Automatic feeding mechanism of assembling of grip head and grip shaft of watch

A technology of automatic feeding and feeding mechanism, which is applied to clocks, clocks, clock support equipment, etc., can solve the problems of slow manual loading speed, easy fatigue of workers, and hand injury of workers, so as to achieve accurate and reliable feeding, improve the operating environment, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

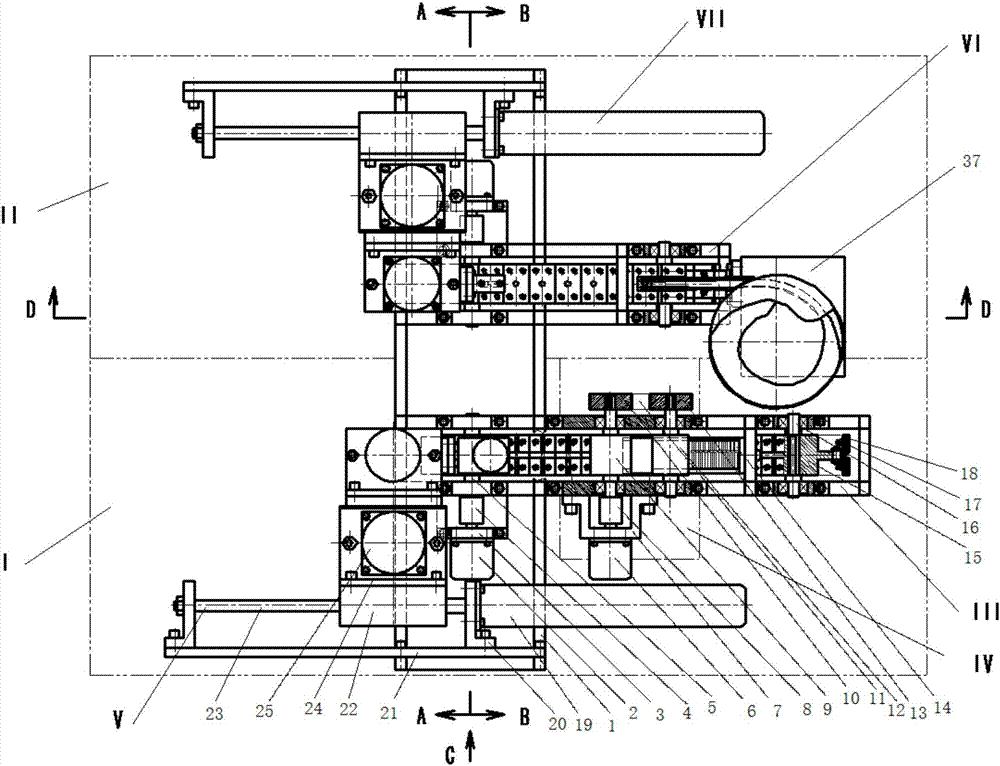

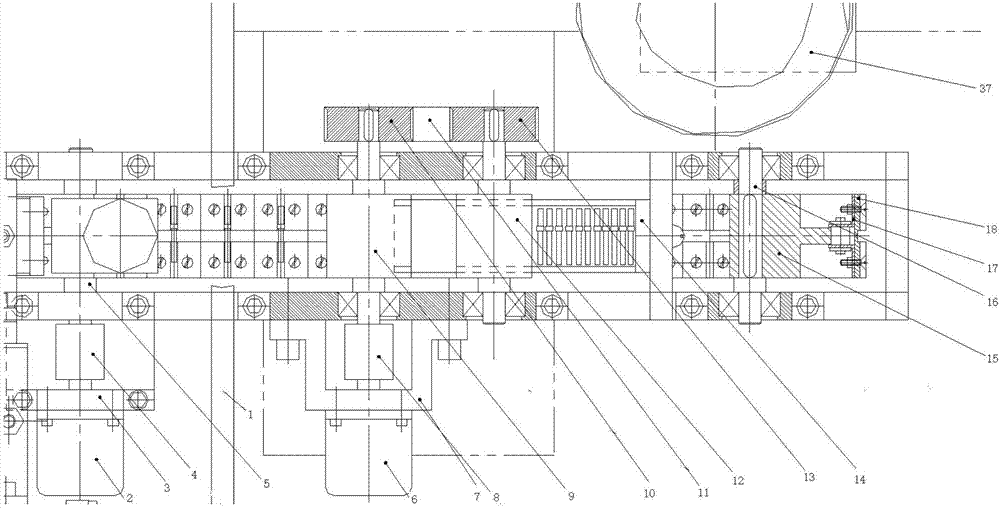

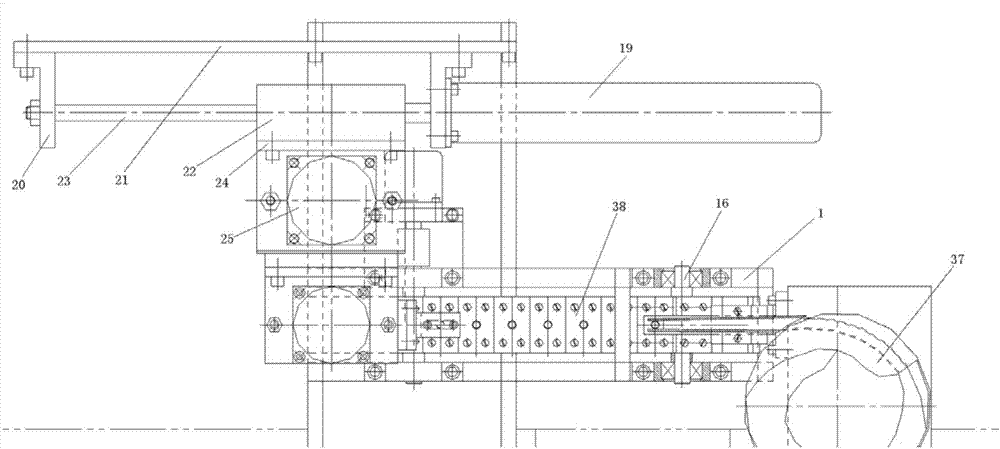

[0029] refer to Figure 1 to Figure 7 , propose an embodiment of the watch crown stem assembly automatic feeding mechanism of the present invention:

[0030] Disclosed is an automatic feeding mechanism for watch crown and stem assembly, which is composed of a frame 1, a stem feeding mechanism I, and a crown feeding mechanism II, and the stem feeding mechanism I and the crown feeding mechanism II are arranged in parallel front and back.

[0031] The arbor feeding mechanism I is composed of the arbor feeding transmission assembly III, the arbor automatic unloading assembly IV, and the arbor monitoring and feeding manipulator assembly V. The automatic arbor unloading component IV is installed on the upper right of the arbor feeding drive component III, and the arbor monitoring and feeding manipulator component V is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com