Feeding device for paper and plastic packaging machine

A feeding device and packaging machine technology, applied in packaging and other directions, can solve problems such as unsmooth blanking, easy jamming of gaps, poor controllability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

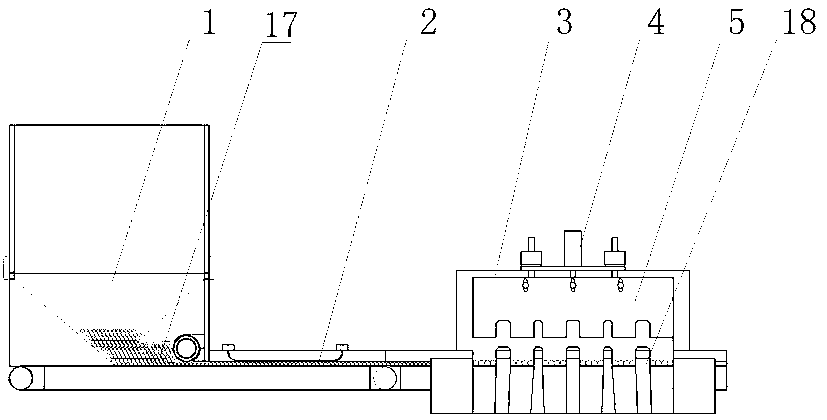

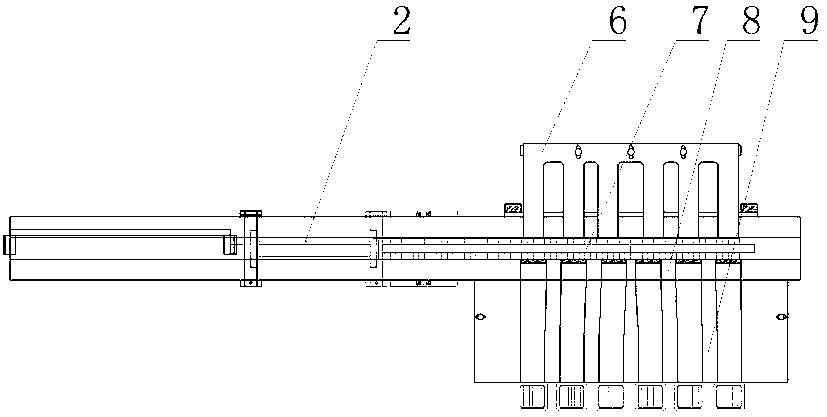

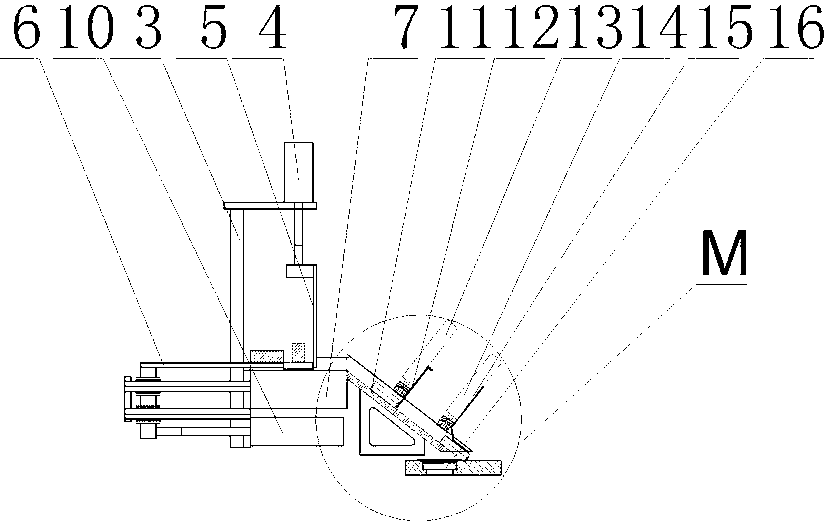

[0017] With reference to the drawings, the feeding device of this paper-plastic packaging machine includes a silo 1, a conveyor belt 2. One end of the conveyor belt 2 is placed at the bottom of the silo 1, and the other end is connected to the feeding platform 7, the conveyor belt 2 and the silo The article 1 has friction. After the conveyor belt 2 works, the article 17 in the silo 1 is moved out and arrives on the feeding platform 7. As the conveyor belt 2 is transported, the article 17 is sent to the feeding platform 7, and then Push the previous one one by one and place them on the feeding platform 7 one by one. The feeding platform 7 has a discharging groove 8 on one side, and a pushing plate 6 corresponding to the discharging groove 8 on the other side. The pushing plate 6 is connected to the third cylinder 10. When the third cylinder 10 is working, Push the pushing plate 6 to push out the articles 17 sequentially placed on the feeding platform 7 through the discharging sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com