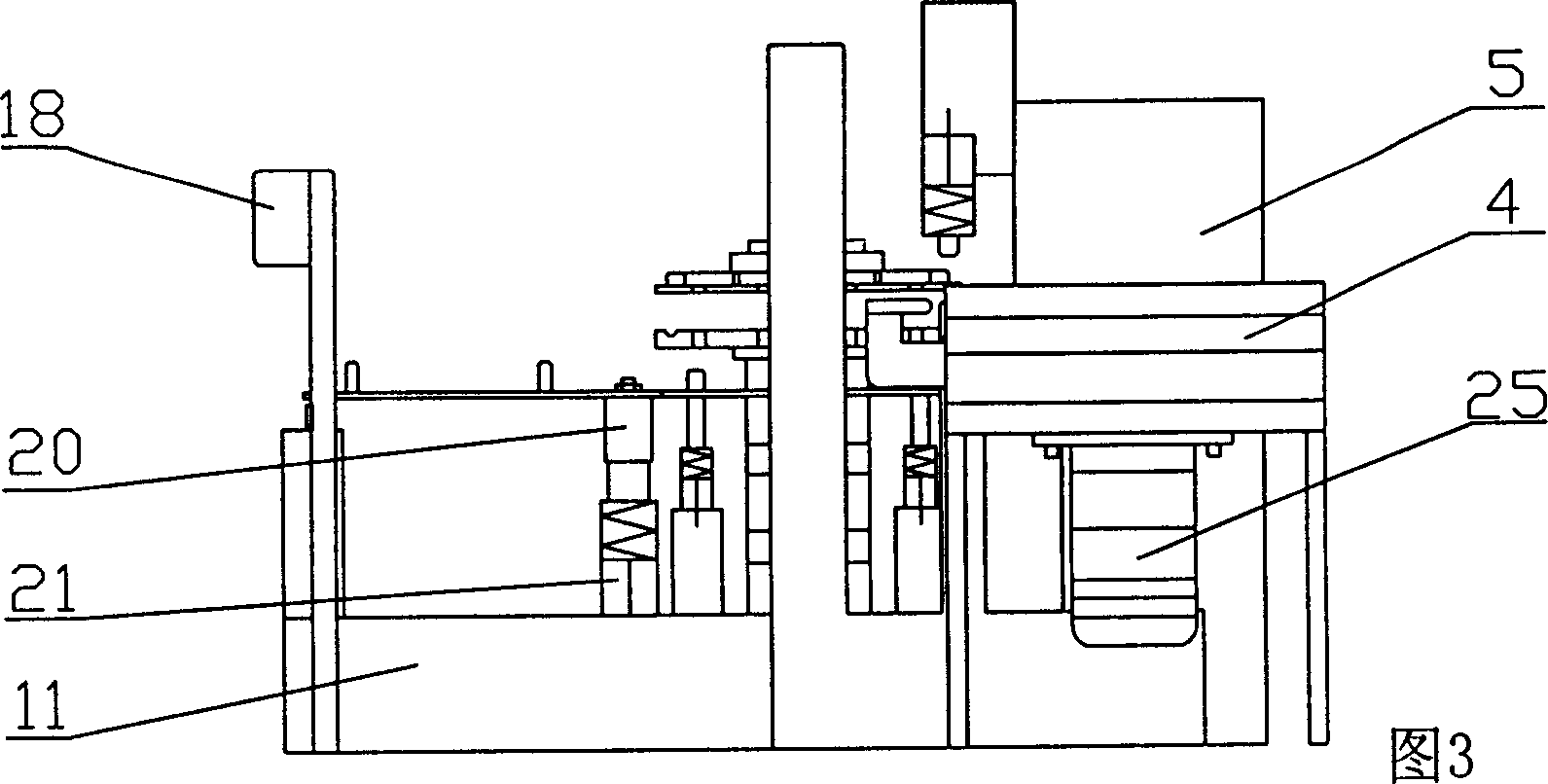

Special automatic grinding machine capable of loading and unloading automatically for crankshaft processing and processing method of special automatic grinding machine

InactiveCN108214137AFlexible rotationHigh degree of automationRevolution surface grinding machinesAutomatic grinding controlEngineeringDrive motor

The invention discloses a special automatic grinding machine capable of loading and unloading automatically for crankshaft processing. The special automatic grinding machine comprises a rack, a clamping part, a grinding part, a power distribution box and a loading-unloading mechanism, wherein the clamping part comprises a first main shaft, a first drive motor, a main shaft tip end, a tail base anda tail base tip end; the grinding part comprises a grinding wheel, a second main shaft and a second drive motor; a crankshaft position measuring head is arranged at one side of the grinding wheel; aPLC controller is arranged in the power distribution box; the loading-unloading mechanism comprises a transmission frame, a loading mechanism and an unloading mechanism, a loading conveyor belt, an unloading conveyor belt and a supporting beam; the loading mechanism comprises a loading clamping jaw, a loading clamping air cylinder and a loading lifting air cylinder; the unloading mechanism comprises an unloading clamping jaw, an unloading clamping air cylinder and an unloading lifting air cylinder; and a crankshaft position measuring head, the first drive motor, the second drive motor, the loading mechanism and the unloading mechanism are connected with the PLC controller. The special automatic grinding machine is high in degree of automation, is high in grinding efficiency, reduces laborpower, reduces cost, is stable and reliable in clamping, and is high in loading and unloading efficiency.

Owner:金华市方易机械有限公司

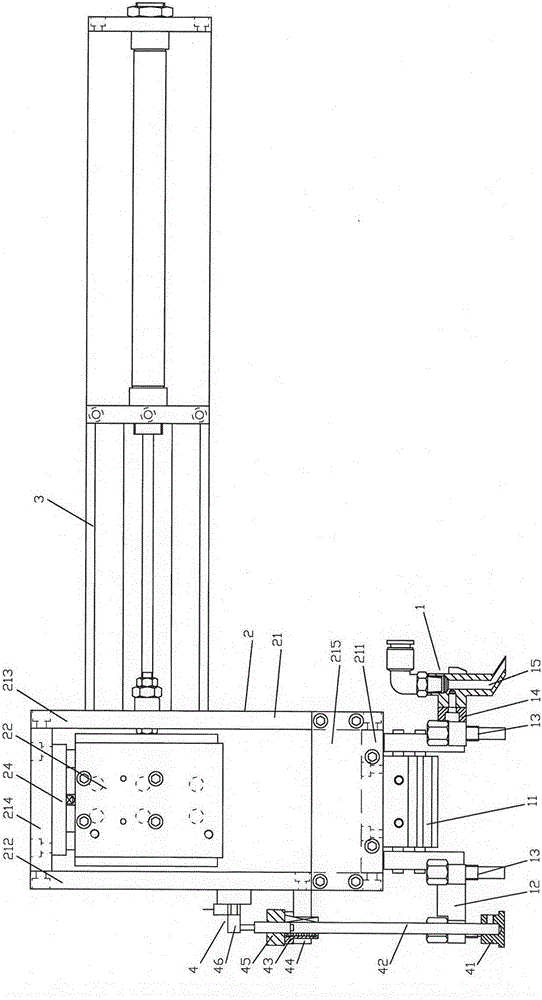

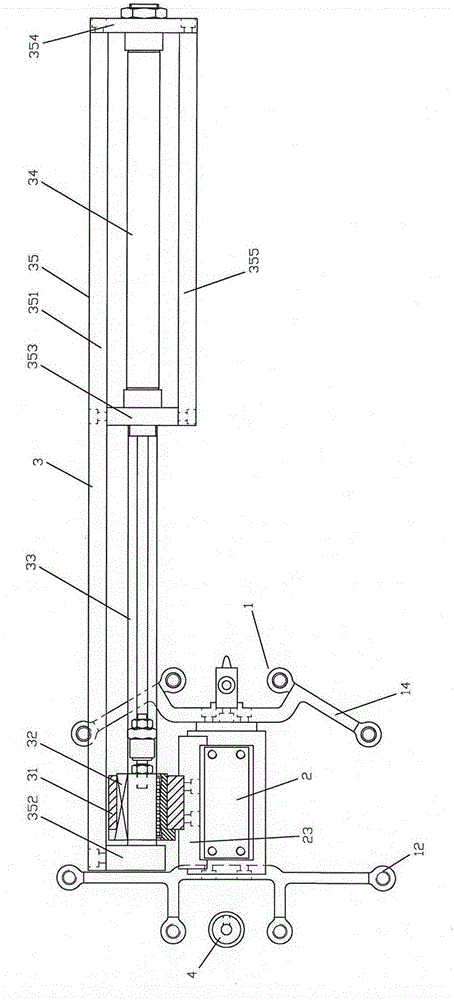

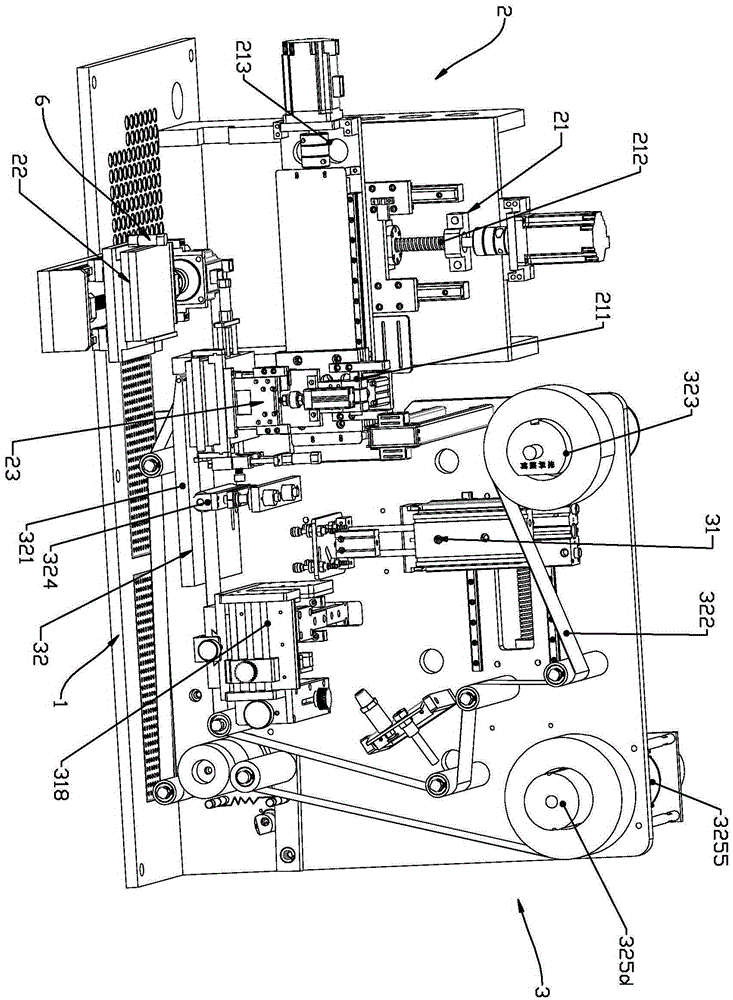

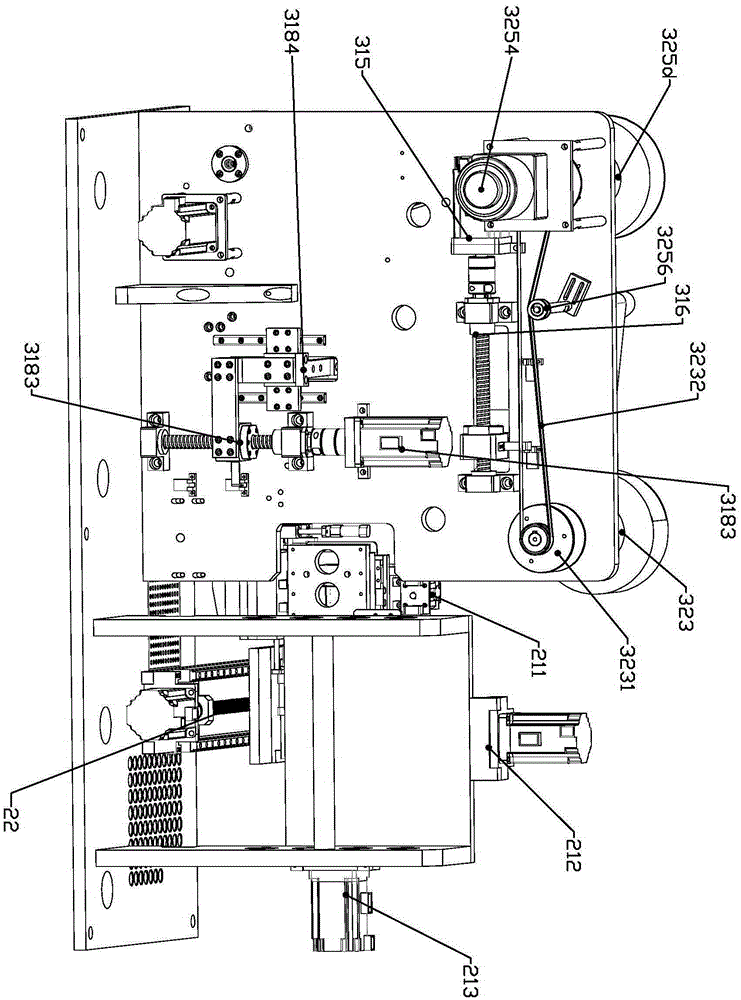

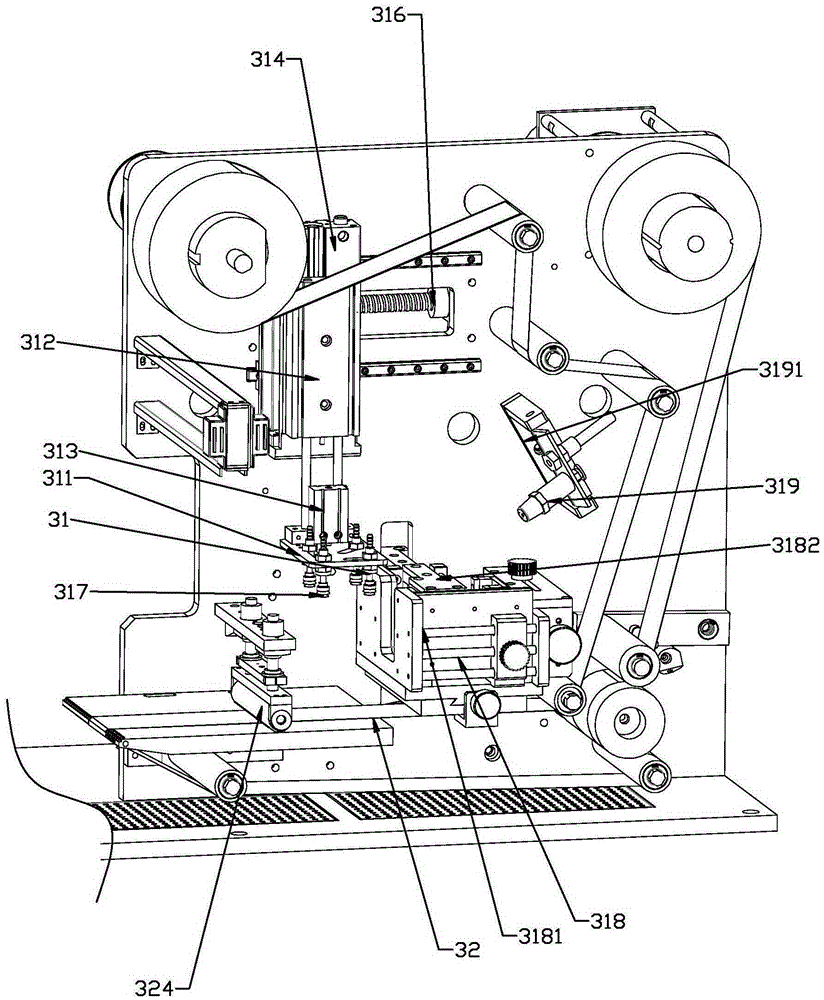

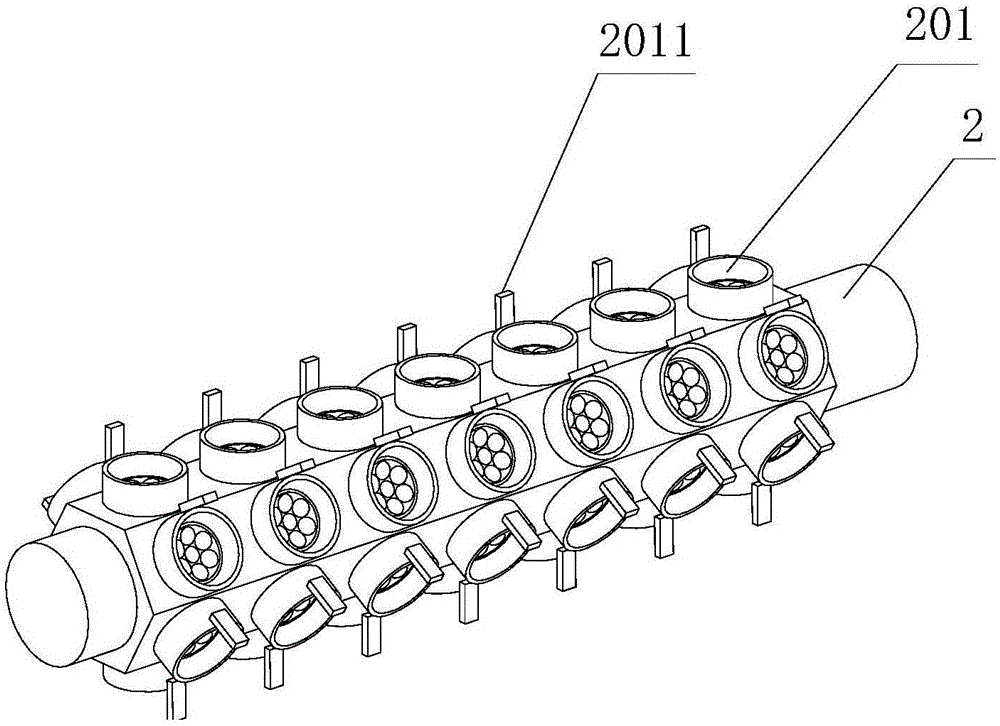

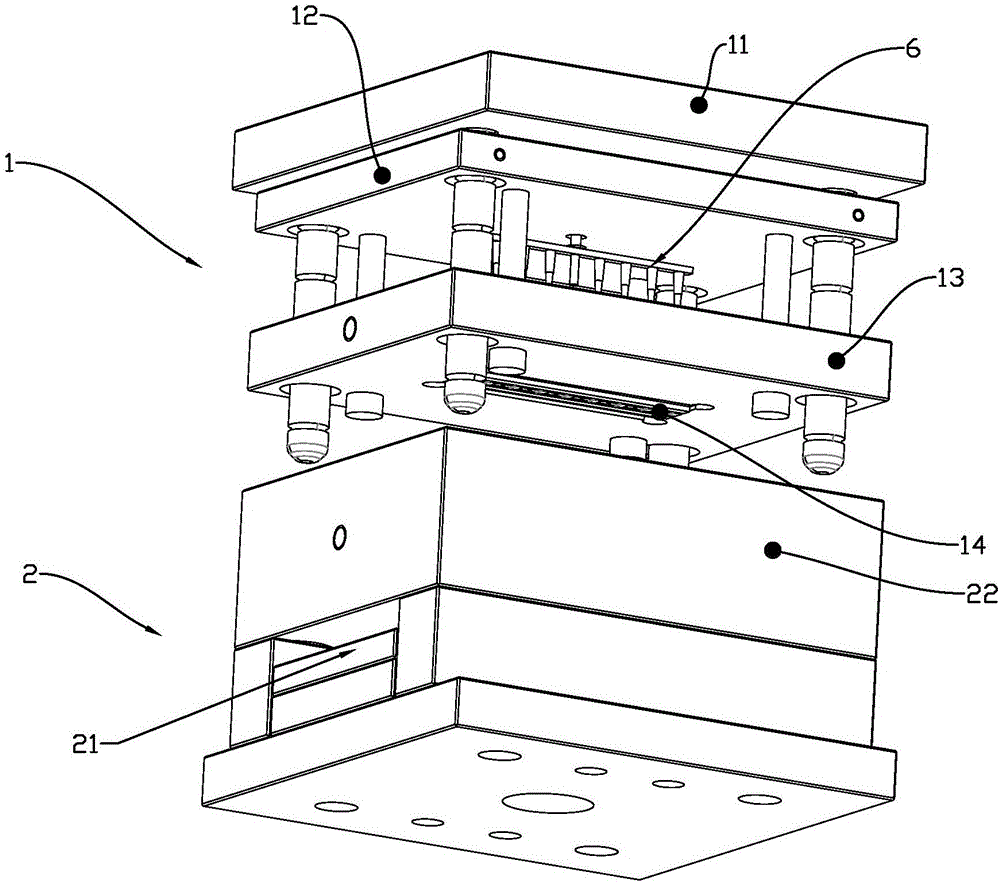

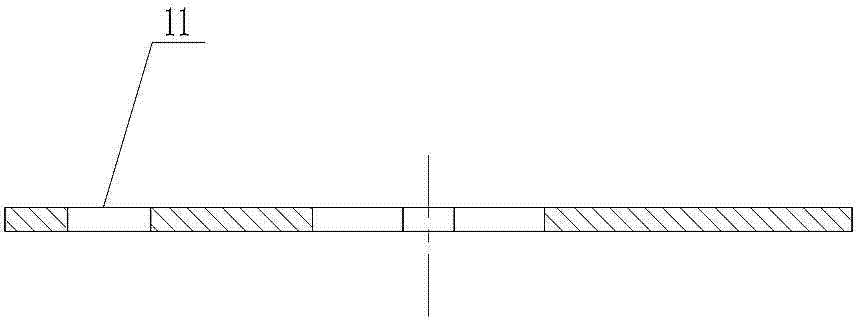

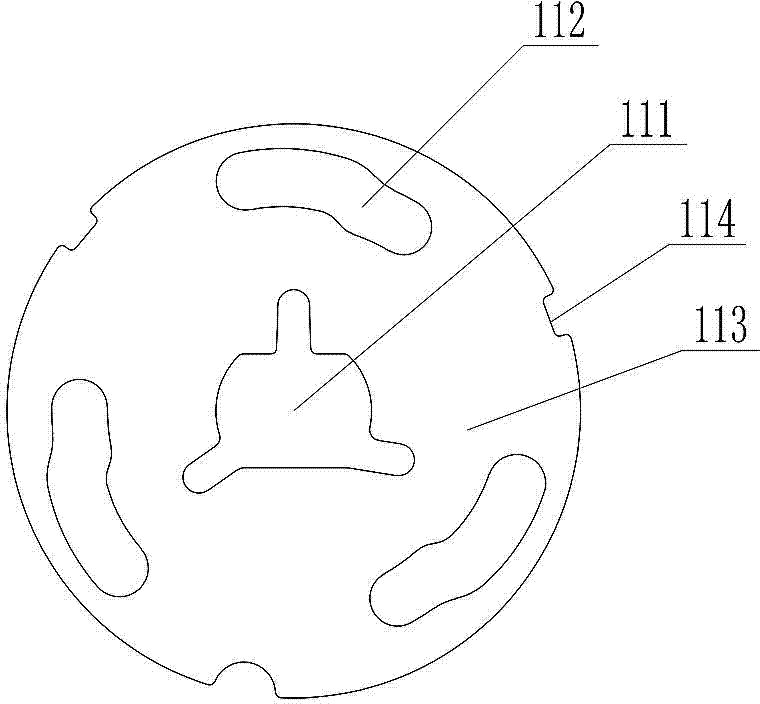

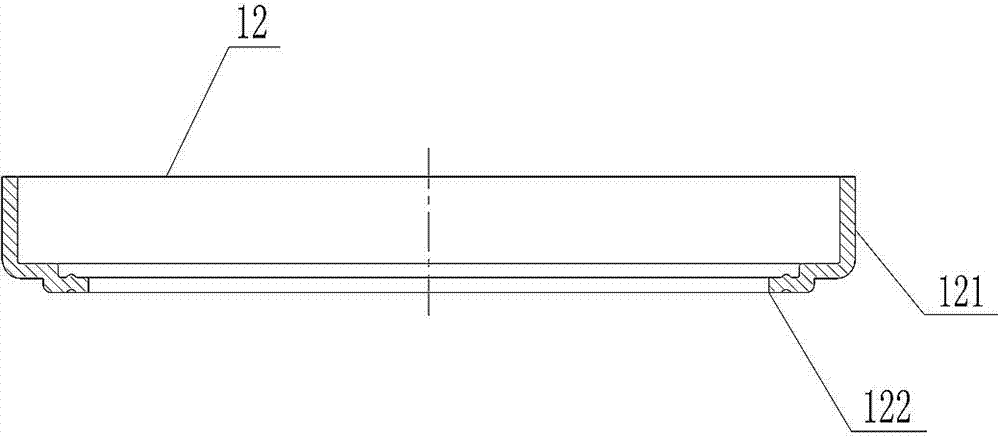

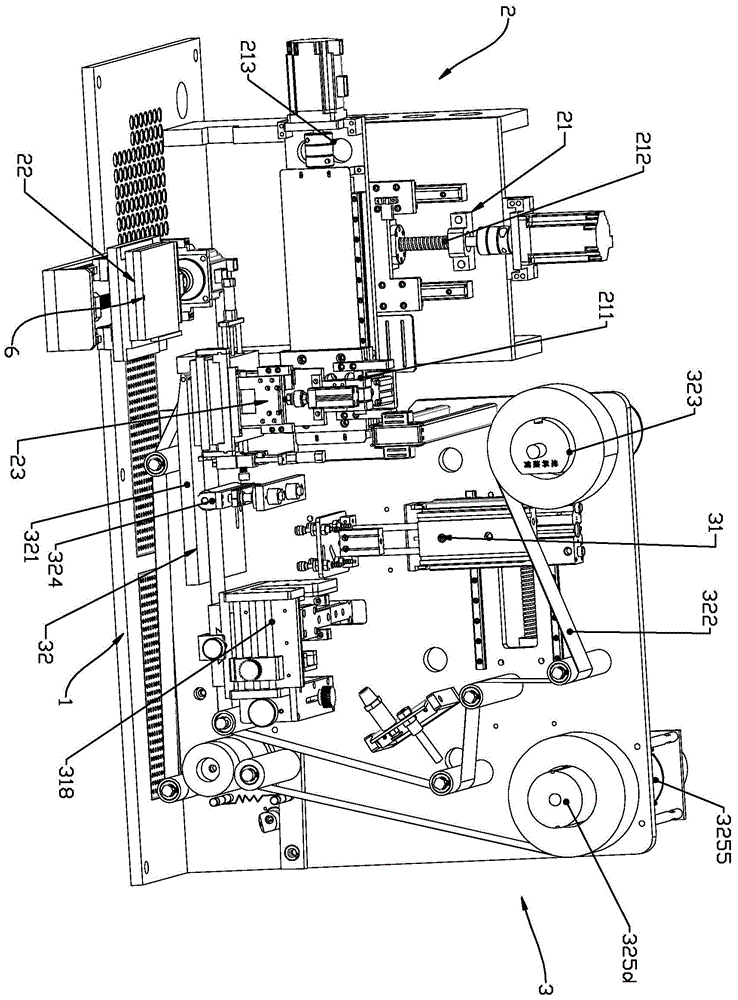

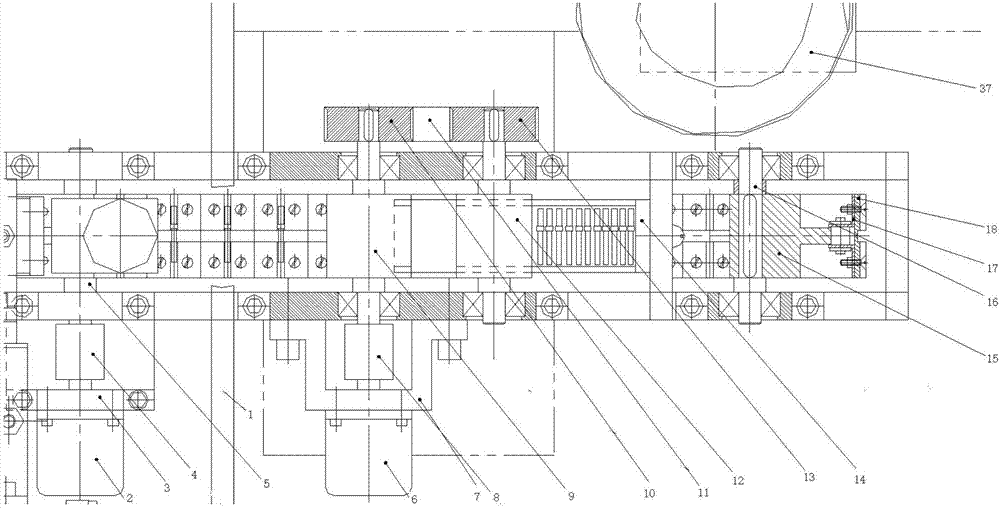

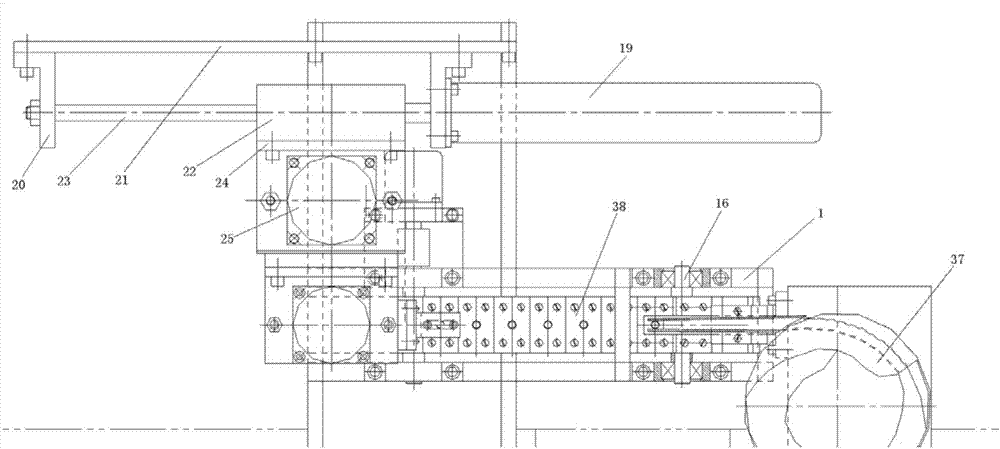

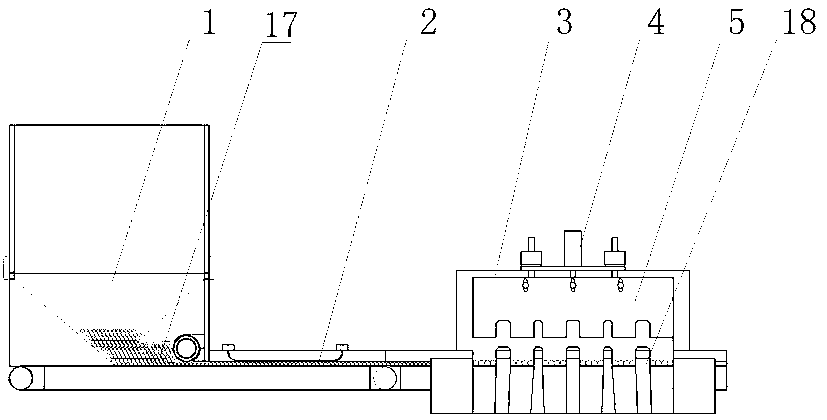

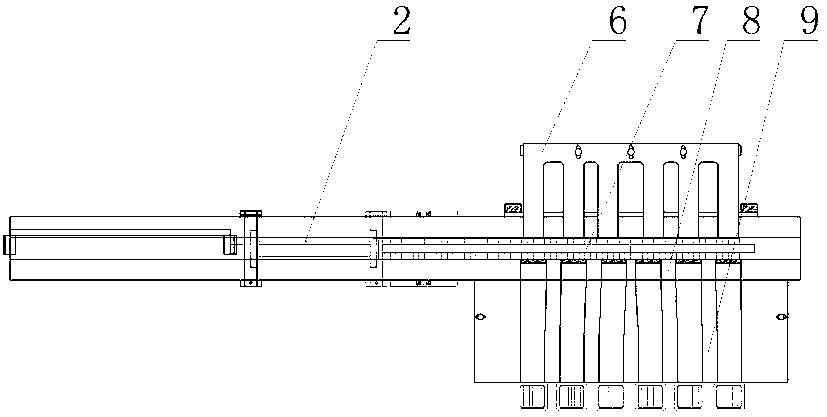

Injection molding machine for flat needle material strap

ActiveCN106217750AStable and reliable feedingReliable tractionCoatingsInjection molding machineIntermittent traction

The invention relates to an injection molding machine for a flat needle material strap. The injection molding machine comprises a machine frame, an injection molding mechanism and an injection mold located on the injection molding procedure. The injection mold comprises an upper mold body and a lower mold body. The upper mold body comprises an upper mold base plate, a stripper plate, an upper mold core board and an upper mold core which are correspondingly matched. The lower mold body comprises an ejection mechanism, a lower mold core board and a lower mold core. The lower mold core is installed on the lower mold core board, and the upper mold core and the lower mold core are correspondingly matched. The lower mold core is provided with a plurality of pouring cavities. The lower mold core is provided with a material strap guide base which is correspondingly matched with the pouring cavity. The material strap guide base is provided with a material strap guide groove with the two ends being through. A material strap feeding device is arranged at the material strap led-in end opening side of the material strap guide groove, and a material strap intermittent traction device which is adapted to the injection molding procedure and used for intermittent traction of the flat needle material strap is arranged at the material strap led-out end opening side of the material strap guide groove. The injection molding machine can automatically convey the flat needle material strap and has the advantages of being high in degree of automation and high in working efficiency.

Owner:WENZHOU YIHUA CONNECTOR

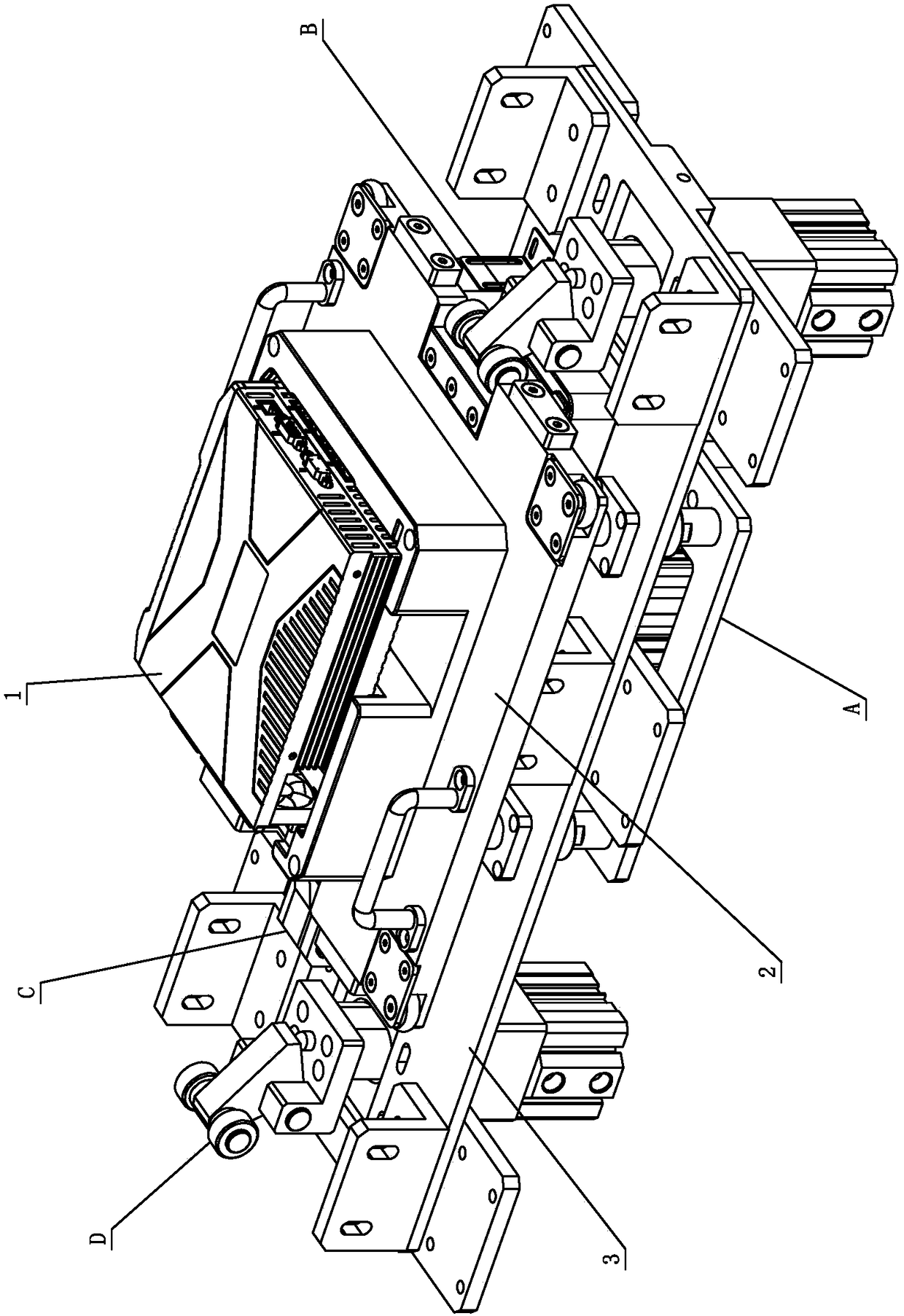

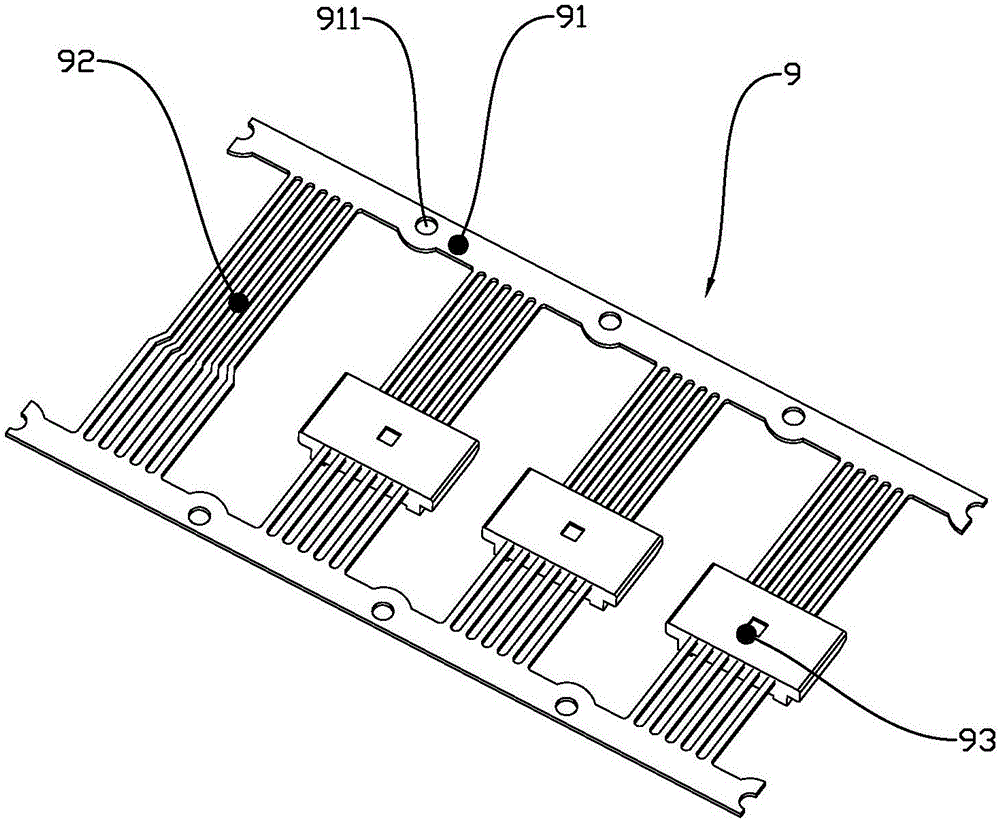

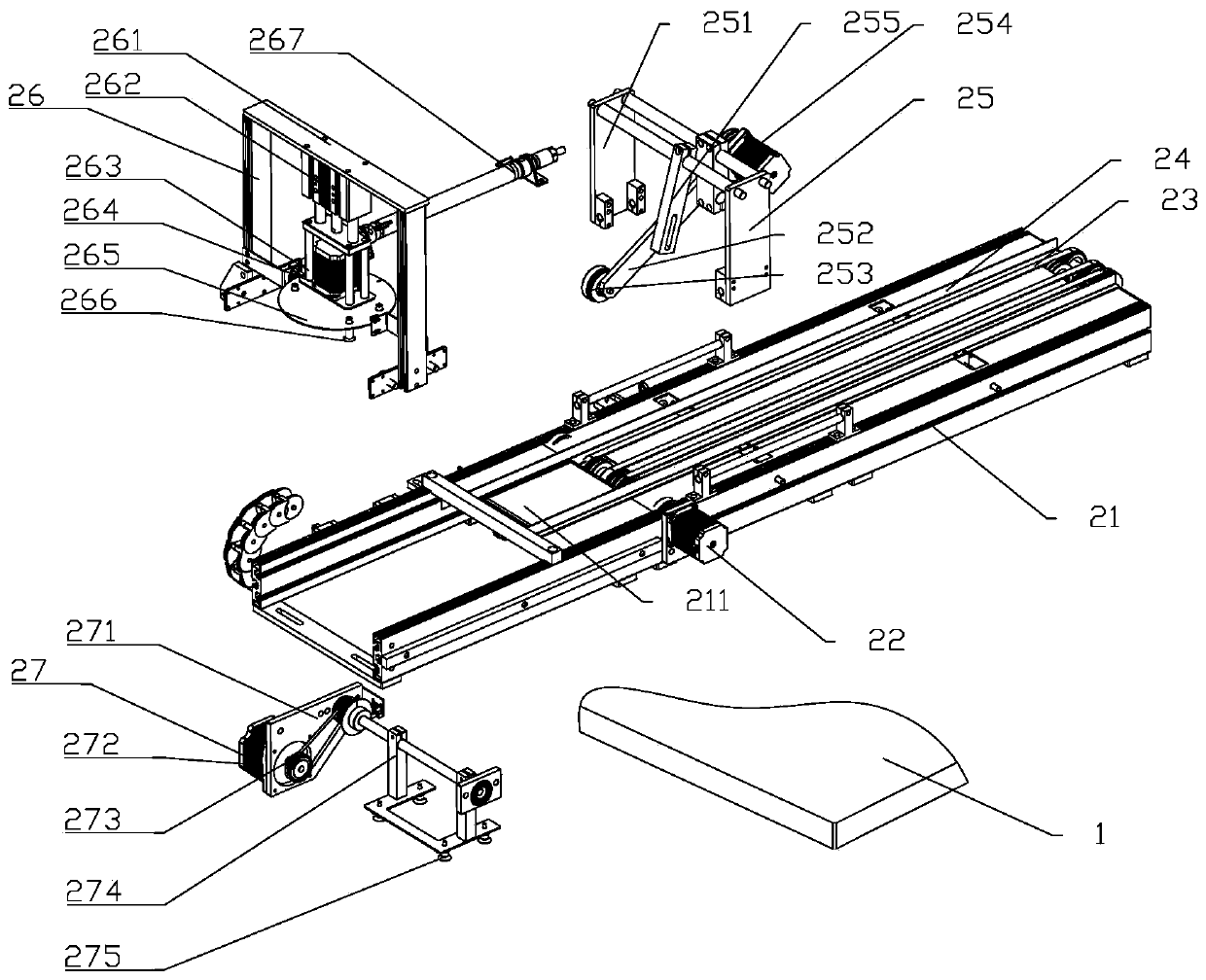

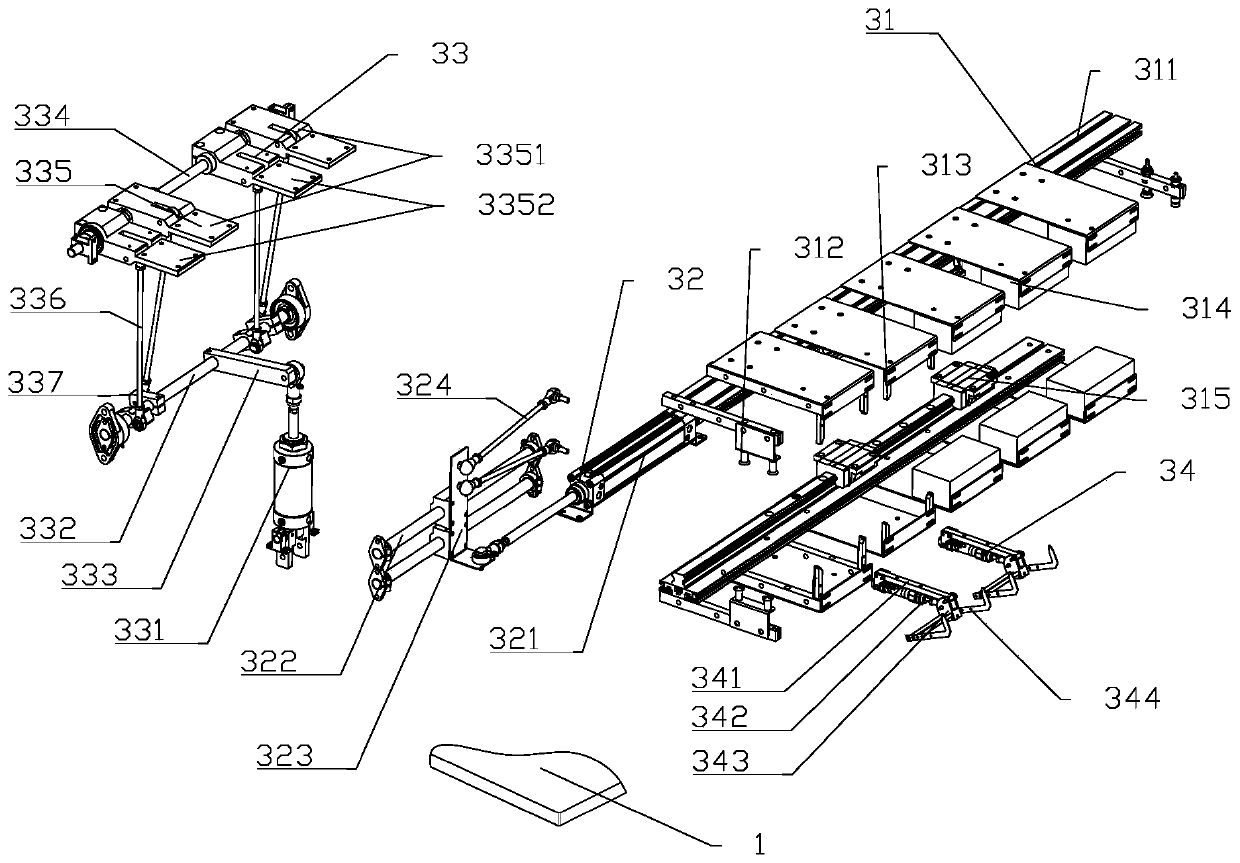

Carrier plate conveying line device of integrated circuit film removing machine

InactiveCN110422415AThere will be no speed inconsistenciesStable and reliable feedingSemiconductor/solid-state device manufacturingArticle unpackingIntegrated circuit manufacturingIntegrated circuit layout

The invention relates to the technical field of electronic integrated circuit manufacturing, and discloses a carrier plate conveying line device of an integrated circuit film removing machine. The carrier plate conveying line device comprises conveying frames, a direct current motor, a conveying belt, heating plates, driving friction wheels, a stepping motor, a pressing wheel assembly, a receivingplate assembly, an empty plate collecting assembly and a prepressing wheel assembly; the conveying frames are arranged on a frame; feeding ends of the conveying frames are provided with the driving friction wheels; the driving friction wheels are driven by the stepping motor; the prepressing wheel assembly is arranged above the driving friction wheels; the prepressing wheel assembly presses a roller towards the driving friction wheels through elasticity of springs; the heating plates are arranged at the ends of the two conveying frames; the pressing wheel assembly is arranged above the heating plates and comprises a pressing cylinder, a roller mounting plate and a plurality of rollers; the rollers are connected to a telescopic end of the pressing cylinder through a roller mounting plate;the rollers correspond to the edge frame strip of a carrier plate; and the rear end of each heating plate is provided with a limiting assembly. The carrier plate conveying line device is capable of automatically feeding and discharging, high in adaptability, reliable in conveying and accurate in positioning.

Owner:NINGBO YINZHOU TEERFEI ELECTRONICS CO LTD

Garment bagging packaging device and packaging method

InactiveCN110589096AFunction increaseStable and reliable feedingWrapper twisting/gatheringIndividual articlesControl systemEngineering

The invention relates to the field of garment packaging, and discloses a garment bagging packaging device. The garment bagging packaging device comprises a machine frame, a packaging bag conveying device, a packaging bag transferring device, a garment bagging device, a packaging bag mouth treatment device, a garment feeding device and a control system, wherein the packaging bag conveying device, the packaging bag transferring device, the garment bagging device, the packaging bag mouth treatment device, the garment feeding device and the control system are mounted on the machine frame, the packaging bag conveying device is located right above the packaging bag transferring device, the packaging bag mouth treatment device is located on the side of the packaging bag transferring device, and corresponds to an open mouth of a packaging bag, the packaging bag transferring device and the packaging bag mouth treatment device each are provided with multiple stations for corresponding processingcorrespondingly, and the garment bagging device is mounted on the machine frame, is connected with the garment feeding device, and corresponds to the packaging bag mouth treatment device. The garmentbagging packaging device has the advantages that the opening success rate is high, the sealing effect is good, and assembly is efficient.

Owner:王泽凯

Mould for manufacturing cover ring of auto seat and method thereof

ActiveCN104759533AEasy to wash downAccurateShaping toolsMetal-working feeding devicesPunchingRobotic arm

The invention relates to a mould for manufacturing a cover ring of an auto seat and a method thereof. The mould is characterized in that a wafer blanking die, a forming and punching die, a first shaping die, a second shaping die, a punching and raising die, a linkage piece blanking die, a forming die, a punching die and a shaping die are sequentially arranged and are mutually separated from all stations corresponding to the continuous die; a manipulator device further comprises a manipulator push plate, and the manipulator push plate and a mechanical arm can move simultaneously, and a certain end of the manipulator push plate is located below a die blanking frame; the wafer blanking die is internally provided with the die blanking frame fixed with a lower die, and wafer discharging die is provided with a vertical hole and a discharge hole which penetrates through the die blanking frame, the vertical hole is matched with an upper die blanking punch, and the discharge hole is matched with the lower die and the manipulator push plate. According to the structure and the manufacturing method provided by the invention, the functions of the feeding, the manipulator reclaiming and the die punching can be organically integrated, and the linkage pieces and the cover rings of the auto seat of different shapes can be finally formed, therefore the cost can be saved, and the quality can be improved.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

High-speed metal cutting circular saw

ActiveCN106001757AFast cutting speedImprove automation and work efficiencyMetal sawing devicesReciprocating motionMetal cutting

The present invention belongs to the technical field of metal cutting, and relates to a high-speed metal cutting circular saw. The high-speed metal cutting circular saw comprises a machine base, a cutting mechanism is disposed on the machine base, the machine base is connected with a feed mechanism, the cutting mechanism comprises a cutting disc and a cutting disc driver in drive connection with the cutting disc, a cutting base driver with an output end capable of reciprocating motion in an axial direction is disposed on the machine base, the cutting disc is disposed inside a cutting base and is flexibly connected with the cutting base, and the bottom of the cutting base is hinged to the machine base while the top of the cutting base is hinged to an output end of the cutting base driver. The circular saw provided by the invention is high in speed, efficiency and precision.

Owner:ZHEJIANG LONGLI MACHINERY

Magnetic tile assembly system and magneto rotor production equipment

InactiveCN109378950AEfficient and accurate assemblySolve assembly inefficienciesManufacturing stator/rotor bodiesElectric machineEngineering

The invention relates to the technical field of motor rotor production. A magnetic tile assembly system comprises a magnetic tile loading assembly device. The magnetic tile loading assembly device comprises a magnetic tile bin unloading mechanism, an unloading pushing mechanism, a magnetic tile assembly mechanism and a magnetic tile mounting plate. The unloading pushing mechanism and the magnetictile assembly mechanism are mounted on the magnetic tile mounting plate. The unloading pushing mechanism is coupled with the magnetic tile bin unloading mechanism. The unloading pushing mechanism pushes the unloaded magnetic tile into the magnetic tile assembly mechanism. The advantage of the magnetic tile assembly system is that a plurality of magnetic tiles can be stored by the magnetic tile binunloading mechanism, and the assembly of the magnetic tiles can be efficiently and accurately completed through the cooperation between the mechanisms.

Owner:陈荣乾

Automatic mechanical hand film feeding/fetching device

InactiveCN102166748APrecise positioningAvoid pollutionProgramme-controlled manipulatorGripping headsEngineeringElectrical and Electronics engineering

The invention discloses an automatic mechanical hand film feeding / fetching device, which comprises two grappling hooks, six hinges, two connecting rods, two hand grips, a positioning shaft, a photoelectric switch, a spindle, a shaft sleeve, a film clip, a film clip pin, a stopper and a computer, wherein the two hand grips are connected with the shaft sleeve through a fifth hinge and a sixth hinge; one end of one connecting rod and one end of the other connecting rod are connected with the spindle through a third hinge and a fourth hinge respectively; end faces of the two grappling hooks are connected with an end face of the film clip pin; the other ends of the two connecting rods are connected with the middle parts of the two grappling hooks through a first hinge and a second hinge respectively; the positioning shaft is arranged on the shaft sleeve and operates together with the shaft sleeve; the photoelectric switch is fixed on the shaft sleeve; the photoelectric switch positions the film feeding and fetching position of the shaft sleeve through a positioning stopper on the positioning shaft; and the computer detects the position of the shaft sleeve through a feedback signal of the photoelectric switch and controls motion of the spindle according to the position state of the shaft sleeve. Therefore, the two grappling hooks are opened and closed at specified positions, and fed and fetched films are provided for exposure work.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

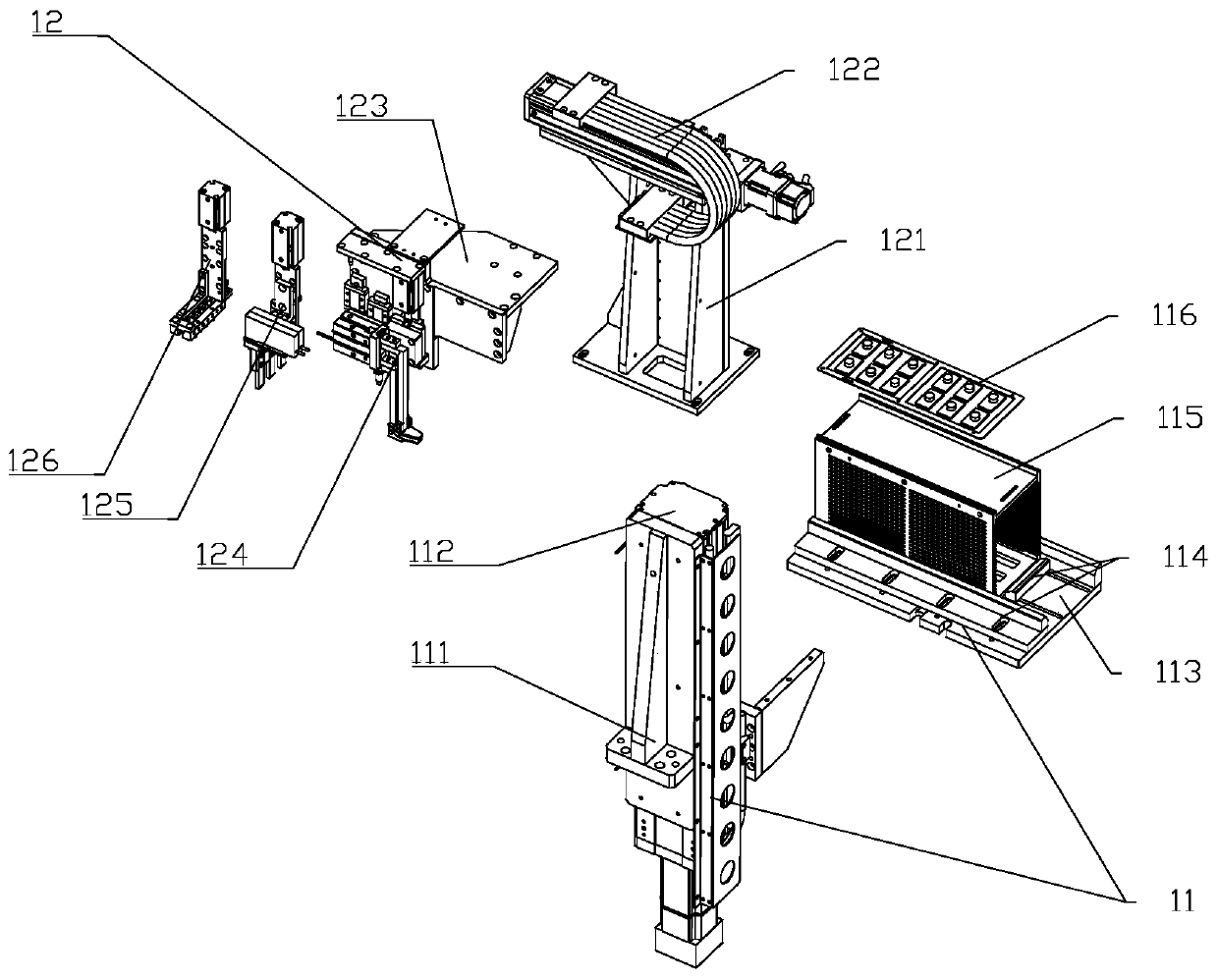

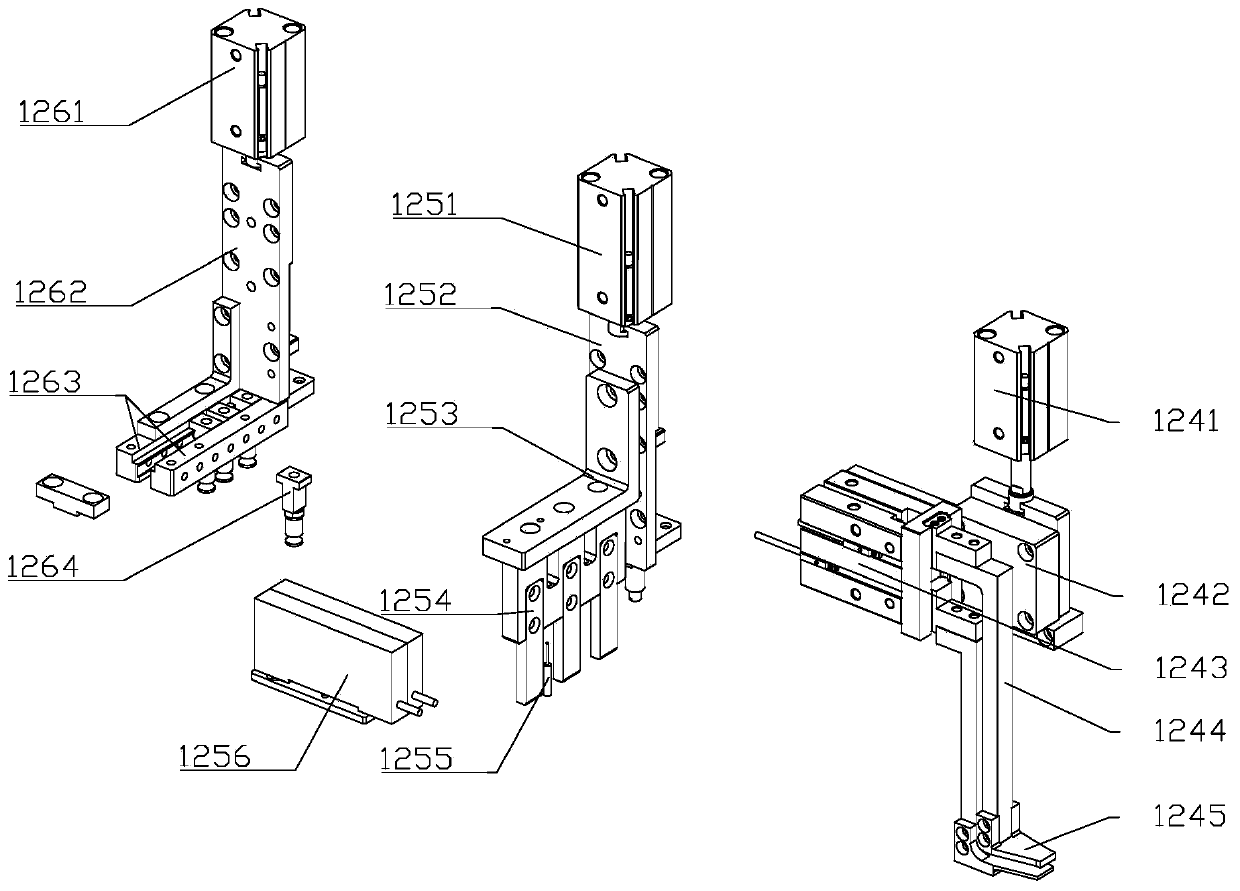

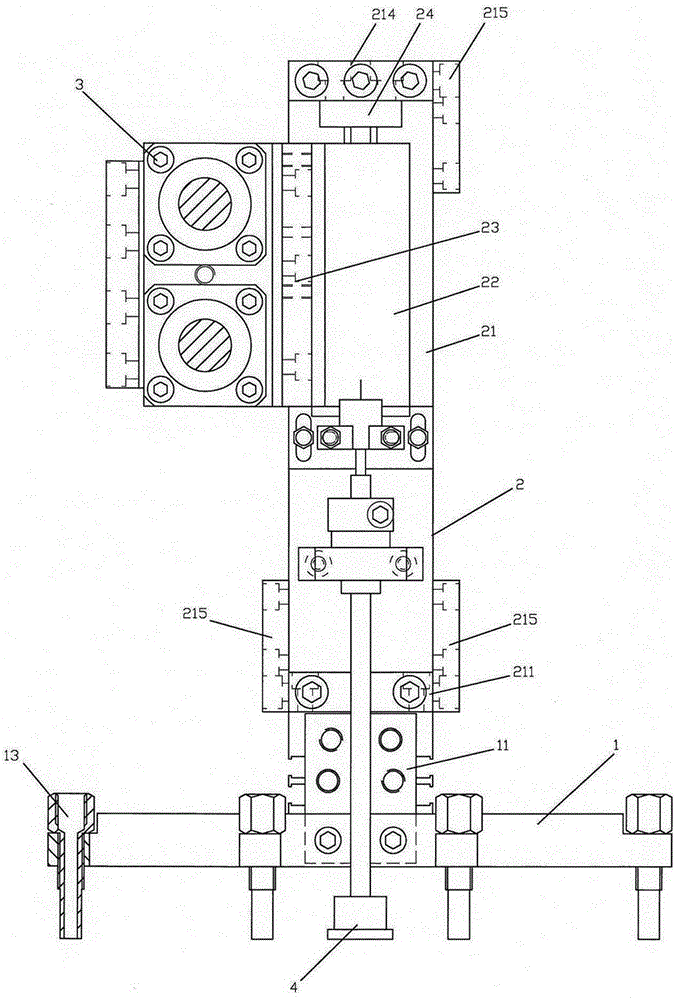

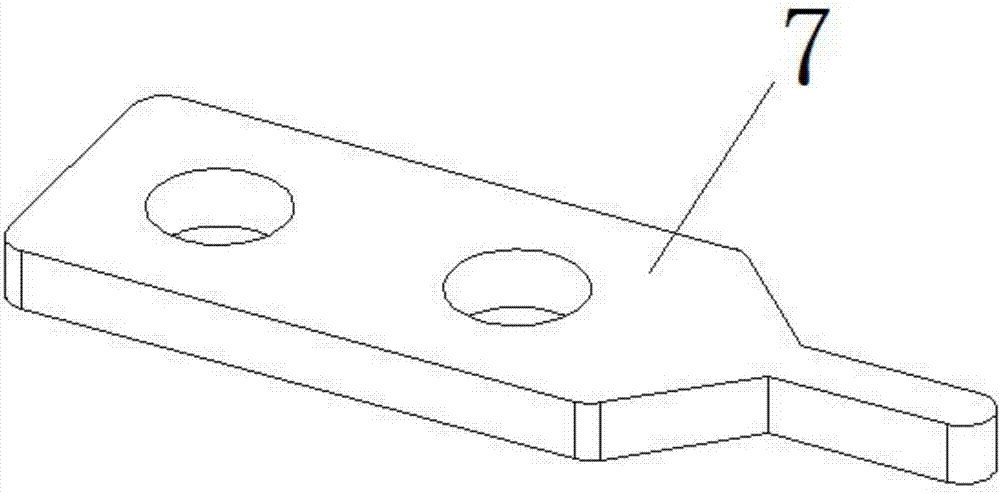

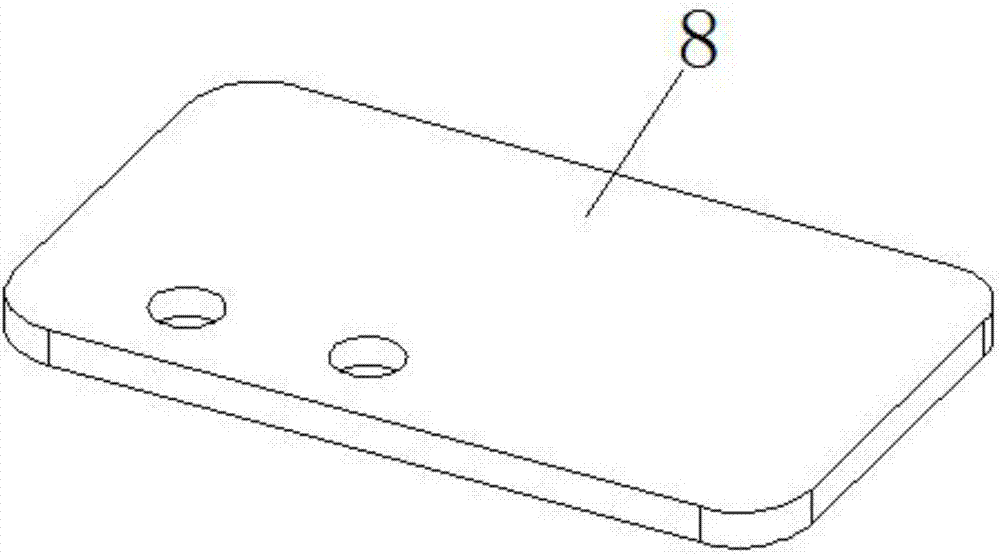

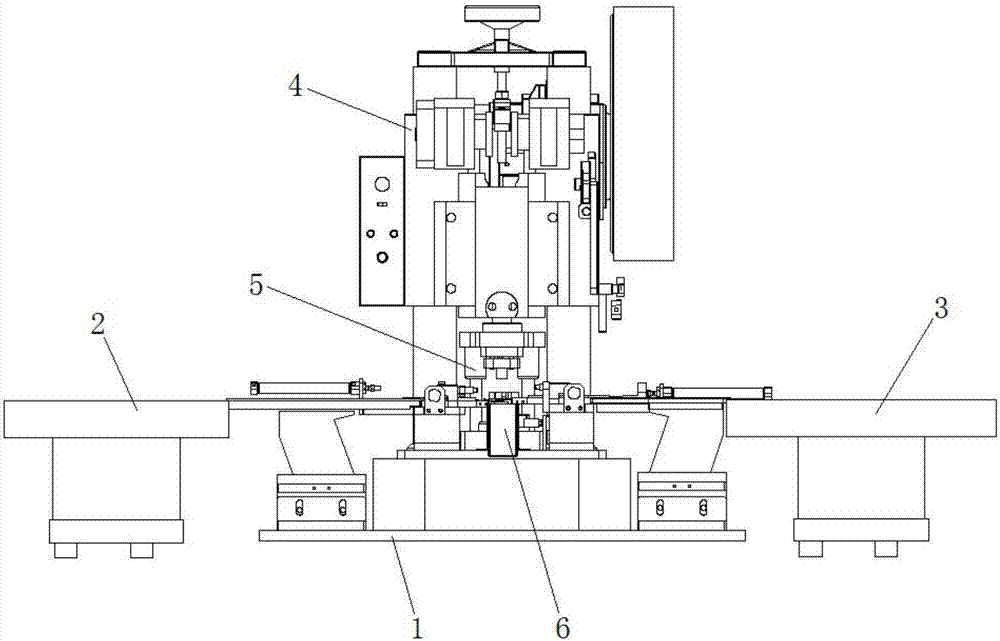

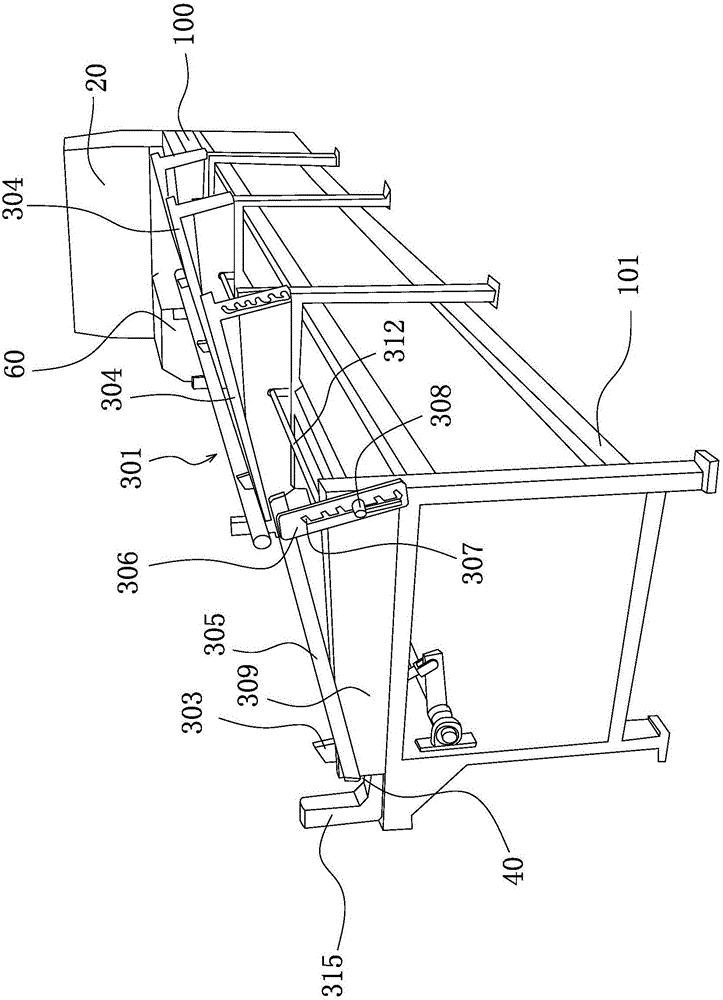

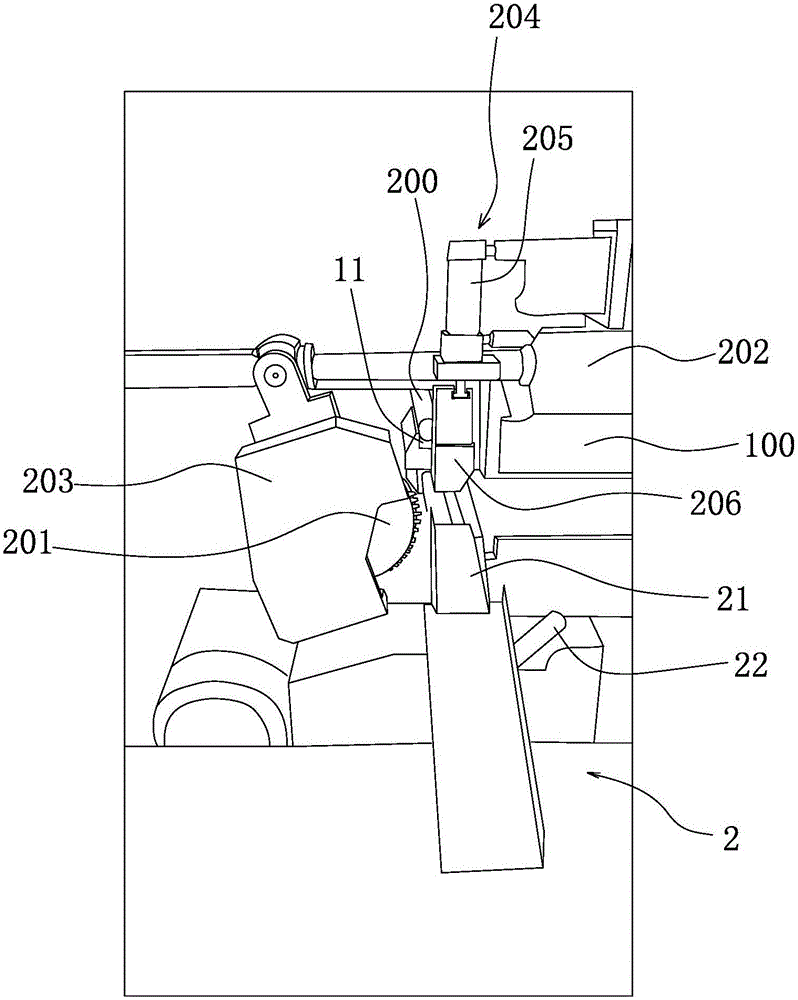

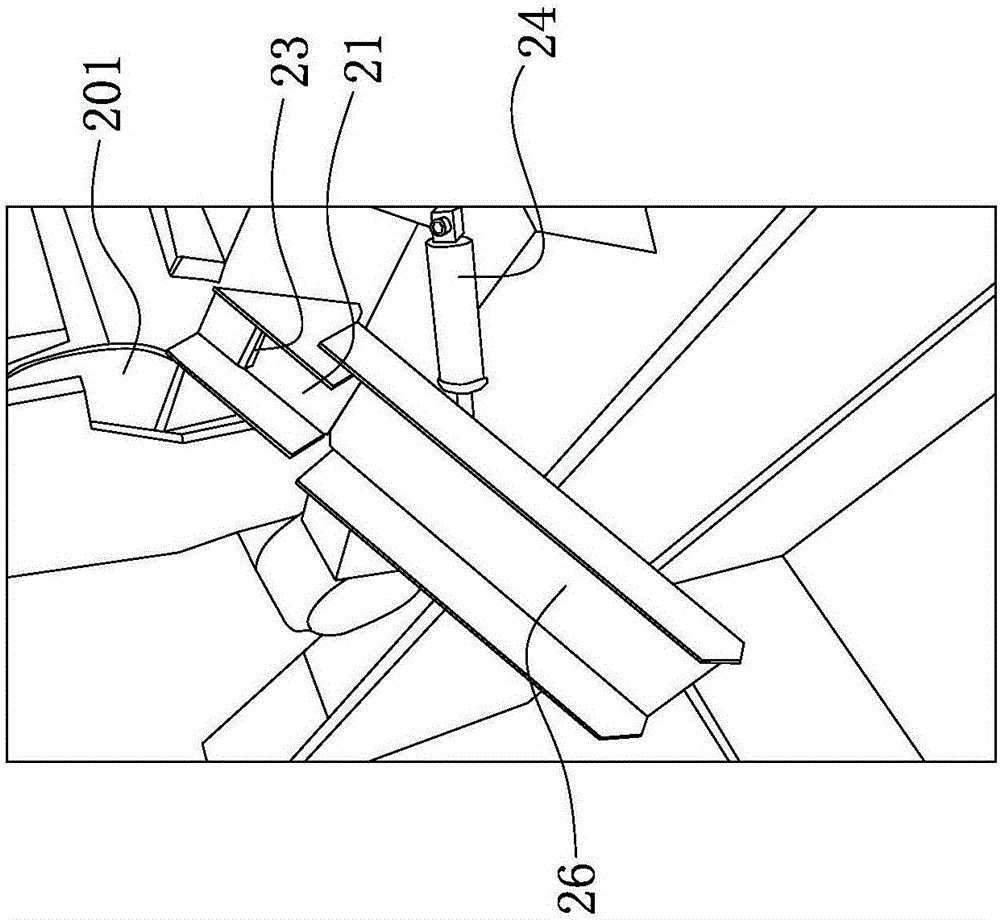

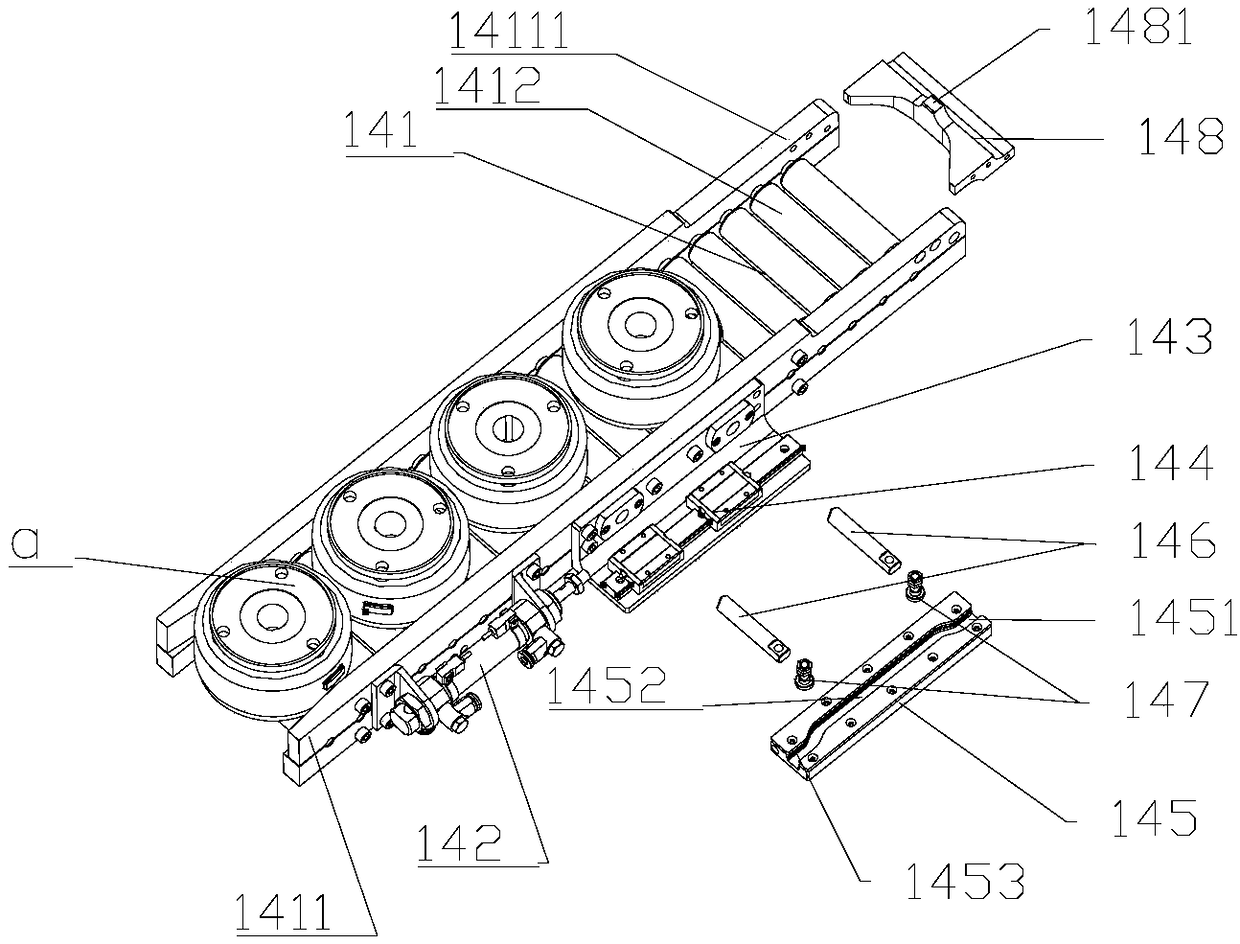

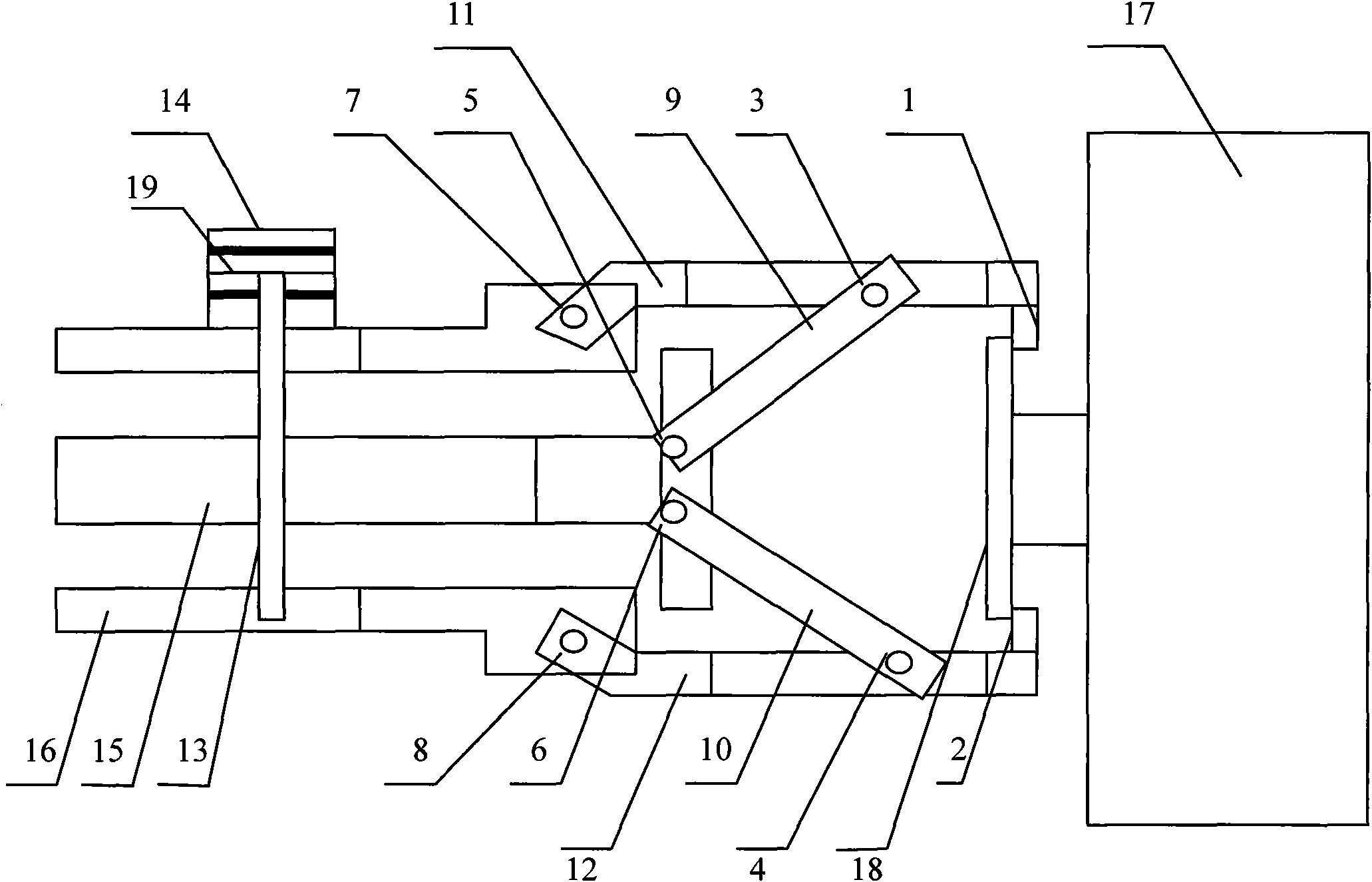

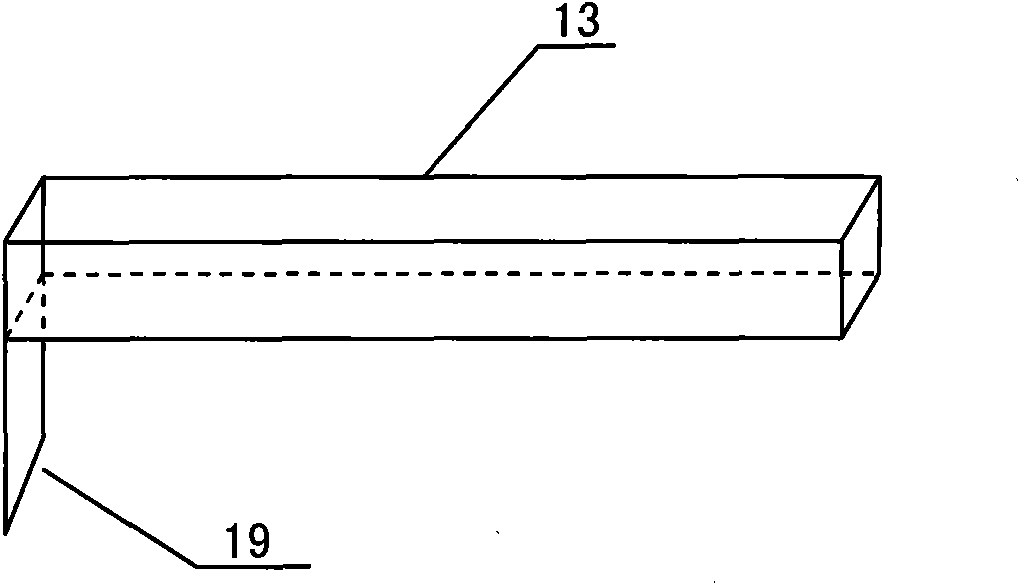

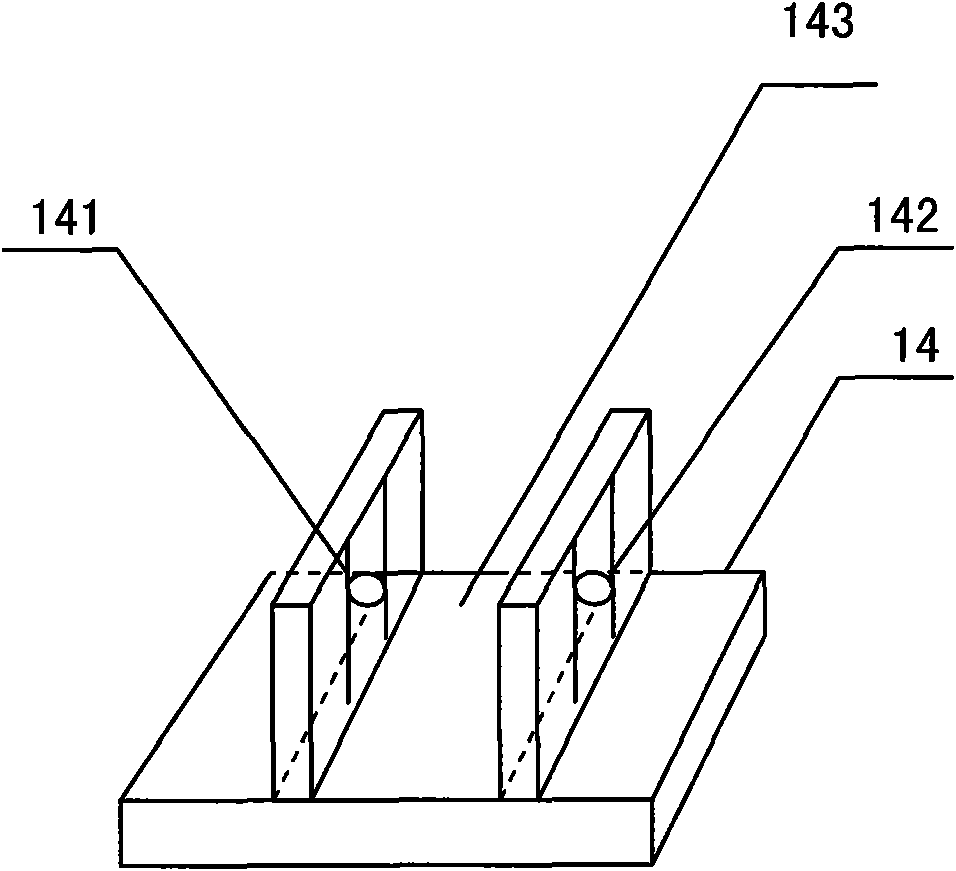

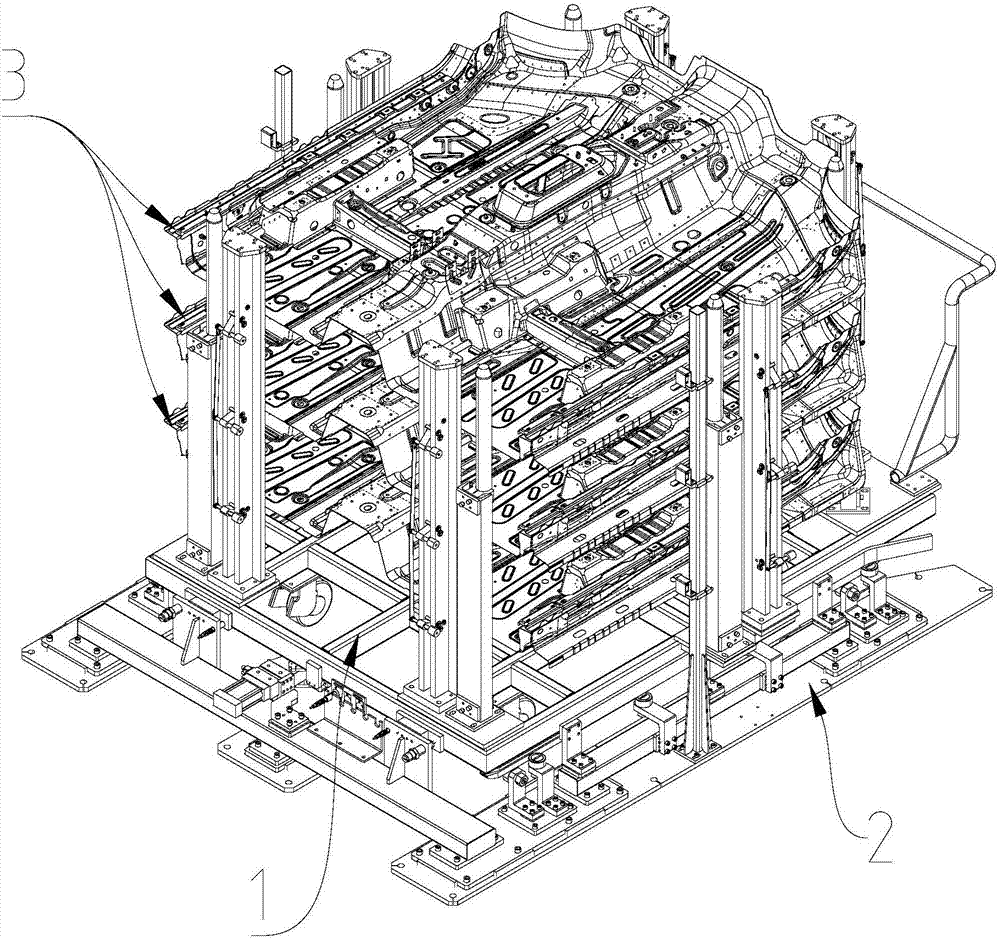

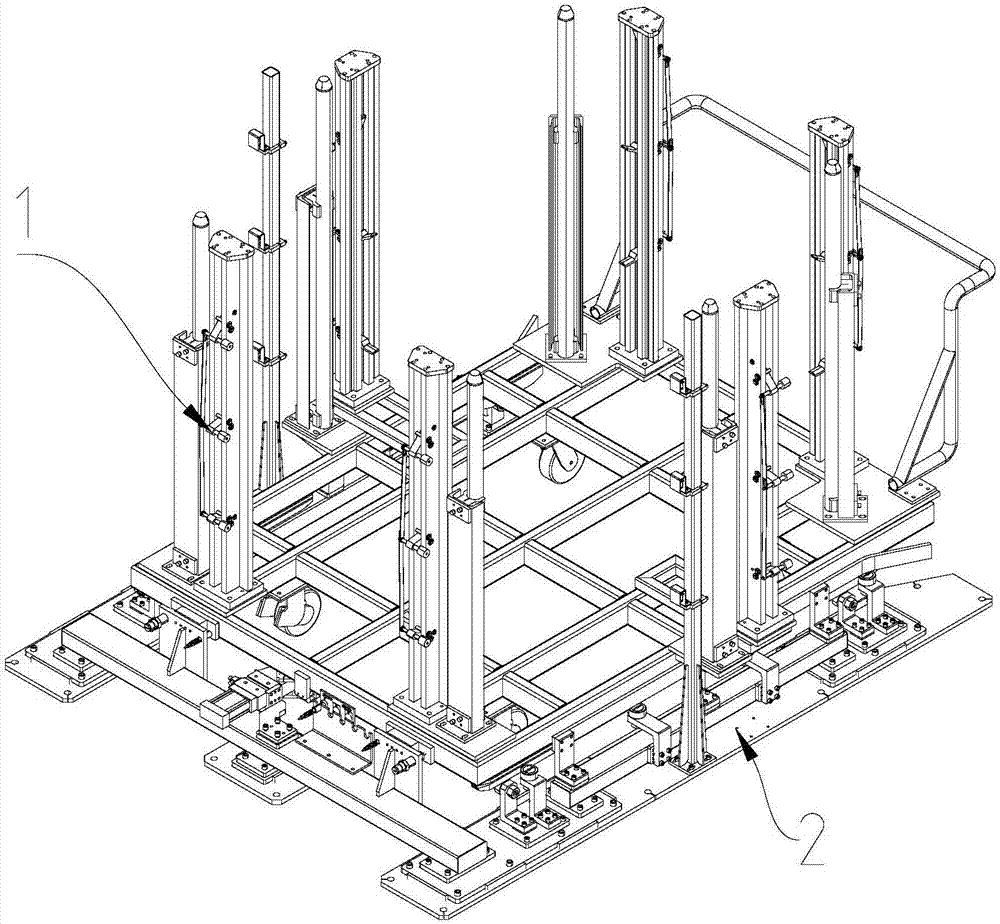

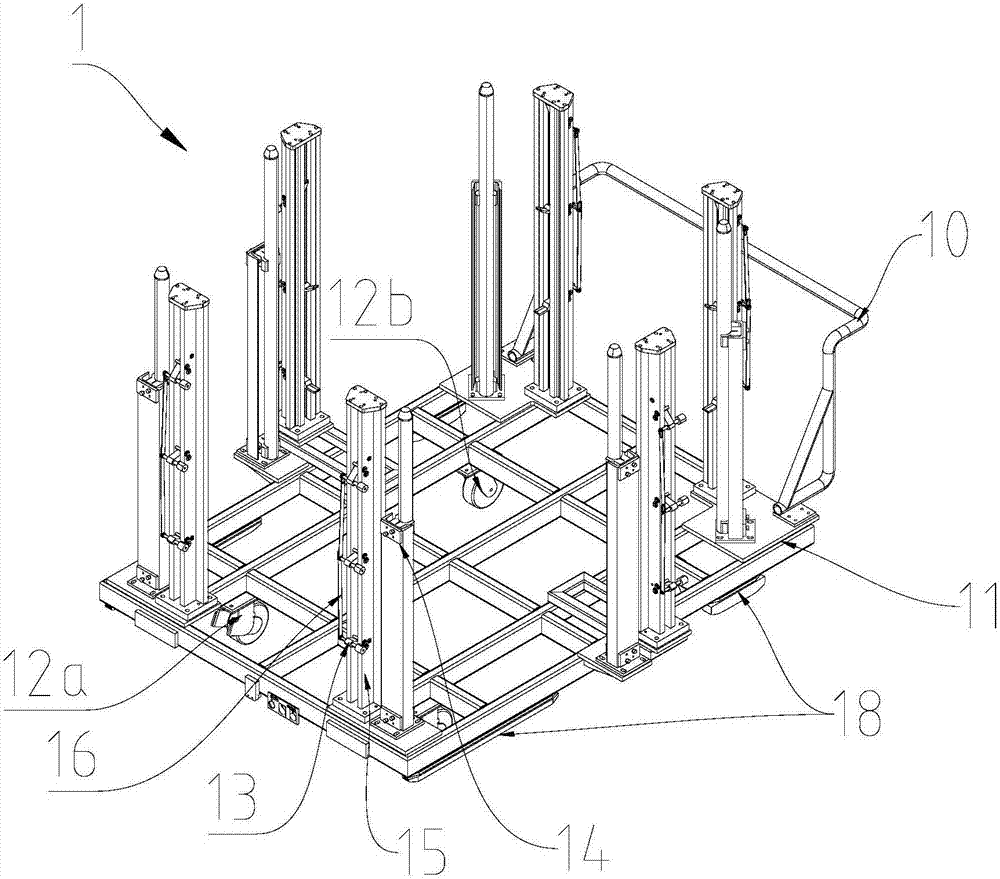

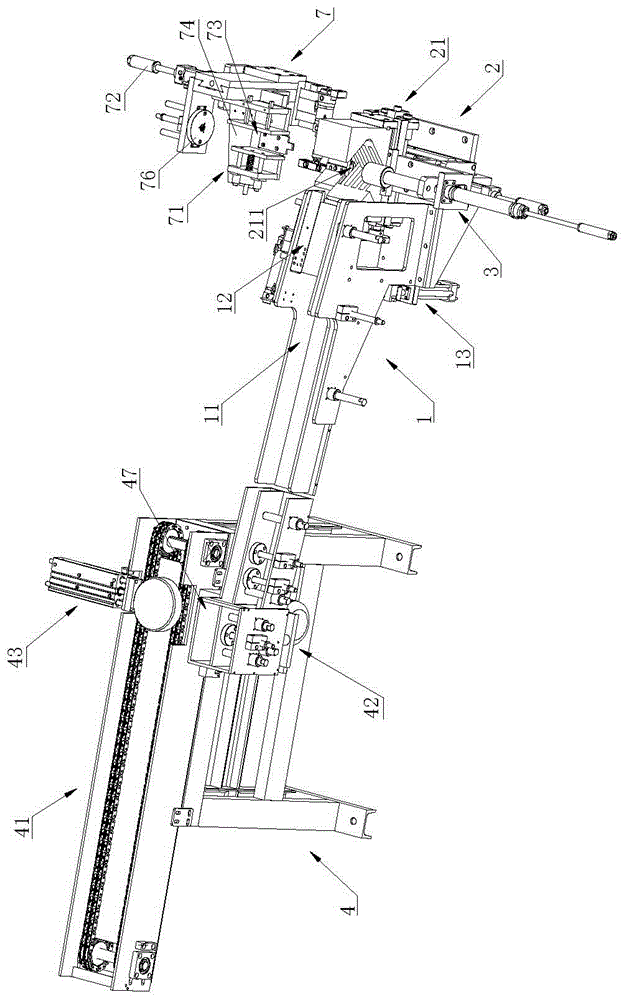

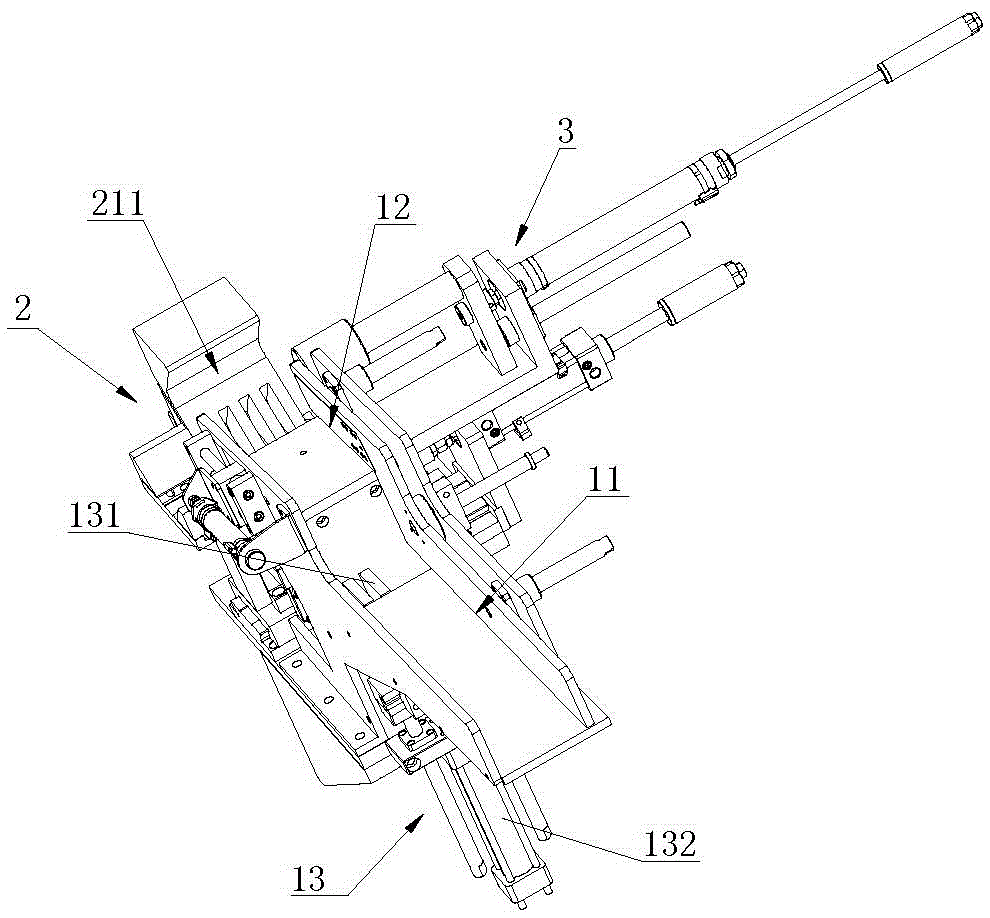

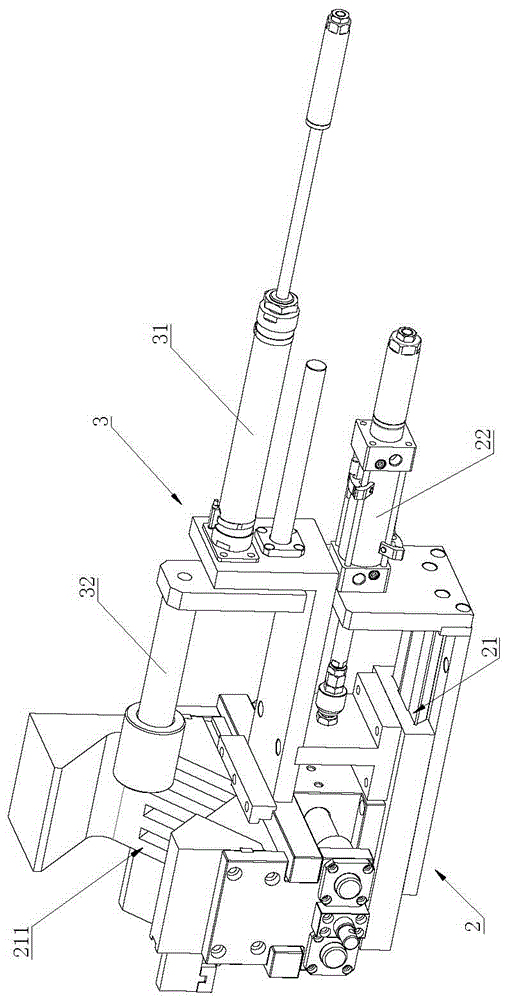

Rack, loading device and system for automatically taking and placing workpieces

ActiveCN107486825AAchieve precise positioningAvoid manual handlingWork tools storageEngineeringMechanical engineering

The invention relates to a rack, a loading device and a system for automatically taking and placing workpieces. The loading device comprises a rack vehicle (1) and a positioning mechanism (2), wherein the rack vehicle (1) comprises a bottom framework (11), a wheel group arranged on the lower part of the bottom framework as well as workpiece supporting parts (13) and workpiece limiting parts (14), which are arranged on the upper part of the bottom framework (11); and the positioning mechanism (2) comprises an X-direction positioning part (21) used for limiting the transverse position of the rack vehicle (1), a Y-direction positioning part (22) used for limiting the longitudinal position of the rack vehicle (1) and a Z-direction positioning part (23) used for limiting the height position of the rack vehicle (1). With the adoption of the technical scheme, the loading device provided by the invention saves time and labor, and reliably completes positioning of to-be-loaded workpieces.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

Lining machine for mobile phone polarizer with reliable alignment

The invention relates to a lining machine for a mobile phone polarizer with reliable alignment. A polarizer loading mechanism comprises a loading platform longitudinal lifting mechanism, a loading platform station switching mechanism and a polarizer loading platform, wherein the loading platform station switching mechanism is mounted on the loading platform longitudinal lifting mechanism; the polarizer loading platform is mounted on the loading platform station switching mechanism; the polarizer loading platform comprises a lining transferring base plate and a lining transferring hinge lateral plate; the lining transferring hinge lateral plate is mounted on the loading platform station switching mechanism; the lining transferring base plate is hinged with the bottom end of the lining transferring hinge lateral plate; a lateral edge of the lining transferring base plate opposite to a hinge point can be rotated along the longitudinal direction of the lining transferring hinge lateral plate; a lining transferring cylinder which is used for driving the lateral edge of the lining transferring base plate to rotate is connected with the lining transferring base plate; a polarizer aligning mechanism is mounted on the lining transferring base plate; a vacuum absorbing plate which is used for absorbing and fixing a polarizer is lined at the bottom of the lining transferring base plate; a high-speed camera is arranged on the lateral side of a vacuum absorbing base fixed by the lining transferring base plate. The lining machine for the mobile phone polarizer with reliable alignment has the advantages of reasonable lining action and high lining quality.

Owner:WENZHOU ZHIXIN ELECTROMECHANICAL TECH

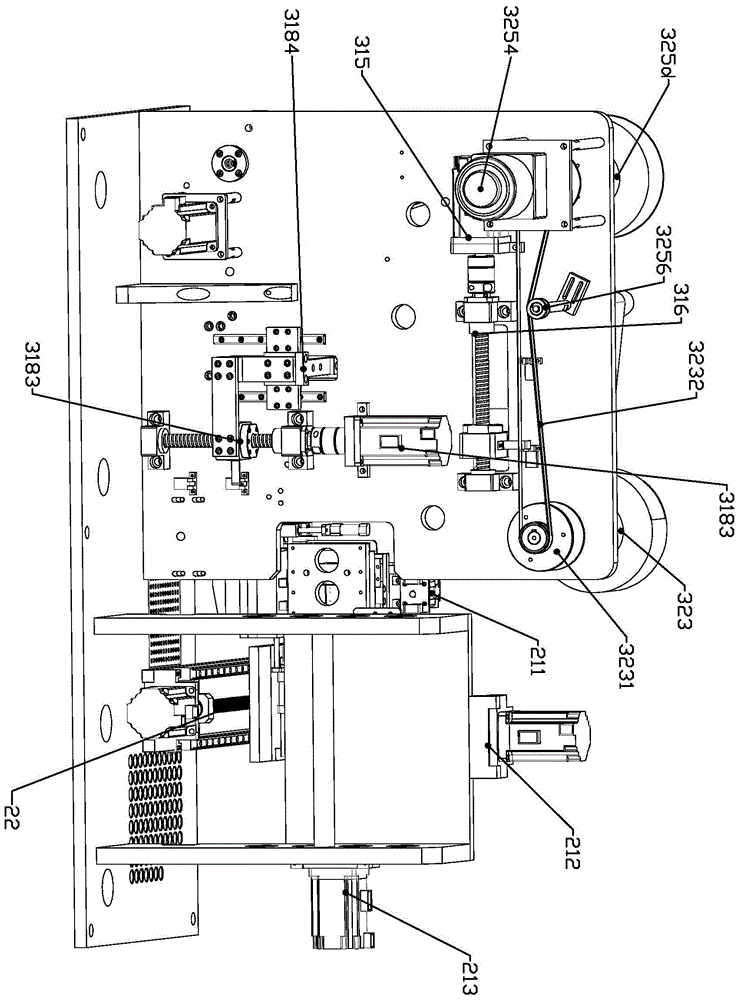

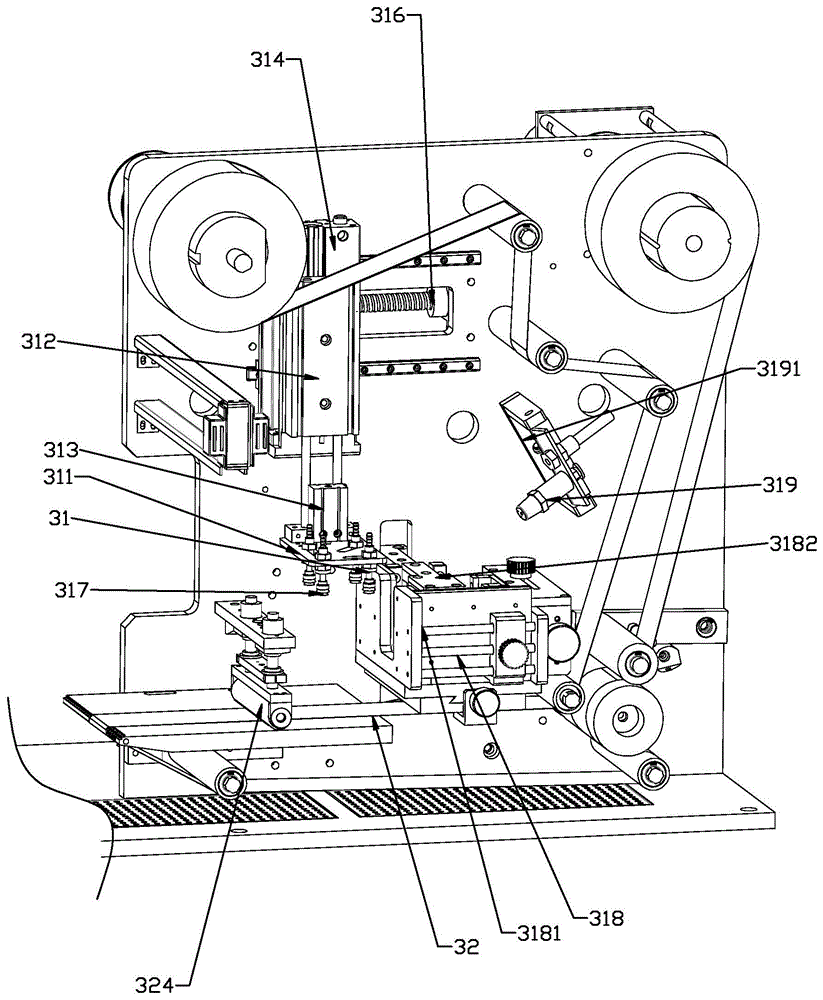

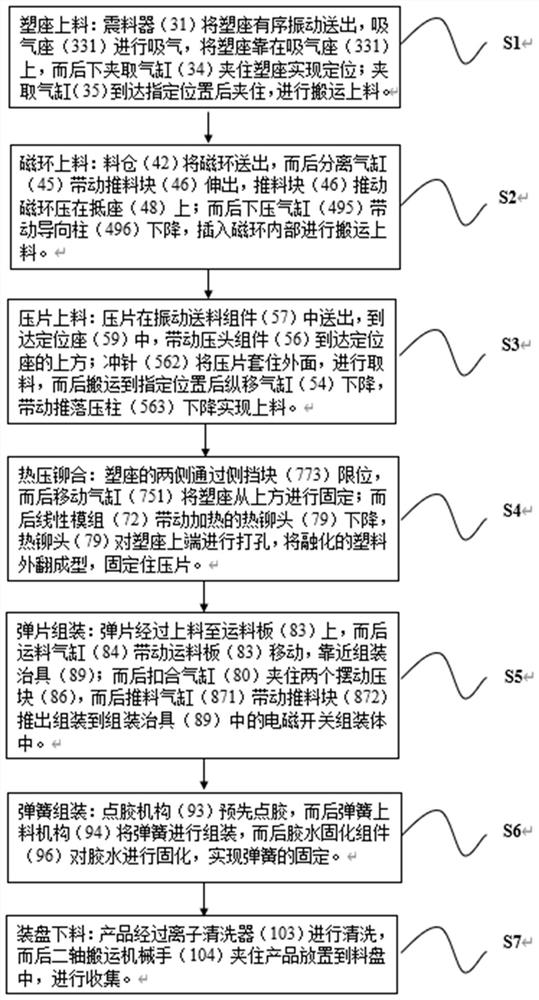

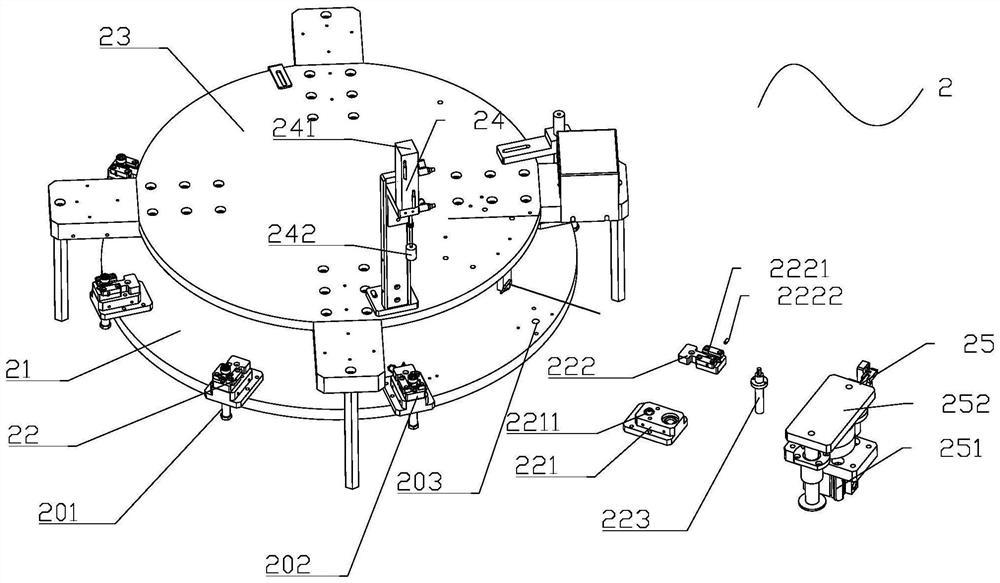

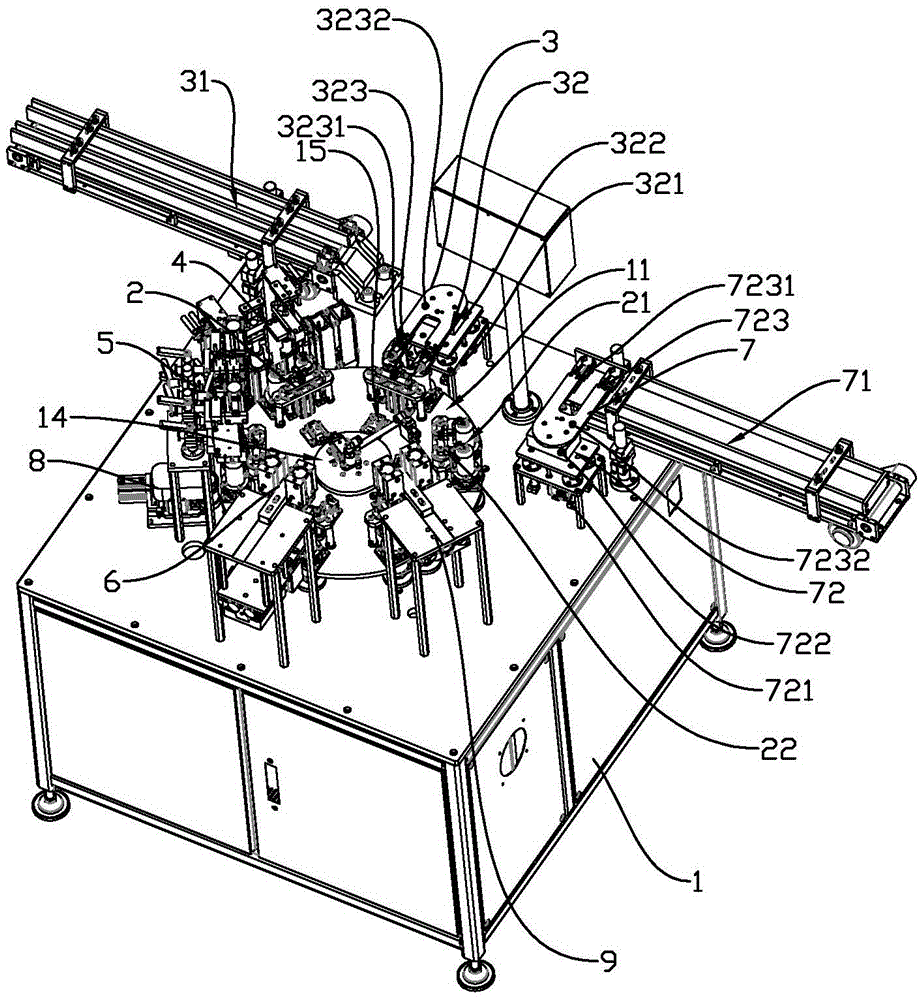

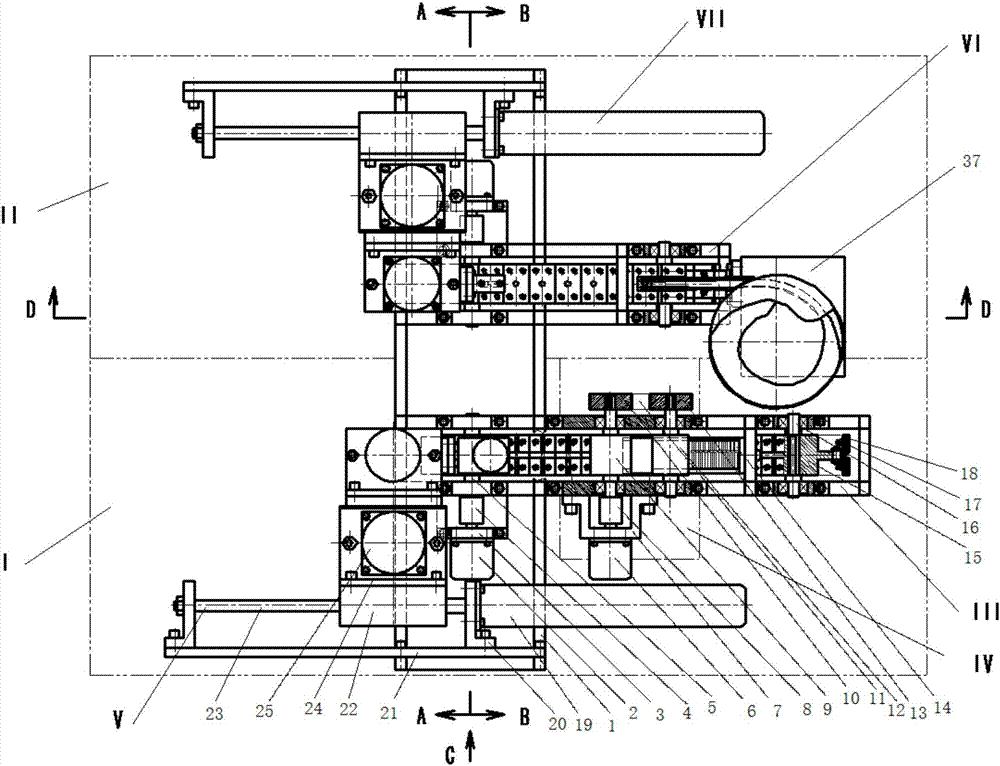

Electromagnetic switch production method and production equipment thereof

InactiveCN112017884AAvoid bending deformationAchieve positioningElectric switchesAdhesive glueEngineering

The invention discloses electromagnetic switch production equipment. The electromagnetic switch production equipment comprises a rack and a turntable conveying device, a plastic seat feeding device, amagnetic ring feeding device, a pressing sheet feeding device, a linear conveying device, a hot melting assembling device, a fixed clamping seat assembling device, a spring assembling device and a cleaning discharging device which are mounted on the rack, wherein the turntable conveying device is connected with the linear conveying device, and the plastic base feeding device, the magnetic ring feeding device and the pressing sheet feeding device are sequentially arranged on the outer side of the turntable conveying device. The hot melting assembling device and the fixed clamping seat assembling device are arranged on the side of the linear conveying device; the linear conveying device and the spring assembling device are connected through a transferring jig mechanism. And the cleaning discharging device is connected with the spring assembling device. The turntable is efficient in conveying and accurate in machining; the plastic base, the pressing sheet and the fixed clamping base areaccurate in feeding, efficient, accurate in spring separation and firm in glue connection; and cleaning and discharging are conducted in sequence, and the product collecting efficiency is high.

Owner:李丹

Automatic feeding device and automated grinding machine

PendingCN110217554AThe feeding beat is consistentAvoid shortageControl devices for conveyorsGrinding feedersEngineeringMechanical engineering

The invention discloses an automatic feeding device of a grinding machine. The automatic feeding device is provided with a plurality of suckers, a plurality of workpieces can be sucked and placed on athird station through the plurality of suckers each time, and then a second conveying mechanism conveys the plurality of workpieces on the third station to the grinding tool for grinding. According to the automatic feeding device, the feeding rhythm is kept consistent all the time, so that the starved feeding due to the fact that the feeding speed is sometimes fast and sometimes slow can be avoided; and the feeding speed of the automatic feeding device is high, and the feeding is stable and reliable.

Owner:宁波享昇机械有限公司

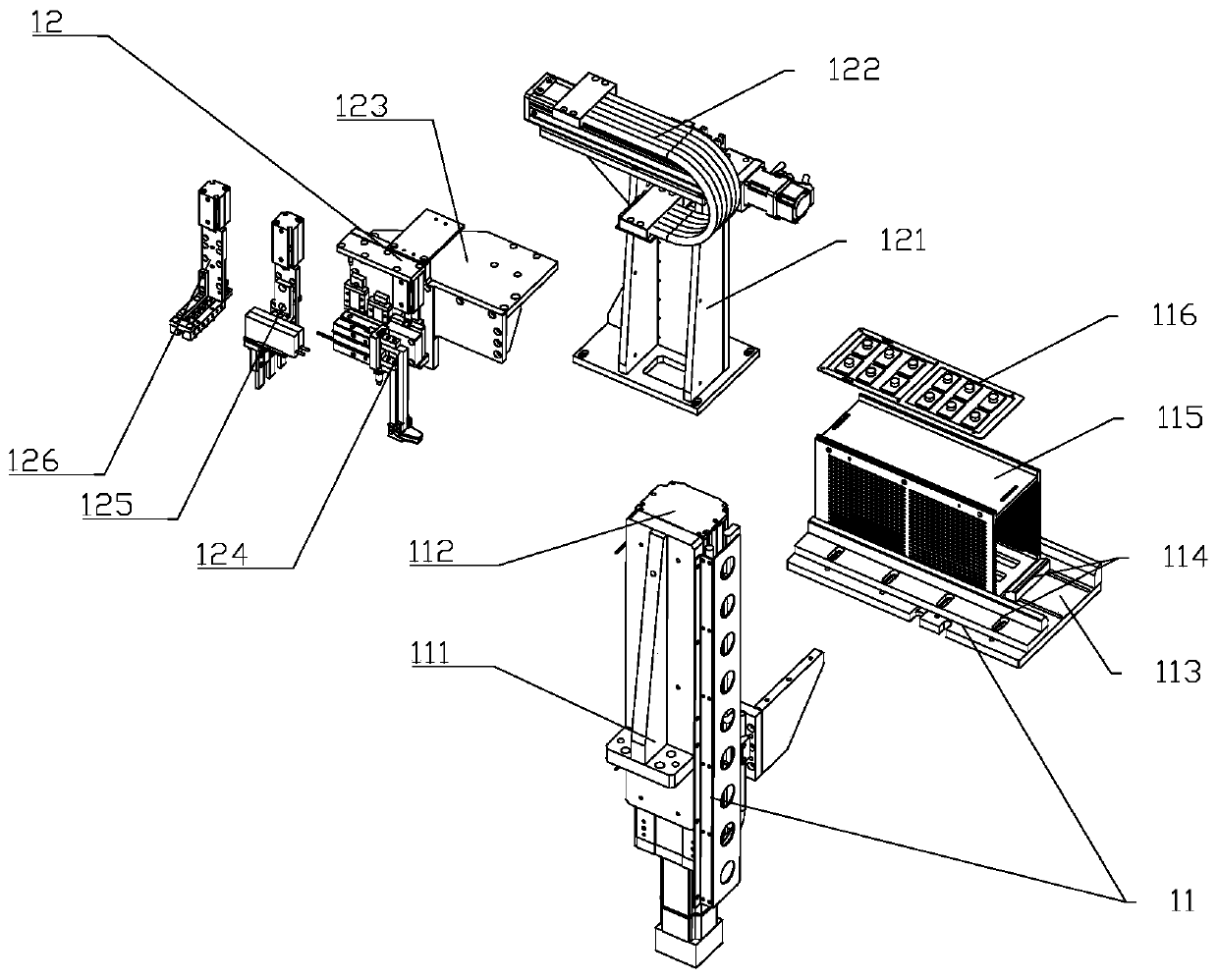

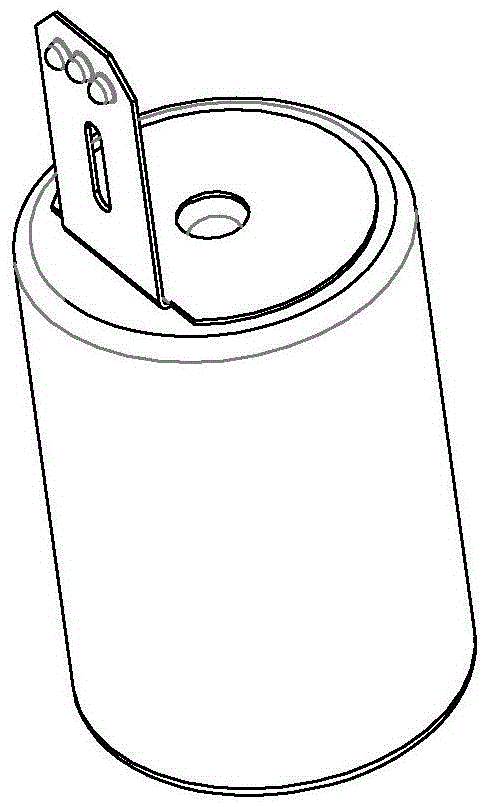

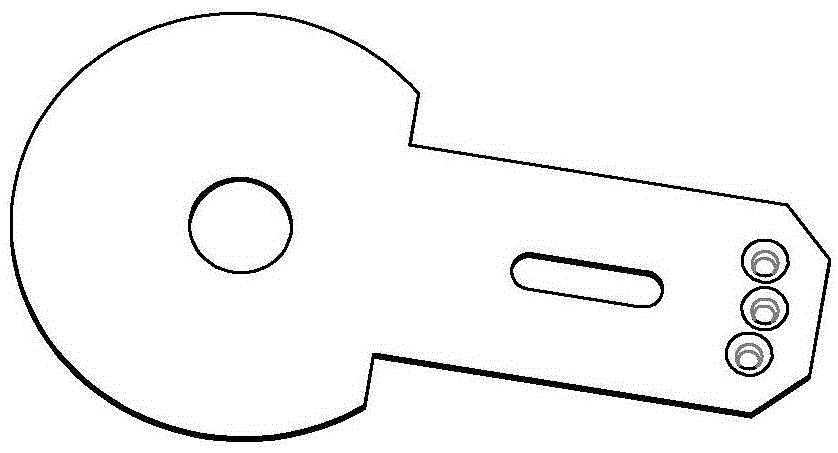

Cylindrical lithium-ion battery current collector welding machine capable of realizing reliable current collector loading

InactiveCN105666139AReasonable structural designStable and reliable feedingOther manufacturing equipments/toolsMetal working apparatusOn cellsCurrent collector

The invention relates to a cylindrical lithium-ion battery current collector rotary-disc welding machine capable of realizing reliable current collector charge. A current collector welding production line comprises a rotary disc, a material location device arranged on the rotary disc, as well as a cell charge device, a current collector charge device, a welding device, a charge device bending device and a finished product discharge device which are sequentially arranged along the rotary disc and matched with a transfer working position of the material location device, wherein the current collector charge device comprises a current collector storage box and a current collector charge mechanism; the current collector charge mechanism comprises an adsorption seat installation frame movably fitting a machine body in a rotating manner, as well as a current collector adsorption seat and a current collector charge drive device which are installed on the adsorption seat installation frame; the current collector charge drive device comprises a position rotating switchover motor connected with the adsorption seat installation frame in a driving manner, and a current collector charge lifting cylinder used for driving the position rotating switchover motor. The cylindrical lithium-ion battery current collector rotary-disc welding machine capable of realizing reliable current collector charge, which is disclosed by the invention, realizes automatic welding for current collectors on cells and automatic bending of the current collectors, and has the advantages of high product machining quality, compact structure and high working efficiency.

Owner:周胡琴

Automatic feeding mechanism of assembling of grip head and grip shaft of watch

ActiveCN106990705AImprove the operating environmentWon't hurtClock support devicesMetal working apparatusEngineeringManipulator

The present invention discloses an automatic feeding mechanism of assembling of a grip head and a grip shaft of a watch. The automatic feeding mechanism comprises a grip shaft feeding mechanism and a grip head feeding mechanism which are arranged in parallel front and back. The grip shaft feeding mechanism comprises a grip shaft feeding transmission module, a grip shaft automatic blanking module and a grip shaft monitoring and feeding manipulator module. The grip head feeding mechanism comprises a grip head feeding transmission module, a grip head vibration stock layout machine and a grip head feeding manipulator module. The grip head and the grip shaft are subjected to stock layout through each blanking stock layout machine and then are put to the location notch on a bending plate chain piece by piece and are transmitted to an assigned position through the transmission of the chain, and after a manipulator realizes correlated movement, the grip head and the grip shaft are put into the grip head and the grip shaft automatic feeding mechanism for assembling. The automatic feeding mechanism of assembling of the grip head and the grip shaft of the watch are high in production efficiency, and accurate and reliable in feeding, and can replace manual assembling.

Owner:TIAN WANG ELECTRONICS (SHENZHEN) CO LTD

Feeding device for paper and plastic packaging machine

The invention discloses a feeding device for a paper and plastic packing machine. The feeding device comprises a storage bin and a conveying belt, and is characterized in that one end of the conveying belt is arranged at the bottom of the storage bin; the other end of the conveying belt is connected with a feeding platform; a discharge groove is formed on one side of the feeding platform; a material pushing plate corresponding to the discharge groove is formed on the other side of the feeding platform; and a gate corresponding to the discharge groove is formed above the discharge groove. The structure of the feeding device specifically feeds cylindrical materials; and the cylindrical materials in the storage bin are pushed out under the effect of the material pushing plate after being conveyed to the feeding platform through the conveying belt, are discharged along the discharge groove, and are pushed into a blister pack conveyed by the paper and plastic packaging machine. The feeding device for the paper and plastic packaging machine has the advantages that the automation degree is high, the production efficiency is improved, and the labor intensity is reduced.

Owner:WENZHOU BOYANG PACKAGING MACHINERY

Automatic electric resistance welding equipment for hoop spring hook

InactiveCN1799750AImprove working conditionsEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesElectrical resistance and conductanceCompression device

The invention relates to a basket spring hook automatic electric welding device which comprises a feeding device, an electric welding machine, a basket exchange rotation compression device fixed on the support and formed by a rotation lifting device, an air-powered compression device, a servo-rotation device and an air-powered supporting device, and a control board. The basket is arrange don the dual-position clamping-material station of said rotation lifting device; the spring hook via vibration automation discharging and high-pressure air nozzle is blown to the air-powered clamp and absorbed by another air-powered clamp to be transferred to the basket welding position; two electrodes of said electric resistance welding machine will clamp two work-pieces to weld a spring hook via electric loop, then said two electrodes are reset; and the servo-rotation device can rotate the basket for 30 degrees to repeat aforementioned steps until welding 12 spring hooks on the basket. The inventive device has the advantages of lower technique demand; continuous operation; improved efficiency; quick operation of air-powder clamp; accurate welding positioning; improved product quality; and smooth welded appearance.

Owner:孙光斌

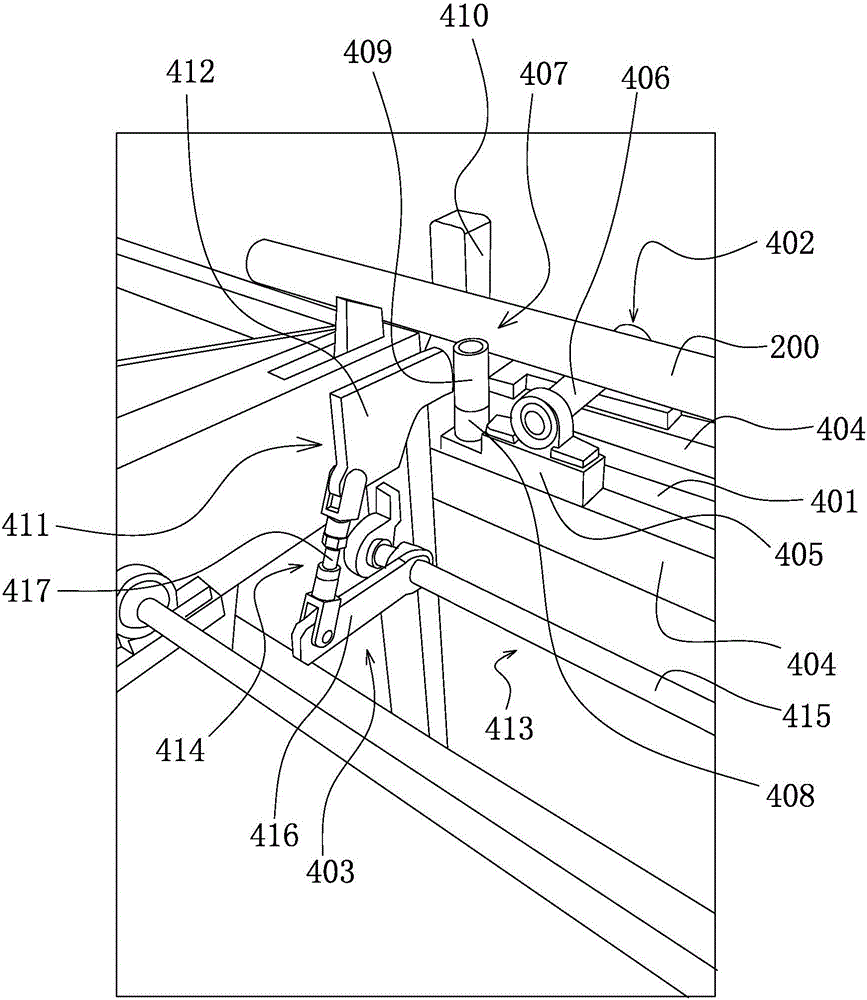

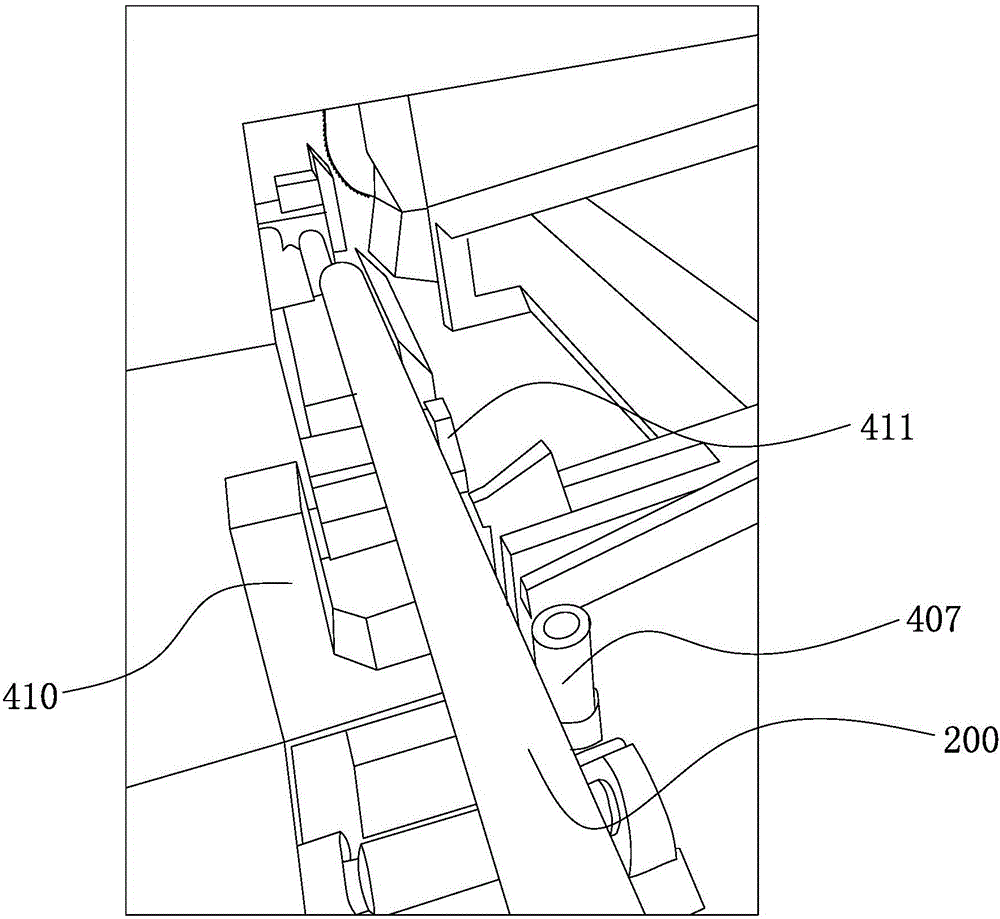

Feed trough mechanism of metal cutting circular sawing machine

InactiveCN106001753AStable and reliable feedingImprove cutting accuracyMetal sawing devicesCircular sawEngineering

The invention belongs to the technical field of metal cutting and relates to a feed trough mechanism of a metal cutting circular sawing machine. The feed trough mechanism comprises a feed trough located at the top of a rack and used for holding to-be-cut metal. The feed trough is connected with a cutting mechanism. The feed trough mechanism is characterized in that the bottom of the feed trough is provided with a plurality of rolling feed assemblies arranged evenly at intervals in the axial direction of the feed trough, and the rack is further provided with a clamping assembly capable of moving towards the direction of the feed trough so as to clamp the to-be-cut metal in the feed trough. According to the feed trough mechanism, the feed process is stable and reliable, the metal can be clamped during cutting, and the cutting precision is improved.

Owner:ZHEJIANG LONGLI MACHINERY

Material conveying device

ActiveCN106006000AEasy to batch processEasy to processConveyor partsAssistive device/technologyEngineering

The invention relates to the technical field of machining assisting devices for cylinder elements, pipes and other materials, in particular to a material conveying device. The material conveying device comprises a feeding device, a material positioning mechanism arranged on a discharge opening of the feeding device, and a pushing mechanism used for pushing materials. The feeding device comprises a feeding chute, a discharge chute and an ejecting mechanism used for pushing materials in the feeding chute into the discharge chute. The material positioning mechanism comprises a positioning base and a positioning base drive mechanism used for driving the positioning base to move. The positioning base is provided with a positioning groove. Materials are automatically conveyed, manual work is replaced, conveying is reliable, the automation degree is high, the materials can be processed on a large scale, and production efficiency is improved.

Owner:东莞市晋诚机械有限公司

Receiving device for bipolar plate production

InactiveCN110589514AStable and reliable feedingImprove receiving efficiencyConveyorsFinal product manufactureDrive wheelDrive motor

The invention discloses a receiving device for bipolar plate production. The receiving device comprises a base and a support frame, wherein a transfer mechanism is mounted above the support frame; thetransfer mechanism comprises a transfer table, a conveyor belt and a guiding port; the right side of the base is provided with a receiving mechanism, and the receiving mechanism comprises a driving motor, an intermittent rotating assembly and receiving boxes; and the intermittent rotating assembly is connected with a driving wheel of the transfer mechanism through a synchronous transmission mechanism. The receiving device for the bipolar plate production realizes the periodic intermittent rotation of the receiving boxes through the intermittent rotating assembly, meanwhile, the moving beat ofthe conveyor belt is consistent with that of each receiving box through the synchronous transmission mechanism, the number of workpieces received by each receiving box below the guiding port is keptconsistent, the receiving process is stable and reliable, and the receiving efficiency is high; and the multiple receiving boxes are arranged, the operation of performing shutdown for replacement is not required after the receiving boxes are full, so that the production takt is not delayed, and thus the production efficiency is greatly improved.

Owner:深圳市金牌新能源科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com