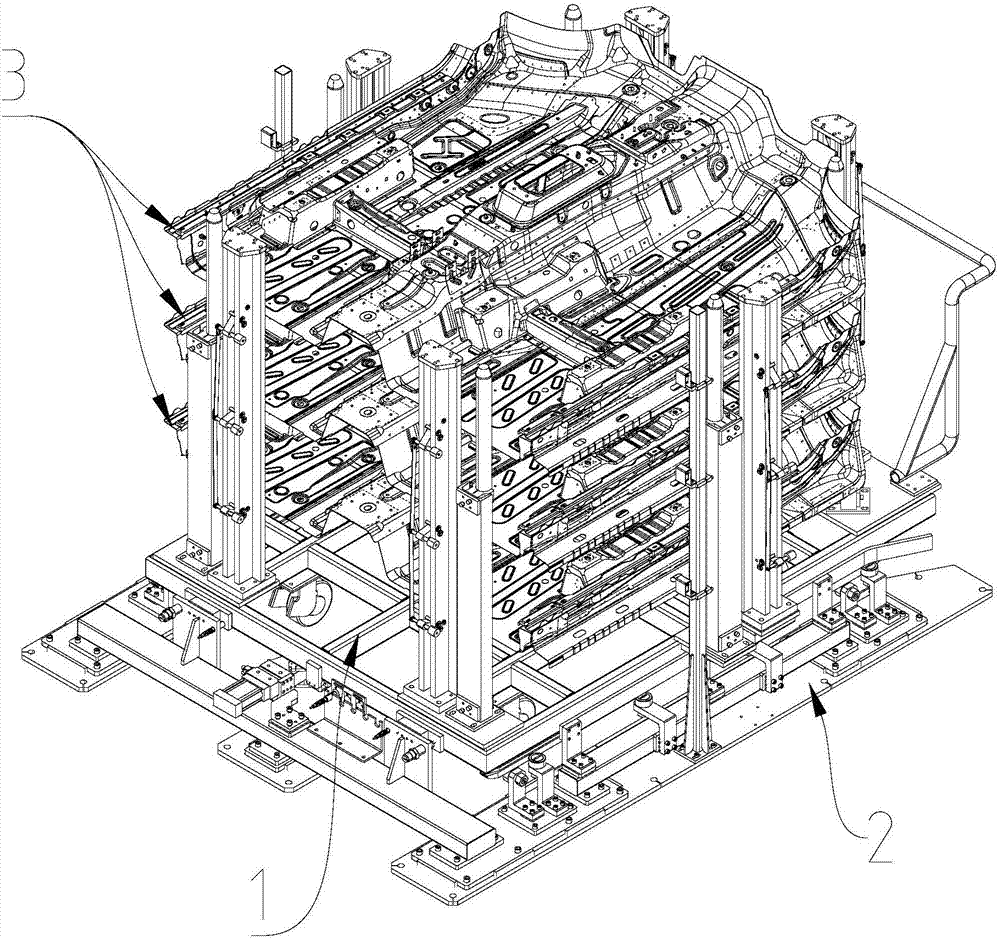

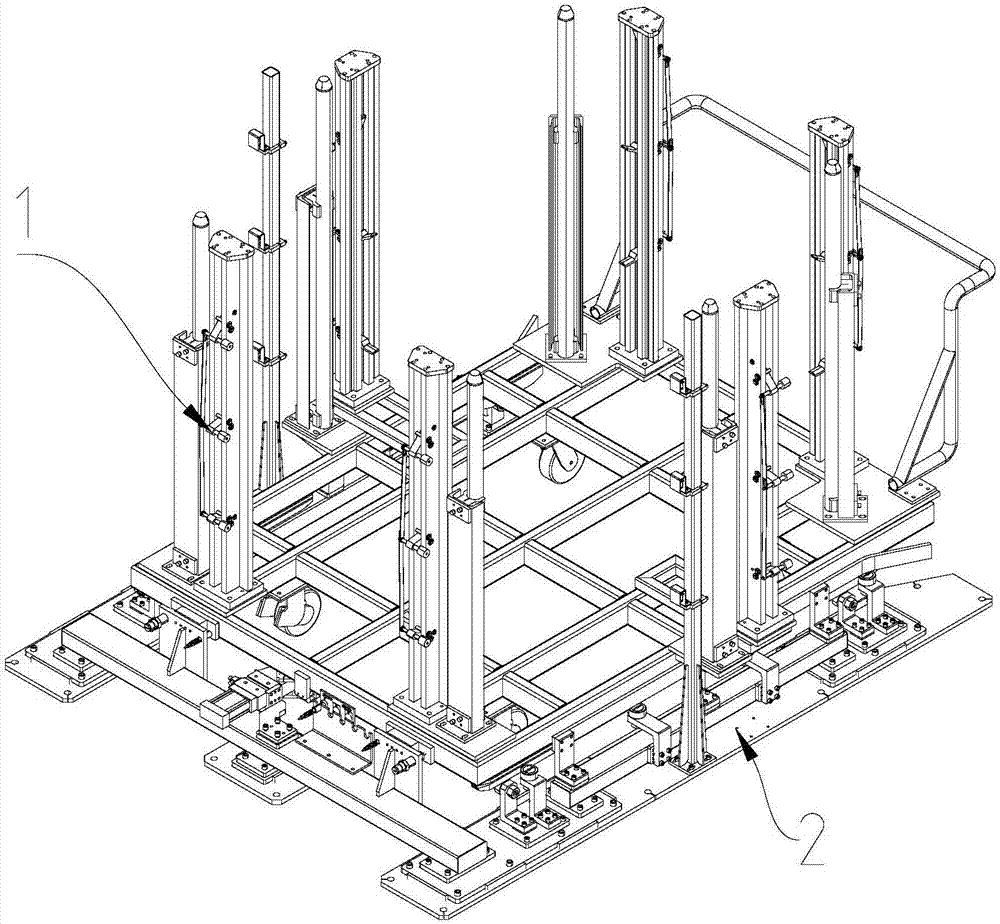

Rack, loading device and system for automatically taking and placing workpieces

A technology of workpiece and material rack car, which is applied in the direction of tool storage device, manufacturing tools, etc., which can solve the problems of high risk of workpiece bumping, labor and time-consuming, etc., and achieve the effects of avoiding bumping, reliable feeding, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

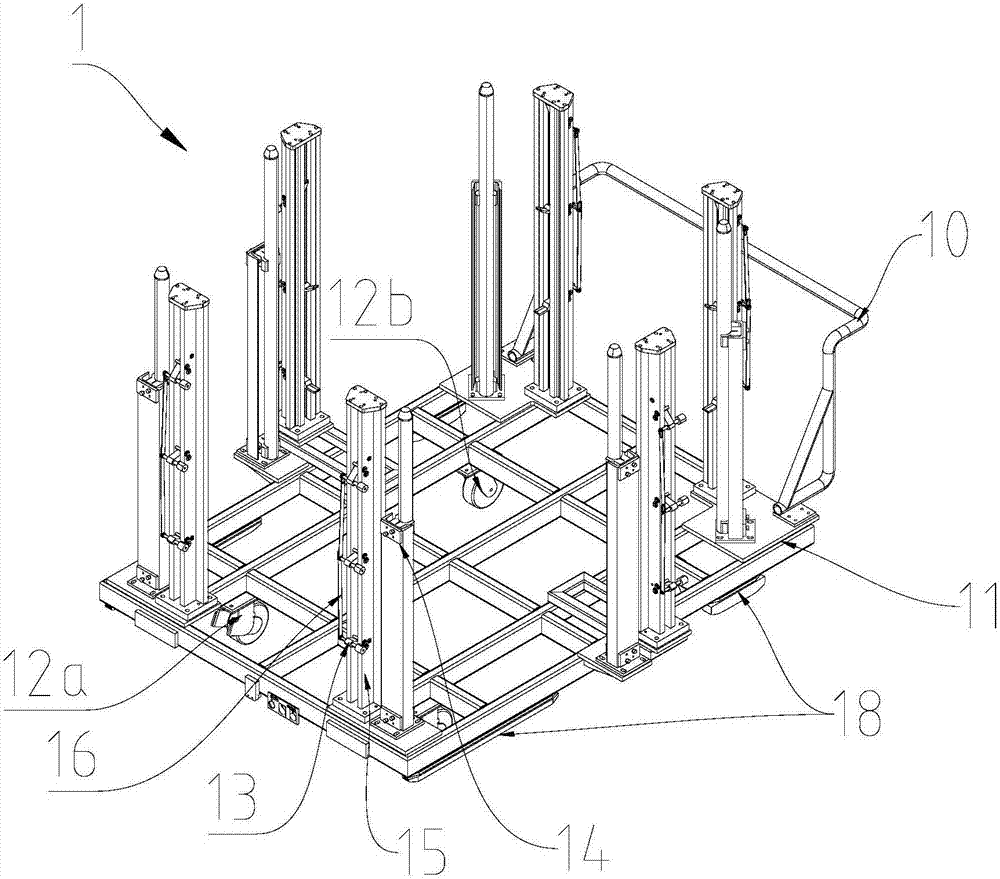

[0029] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0030] For ease of understanding, in this disclosure, an XYZ orthogonal coordinate system is defined, wherein, unless stated otherwise, the X direction corresponds to the transverse direction, the Y direction corresponds to the longitudinal direction, and the Z direction corresponds to the height direction, using Orientation words such as "up and down" usually refer to up and down in the height direction, and "left, right, front and back" usually refer to the left, right, front and back when the worker holds the handrail 10 to push the rack car 1 For the reference definition, "inside and outside" refer to the inside and outside of each part itself. However, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com