Feed trough mechanism of metal cutting circular sawing machine

A metal cutting and feeding trough technology, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of unsuitable for conveying strip metal, inconvenient cutting, etc., to achieve stable and reliable feeding process and improve cutting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

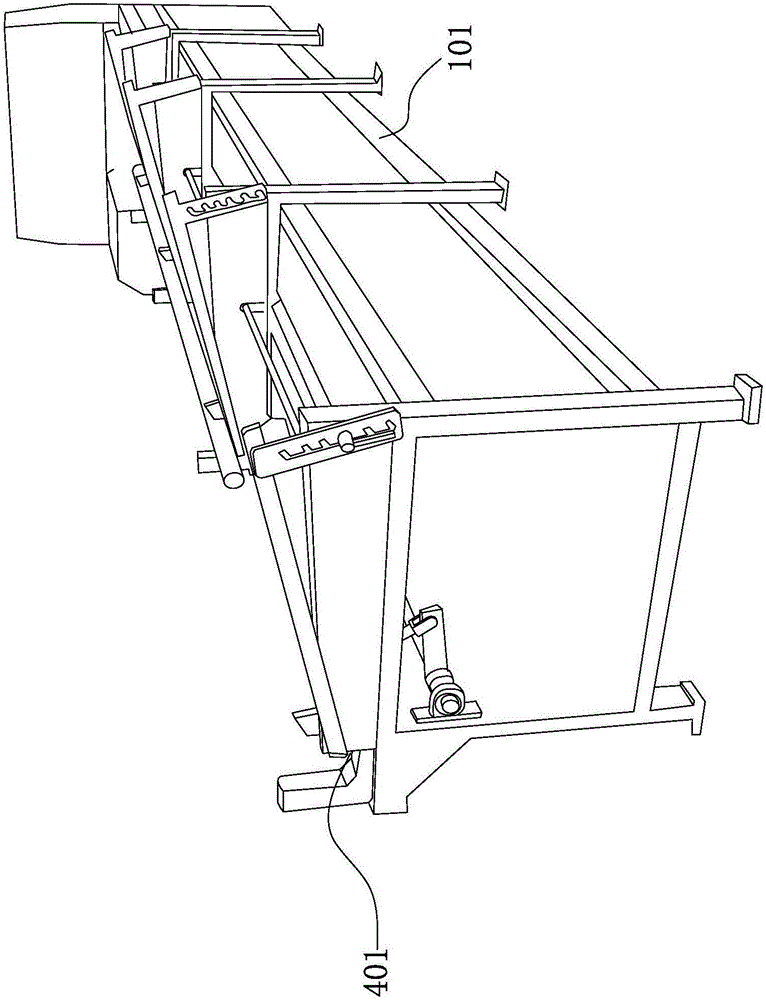

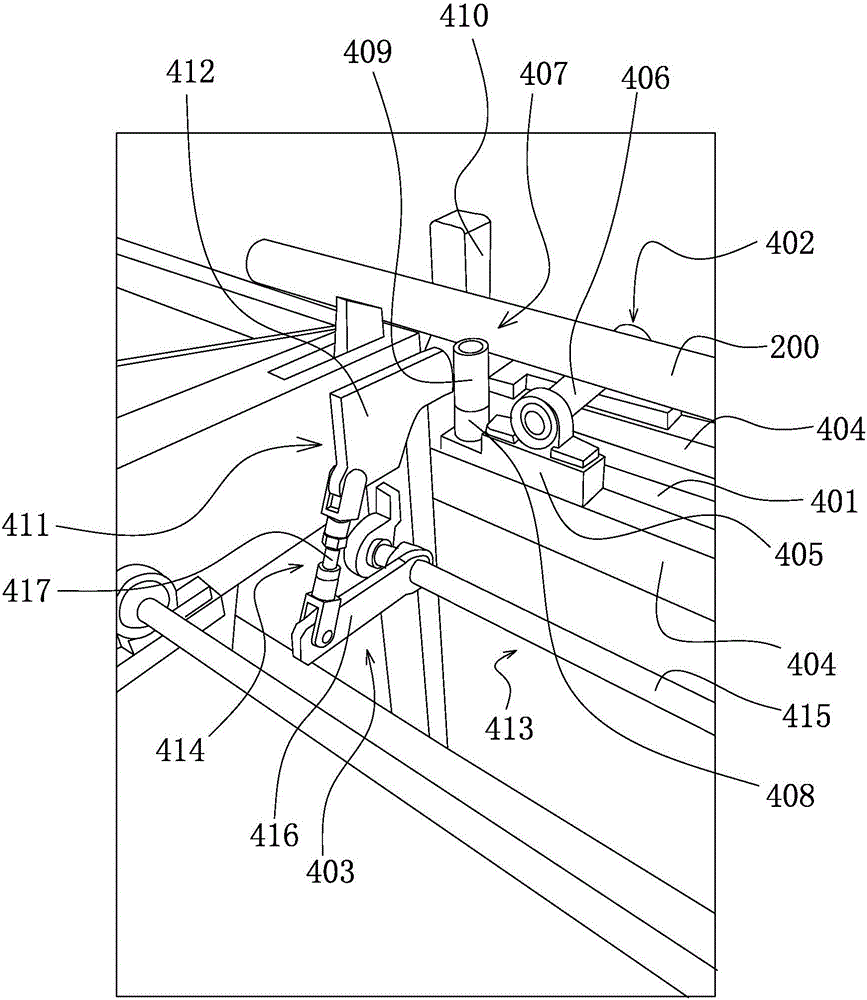

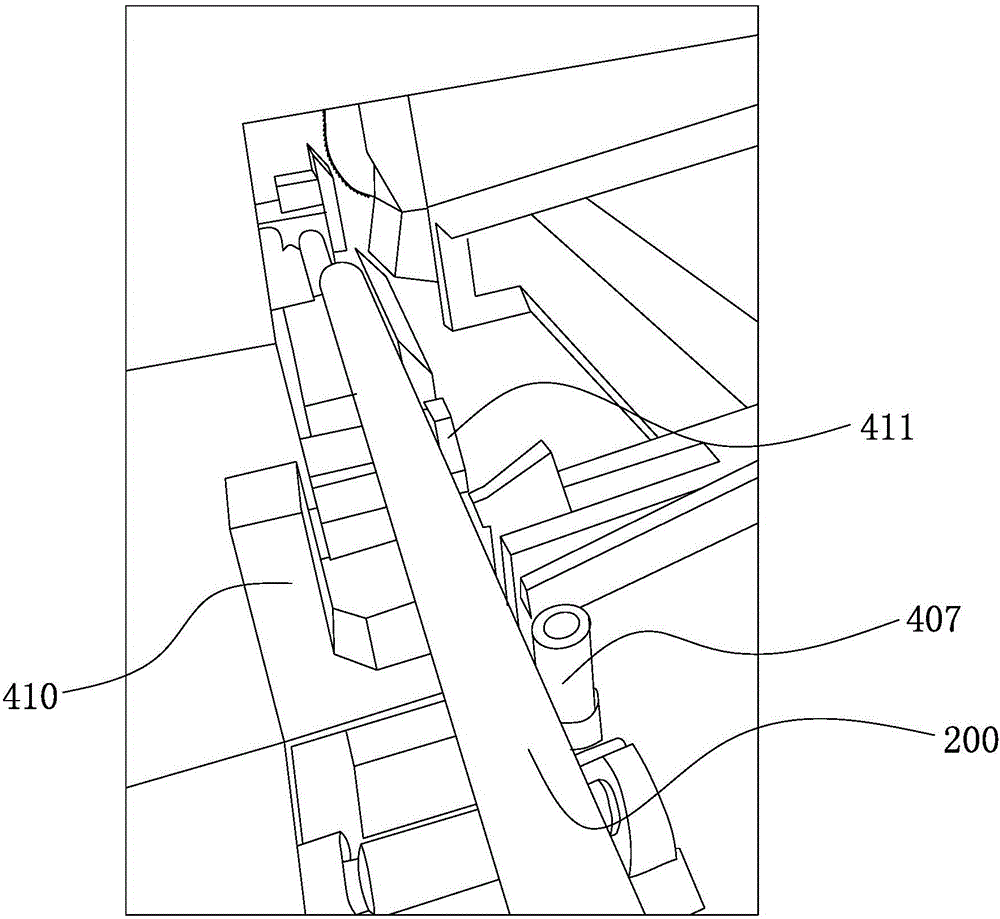

[0020] Such as figure 1 and figure 2 As shown, a feed chute mechanism of a metal cutting circular saw machine includes a feed trough 401 on the top of the frame 101 for placing the metal 200 to be cut. The feed chute 401 is connected to the cutting mechanism. Rolling feeding assemblies 402 are evenly spaced along the axial direction of the feeding trough 401, and the frame 101 is also provided with a clamping assembly that can move in the direction of the feeding chute 401 to clamp the metal to be cut in the feeding chute 401 403.

[0021] The metal to be cut 200 is put into the feeding trough 401 and clamped by the clamping assembly 403 , and the metal is cut when clamped, preventing the metal to be cut from shaking during the cutting process, thereby improving the cutting accuracy. The rolling feeding assembly 402 is used for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com