Receiving device for bipolar plate production

A material splicing device and bipolar plate technology, applied in the directions of loading/unloading, transportation and packaging, final product manufacturing, etc., can solve the problems of difficult to control the splicing rhythm, delay the production rhythm, affect the production efficiency, etc., and improve the production efficiency. , High feeding efficiency, stable and reliable feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

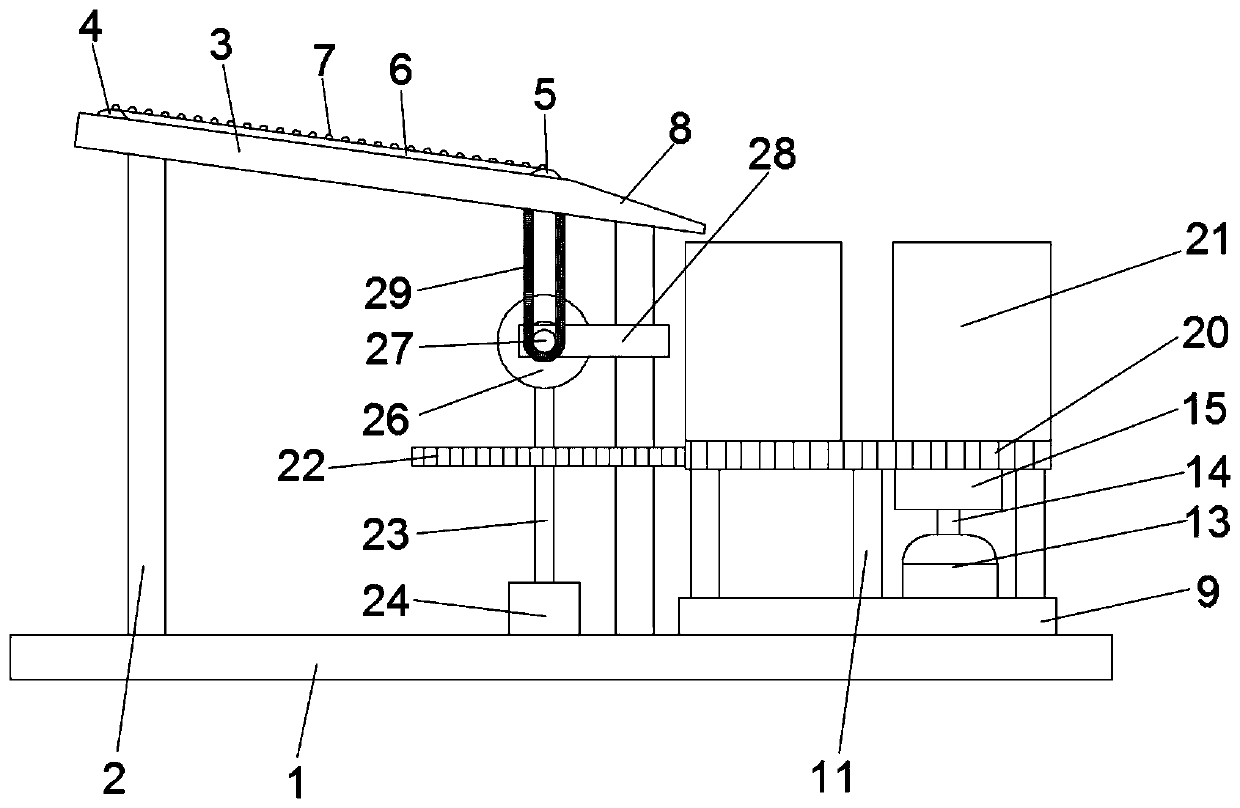

[0023] see figure 1 , a material receiving device for bipolar plate production, comprising a base 1 and a support frame 2, a transfer mechanism is installed above the support frame 2, and the transfer mechanism includes a transfer platform 3, a conveyor belt 6 and a material guide port 8, the The two ends of the conveyor belt 6 are provided with a drive wheel 5 and a driven wheel 4; the right side of the base 1 is equipped with a material receiving mechanism, and the material receiving mechanism includes a drive motor 13, an intermittent rotating assembly and a material receiving box 21. The drive The motor 13 drives the intermittent rotating assembly to move, and above the intermittent rotating assembly is fixed a number of receiving boxes 21 uniformly distributed in the circumferential direction, and the receiving box 21 is located below the material guide port 8; are connected by a synchronous transmission mechanism;

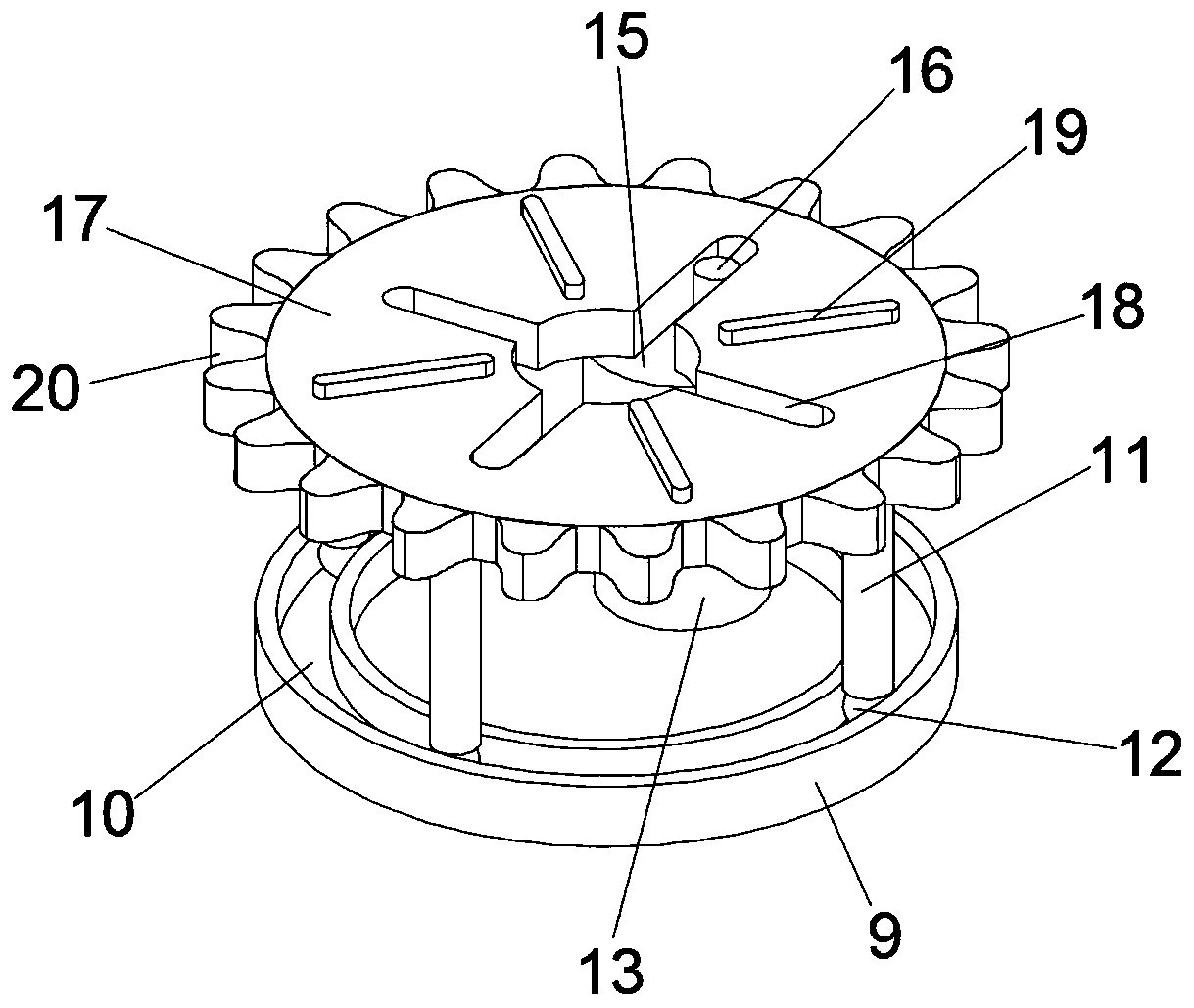

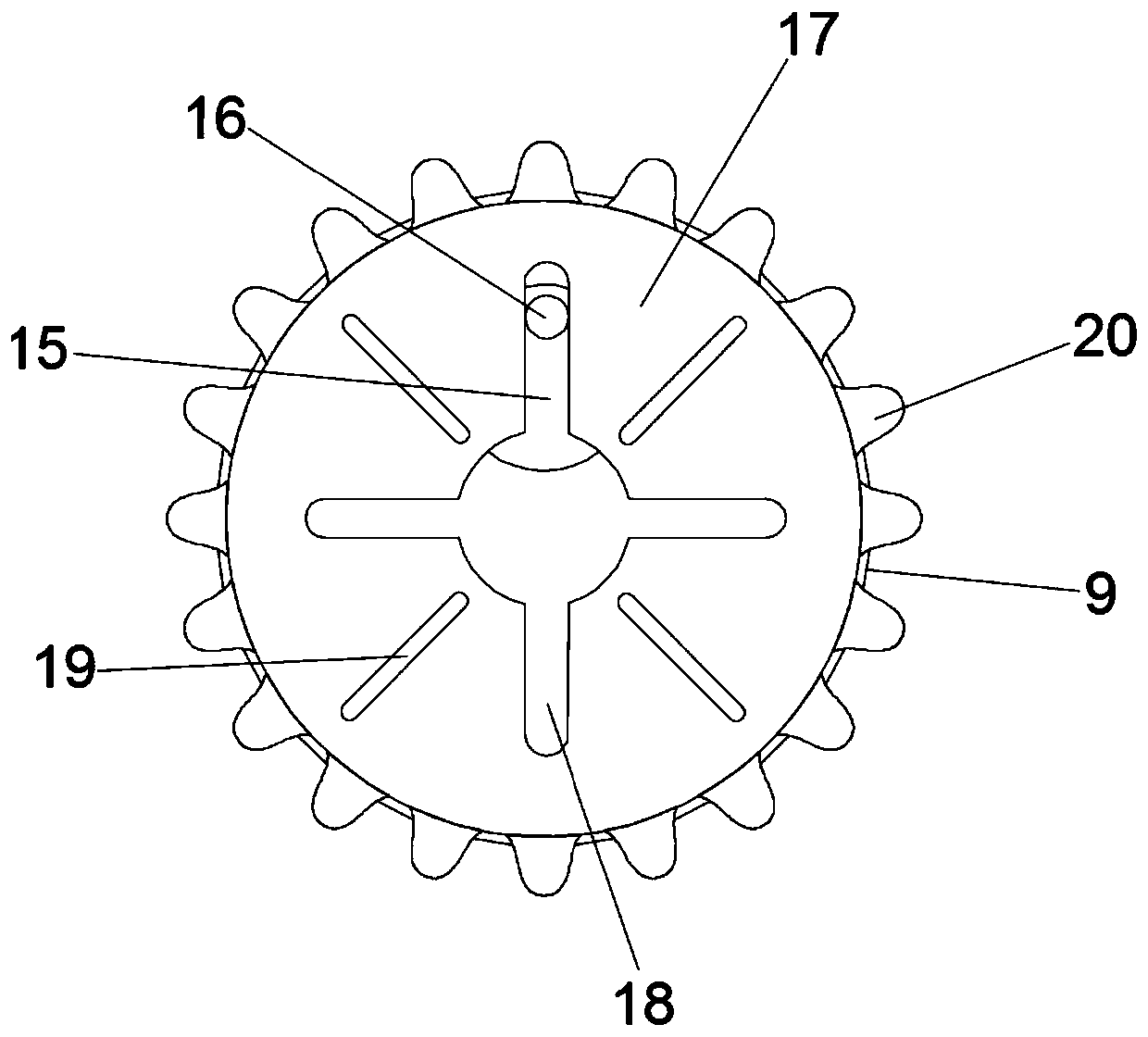

[0024] see Figure 2-4 The specific form of the inter...

Embodiment 2

[0035] In order to prevent the receiving box 21 from overturning when it rotates on the turntable 17, this implementation has made further improvements on the basis of Embodiment 1. The improvements are: the turntable 17 is also provided with bumps 19 evenly, and the The bottom of the material receiving box 21 is provided with a concave part matching with the protrusion 19 .

[0036] The material receiving device for bipolar plate production realizes the periodic intermittent rotation of the material receiving box 21 through the intermittent rotating assembly, and at the same time makes the movement rhythm of the conveyor belt 6 consistent with the material receiving box 21 through the synchronous transmission mechanism, so that each material receiving box 21 The number of workpieces connected under the material guide port 8 is consistent, the material receiving process is stable and reliable, and the material receiving efficiency is high; moreover, a plurality of material rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com