Electromagnetic switch production method and production equipment thereof

A technology for electromagnetic switches and production equipment, which is applied to electrical switches, circuits, electrical components, etc., and can solve the problems of weak connection of pressing pieces, huge installation structure of electromagnetic switches, and difficulty in insertion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

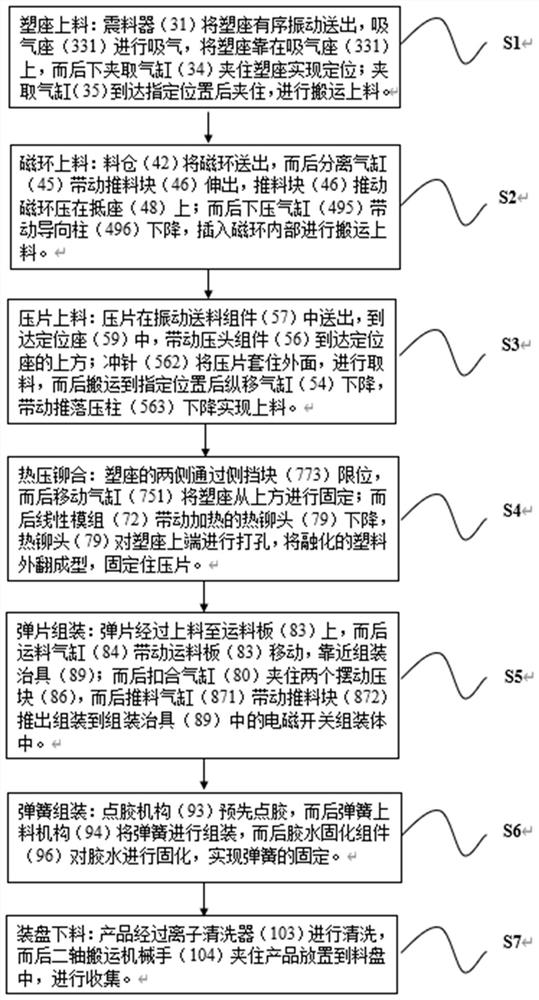

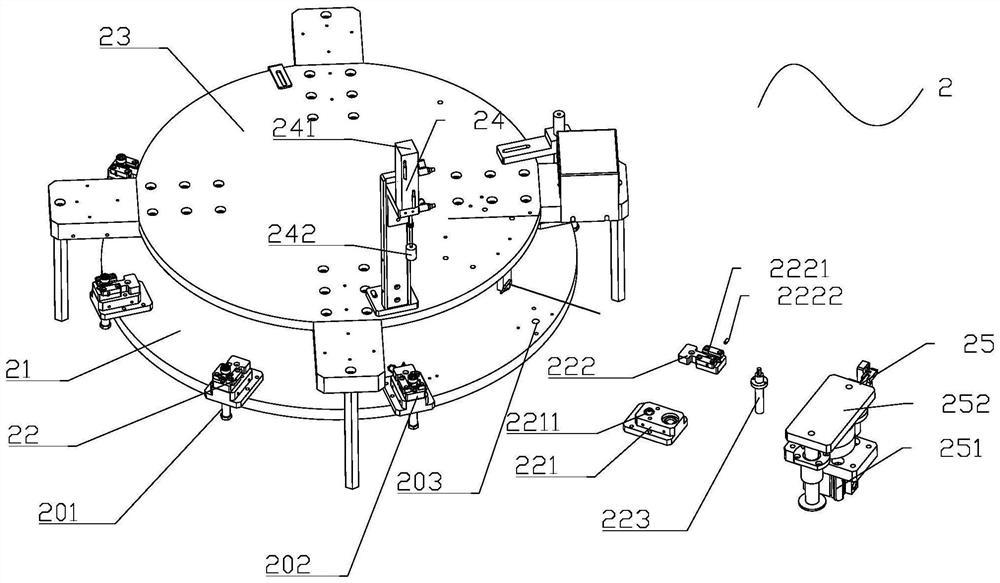

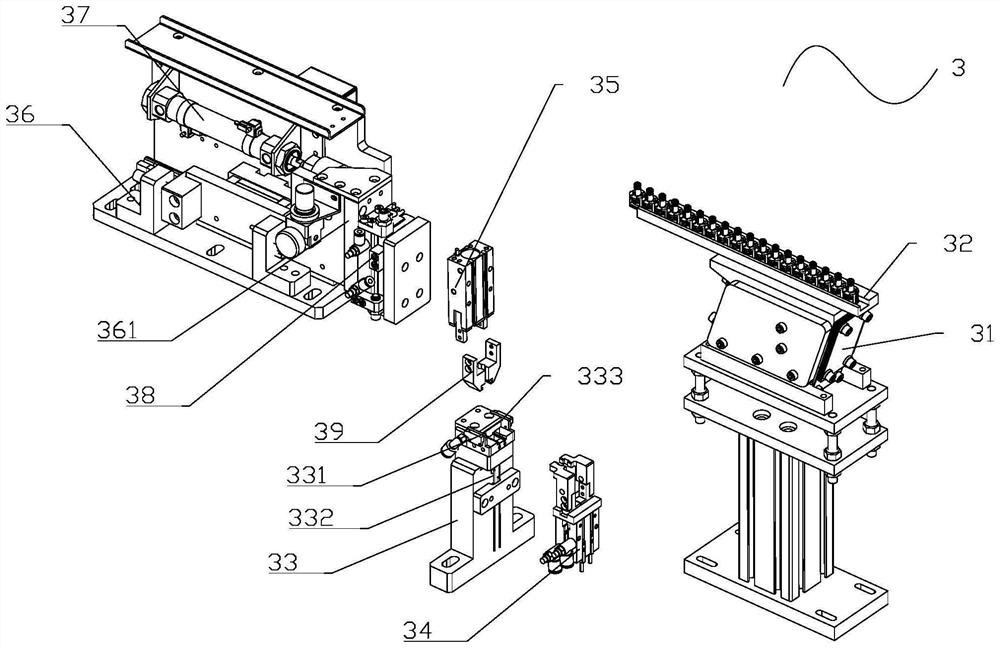

[0050] like Figure 2-16 As shown in, producing an electromagnetic switching device comprising a frame and a carousel conveying device 1 mounted on a frame 2 of plastic material seat means 3, the ring feed means 4, 5 on a tablet feeding apparatus, the linear transport device 6 , for 7, 8 fixed deck, the assembly means of the spring assembly and a cleaning means 9 melt feeding device assembly apparatus 10; carousel conveying means 2 according to the linear transport device 6 are connected, said plastic base material means 3, feed means 4 and feeding device 5 sequentially on a tablet magnetic ring disposed outside of the delivery device 2 of the turntable; hot melt packaging device 7 and the cartridge assembly fixing means 8 disposed side linear transport device 6; said linear transport device 6 is provided with a shift operation mechanism fixture 11 is assembled with the interface between the spring means 9; feeding means 10 is assembled with the spring means 9 according to the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com