Vacuum absorption rubbing type separating and fetching mechanism and method

A technology of vacuum adsorption and reclaiming mechanism, which is applied in the direction of paper product packaging, packaging, packaging items, etc., can solve the problems of poor reliability of separation masks, reduced equipment durability, and difficult suction control, and can solve the problems of mask absorption and separation, Cost saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiment of the present invention is described with a preferred example.

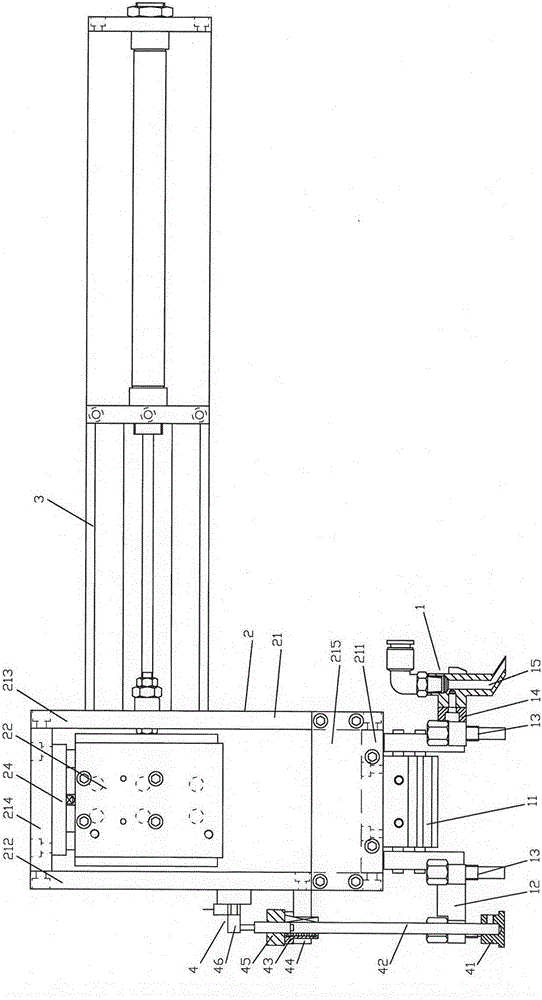

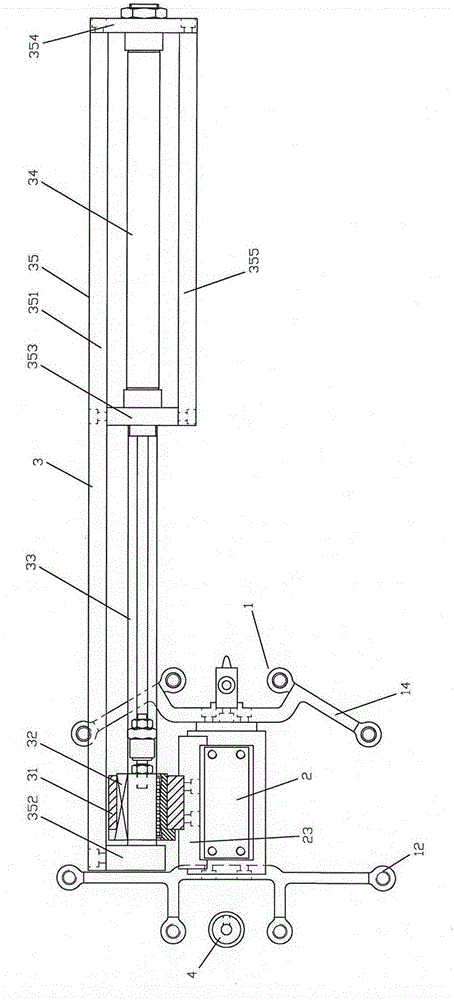

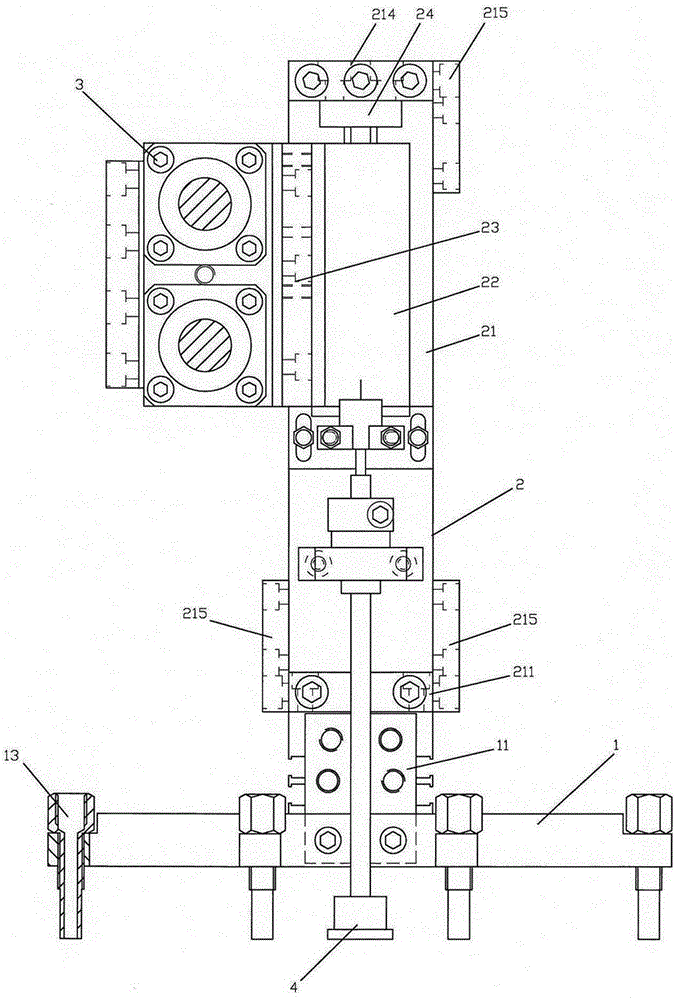

[0029] as attached figure 1 , figure 2 and image 3 As shown, the vacuum adsorption rubbing type separation and reclaiming mechanism includes an adsorption rubbing mechanism 1 , a lifting mechanism 2 , a horizontal moving mechanism 3 and a detection mechanism 4 . Described adsorption rubbing mechanism 1 comprises a wide type finger cylinder jaw 11, and the left jaw of wide type finger cylinder jaw 11 is equipped with left suction nozzle seat 12, and four suction nozzles 13 are housed on the left suction nozzle seat 12; Finger cylinder jaw 11 right paw is equipped with right suction nozzle seat 14, and four suction nozzles 13 are housed on the right suction nozzle seat 14, and an oblique suction nozzle 15 is fixed with bolt in the middle of right suction nozzle seat 14, above-mentioned all suction nozzles 13 And the lower end of inclined suction nozzle 15 is on a horizontal plane. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com