Automatic mechanical hand film feeding/fetching device

A manipulator and automatic technology, applied in manipulators, program-controlled manipulators, photolithographic process exposure devices, etc., can solve the problems of difficult and high-precision positioning, low positioning accuracy of manipulators, collision of spring clips, etc., to avoid pollution, ensure Lithography quality, effect of overcoming wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

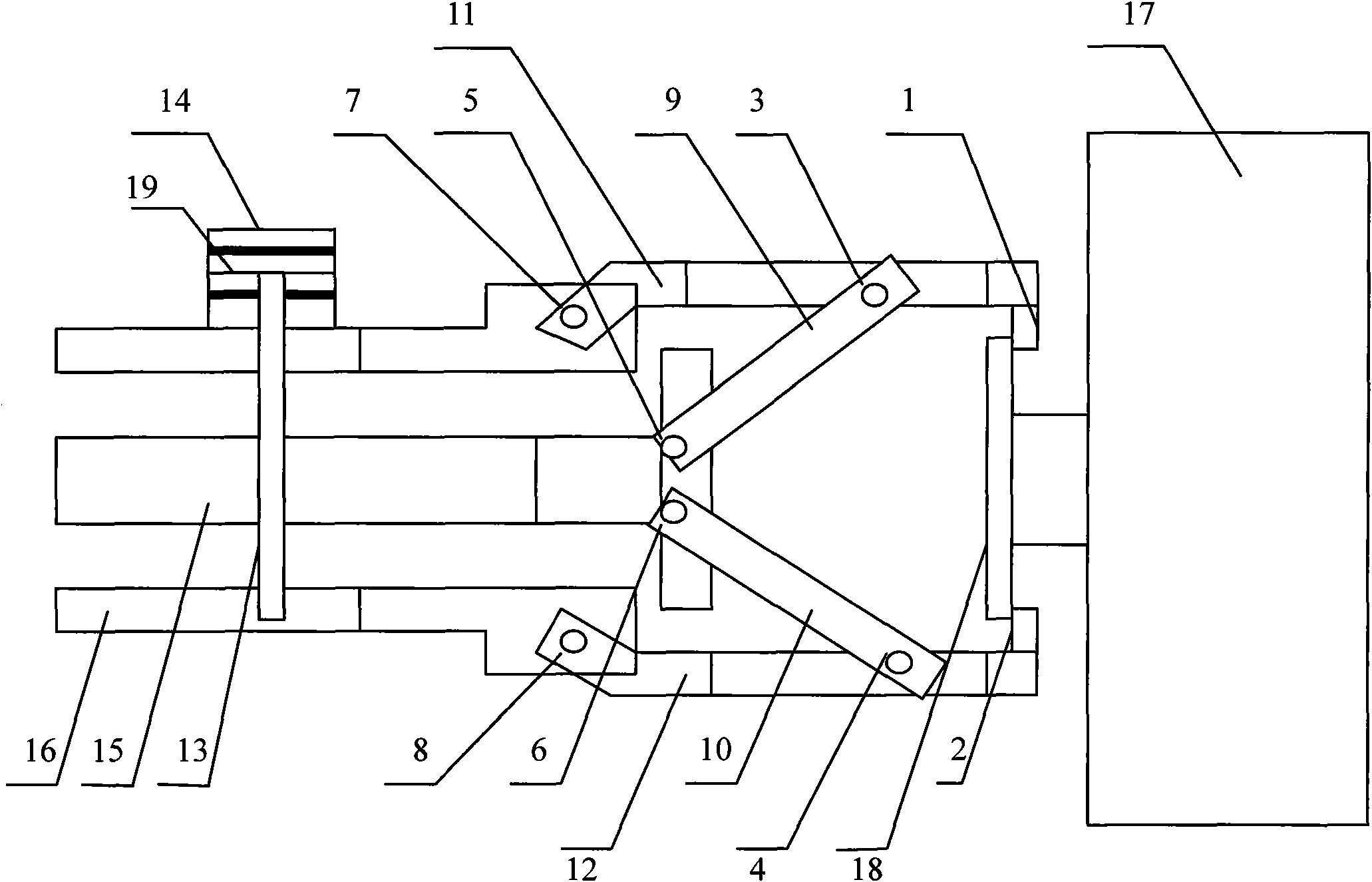

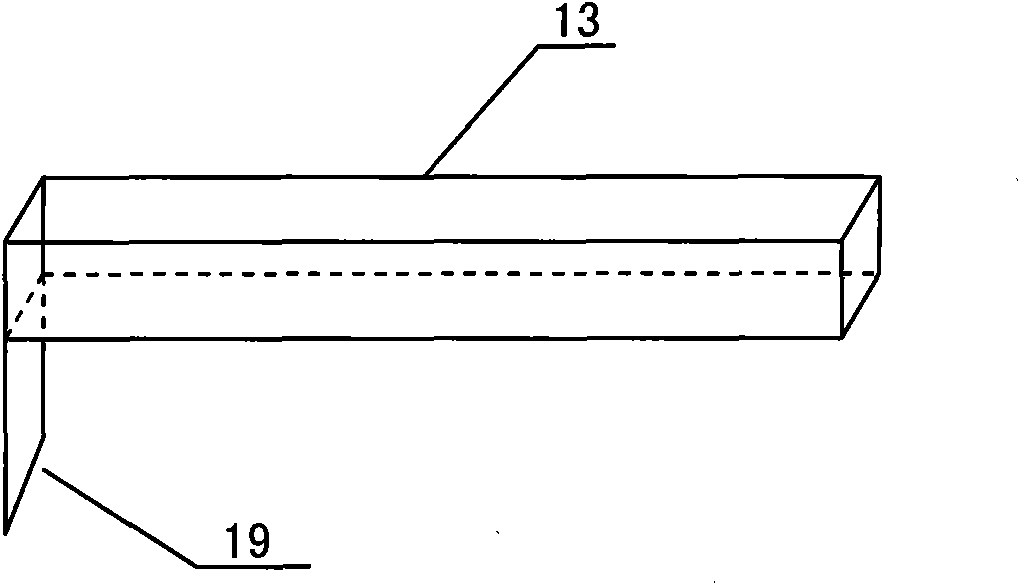

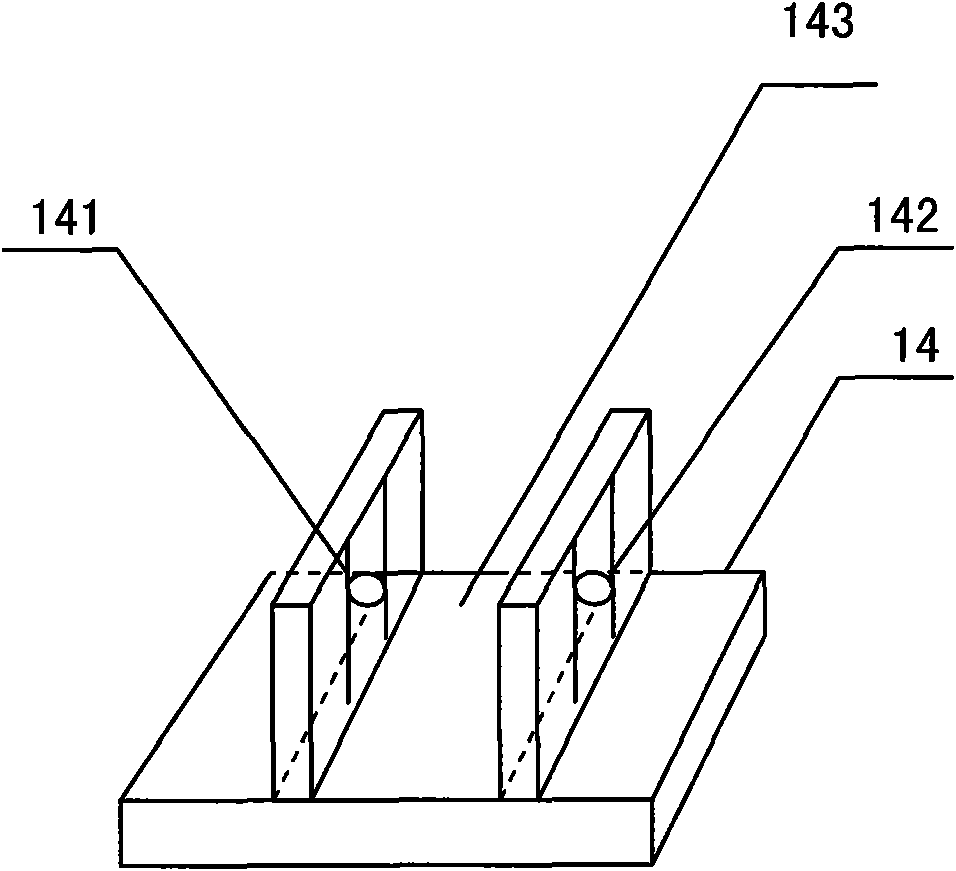

[0023] Such as figure 1 As shown, the embodiment of the present invention consists of a first grapple 1, a second grapple 2, a first hinge 3, a second hinge 4, a third hinge 5, a fourth hinge 6, a fifth hinge 7, a sixth hinge 8, The first connecting rod 9, the second connecting rod 10, the first gripper 11, the second gripper 12, the positioning shaft 13, the photoelectric switch 14, the main shaft 15, the shaft sleeve 16, the sheet clamp 17, the sheet clamp foot 18, the block 19 and computer composition.

[0024] The first handle 11 and the second handle 12 are connected to the shaft sleeve 16 through the fifth hinge 7 and the sixth hinge 8 . One end of the first connecting rod 9 and the second connecting rod 10 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com