Reaction cup loading system for automatically conveying reaction cups to analysis device

An analysis device and loading system technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of high failure rate, high cost, and many modules, and achieve the effect of simple operation control, reduced operation cost, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

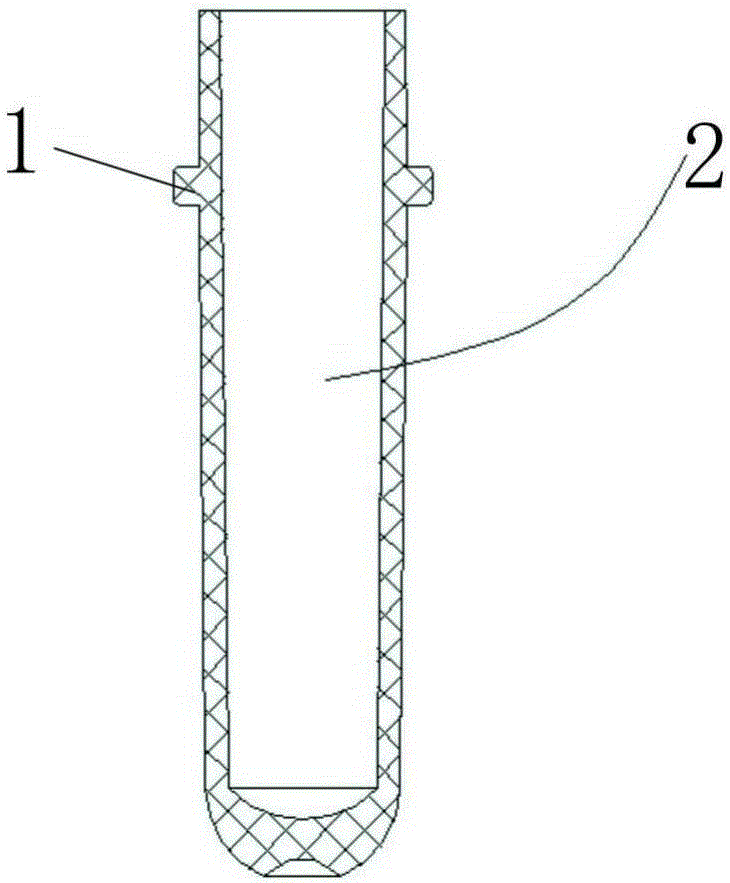

[0039] like figure 1 As shown, the structure of cuvette 2 widely used in current biological sample analysis system is provided with flanges 1 on both sides of the cup body.

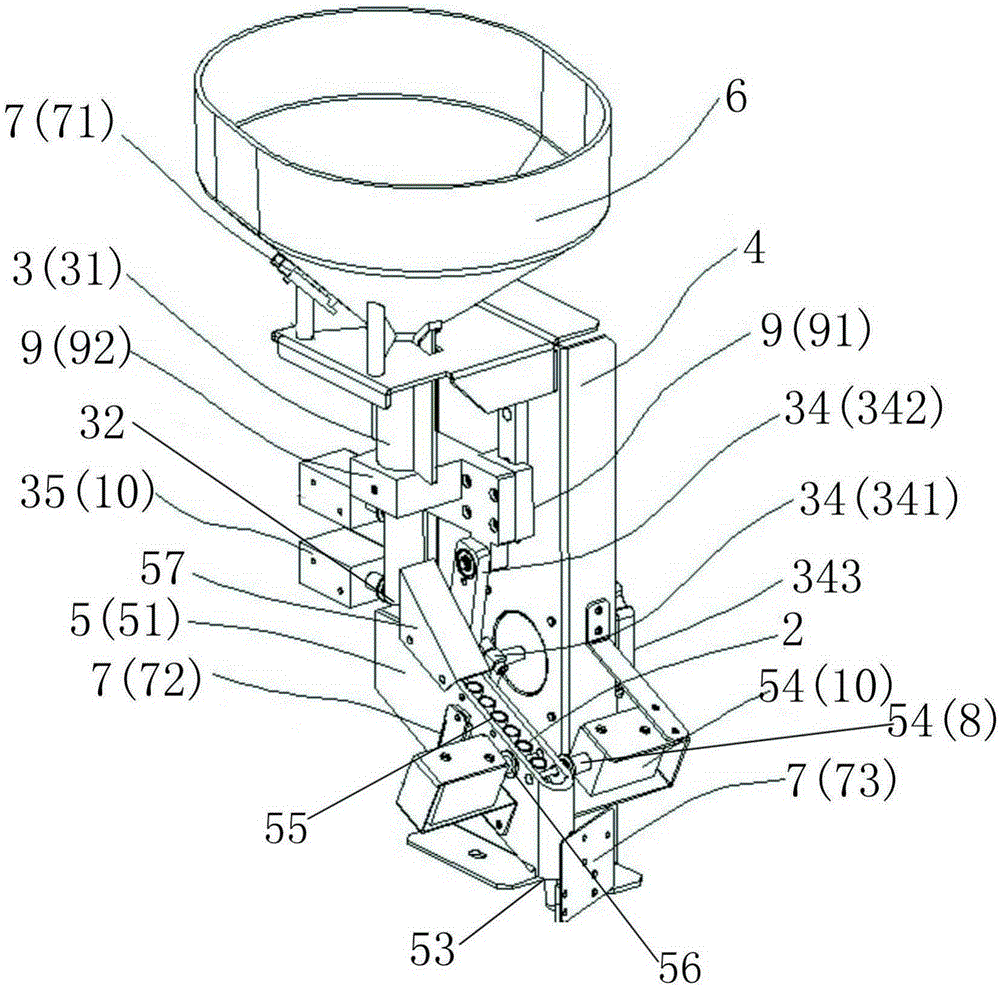

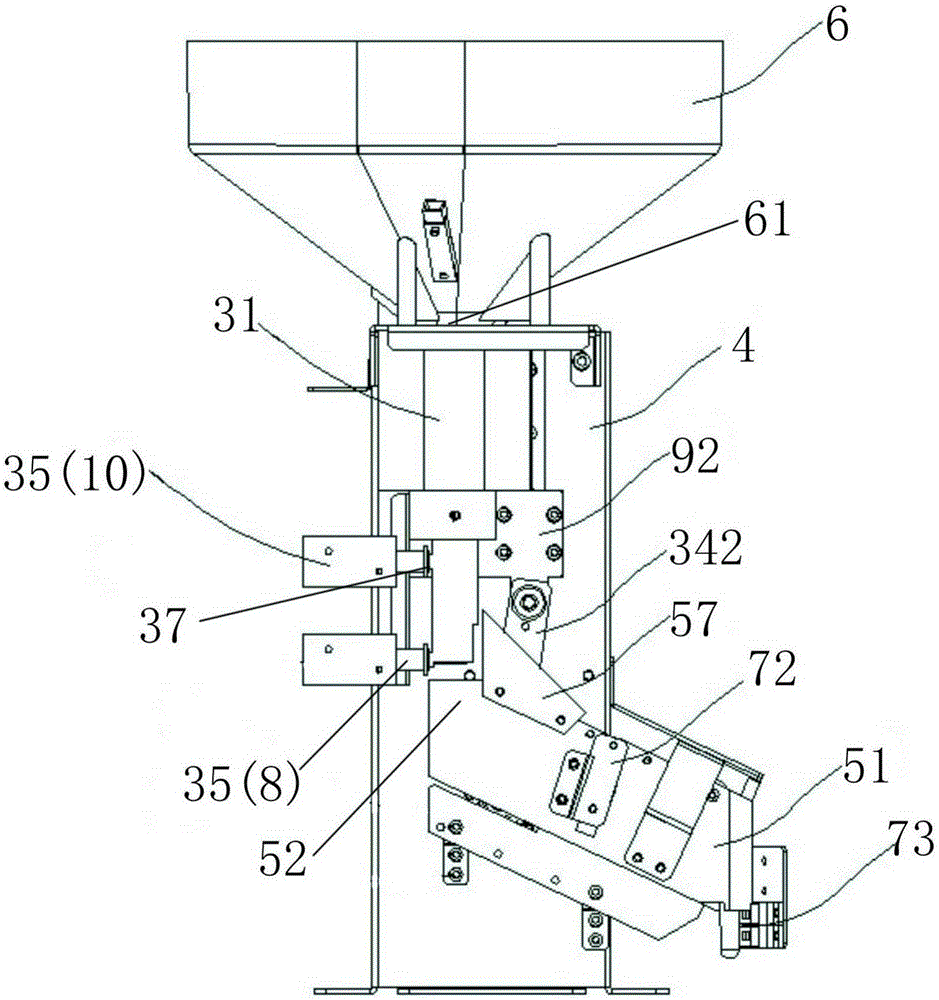

[0040] like figure 2 , 3 , 4, 5, and 6, this embodiment discloses a cuvette loading system for automatically transferring cuvettes for an analysis device, including a frame 4, fixed on the frame 4, and feeding along the cuvette The cup storage bin 6, the cup taking mechanism 3 and the cup feeding mechanism 5 arranged in sequence in the direction, the batch storage in the cup storage bin 6 is like figure 1 In the cuvette 2 shown, the cup fetching mechanism 3 automatically takes the cup from the cup storage bin 6 to the cup feeding mechanism 5, and the cup feeding mechanism 5 automatically feeds the cuvette 2 into the target hole of the biological sample analysis system to complete the reaction. Automatic feeding process for Cup 2.

[0041] Wherein, the storage cup bin 6 is a funnel-shaped structure, a...

Embodiment 2

[0052] like Figure 7 As shown, the second structure of the driver is provided in this embodiment, which includes a first pulley 344 and a second pulley 345 that are rotatably connected by a belt 346, and a motor 343 that drives the first pulley to rotate 344. The fixed The block 92 is fixed on said belt 346 . The motor 343 drives the first pulley 344 to rotate and drive the belt 346 to move up and down, drive the fixed block 92 fixed on the belt 346 to move up and down in the guide rail 91, and finally realize the catheter 31 fixed on the fixed block 92 to move up and down. The driver in the second embodiment can also realize the vertical movement of the conduit 31 to complete the action of taking the cup. Of course, the driver structure of the present invention includes but is not limited to the above two structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com