Cylindrical lithium-ion battery current collector welding machine capable of realizing reliable current collector loading

A current collector and lithium battery technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as inconvenient operation and poor product quality, and achieve convenient processing, high work efficiency, and compact equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

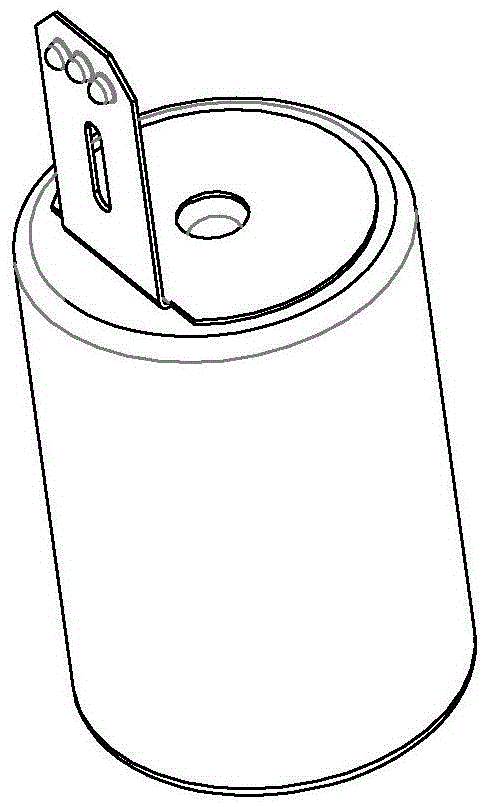

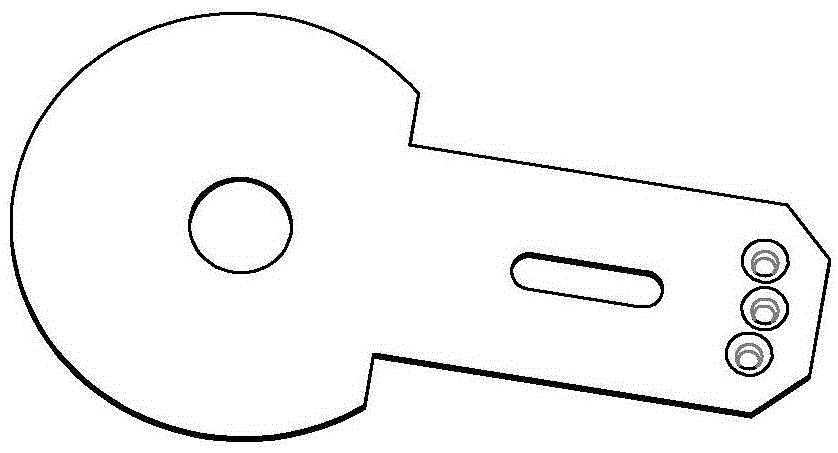

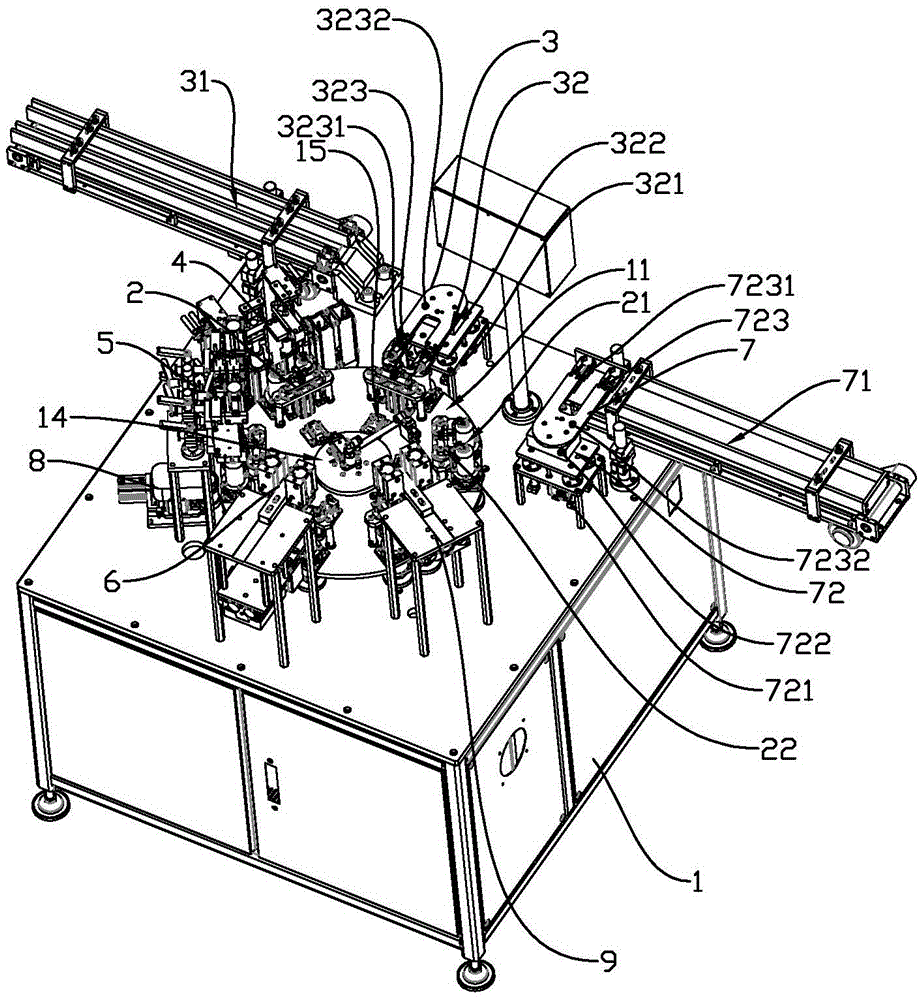

[0046] See attached Figure 1~15 As shown, a cylindrical lithium battery current collector welding machine with reliable current collector feeding disclosed by the present invention includes a fuselage 1, and the fuselage 1 is provided with a current collector welding production line and a current collector welding production line. It includes a turntable, a material positioning device 2 arranged on the turntable, a battery feeding device 3 for feeding the battery cells into the material positioning device 2, a current collector feeding device 4 for combining the current collectors on the battery cells, and The welding device 5 that welds the circular surface of the current collector to the electric core, the current collector bending device 6 that bends the rectangular strip of the current collector, and the finished product discharge device 7 that moves the finished product out of the material positioning device 2, the electric The core feeding device 3, the collector sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com