Patents

Literature

34results about How to "Reliable traction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

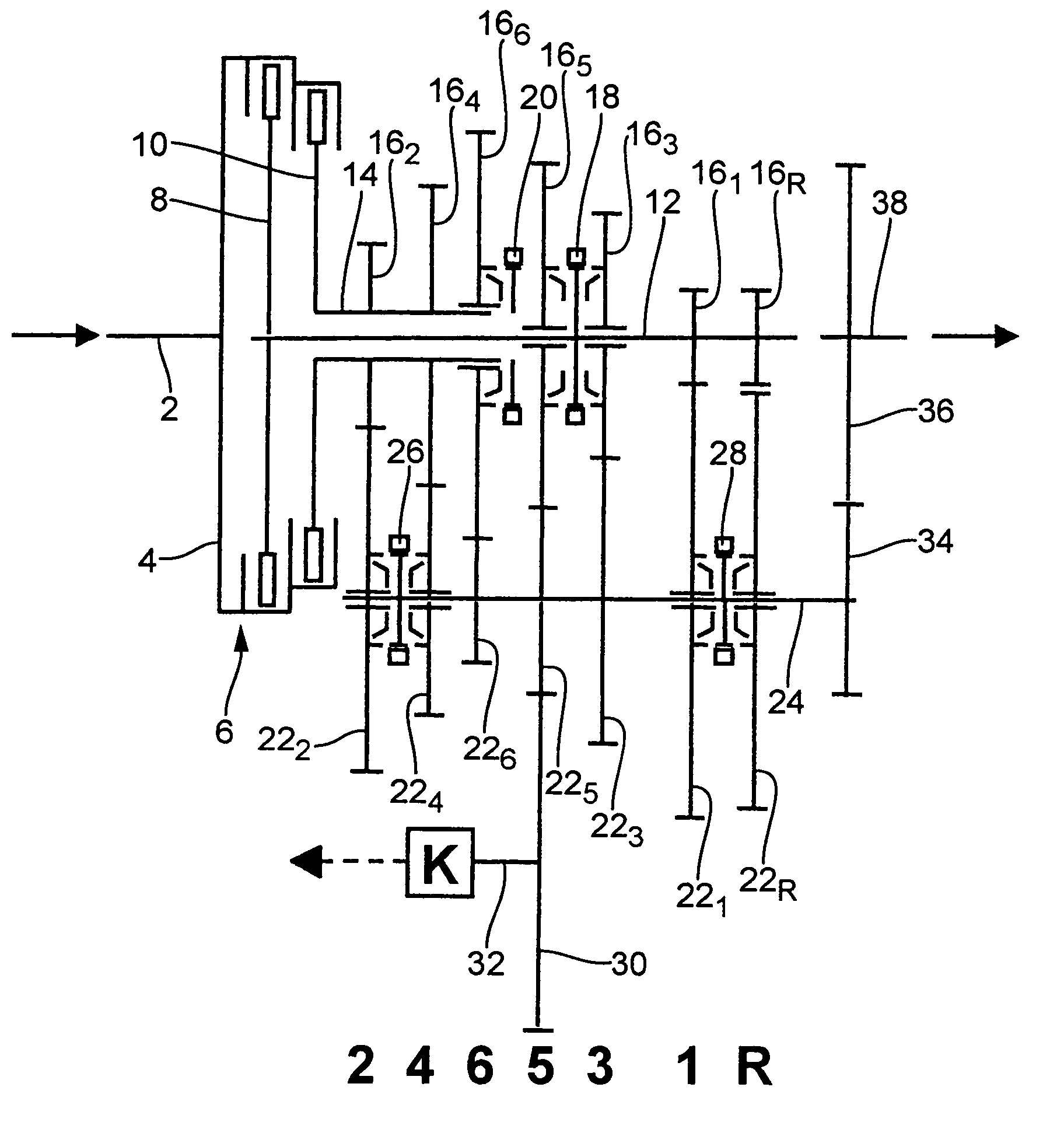

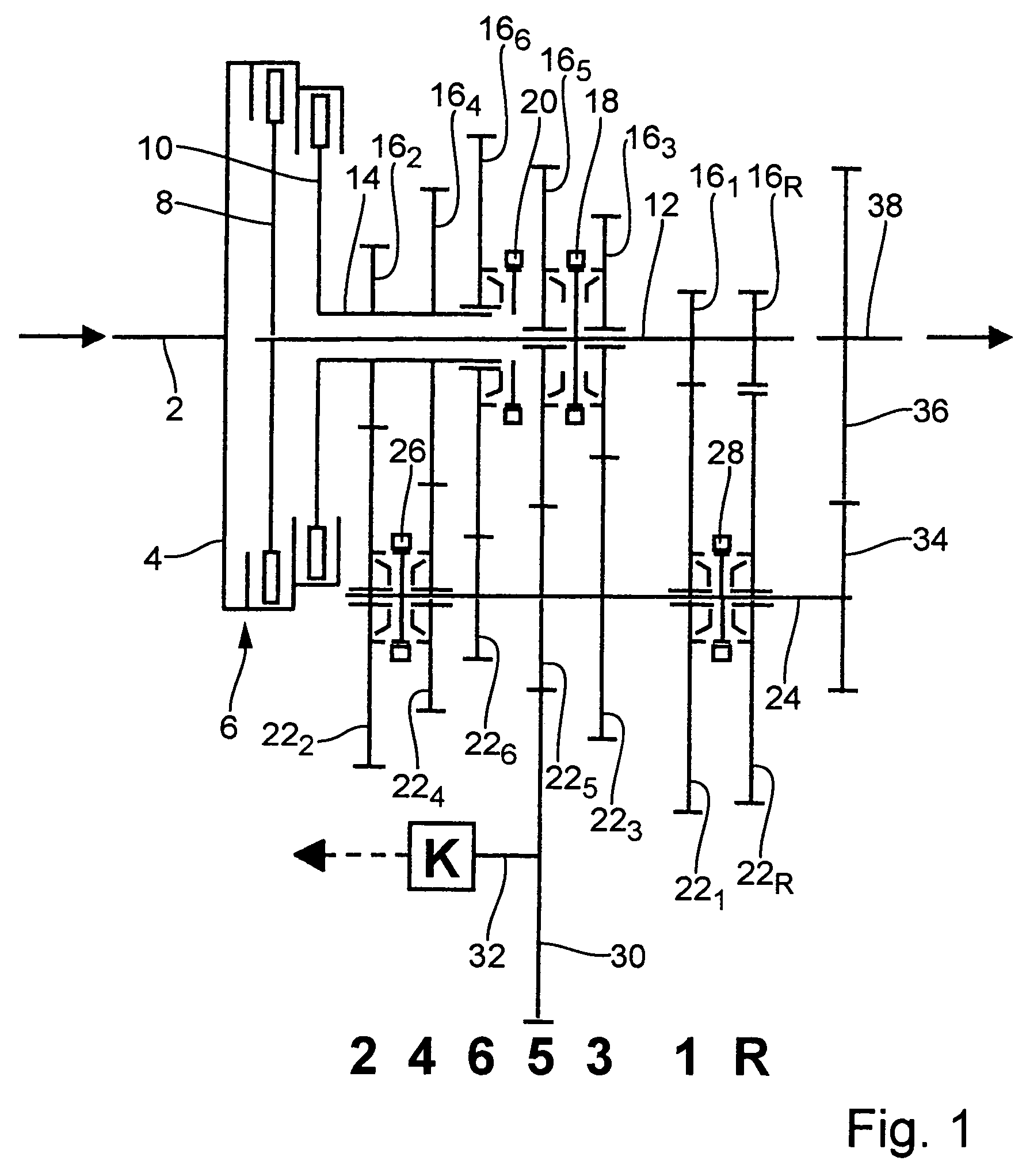

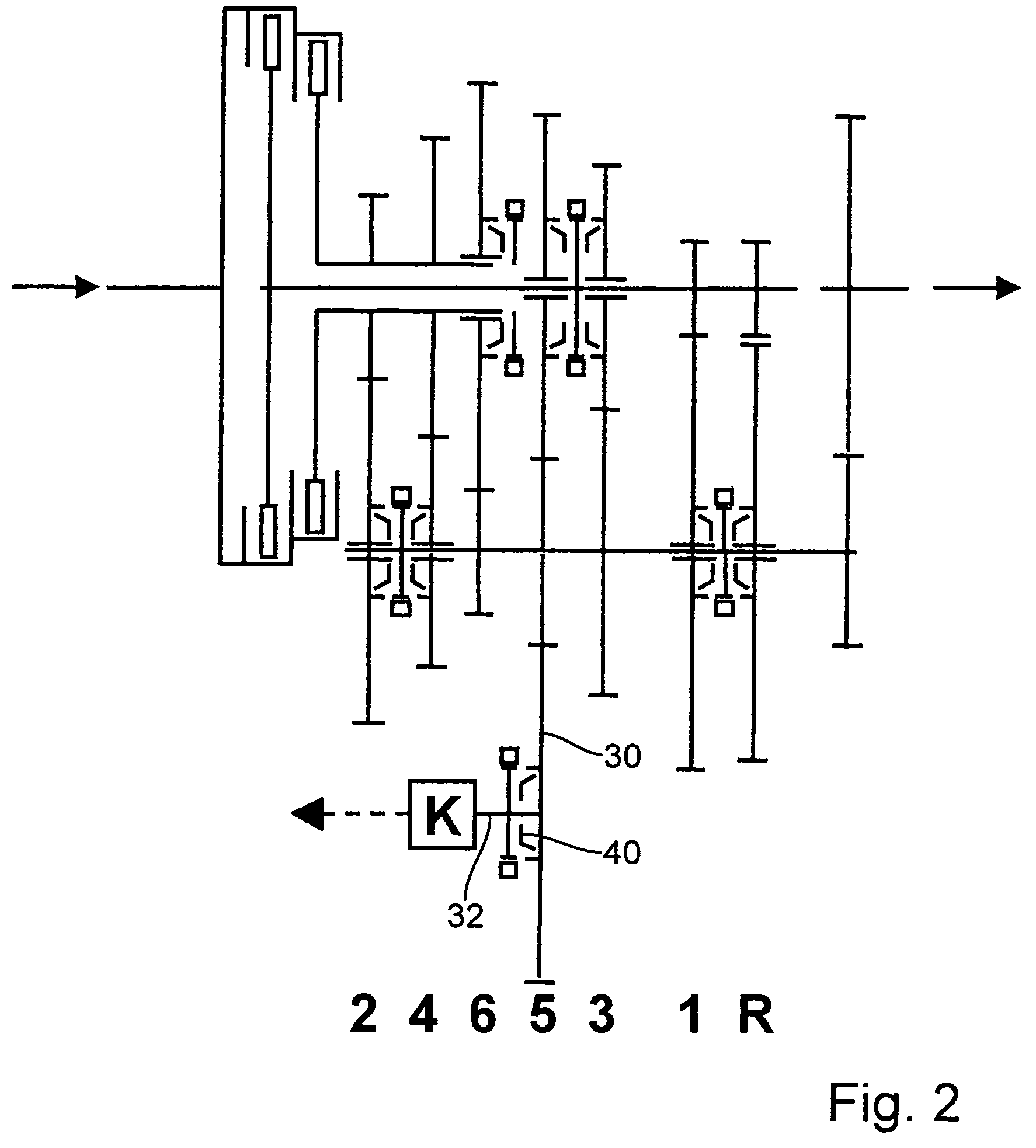

Parallel manual transmission for four-wheel drive and parallel manual transmission for transverse installation in a front-wheel drive vehicle

InactiveUS7040186B2Selectability is easilyReliable tractionToothed gearingsTransmission elementsEngineeringFront-wheel drive

A parallel manual transmission for a four-wheel drive is provided and includes two input shafts, each of which can be non-rotatably coupled via its own clutch to a shaft that is powered by a drive engine.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

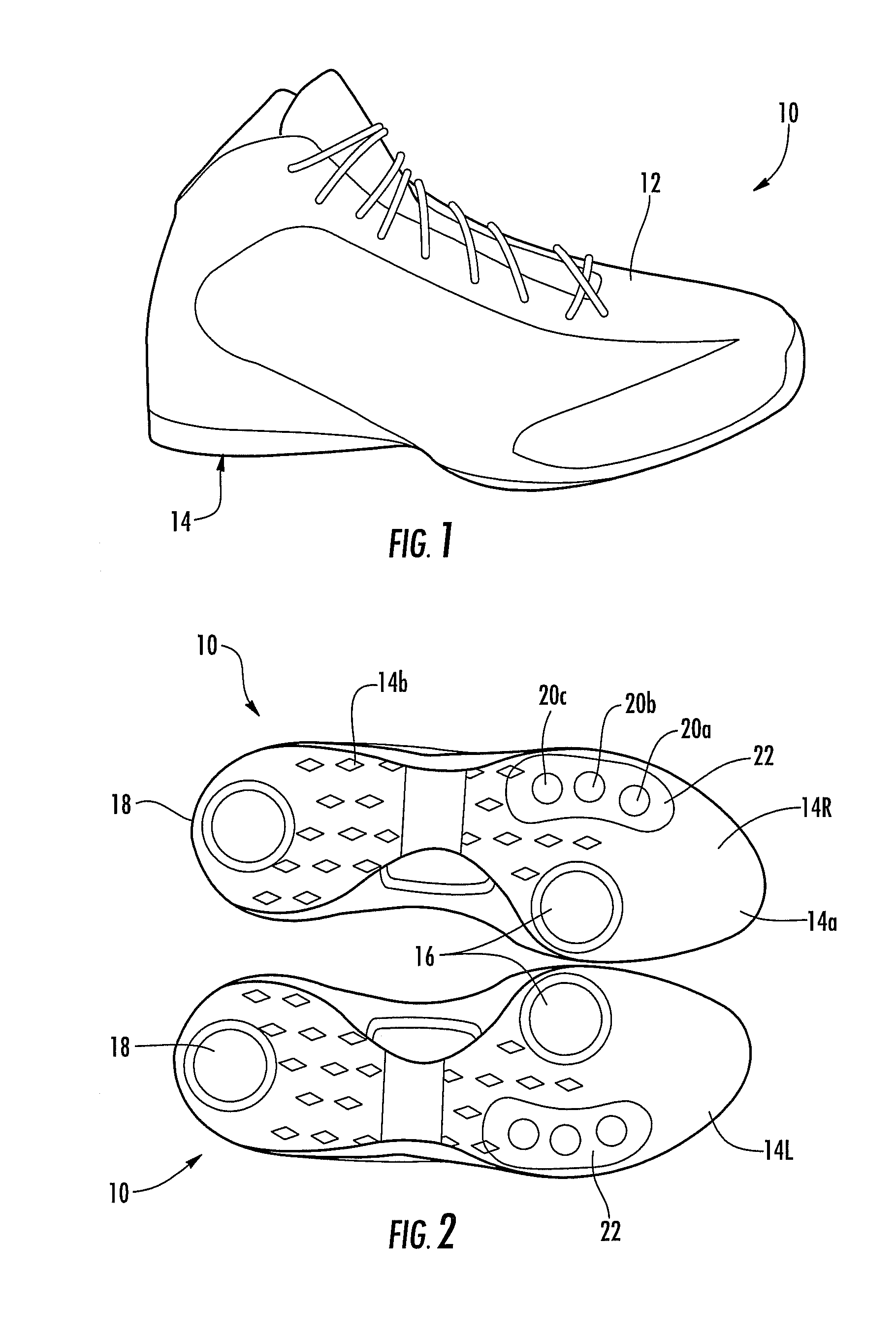

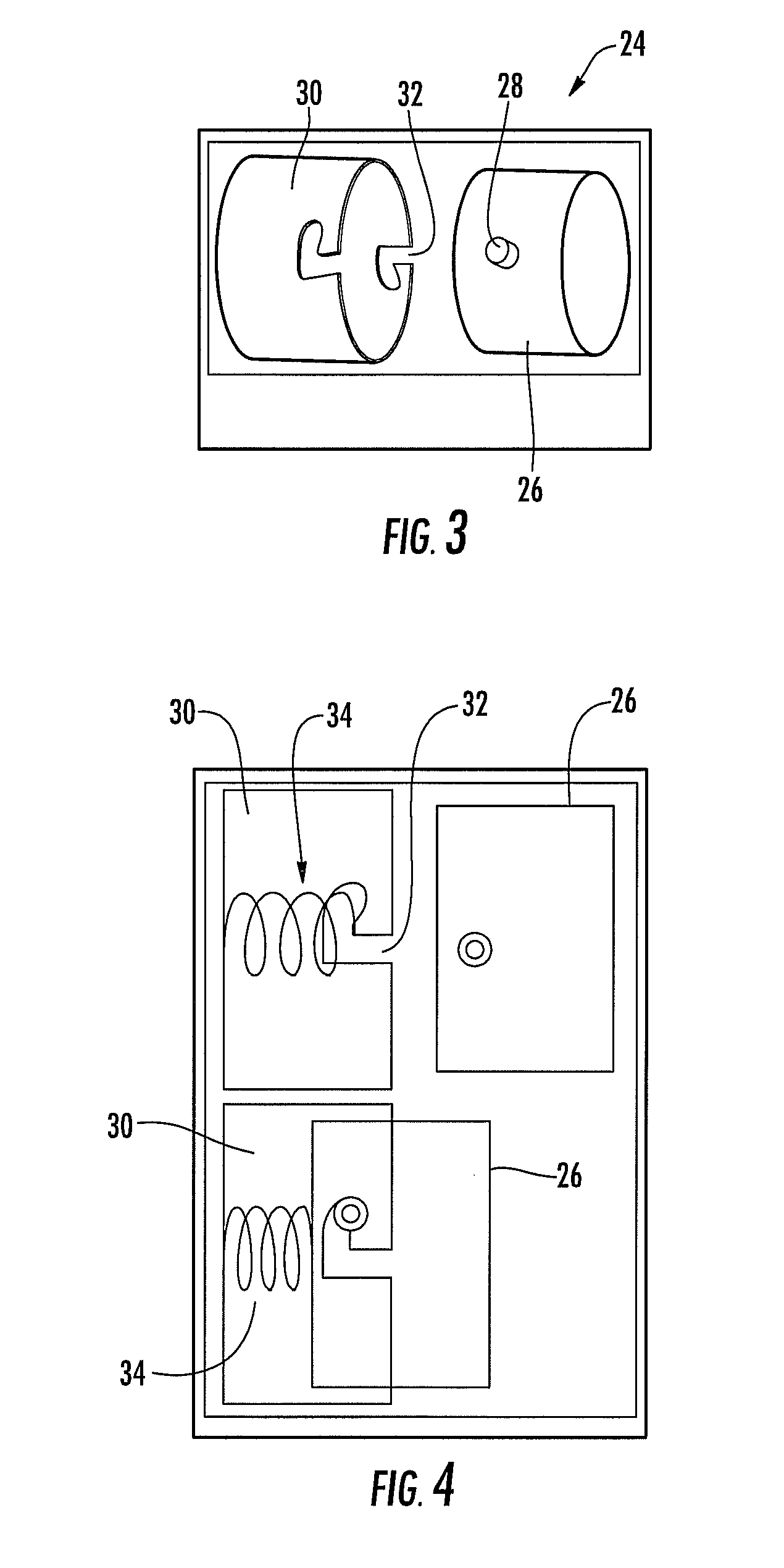

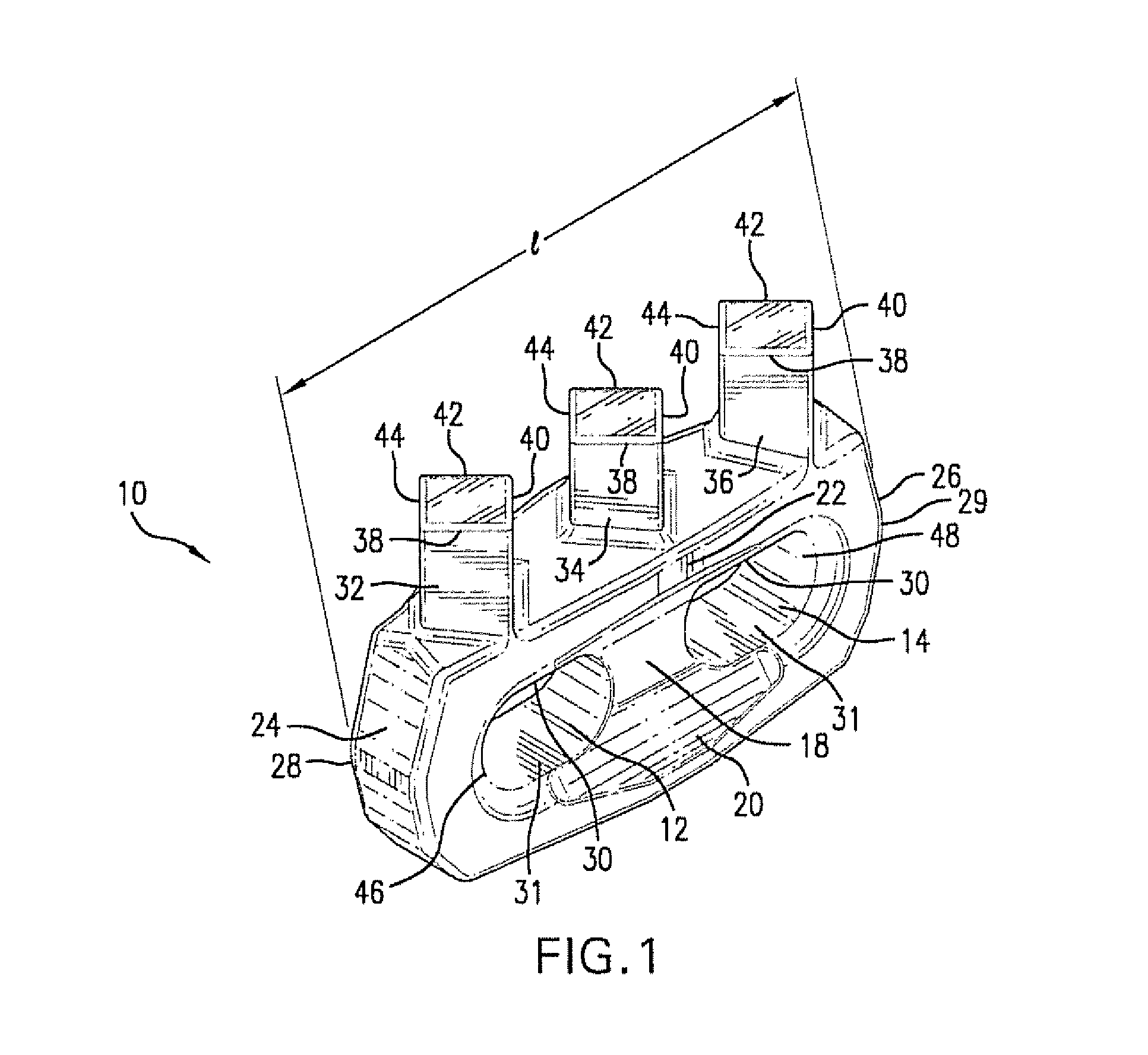

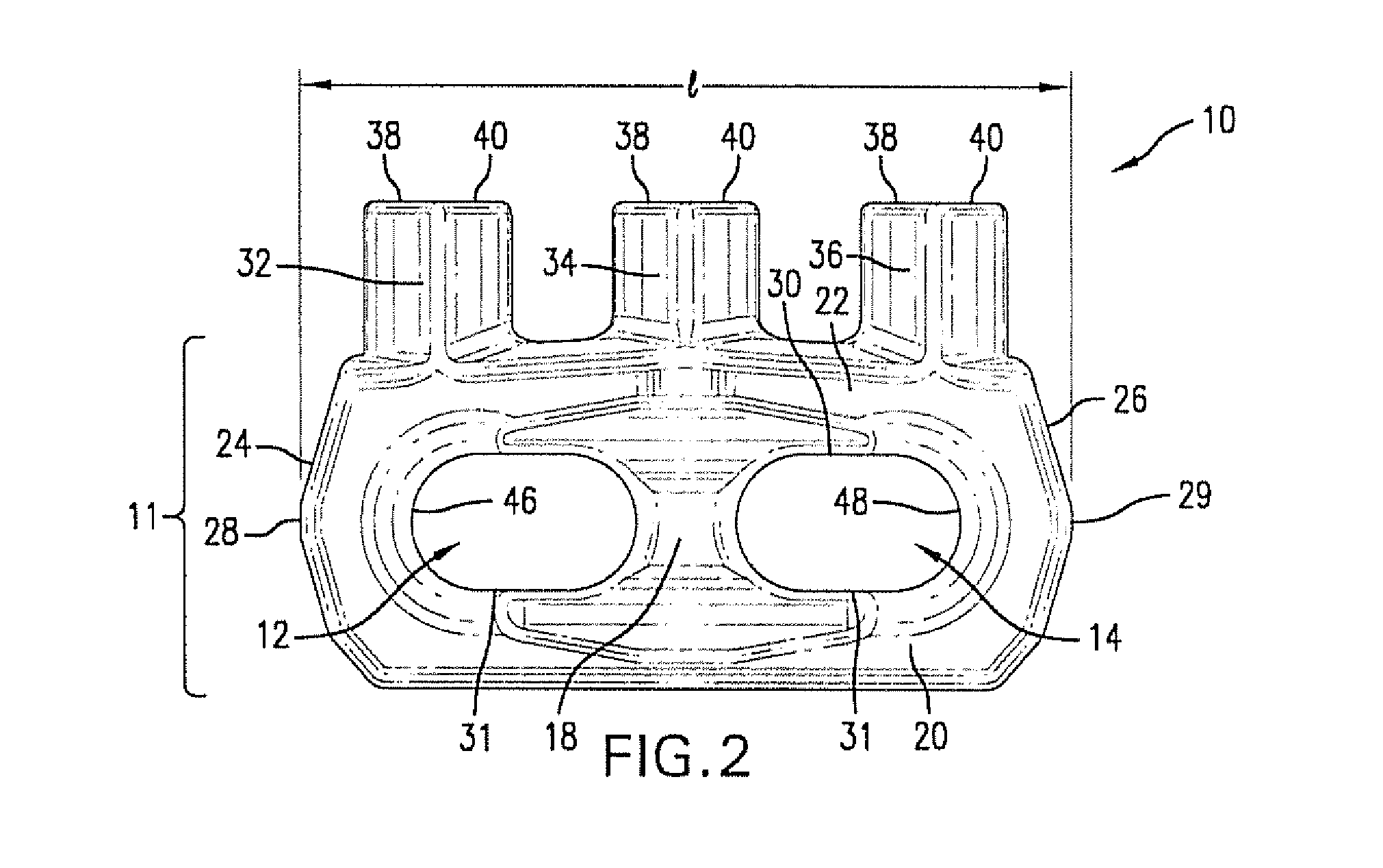

Shoe soles for enhancing gripping with a smooth hard surface

ActiveUS20120066938A1Enhance gripping propertyGreat tractionSolesFasteningsEngineeringVisual perception

Owner:MPCG HLDG LLC

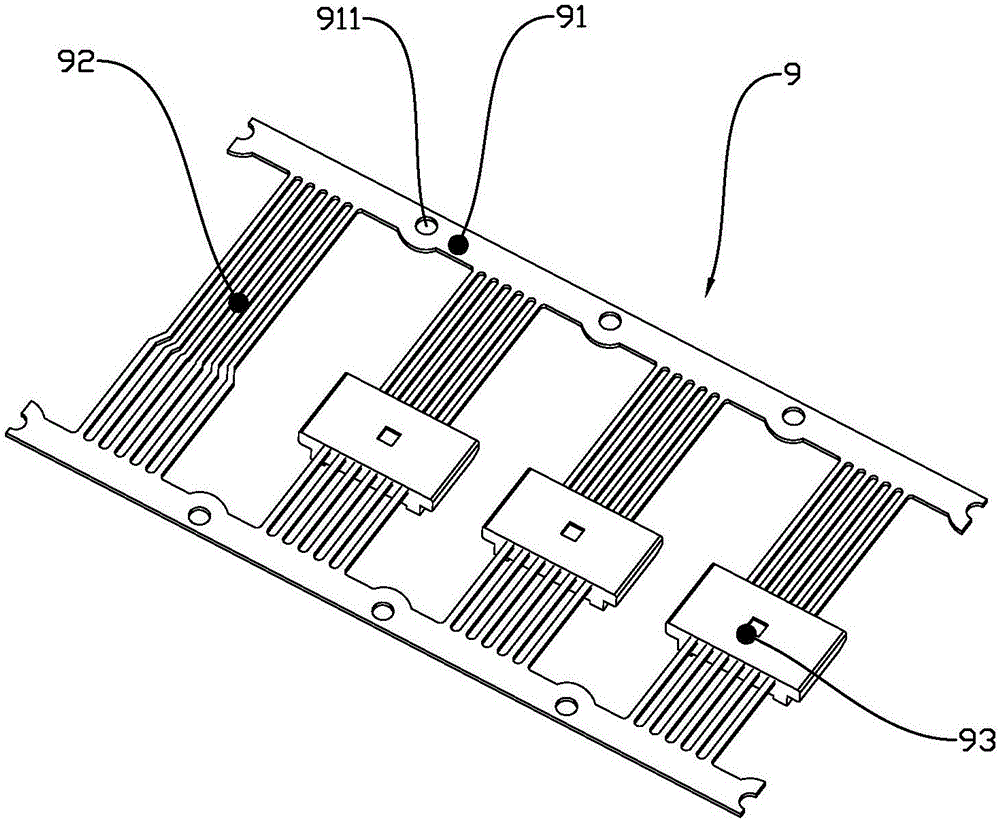

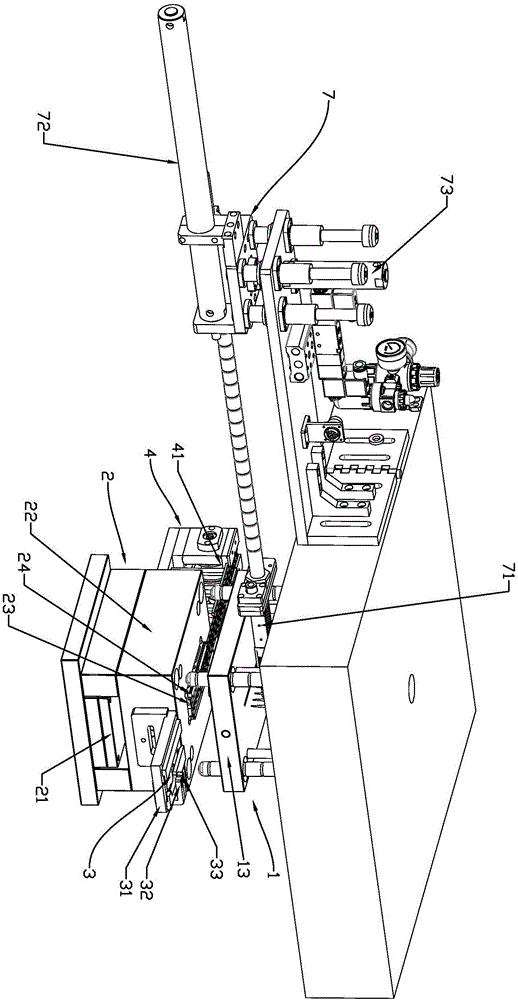

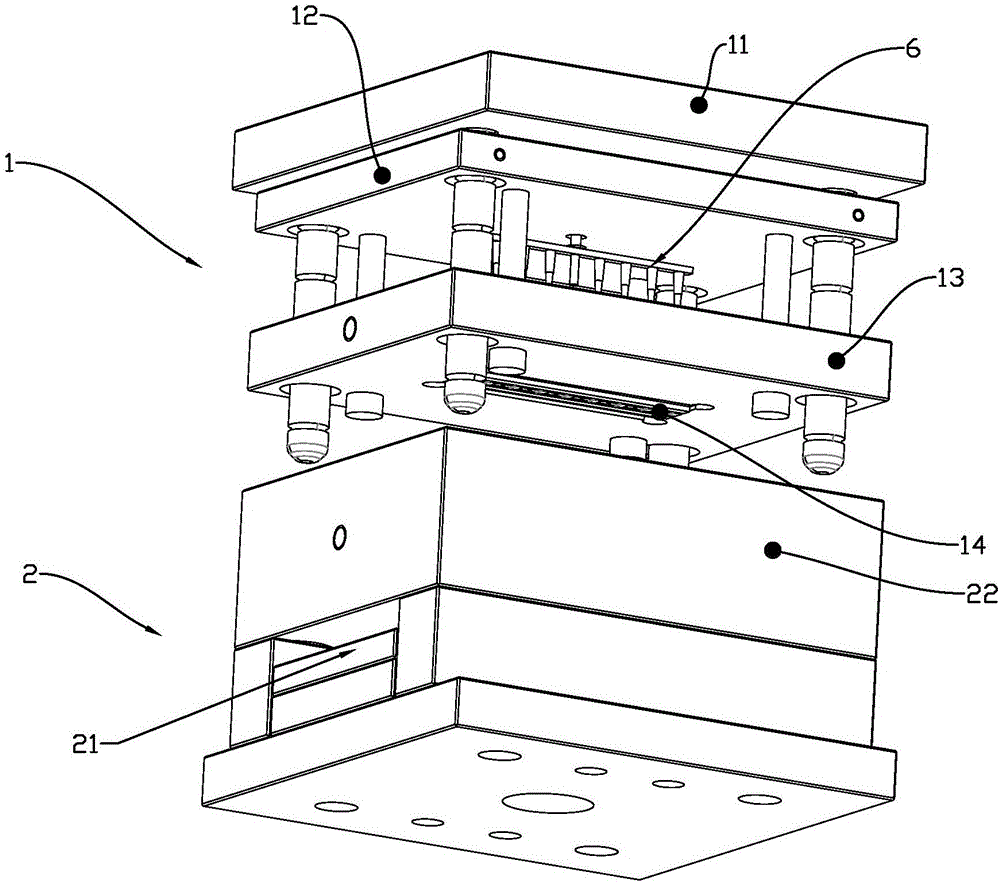

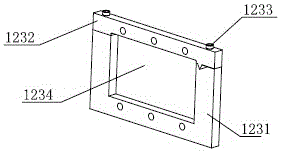

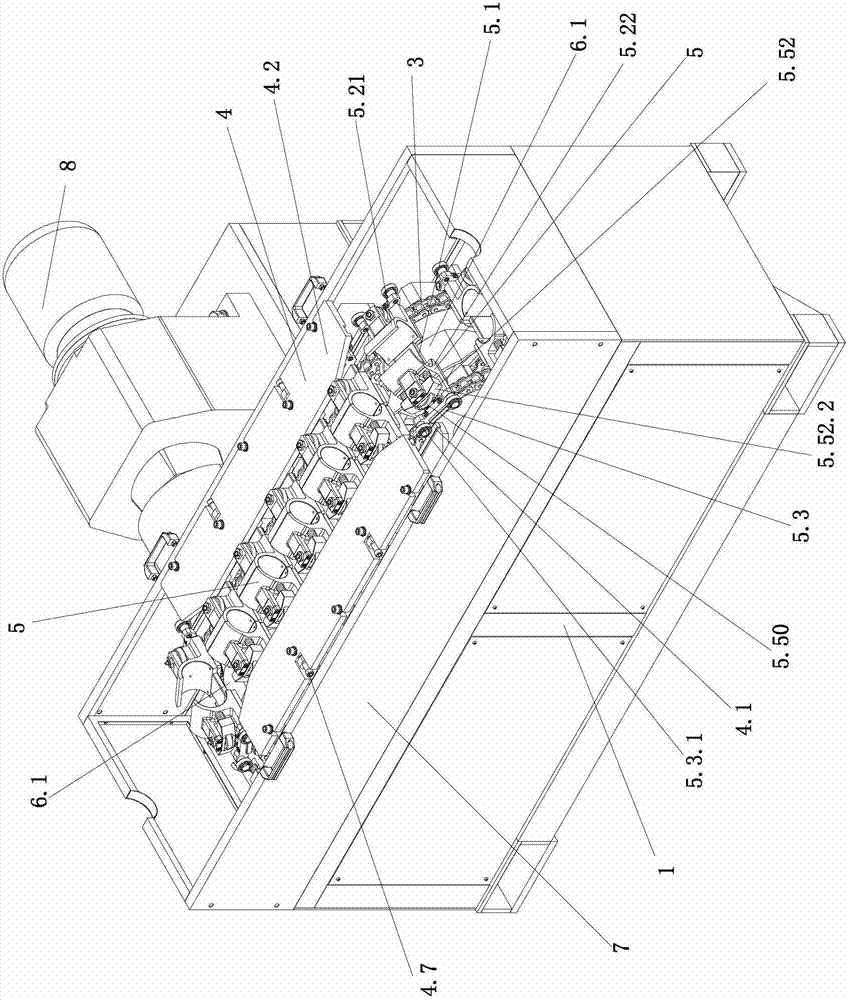

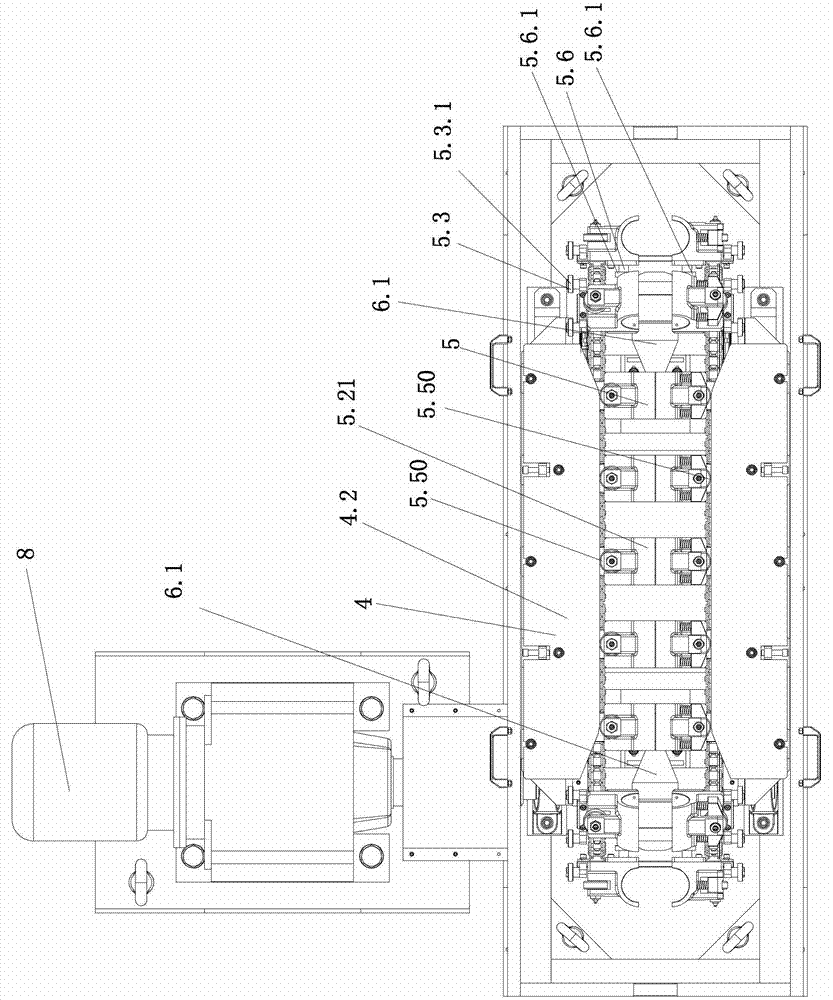

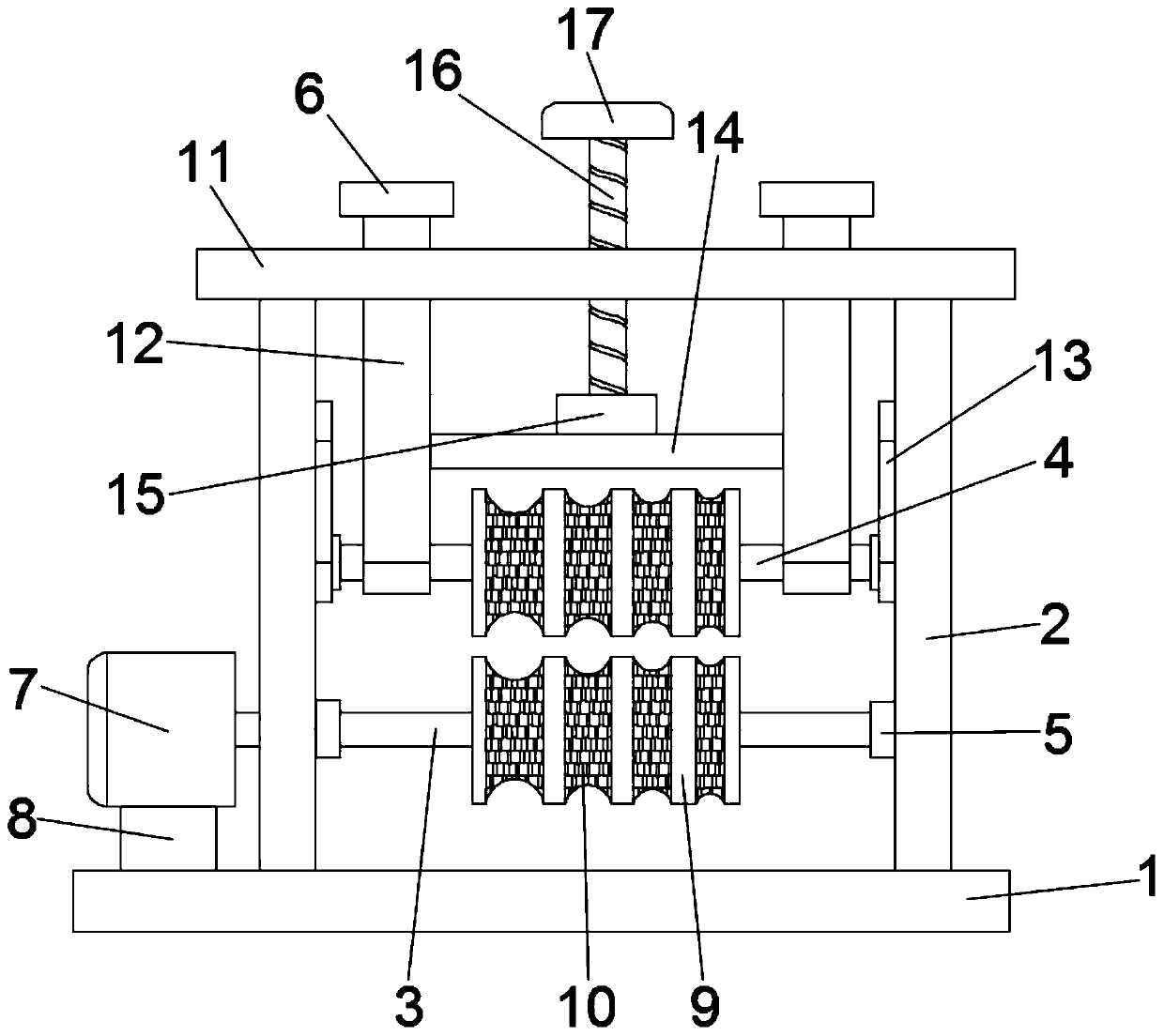

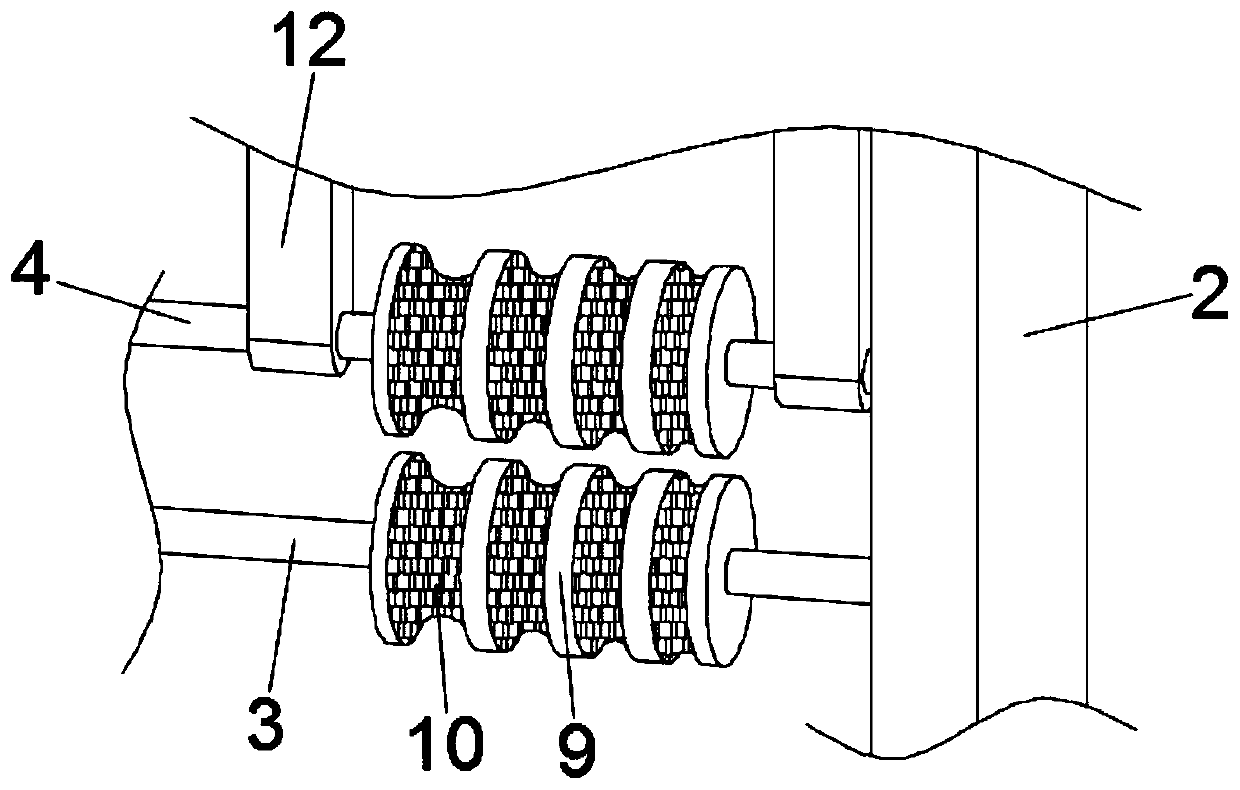

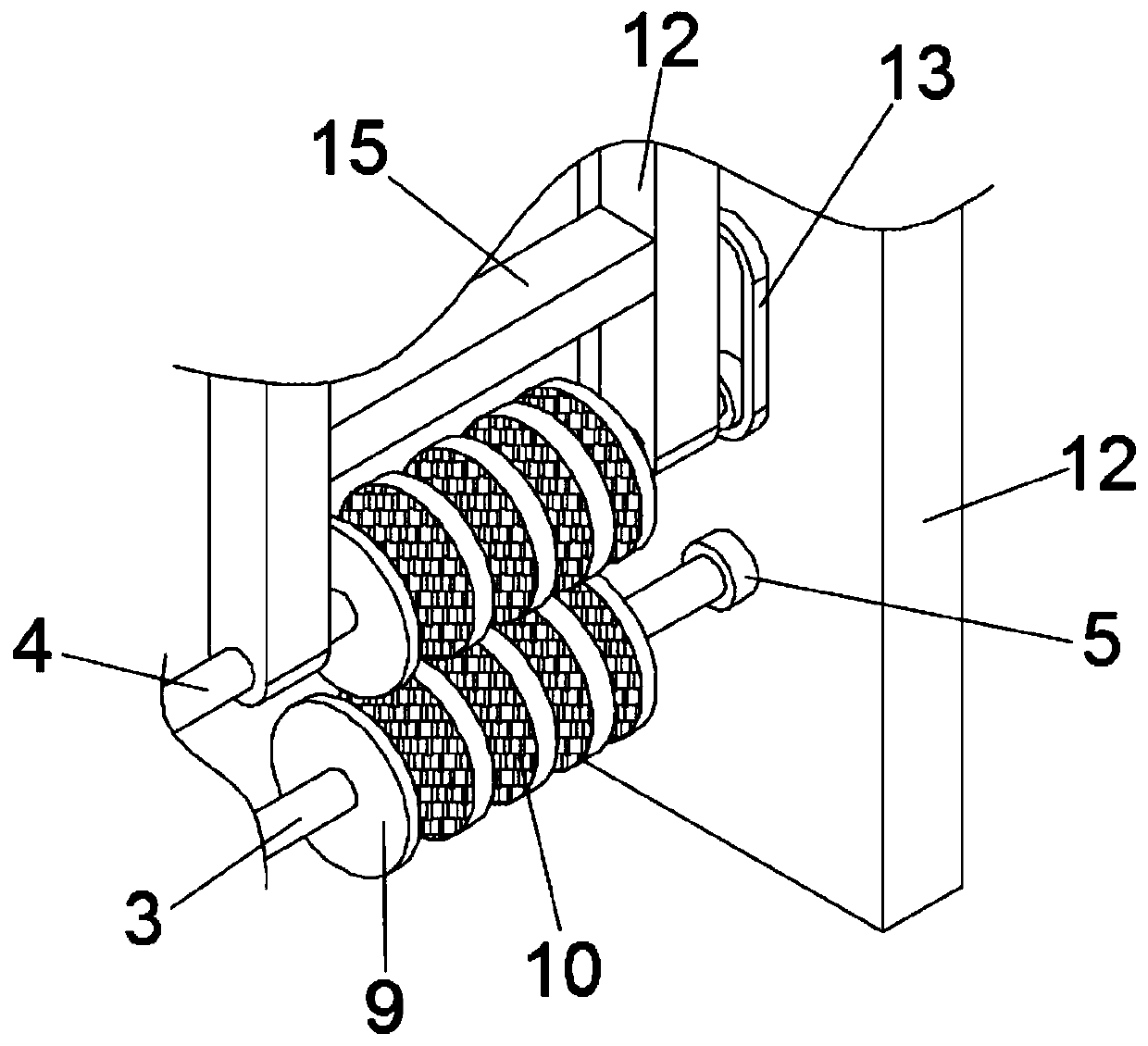

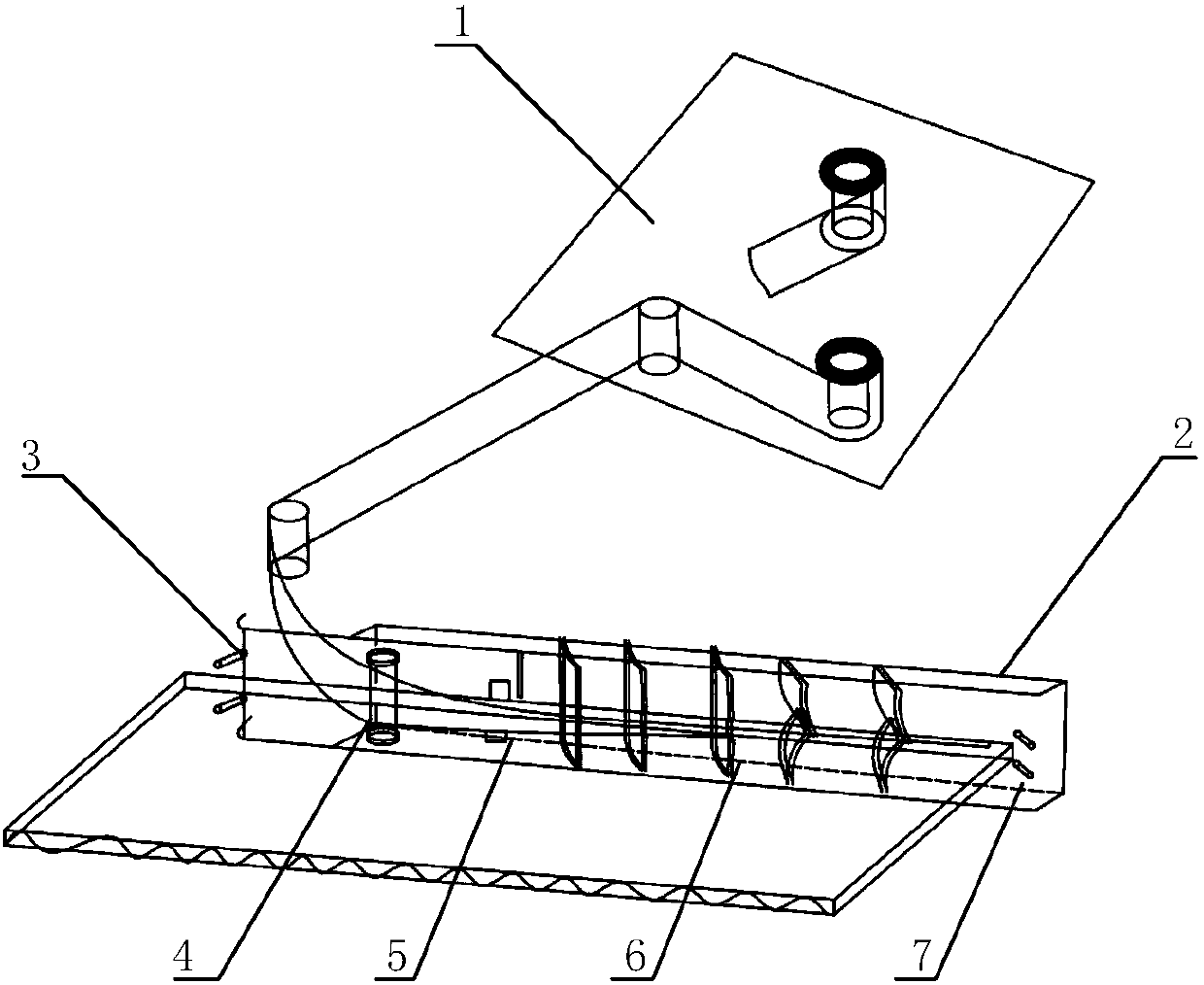

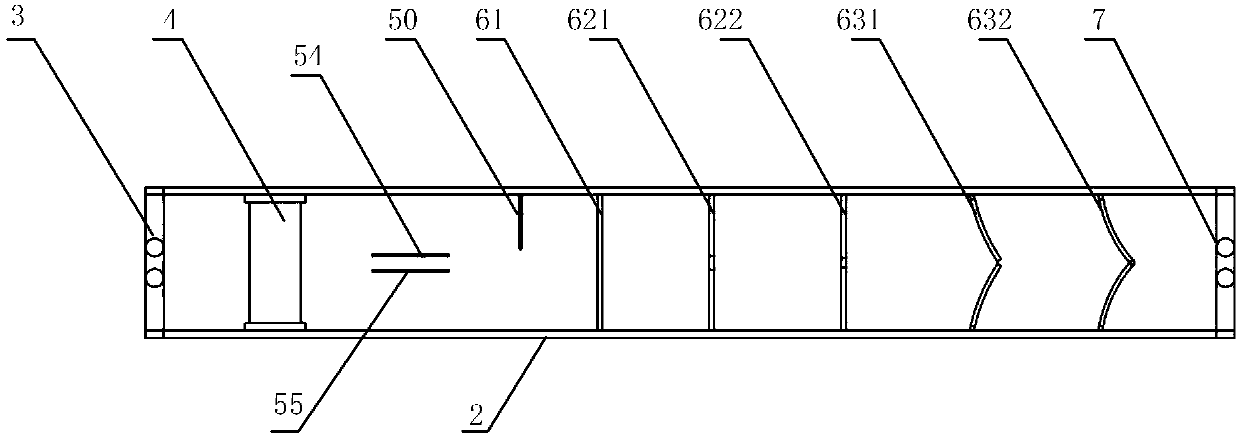

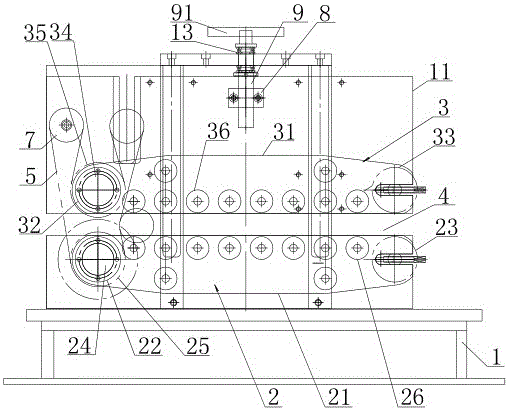

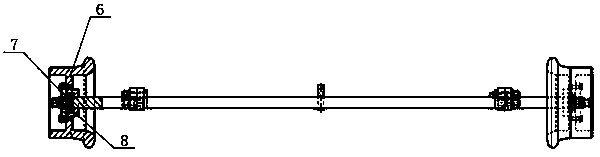

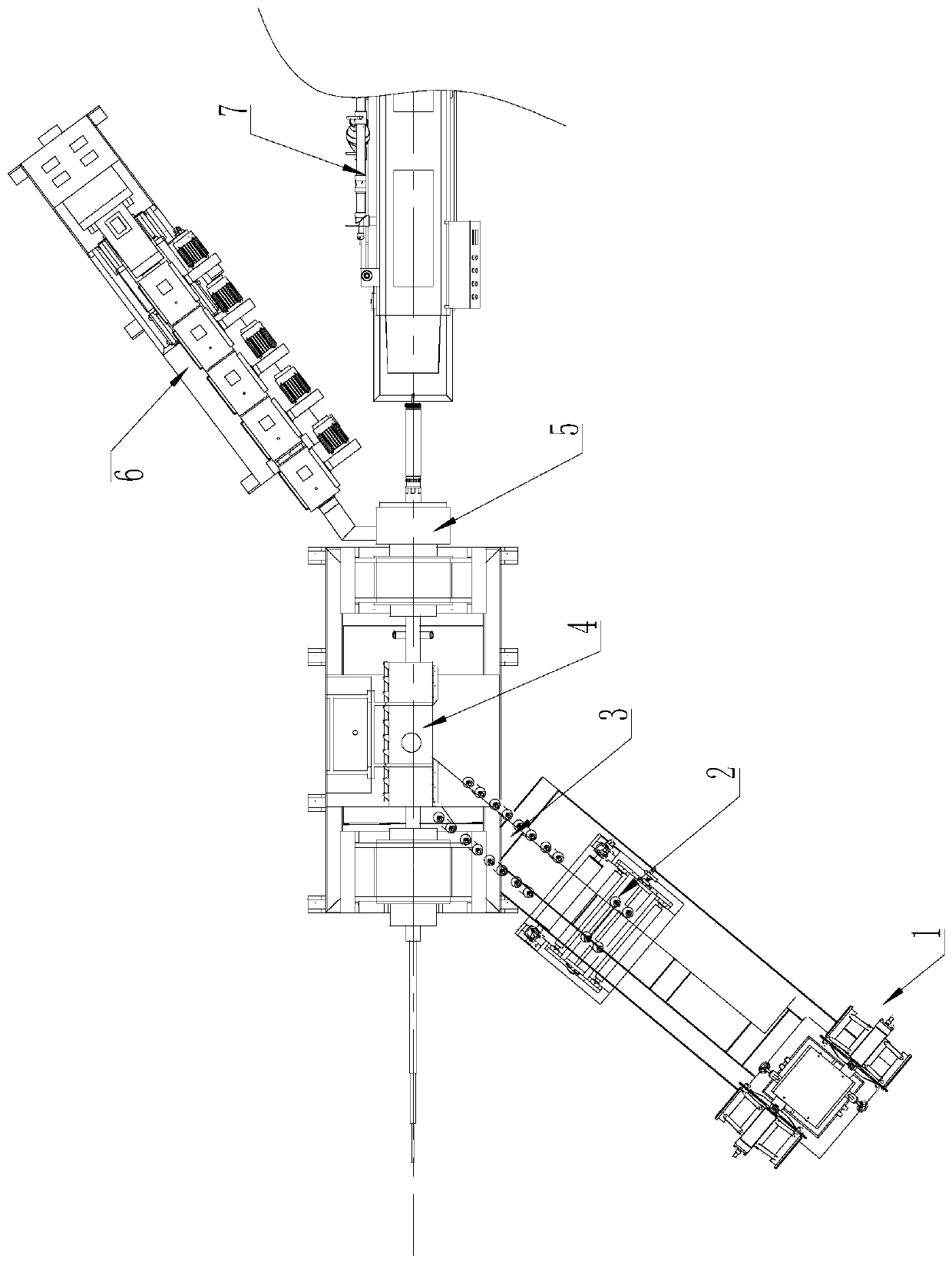

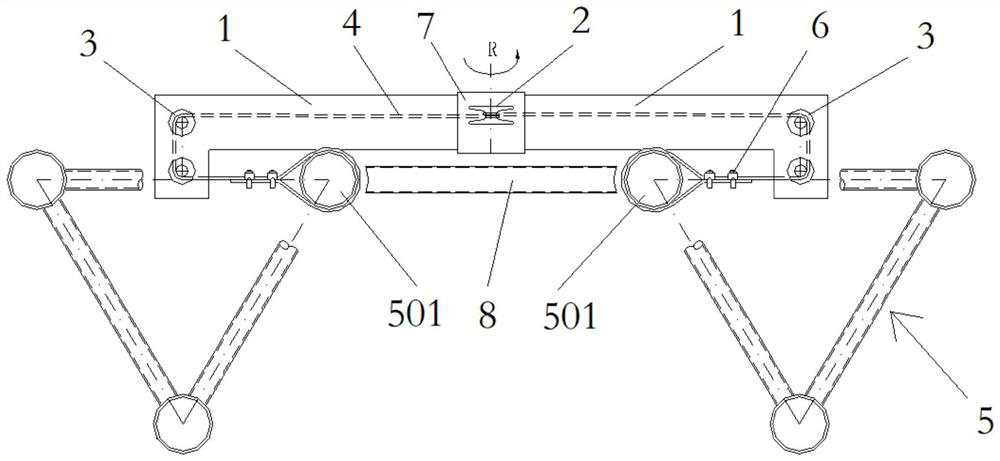

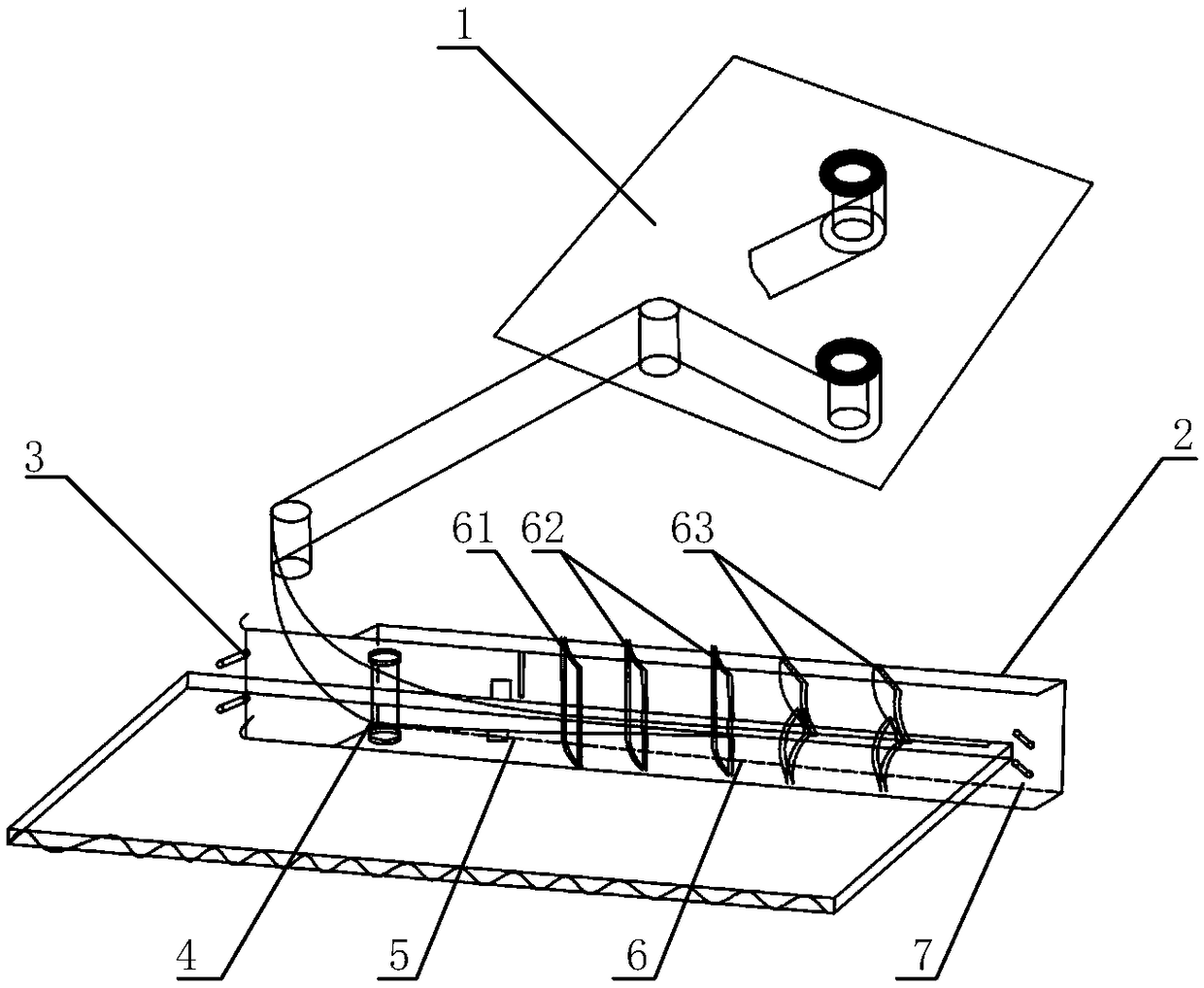

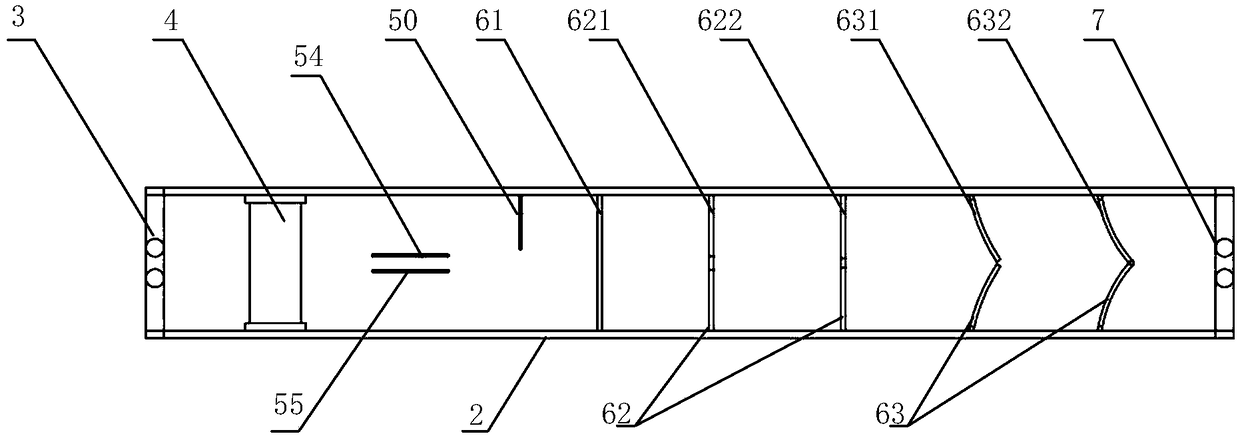

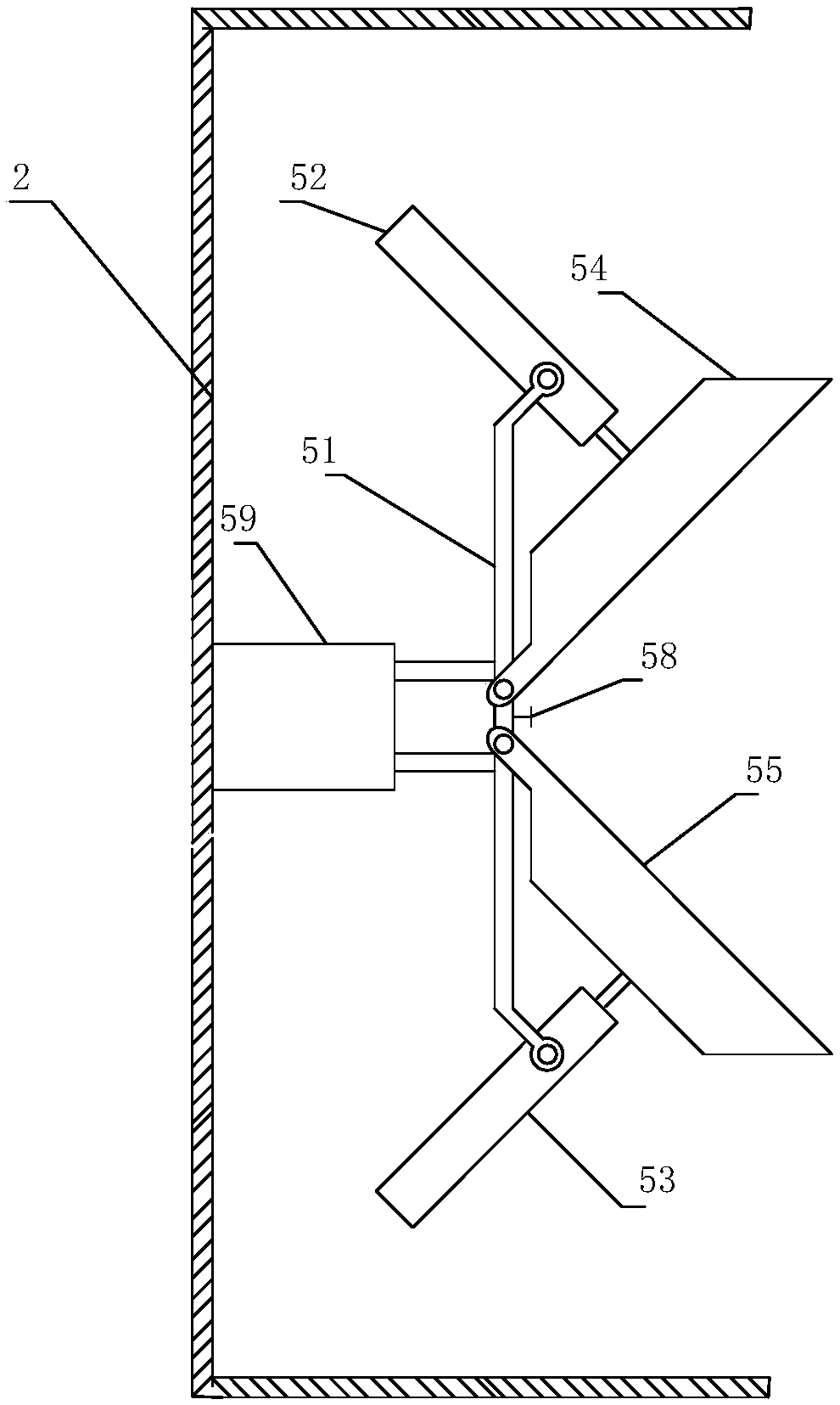

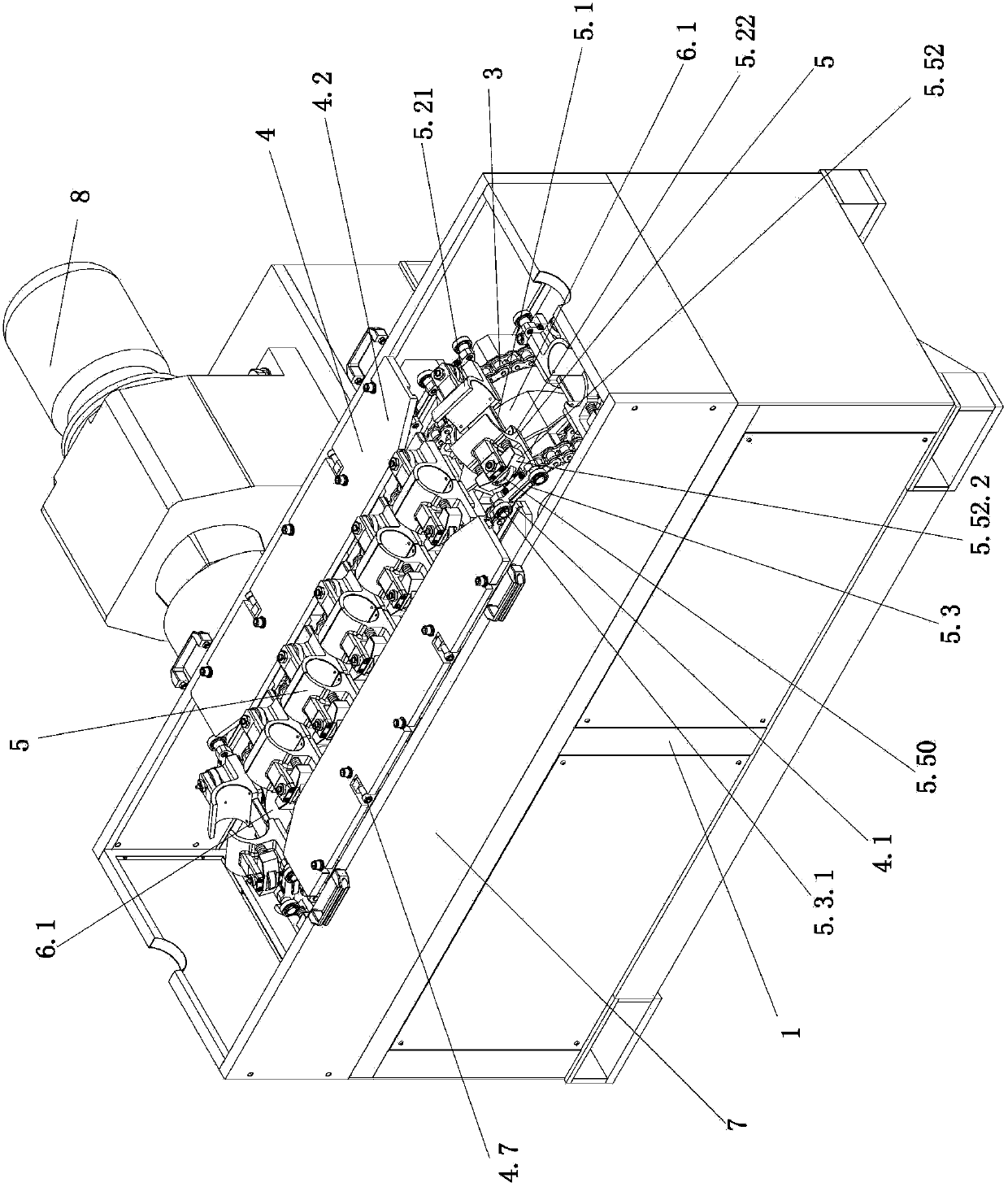

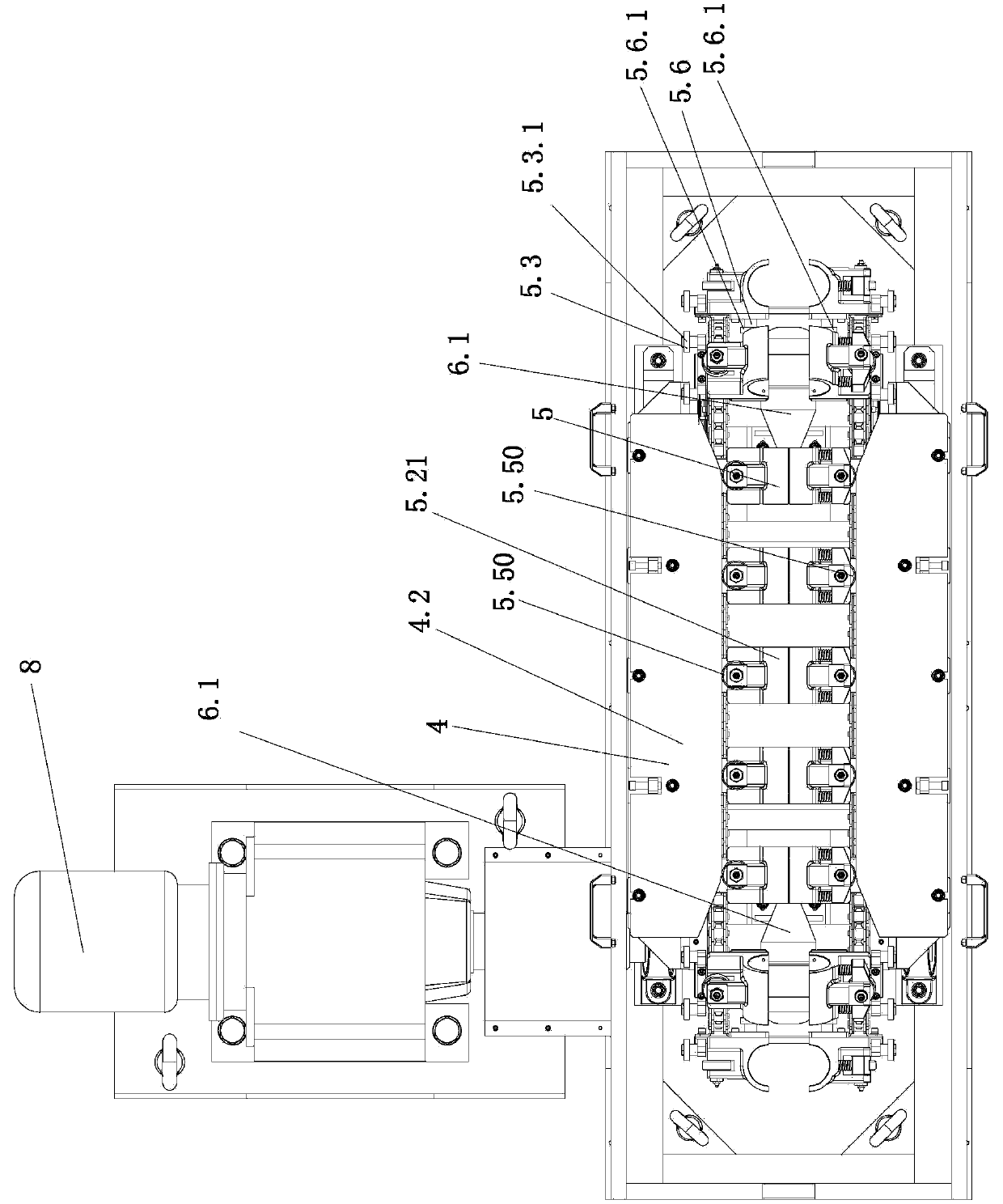

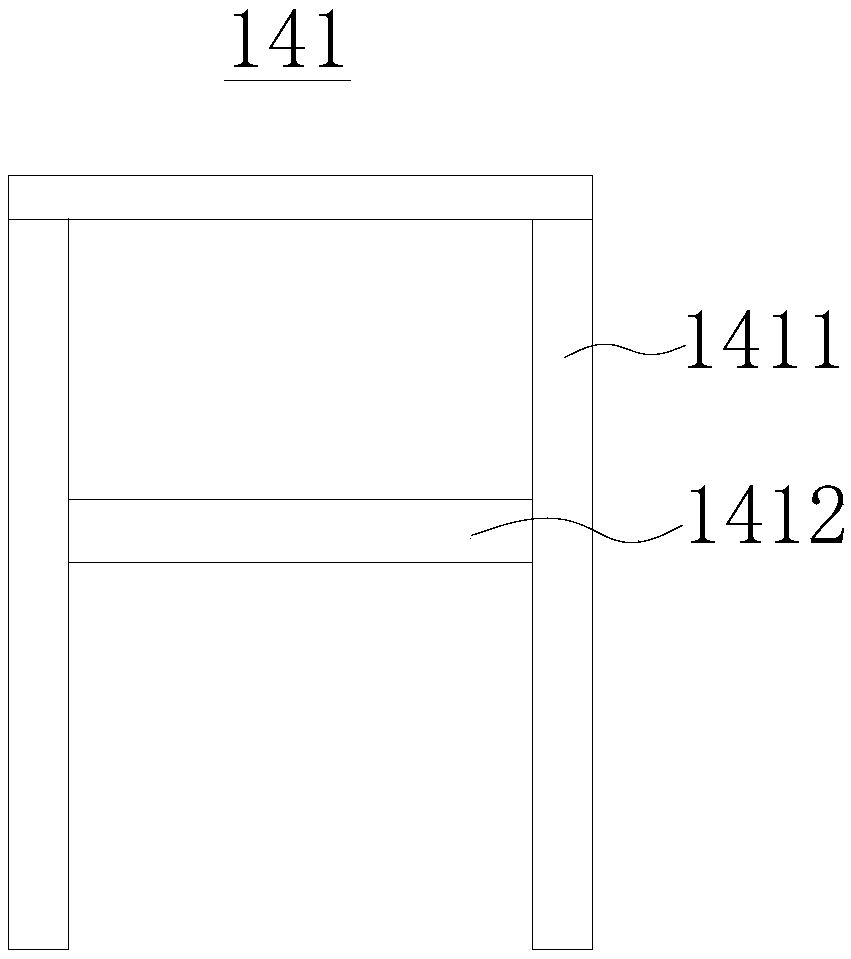

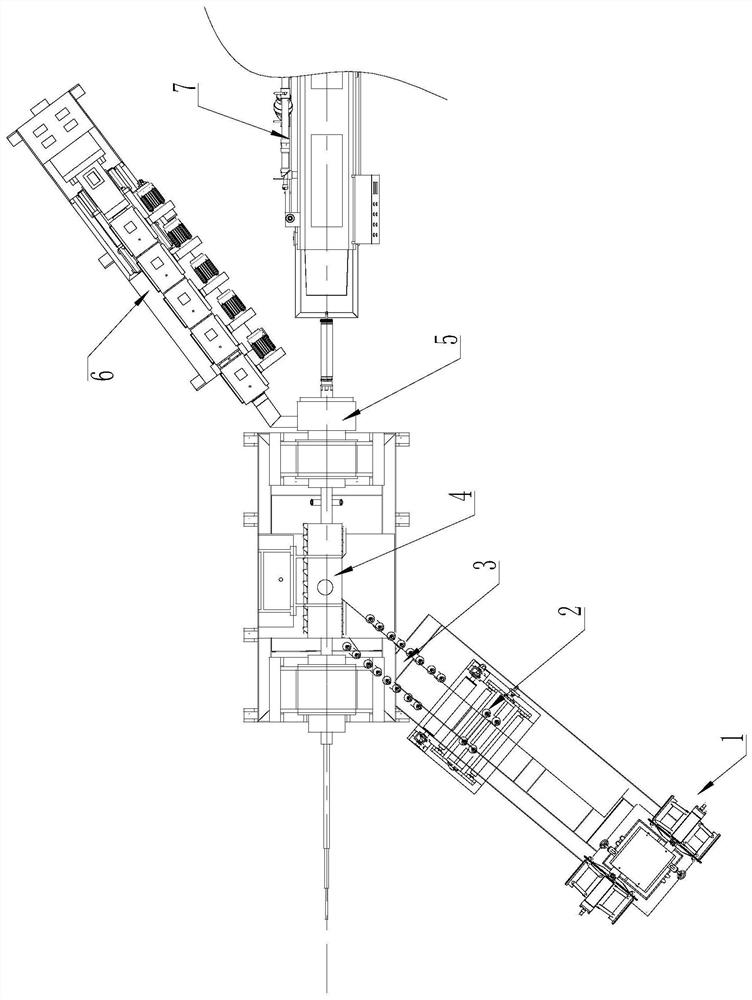

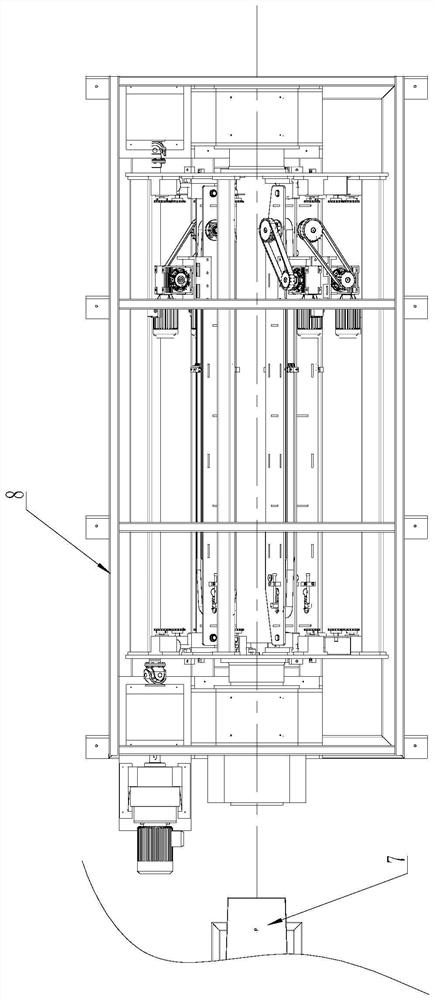

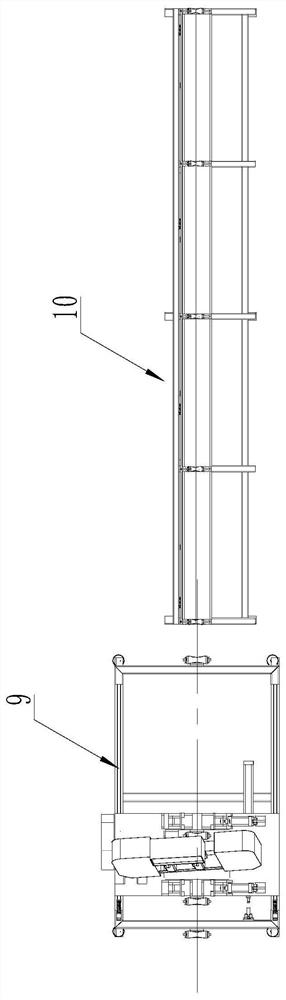

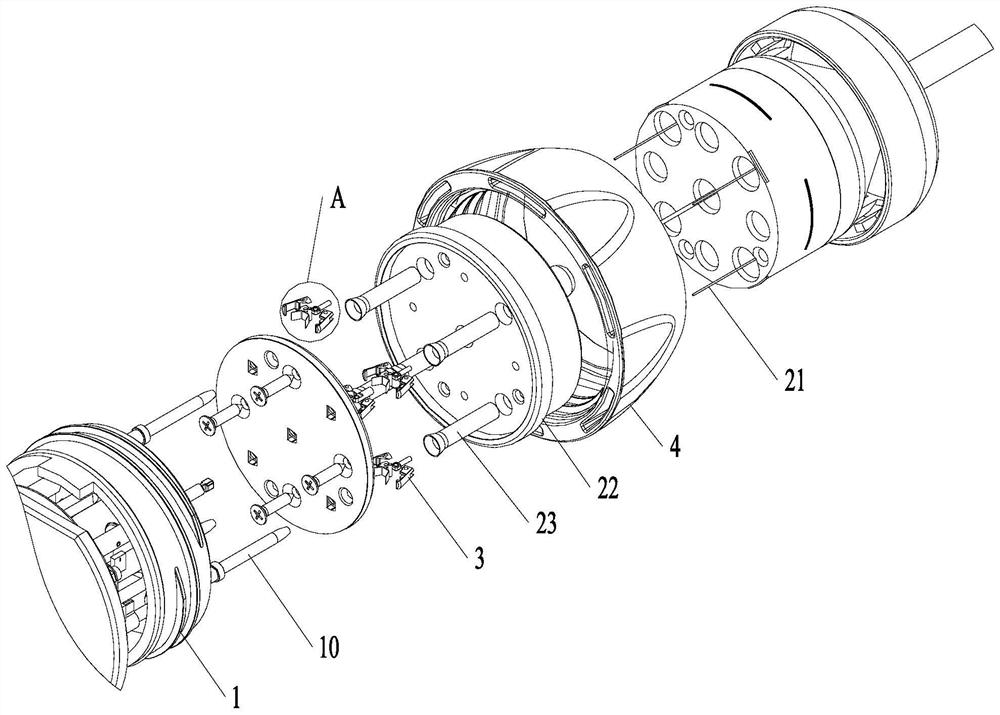

Injection molding machine for flat needle material strap

ActiveCN106217750AStable and reliable feedingReliable tractionCoatingsInjection molding machineIntermittent traction

The invention relates to an injection molding machine for a flat needle material strap. The injection molding machine comprises a machine frame, an injection molding mechanism and an injection mold located on the injection molding procedure. The injection mold comprises an upper mold body and a lower mold body. The upper mold body comprises an upper mold base plate, a stripper plate, an upper mold core board and an upper mold core which are correspondingly matched. The lower mold body comprises an ejection mechanism, a lower mold core board and a lower mold core. The lower mold core is installed on the lower mold core board, and the upper mold core and the lower mold core are correspondingly matched. The lower mold core is provided with a plurality of pouring cavities. The lower mold core is provided with a material strap guide base which is correspondingly matched with the pouring cavity. The material strap guide base is provided with a material strap guide groove with the two ends being through. A material strap feeding device is arranged at the material strap led-in end opening side of the material strap guide groove, and a material strap intermittent traction device which is adapted to the injection molding procedure and used for intermittent traction of the flat needle material strap is arranged at the material strap led-out end opening side of the material strap guide groove. The injection molding machine can automatically convey the flat needle material strap and has the advantages of being high in degree of automation and high in working efficiency.

Owner:WENZHOU YIHUA CONNECTOR

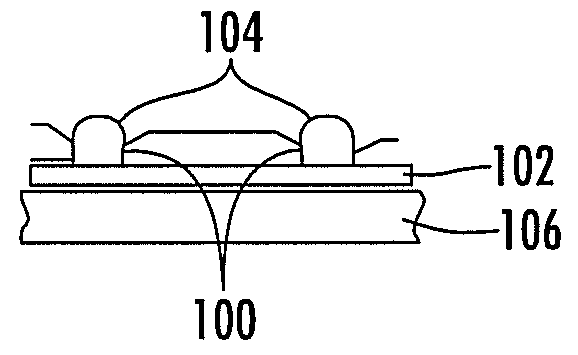

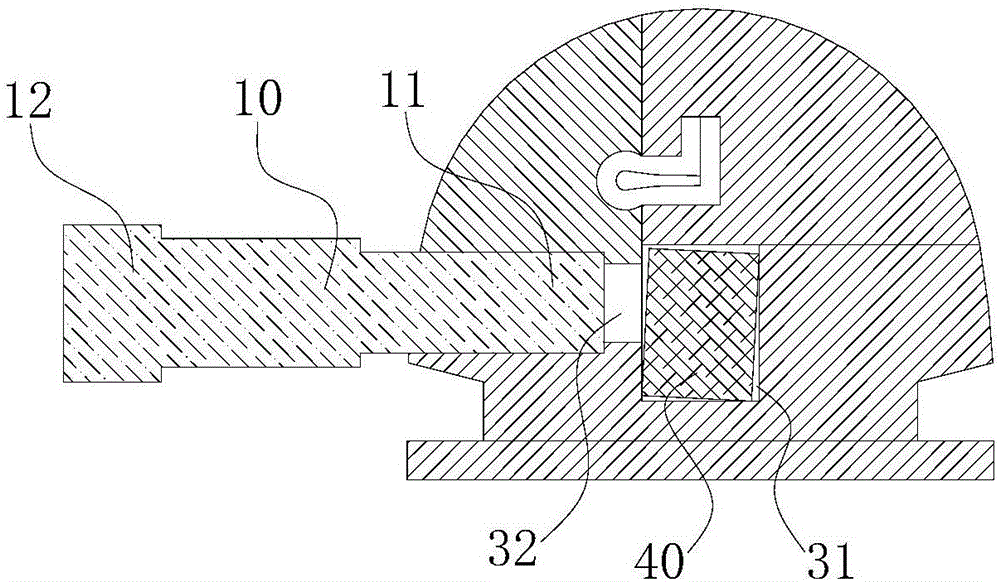

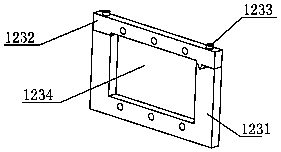

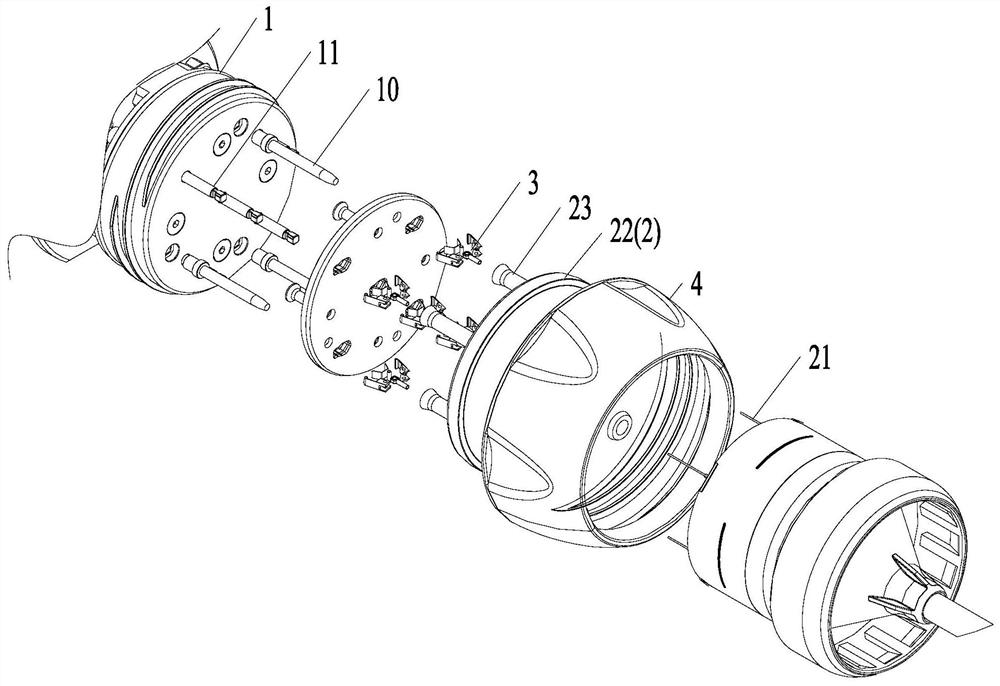

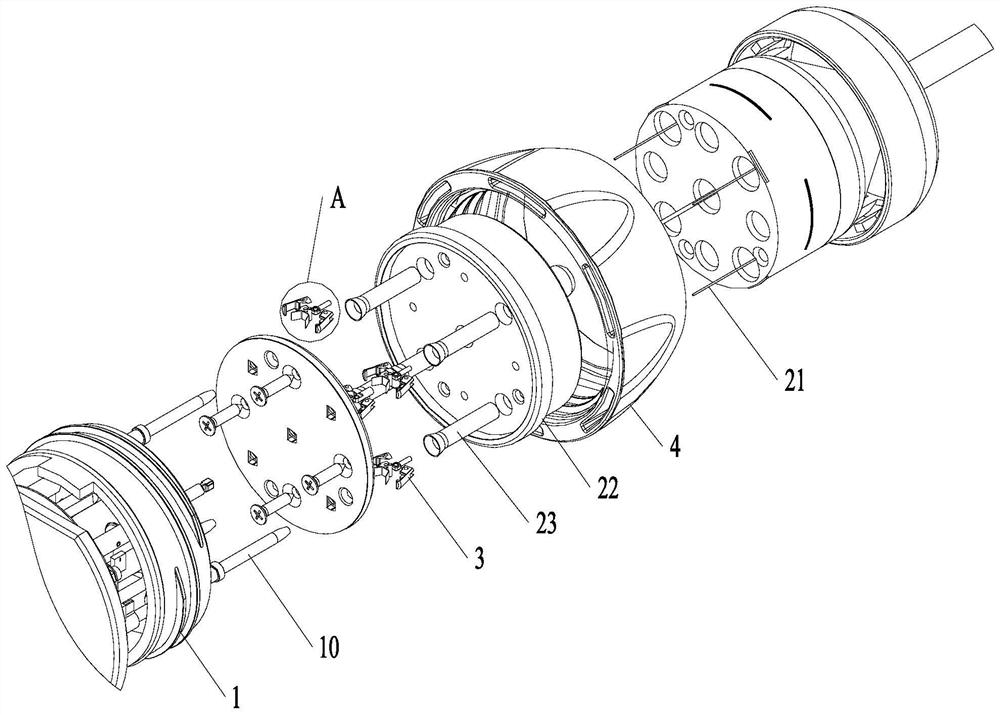

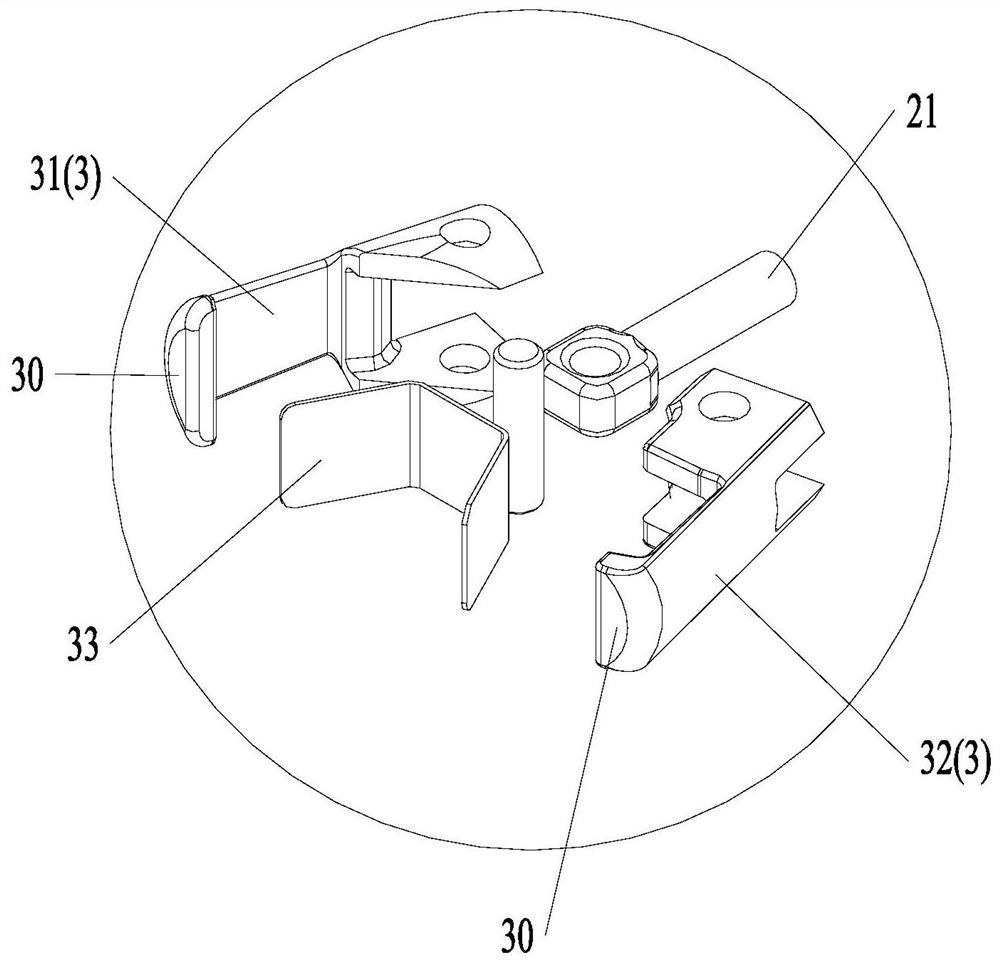

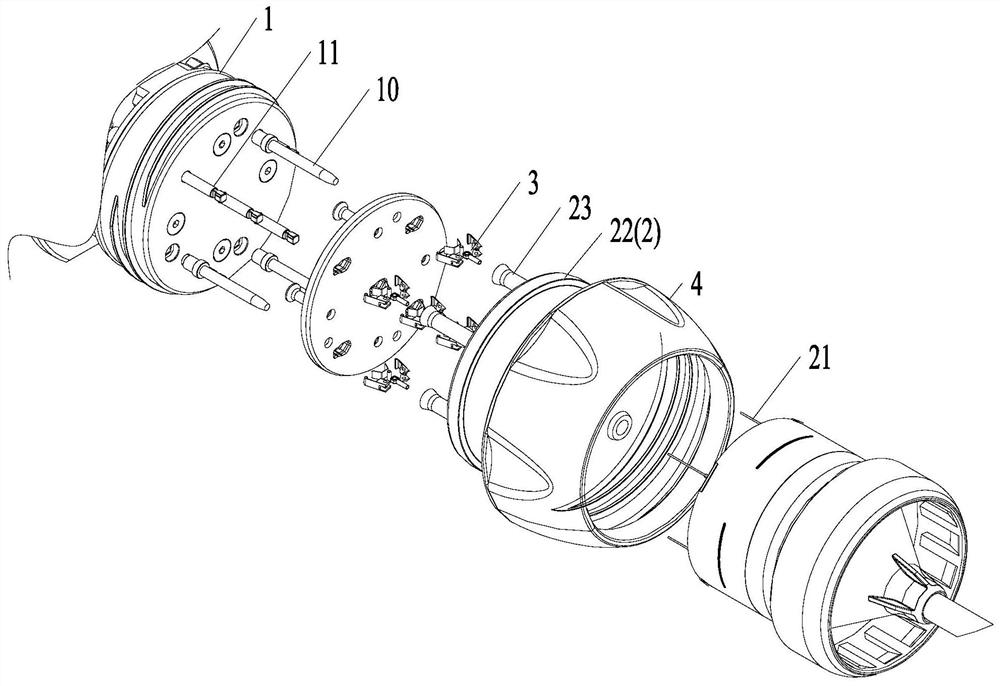

Orthodontic bracket system and tooth orthodontic method

The invention discloses a traction / locking element, a traction / locking set, an orthodontic bracket, an orthodontic bracket system and a tooth orthodontic method. The traction / locking element comprises a strip-shaped nail body, wherein the area of the cross section of the nail body is 0.06-2.5 square millimeters, and the length of the nail body is 0.8-4.5 millimeters; the front end of the nail body is a first fixed end, and the rear end of the nail body is a first screwing end; the first fixed end is provided with a connecting external thread, and the external diameter of the connecting external thread is 0.2-1.6 millimeters; and at least the end position of the first screwing end is provided with a first force application surface. The invention aims at overcoming the defects of the prior art; the traction / locking element can be used for carrying out traction in time according to the traction opportunity of tooth orthodontics, thereby reducing the discomfort of the oral cavity; and the traction / locking element is very convenient to install and disassemble and is very reliable in traction of teeth.

Owner:吉利

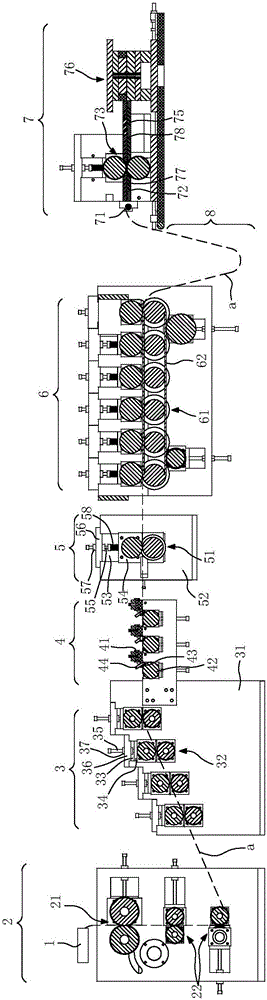

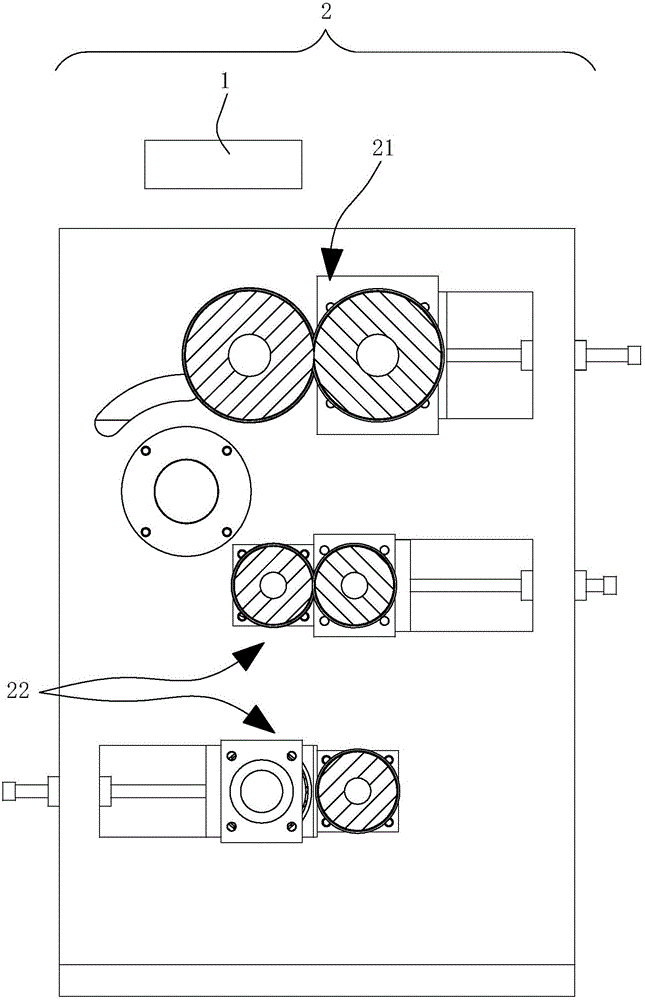

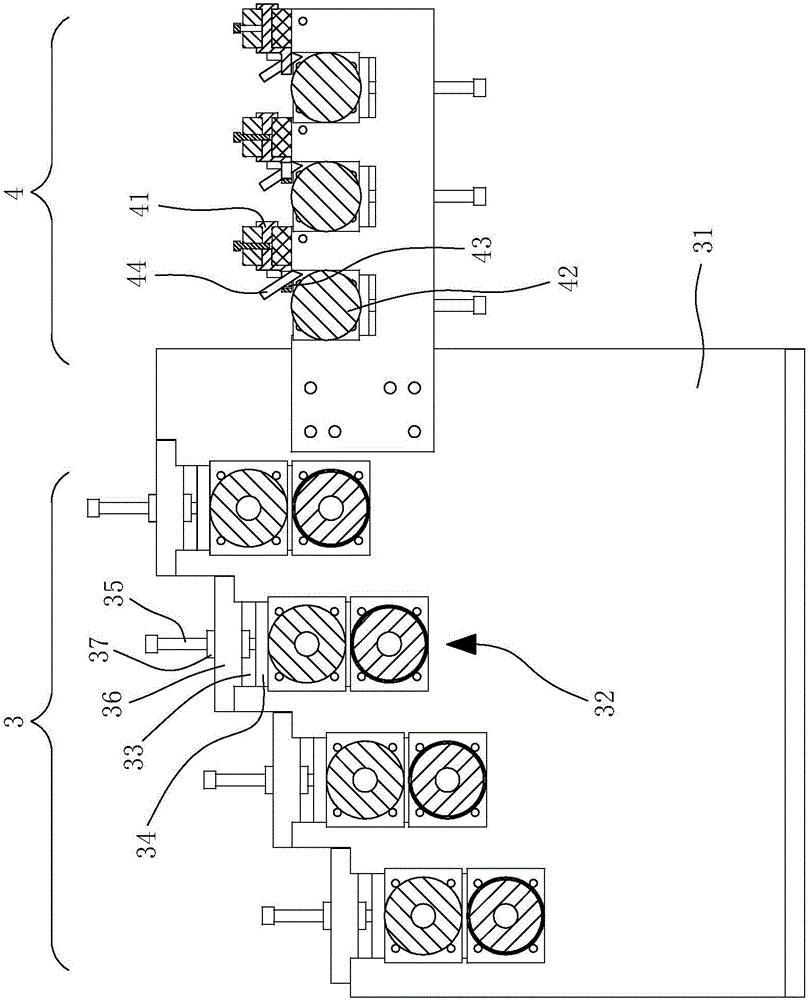

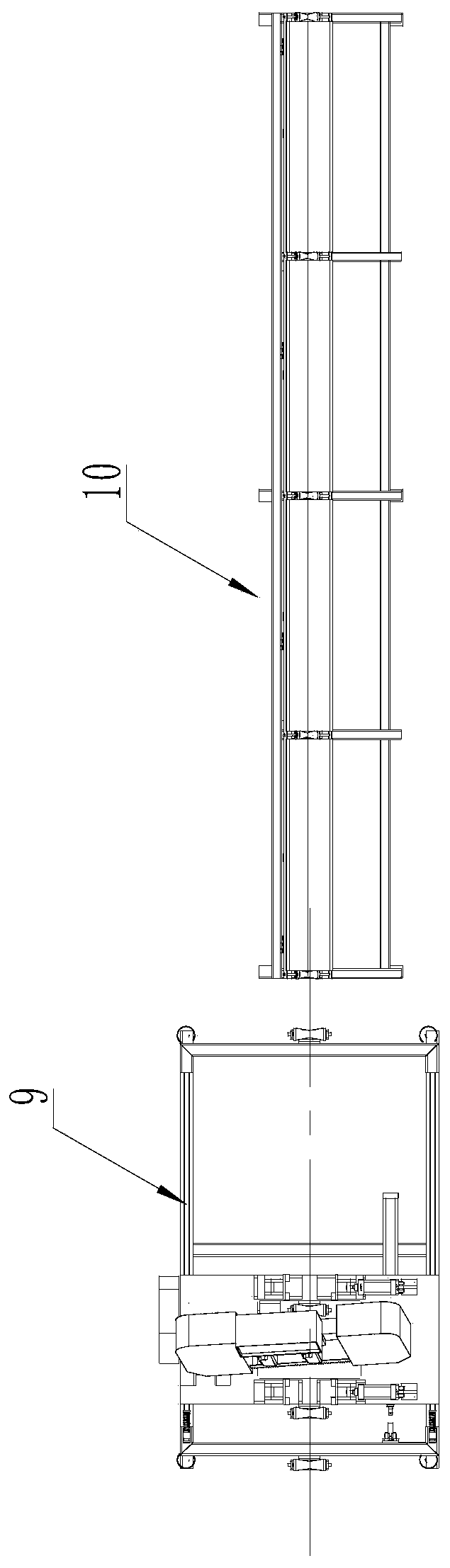

Production line and production method for producing long-strip-shaped plastic parts

InactiveCN106113464AContinuous deliveryImprove efficiencyMetal working apparatusProduction lineEngineering

The invention discloses a production line and production method for producing long-strip-shaped plastic parts. The production line sequentially comprises cooling equipment, traction equipment, cutting-off equipment and collecting equipment in the conveying direction for the long-strip-shaped plastic parts. The production method includes the steps of cooling and sizing, traction, cutting off and collecting for the long-strip-shaped plastic parts. By means of the production line and production method, the production efficiency can be improved, and the labor cost is lowered.

Owner:佛山市南海森蓝环保科技有限公司

Lower limb resetting device for intramedullary nail surgeries

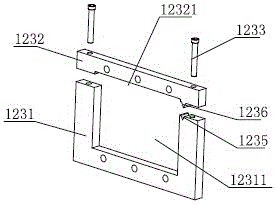

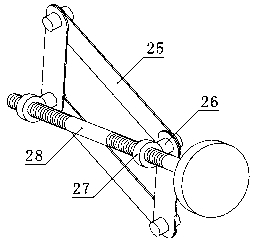

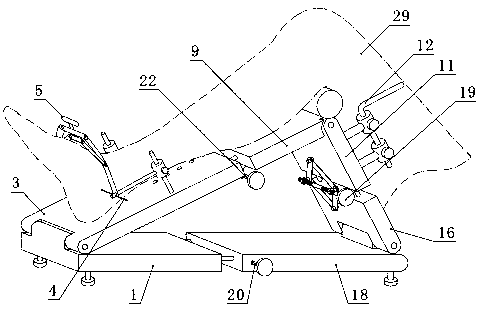

PendingCN110897694AReliable tractionImprove surgical quality and efficiencyOperating tablesDiagnosticsFemoral boneBiomedical engineering

The invention discloses a lower limb resetting device for intramedullary nail surgeries. The lower limb resetting device for intramedullary nail surgeries comprises a rectangular bottom plate, a telescopic shank supporting plate, a thigh backup plate, a kirschner wire and a tensioning bow, wherein the rectangular bottom plate is horizontally placed on an operating bed; the telescopic shank supporting plate is hinged with the upper end of the thigh backup plate; the lower end of the telescopic shank supporting plate and the lower end of the thigh backup plate are respectively hinged with the two ends of the rectangular bottom plate; in surgery, the thigh and the shank of a patient lean against the upper portion of the thigh backup plate and the upper portion of the telescopic shank supporting plate respectively, the kirschner wire penetrates through the far end of the ankle bone or the tibia of the patient, the two ends of the kirschner wire are connected to the two ends of the tensioning bow respectively, and each end of the tensioning bow is connected with the telescopic shank supporting plate through an adjustable support. The patient can be kept in a leg bending state, the tibiaor thighbone of the patient can be reliably pulled, all parts are not higher than the lower limb of the patient, and surgical operation is not affected. The lower limb resetting device can ensure that a tibia or femoral intramedullary nail implantation operation is smoothly carried out, and the operation quality and efficiency are improved.

Owner:THE THIRD HOSPITAL OF HEBEI MEDICAL UNIV +1

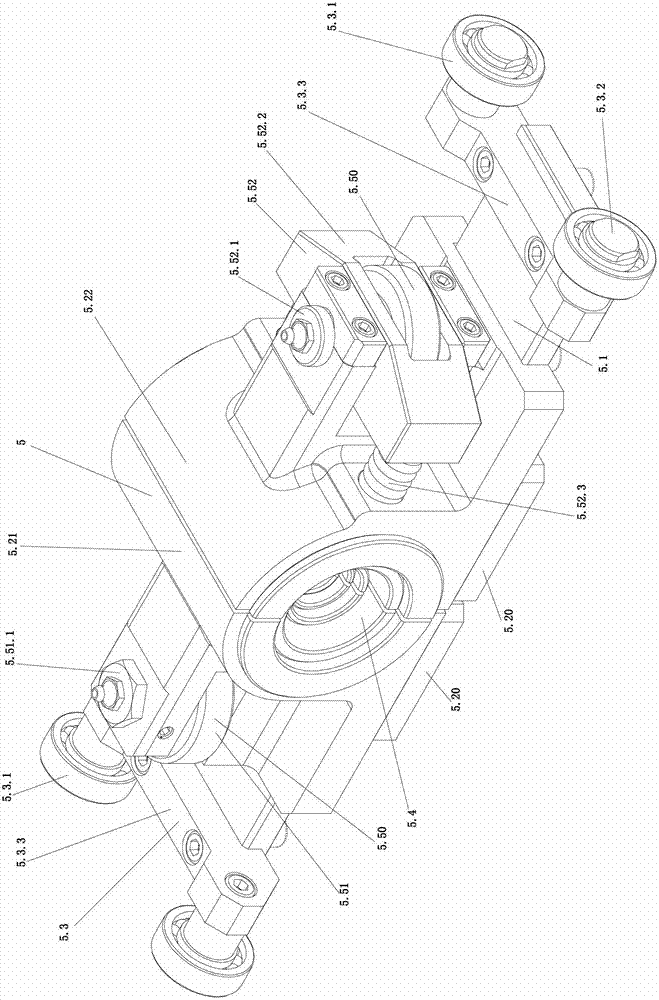

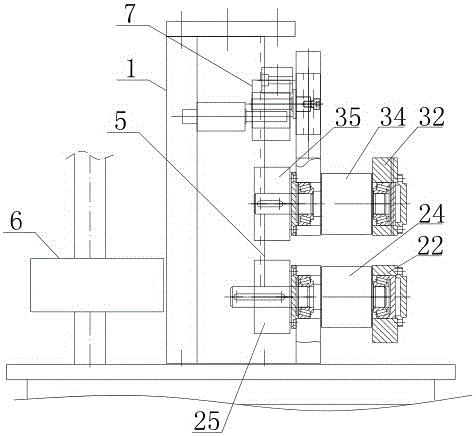

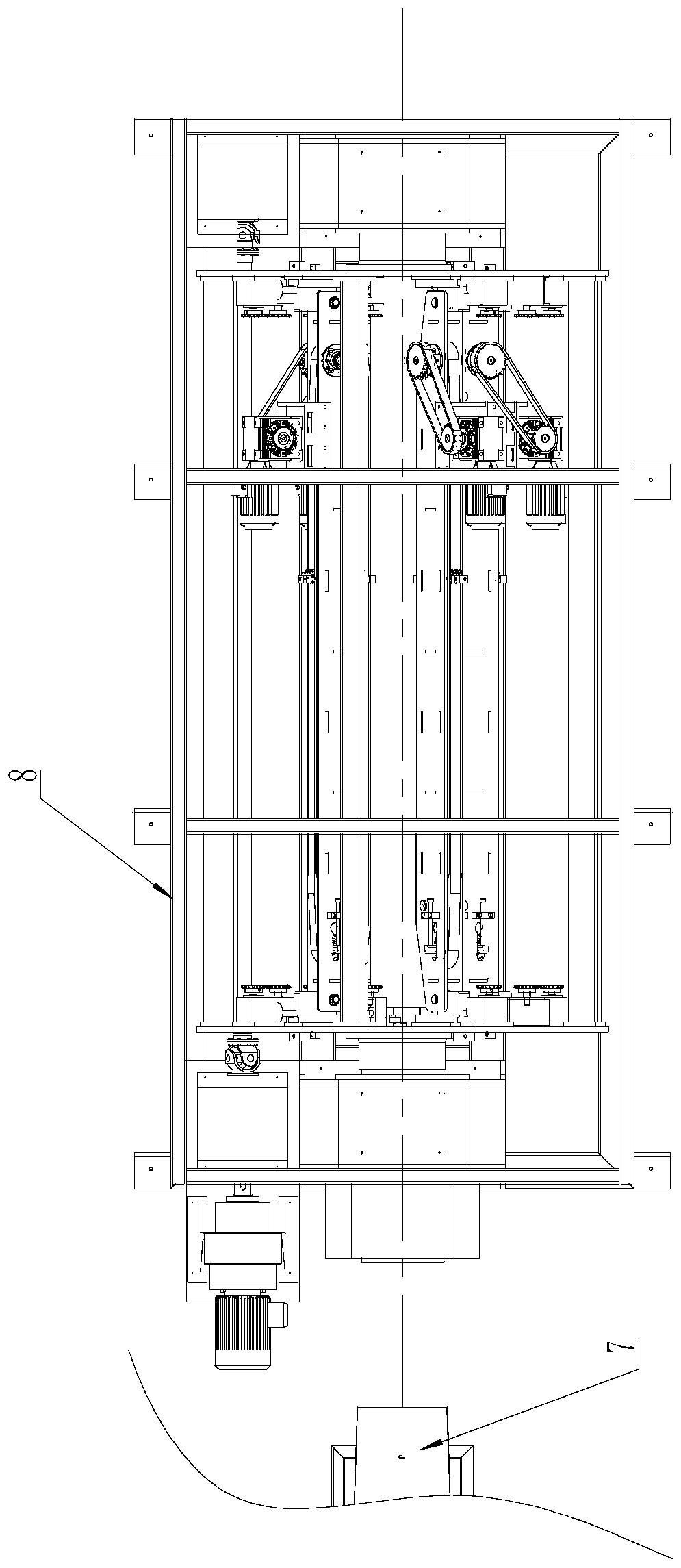

Steel tube traction machine

ActiveCN102786016AAvoid bending deformationEvenly balanced clamping forceLifting devicesHoisting equipmentsPipe fittingDrive shaft

The invention discloses a steel tube traction machine. The machine comprises a rack, a main drive shaft and a driven shaft, two chains which are arranged opposite to each other in front and at the back, a guide support, a chuck opening support and a plurality of chuck parts, wherein two horizontal guide blocks and two clamping guide plates are arranged opposite to each other in the front and at the back of the guide support; each of the chuck parts comprises a sliding plate, a first chuck base, a second chuck base and a chuck; two ends of the sliding plate are connected fixedly with chain plates of the chains and are provided with a guide roller assembly which is matched with the horizontal guide blocks; the first chuck base and the second chuck base are connected with the sliding plates in a sliding mode opposite to each other in the front and at the back and are provided with a chuck opening roller assembly which is matched with the chuck opening support, an opposite end is provided with a chuck installation portion respectively, and the other end is provided with a first clamping roller assembly and a second clamping roller assembly, which are matched with the clamping guide plates respectively, except the chuck which is matched with a pipe fitting with a maximum specification, a plurality of sub-chucks are overlapped to form the other chucks. The steel tube traction machine relates to the field of manufacture devices of steel-plastic composites pipes and has the advantages of being simple in structure, convenient in centering adjustment, high in accuracy, even in clamping force distribution and convenient in pipe fitting specification conversion.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

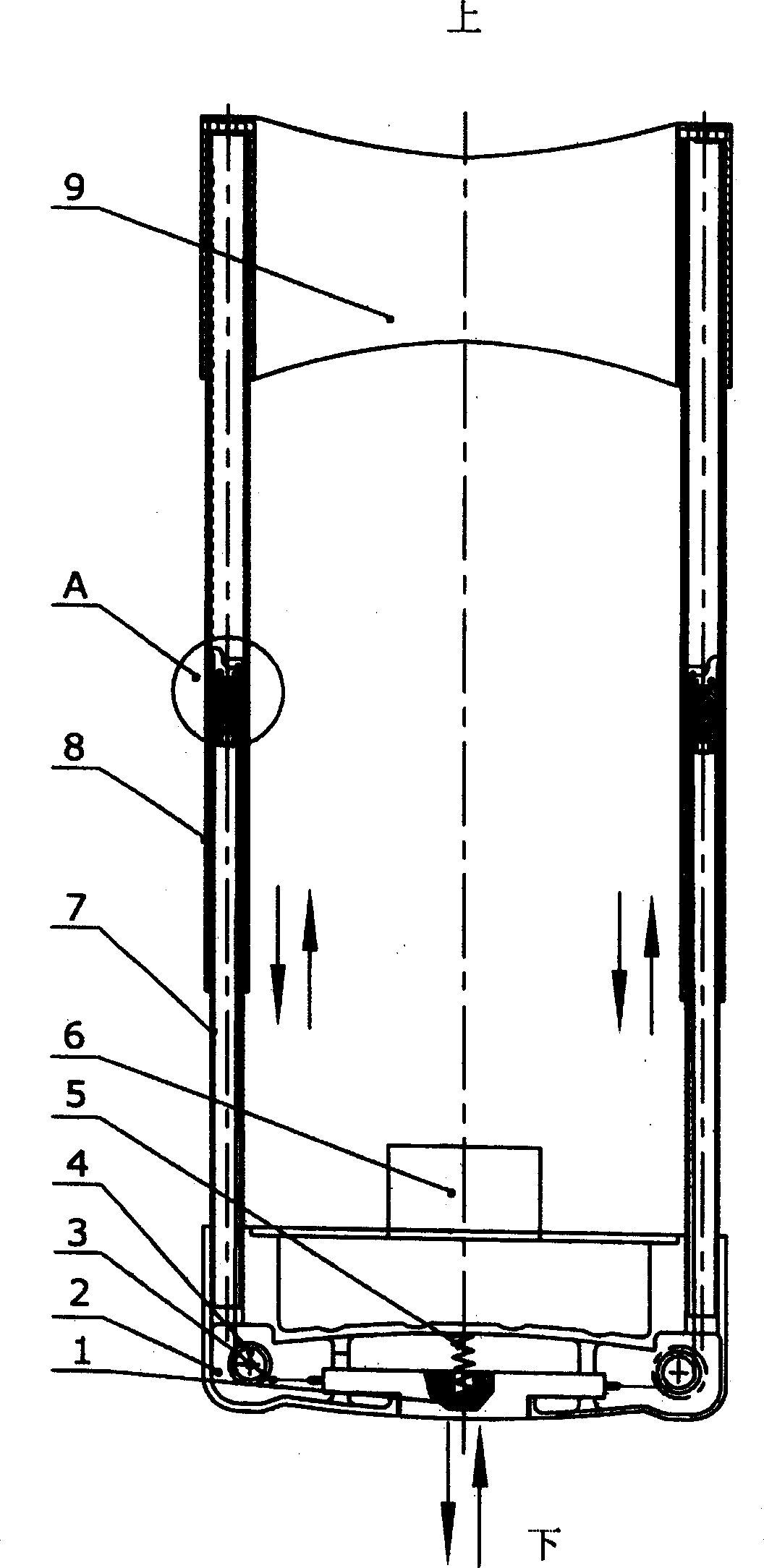

Street lamp cable efficient traction device

InactiveCN111049064AReduce volumeEasy to moveApparatus for laying cablesDrive shaftStructural engineering

The invention discloses a street lamp cable efficient traction device comprising a base. Supporting plates are vertically fixed to the two sides of the upper end face of the base. A plurality of traction assemblies are horizontally arranged between the supporting plates on the two sides, each traction assembly comprises a driving shaft and a driven shaft, the two ends of each driving shaft and thetwo ends of each driven shaft are rotationally installed on the supporting plates through bearing pedestals, traction wheels matched with each other are fixed to the driving shafts and the driven shafts, and a plurality of grooves are formed in the traction wheels; a top plate is fixed to the top of the supporting plate and provided with a lifting mechanism for driving the driven shaft to move upward and downward. According to the street lamp cable efficient traction device, traction force is dispersed through multiple traction assemblies, and traction is more stable and reliable; a pluralityof grooves with different opening widths and depths are formed in the traction wheels so that the cable traction device is suitable for traction of cables of different specifications, wide in application range, convenient and rapid to operate and high in traction efficiency.

Owner:赣州雄安照明科技有限公司

Full-automatic plastics rolling moulder capable of precise length control

The invention discloses a full-automatic plastics rolling moulder capable of precise length control. The full-automatic plastics rolling moulder comprises a material outlet which is connected with an extruder, a moulding unit, a cooling unit, a primary traction unit, a belt-type traction unit and a numerical control punching-off unit; the material outlet is arranged above the moulding unit; the cooling unit, the primary traction unit, the belt-type traction unit and the numerical control punching-off unit are sequentially arranged behind the moulding unit; and a space for free falling of products is preserved between the belt-type traction unit and the numerical control punching-off unit. After the technical scheme is adopted, traction during a production process is reliable; the products are conveyed stably; the lengths of the plastic products are precise; the product qualification rate can reach 99%; and the qualification rate is very high.

Owner:何浩然

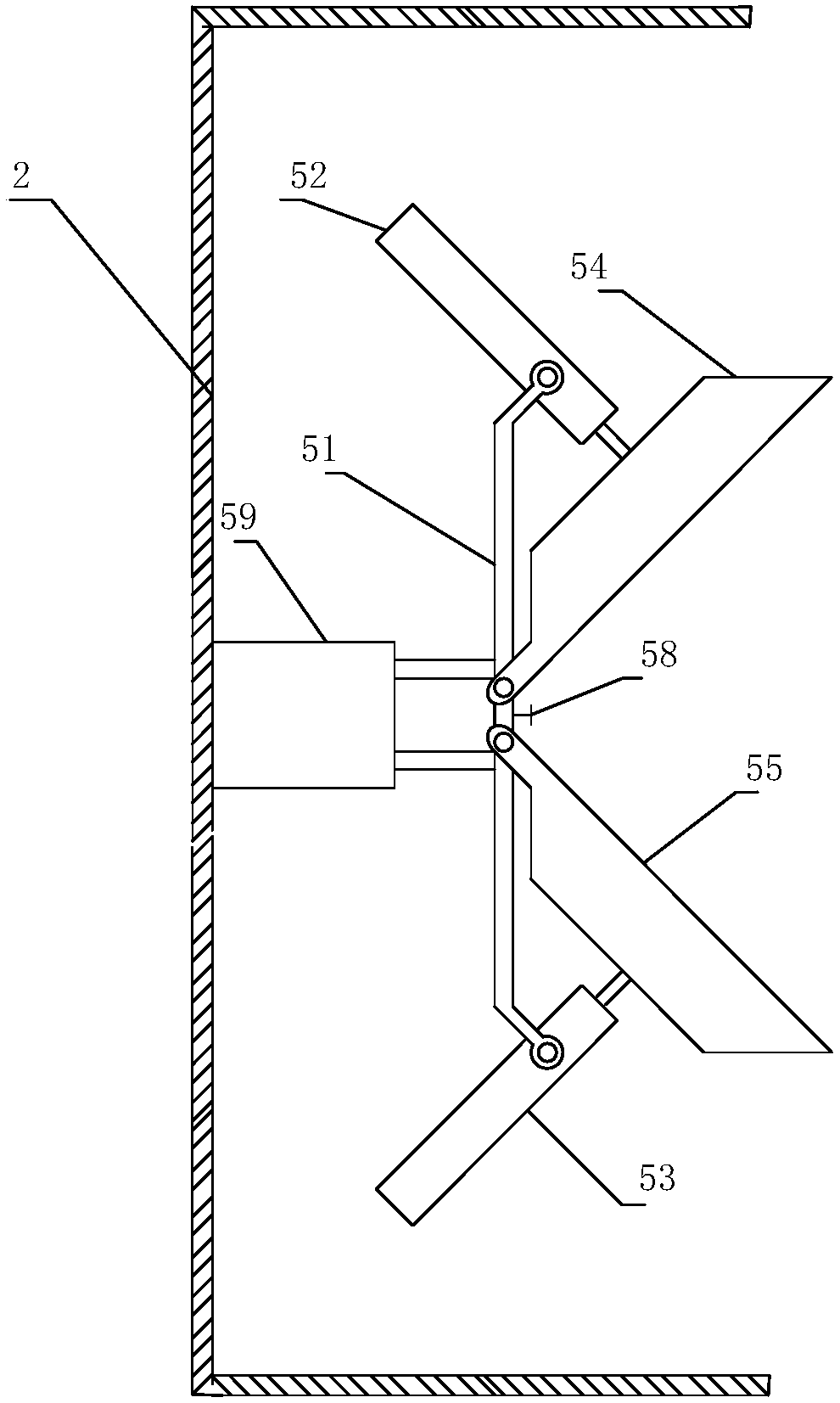

Automatic guiding, sticking and edge sealing equipment for corrugated lines and use method

ActiveCN107813546AReliable tractionEliminate potential safety hazardsMechanical working/deformationBox making operationsProduction linePaperboard

The invention discloses automatic guiding, sticking and edge sealing equipment for corrugated lines. The equipment comprises an adhesive tape unwinding device and a support; and a first limiting device, an adhesive tape guiding wheel, an automatic adhesive tape guiding and sticking device, an adhesive tape overturning and sticking device and a second limiting device are sequentially arranged on the support in the advancing direction of a corrugated paperboard production line. An upper rocker and a lower rocker which are arranged vertically symmetrically are used for performing adsorbing fixingon an adhesive tape guiding head, so that the adhesive tape guiding head can be pulled reliably; after the upper rocker and the lower rocker are closed, the adhesive tape guiding head and corrugatedpaperboards are clamped together in the upward direction and the downward direction, so that the adhesive tape guiding head is ensured to be stuck to the corrugated paperboards. After adhesive tapes are overturned by overturning clamping plates step by step, the overturned adhesive tapes are extruded onto the upper and lower surfaces of the corrugated paperboards by the aid of adhesive tape scraping plates, the structure is simple and reliable, and potential safety hazards caused by manual operations are eliminated.

Owner:ZHEJIANG GREAT SHENGDA PACKING CO LTD

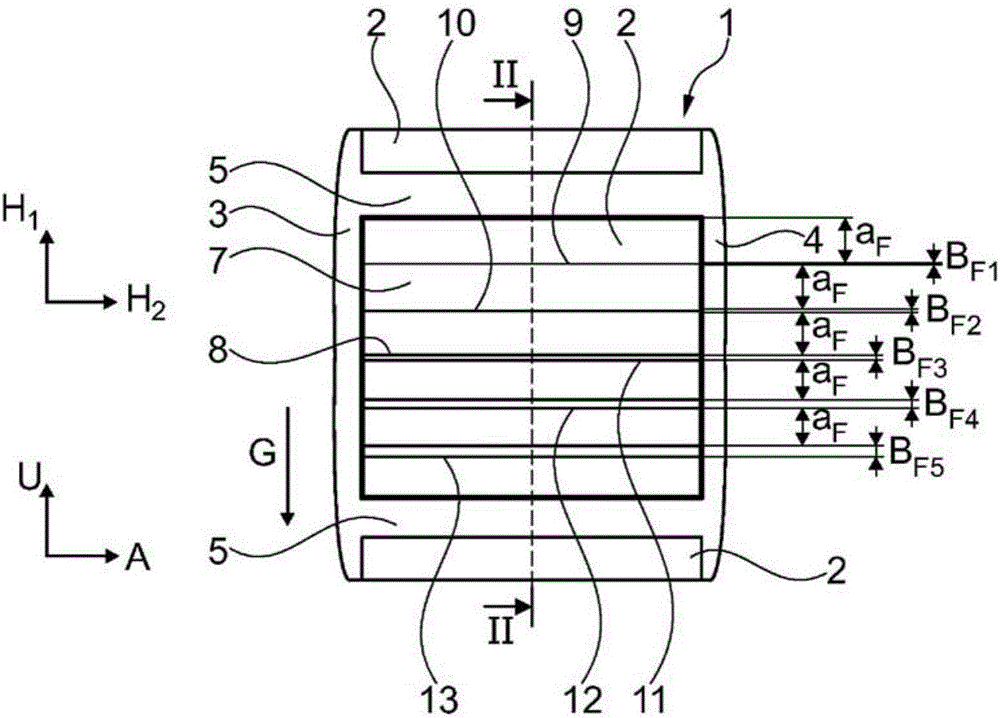

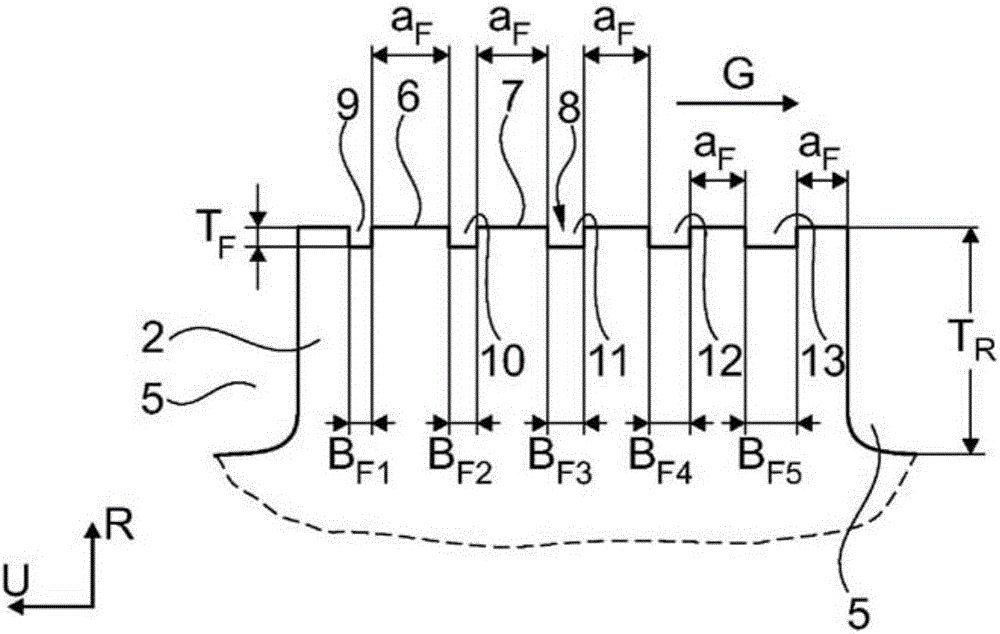

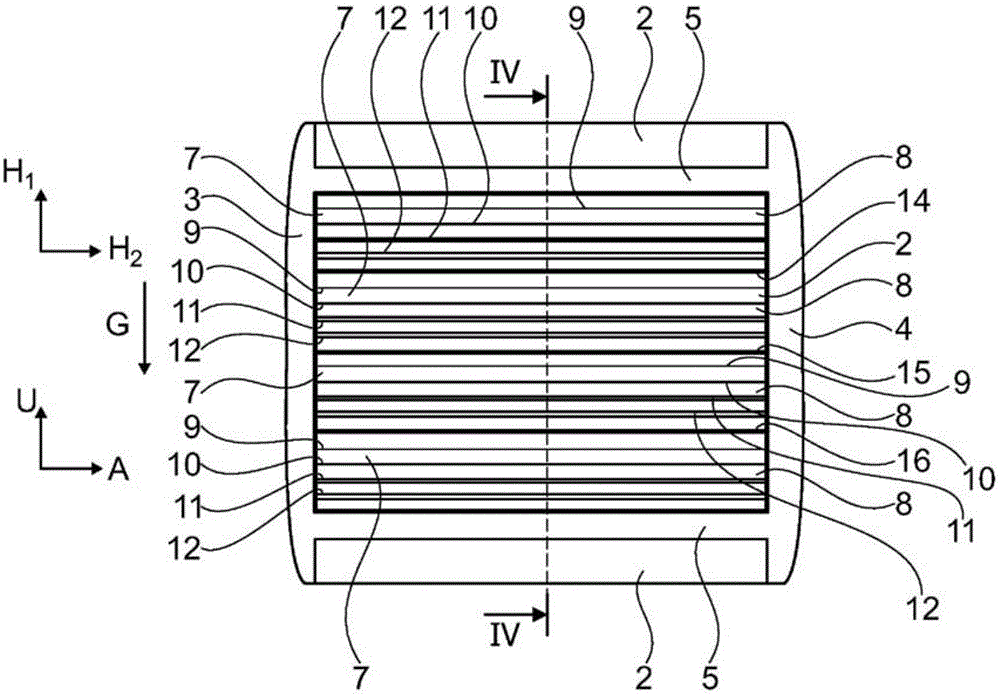

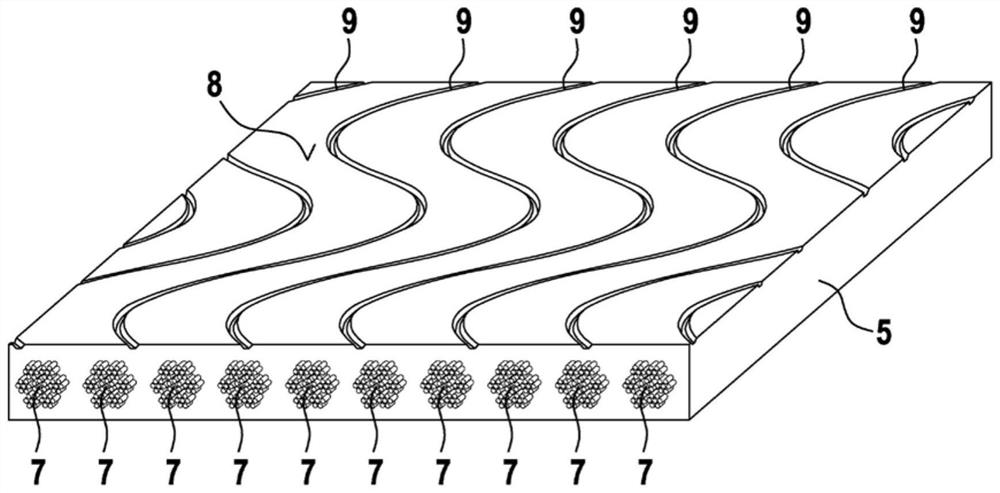

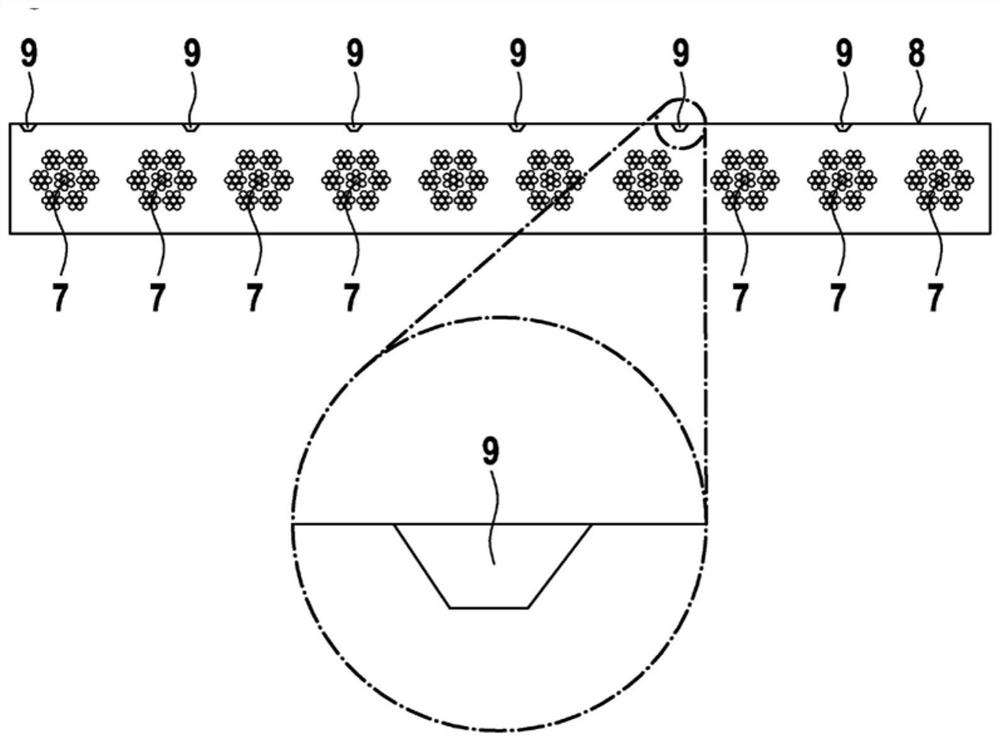

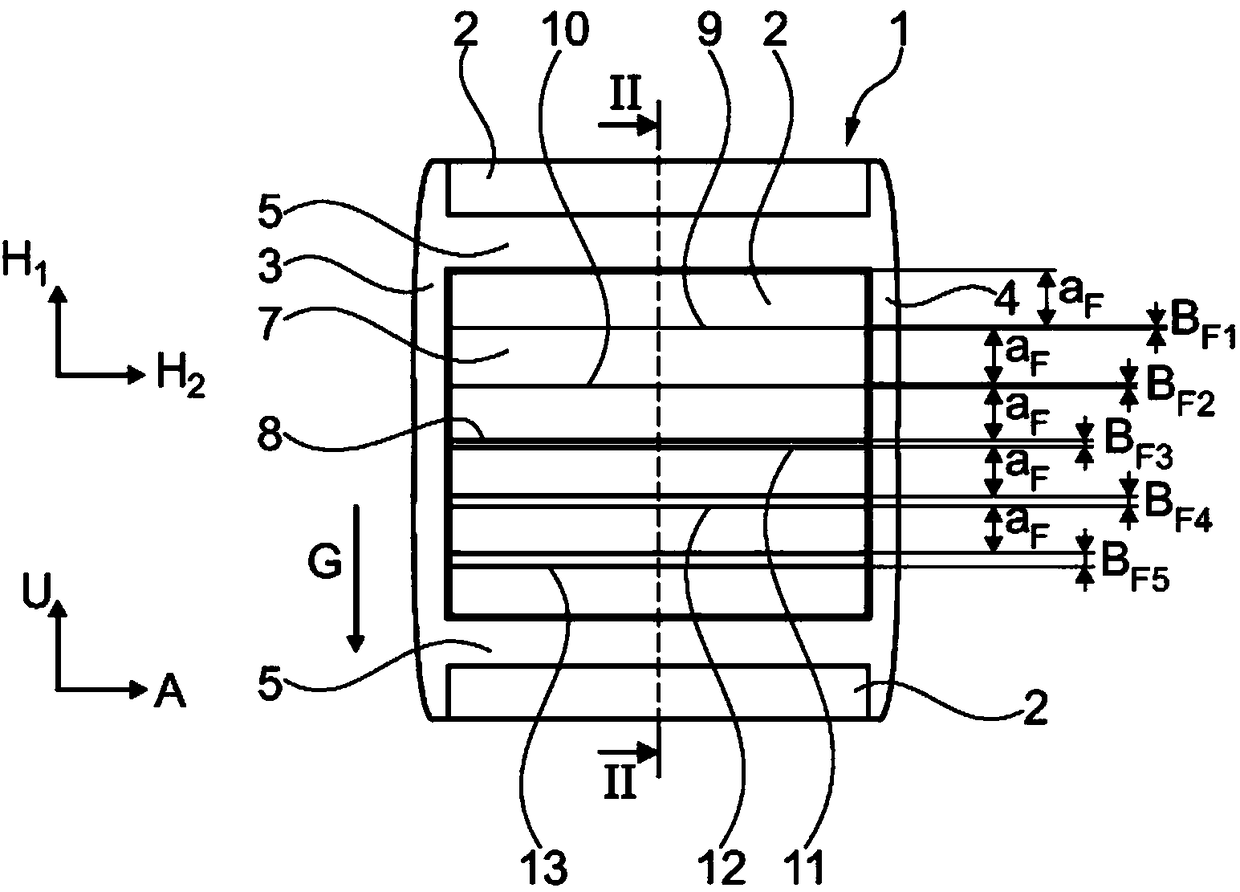

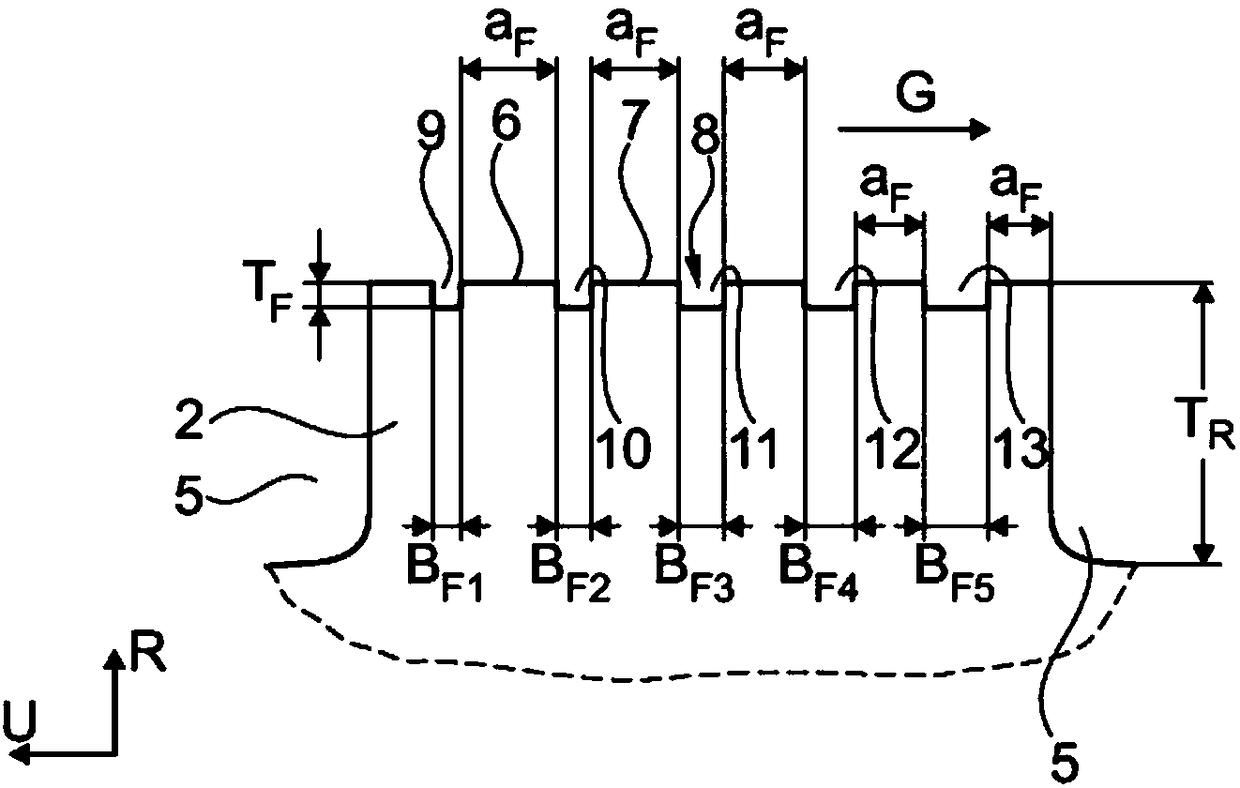

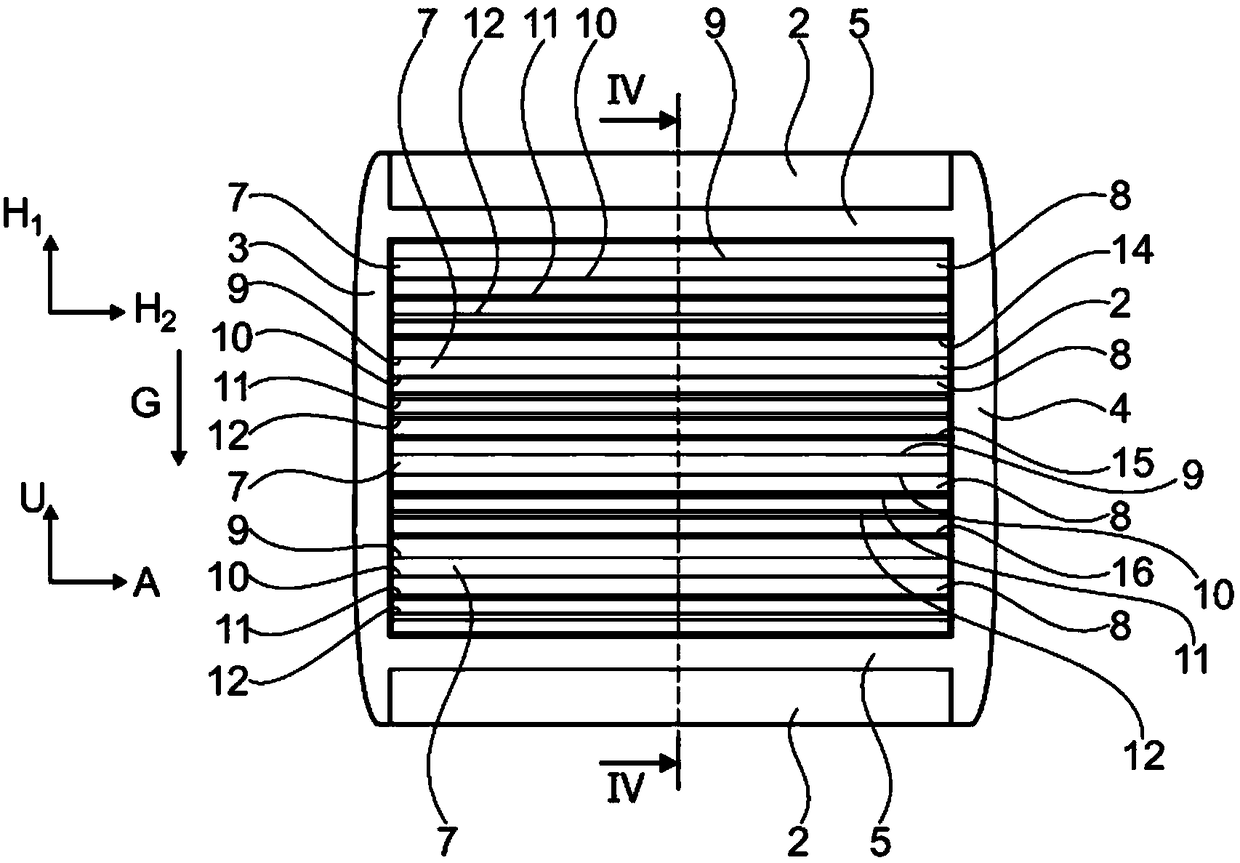

Pneumatic vehicle tyre

ActiveCN106794716AImprove receiving capacityNo lossTyre tread bands/patternsGroove widthGround contact

A tread profile of a pneumatic vehicle tyre having profile block elements (2) which are spaced apart from one another by profile grooves (3, 4, 5) and which are each bounded outwardly by a radially outer surface (6) which forms the ground contact face, wherein a plurality of additional fine grooves (9, 10, 11, 12), which extend along a second main direction of extent and are embodied with a groove width Bp and with a groove depth TF, are arranged one behind the other in a first main direction of extent in the radially outer surface (6) of the profile block elements (2), characterized in that the groove width Bp is 0.05 mm < BF < 0.4 mm and the groove depth TF where TF is < 0.05 mm, and in that at least the fine grooves (9, 10, 11, 12), arranged one behind the other within a surface section (7) of the radially outer surface (6) of a profile block element (2) are embodied with different groove widths Bp, wherein the groove width Bp of these fine grooves (9, 10, 11, 12), arranged one behind the other in the surface section (7), increases in a first orientation of the first main direction of extent, viewed along the extent of the surface section (7) in particular from the fine groove (9, 10, 11) to the fine groove (10, 11, 12).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

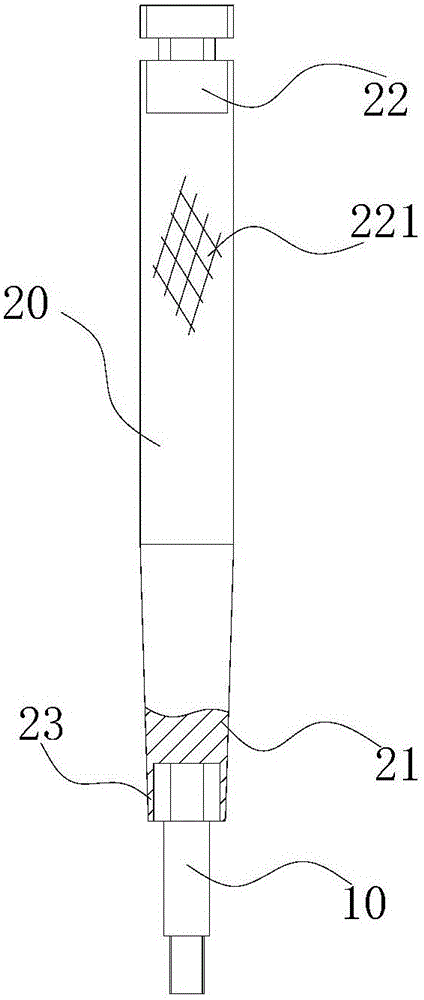

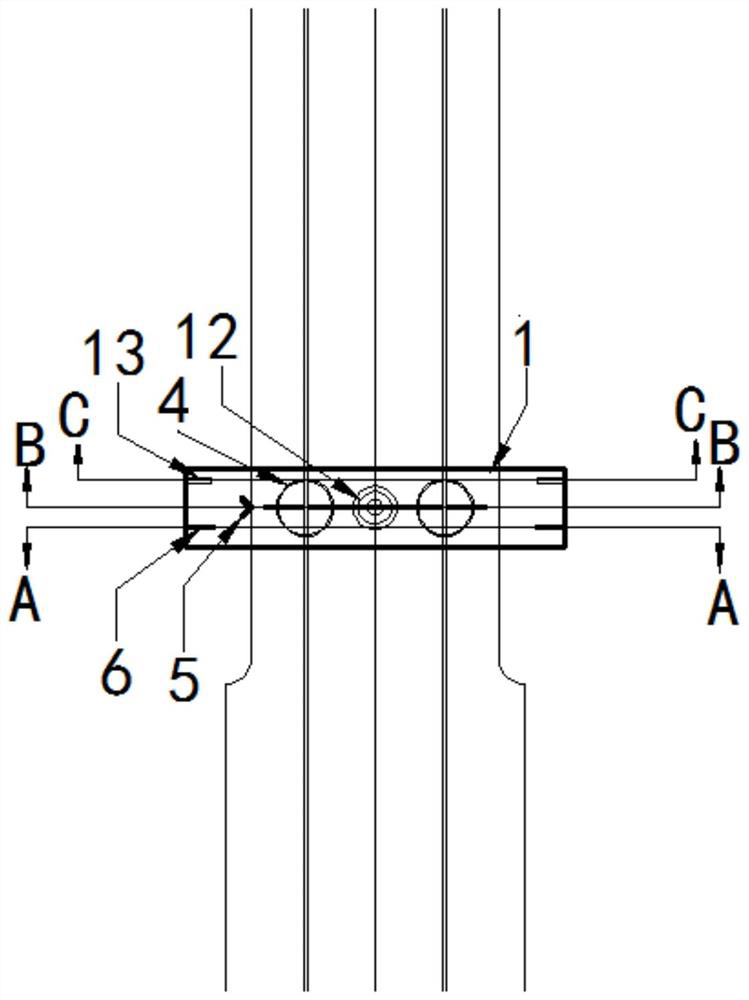

Traction device used for producing medical infusion tube

The invention discloses a traction device used for producing a medical infusion tube. The traction device comprises a first traction assembly and a second traction assembly which are arranged on a rack in an up-down manner; a first traction synchronous belt in the first traction assembly is driven by a first driving belt wheel to perform up-down rotation running on the first driving belt wheel and a first driven belt wheel; a second traction synchronous belt in the second traction assembly is driven by a second driving belt wheel to perform up-down rotation running on the second driving belt wheel and a second driven belt wheel; the rotating directions of the first traction synchronous belt and the second traction synchronous belt are opposite; a traction gap is reserved between the first traction synchronous belt and the second traction synchronous belt; and a tube material located in the traction gap can be pulled by the first traction synchronous belt and the second traction synchronous belt to run forwards. The traction device has the beneficial effects that the speeds of the first traction synchronous belt and the second traction synchronous belt can be precisely controlled, it is effectively guaranteed that the tube material is reliably and steadily pulled, and therefore the quality of the finished medical infusion tube can be greatly improved.

Owner:张家港市繁昌机械有限公司

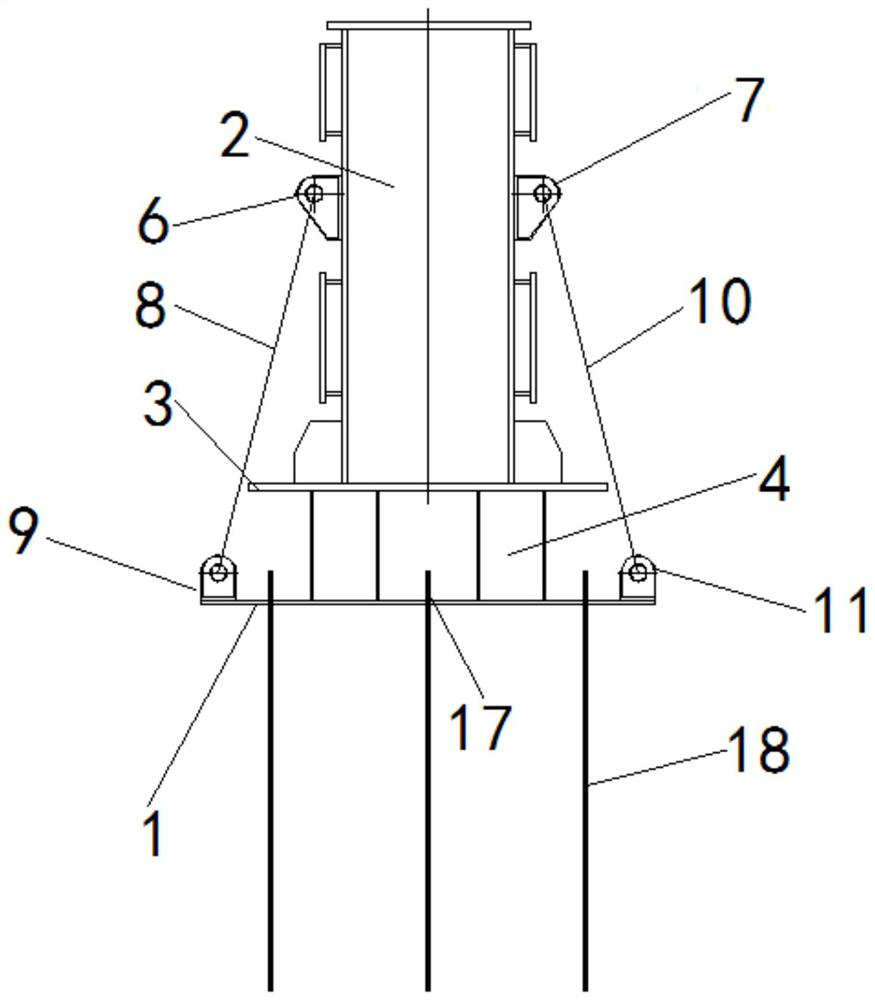

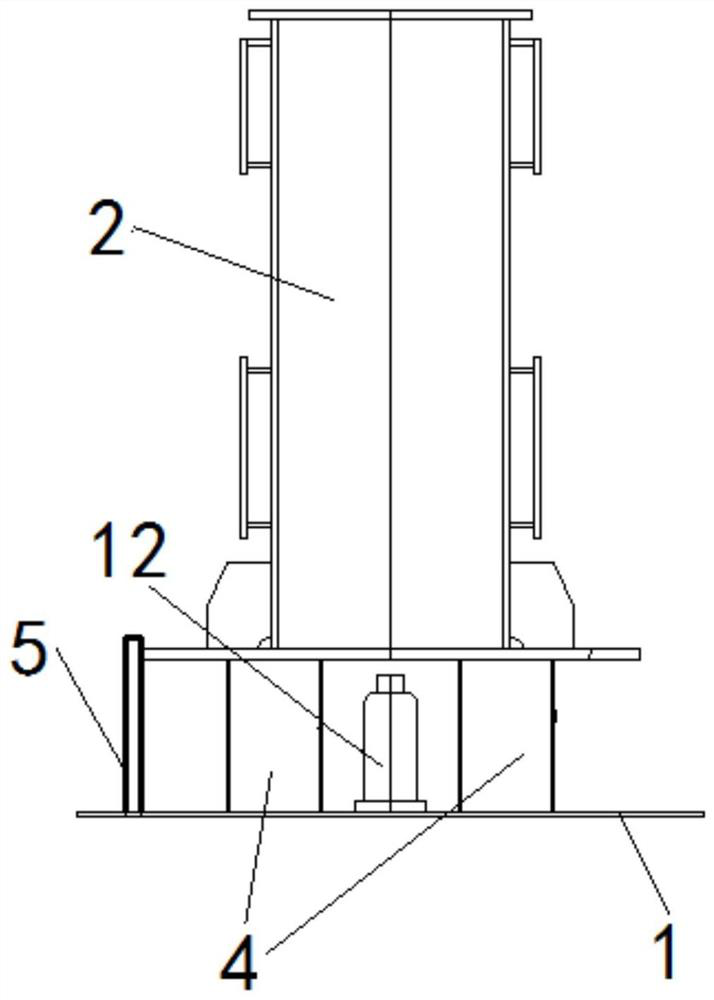

Steel track beam mounting mould and steel track beam mounting method

PendingCN111749058AEasy to installEasy to controlRailway track constructionClassical mechanicsJackscrew

The invention provides a steel track beam mounting mould applied to the technical field of track traffic construction. A mould bottom plate (1) of the steel track beam mounting mould is connected witha reserved steel bar (18); an adjusting pipe (4) is arranged between the mould bottom plate (1) and a steel beam bottom plate (3); a steel beam lug plate I (6) is connected with a bottom plate lug plate I (9) on one side of the mould bottom plate (1) through a chain block I (8); a steel beam lug plate II (7) is connected with a bottom plate lug plate II (11) on the other side of the mould bottomplate (1) through a chain block II (10); a vertical fine adjustment jack (12) is arranged on the mould bottom plate (1); according to the steel track beam mounting mould and the mounting method thereof, accurate, convenient and rapid mounting of the steel track beam is achieved, the steel track beam does not need to be hoisted and adjusted through a crane, adjustment can be rapidly and accuratelyachieved, the quality risk in construction is reduced, the mounting procedure is simplified, the labor intensity of workers is reduced, and the operation efficiency and safety are improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +2

Movable grounding device for railway wagon

PendingCN109941299ASolving Mobile Grounding ProblemsAvoid the risk of damaging the bearingCarriagesConnection contact member materialRelative displacementRotational degrees of freedom

The invention discloses a movable grounding device for a railway wagon. The device comprises a trolley assembly, a pull rod assembly, a traction mechanism and a grounding wire; the trolley assembly isplaced on a steel rail and can move along the steel rail, the traction mechanism is installed on the railway wagon, and the two ends of the pull rod assembly are hinged to the trolley assembly and the traction mechanism respectively to form a rigid force transmitting structure with a rotational degree of freedom; the trolley assembly is pulled by the traction mechanism to run, when the railway wagon brakes and decelerates, the trolley assembly is prevented from moving and self-adapts to the relative displacement change between the traction mechanism and the trolley assembly, and the railway wagon carrying power generation equipment is connected with the trolley assembly through the grounding wire, so that the railway wagon and the steel rail form a dynamically-connected grounding circuit.The movable grounding device achieves the purpose of movable grounding of the railway wagon carrying the power generation equipment, the over-voltage of wagon bearings is effectively avoided, the risk of the bearings is damaged, the life safety of workers is ensured, and the requirement of safe grounding when the railway wagon carrying the power generation equipment runs for power supply can be met.

Owner:CRRC MEISHAN

Production method of porous mesh steel strip reinforced composite tube

The invention discloses a production method of a porous mesh steel strip reinforced composite tube. The production method comprises the following steps: S1, a hole mesh steel strip is unreeled from aunreeling machine; S2, the rolled perforated mesh steel strip obliquely winds a welding support barrel to be welded to form a steel strip welded tube; S3, the steel strip welded tube is rotated and penetrates through a rotary composite forming die, plastic fluid extruded by an extruder enters the rotary composite forming die to form an inner plastic layer and an outer plastic layer which wrap thewelded tube of the steel strip, the front end of the rotary composite forming die is provided with an outer sizing die which is in the same direction as the steel strip welded tube to rotate at the same speed, and the composite tube is subjected to outer sizing through the inner hole of the outer sizing die; S4, the composite tube is conveyed into a cooling box for cooling; S5, the composite tubeis synchronously and rotationally dragged by a rotary traction device; S6, the composite tube is cut through an online synchronous cutting machine; and S7, the cut composite tube is folded and stored.The production method can produce the porous mesh steel strip reinforced composite tube with high surface quality on a continuous production line.

Owner:ZHANGJIAGANG XIEXIN MACHINERY

Traction device for installing vacancy filling rod pieces of circular steel tube trusses and use method

ActiveCN113530262AShorten the blanking lengthPrecise installation of design sizeBuilding material handlingLong armTraction cord

The invention discloses a traction device for installing vacancy filling rod pieces of circular steel tube trusses and a use method. The traction device comprises L-shaped arm rod; the ends, away from short arms, of the two L-shaped arm rods are arranged in a direct facing mode; a rotary winding device is arranged between the ends, away from the short arms, of the two L-shaped arm rods; pulleys are arranged at the ends, away from long arms, of the two L-shaped arm rods and the intersections of the long arms and the short arms; two traction ropes are wound around the rotary winding device; the winding directions of the two traction ropes are opposite; the free end of one traction rope sequentially winds around the two pulleys on one L-shaped arm rod, and the free end of the other traction rope sequentially winds around the two pulleys on the other L-shaped arm rod; and the free ends of the two traction ropes are used for being connected with main pipes of the two circular steel tube trusses which are arranged in a direct facing mode. According to the invention, the vacancy filling rod pieces can be precisely installed according to the design sizes, the construction period is shortened, hidden engineering dangers are eliminated, and relatively good economical efficiency is achieved.

Owner:宁玉欣

A production line and production method for producing strip-shaped plastic parts

InactiveCN106113464BEasy to adjustImprove installation reliabilityMetal working apparatusProduction lineMethods of production

The invention discloses a production line and production method for producing long-strip-shaped plastic parts. The production line sequentially comprises cooling equipment, traction equipment, cutting-off equipment and collecting equipment in the conveying direction for the long-strip-shaped plastic parts. The production method includes the steps of cooling and sizing, traction, cutting off and collecting for the long-strip-shaped plastic parts. By means of the production line and production method, the production efficiency can be improved, and the labor cost is lowered.

Owner:佛山市南海森蓝环保科技有限公司

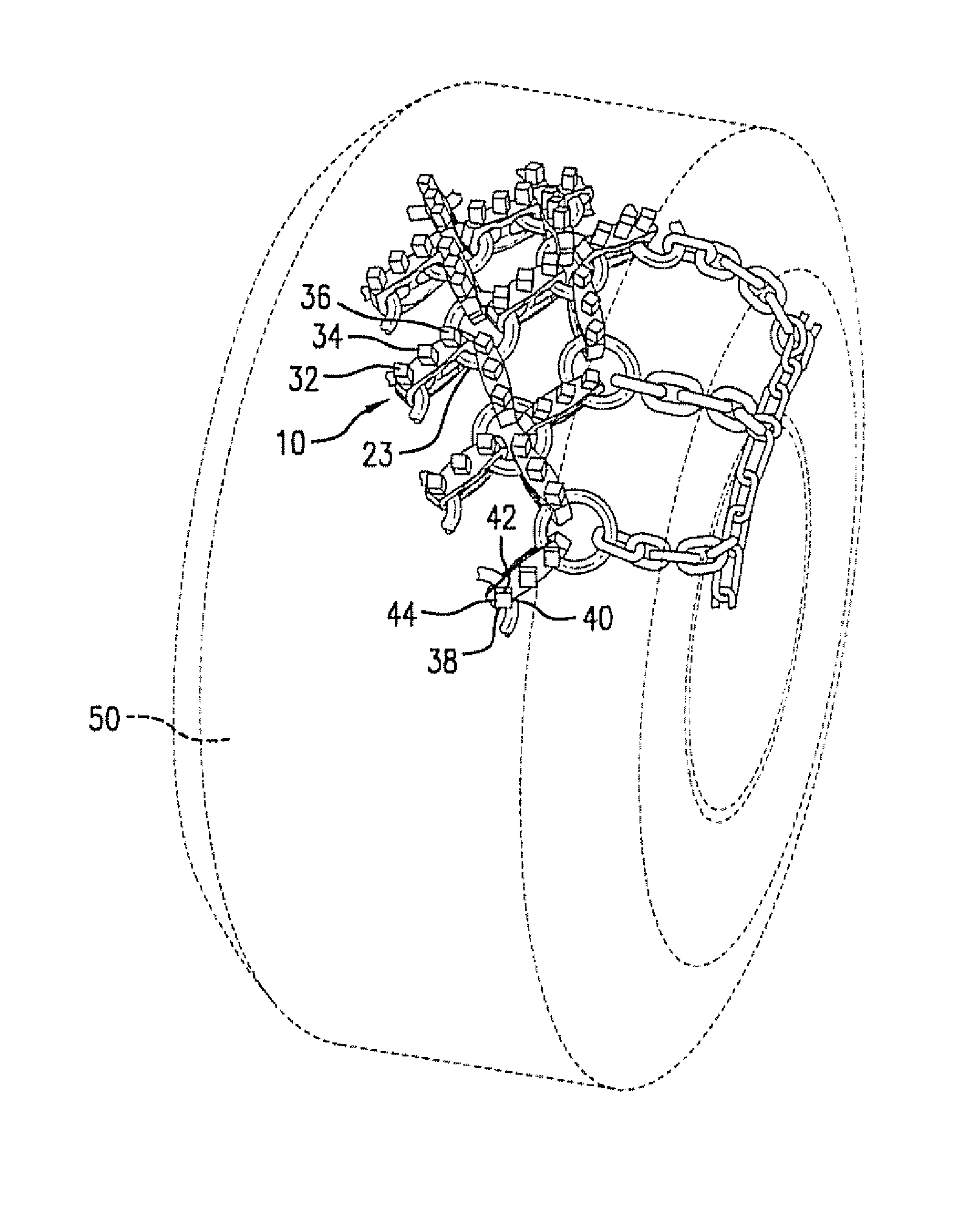

Tire chain link

InactiveUS20160243906A1Maximize contact surfaceMinimizing any tendencyNon-skid devicesSquare cross sectionChain link

A forged tire chain link comprises two attachment apertures and a plurality of integrally forged, spaced upstanding studs having square cross-sections, preferably oriented at 45 degrees to the longitudinal axis of the link. The inside surfaces of the apertures are flat and the base and top of the link body include beveling to the outside in their central portions. The vertical extent of the ends of the link taper to apices. The link provides enhanced traction for forestry and similar environments.

Owner:QUALITY CHAIN CANADA

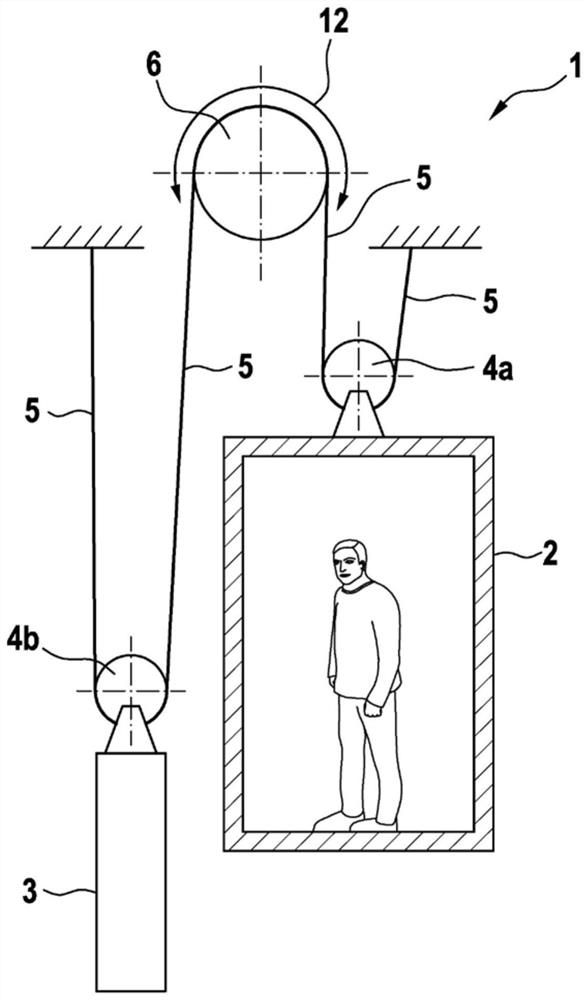

Tension belt or harness

Tension belt or harness made of elastic material with an essentially flat drive side, in particular an elevator belt, in which tension carriers or cords running parallel in its longitudinal direction are embedded in the elastic material of the tension belt or harness , and the tension belt or harness swivels around the pulleys and / or deflection rollers of the belt drive, thereby driving, turning or guiding the tension belt or harness, wherein the flat drive side of the tension belt or harness is provided with a or A plurality of grooves, wherein portions of the grooves extend with varying inclinations relative to the longitudinal direction of the belt and have a periodicity in the longitudinal direction of the belt, wherein, within one period, the orientation of the individual groove portions relative to the longitudinal direction or The inclination is formed such that the lateral force components induced by the orientation or inclination of the grooves and acting on the latter during the rotation of the belt are balanced.

Owner:CONTITECH ANTRIEBSSYST GMBH

Vehicle Pneumatic Tires

ActiveCN106794716BImprove receiving capacityNo lossTyre tread bands/patternsGroove widthGround contact

A tread profile of a pneumatic vehicle tyre having profile block elements (2) which are spaced apart from one another by profile grooves (3, 4, 5) and which are each bounded outwardly by a radially outer surface (6) which forms the ground contact face, wherein a plurality of additional fine grooves (9, 10, 11, 12), which extend along a second main direction of extent and are embodied with a groove width Bp and with a groove depth TF, are arranged one behind the other in a first main direction of extent in the radially outer surface (6) of the profile block elements (2), characterized in that the groove width Bp is 0.05 mm < BF < 0.4 mm and the groove depth TF where TF is < 0.05 mm, and in that at least the fine grooves (9, 10, 11, 12), arranged one behind the other within a surface section (7) of the radially outer surface (6) of a profile block element (2) are embodied with different groove widths Bp, wherein the groove width Bp of these fine grooves (9, 10, 11, 12), arranged one behind the other in the surface section (7), increases in a first orientation of the first main direction of extent, viewed along the extent of the surface section (7) – in particular from the fine groove (9, 10, 11) to the fine groove (10, 11, 12).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

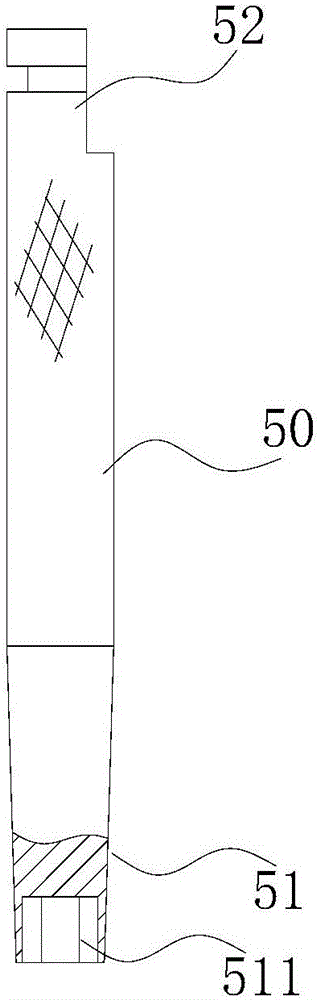

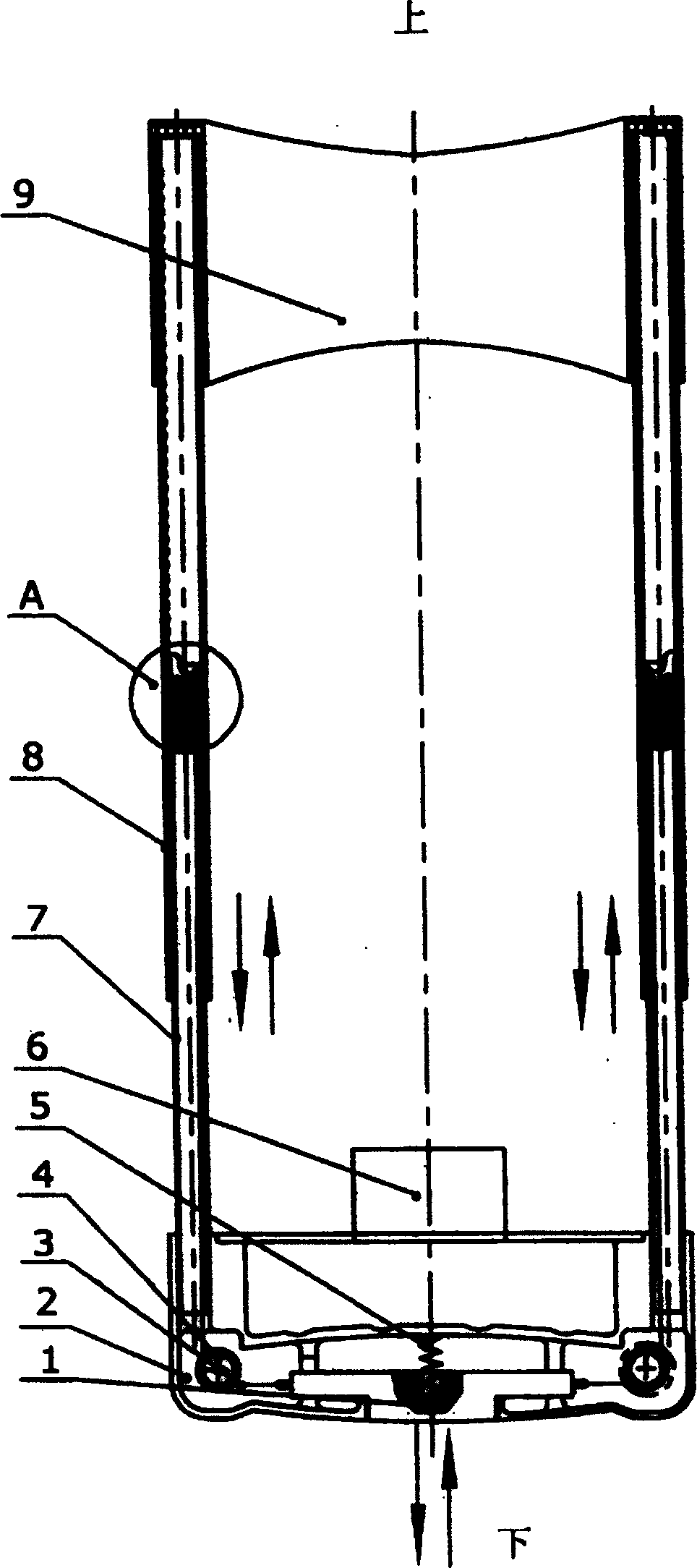

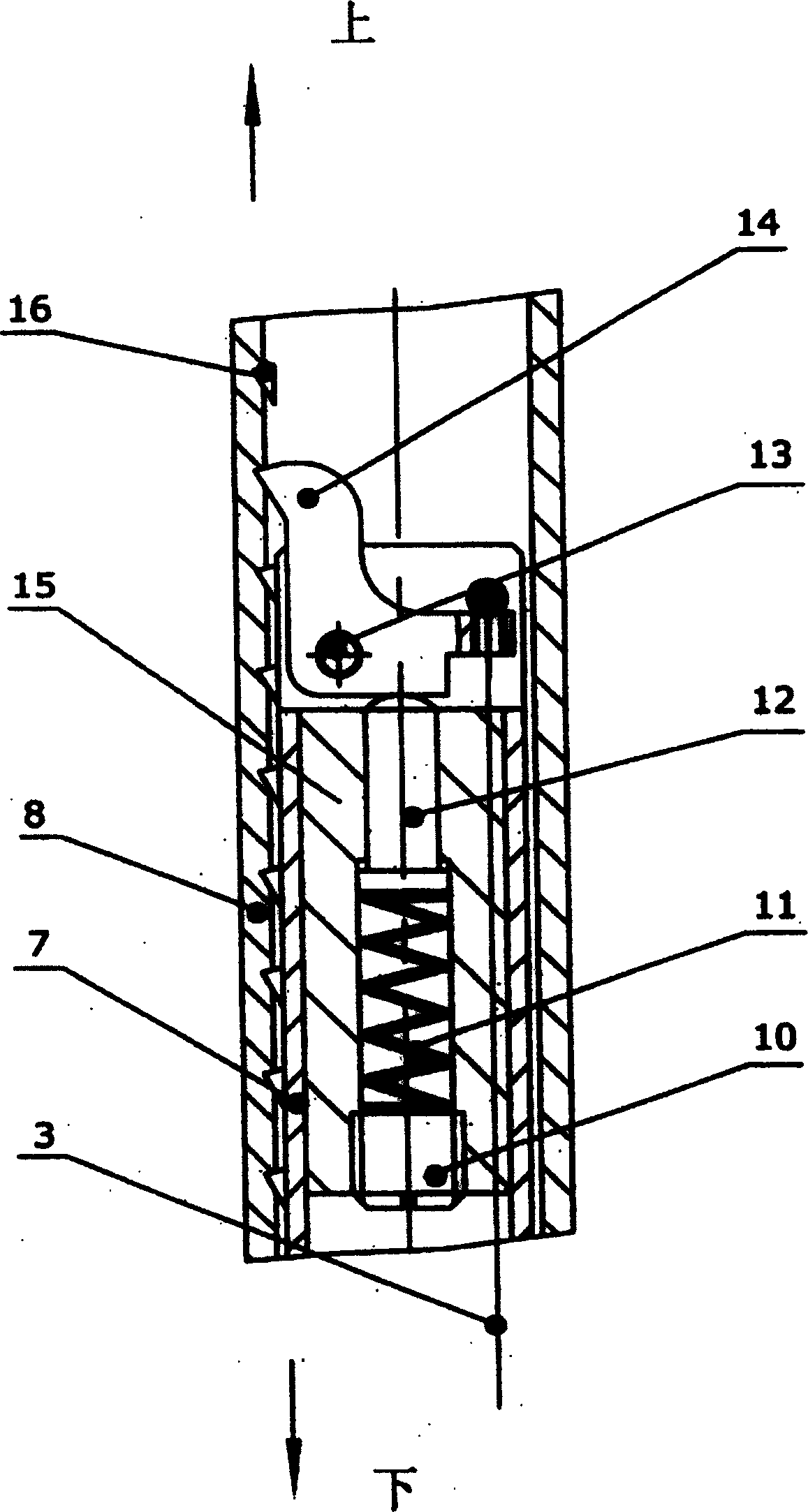

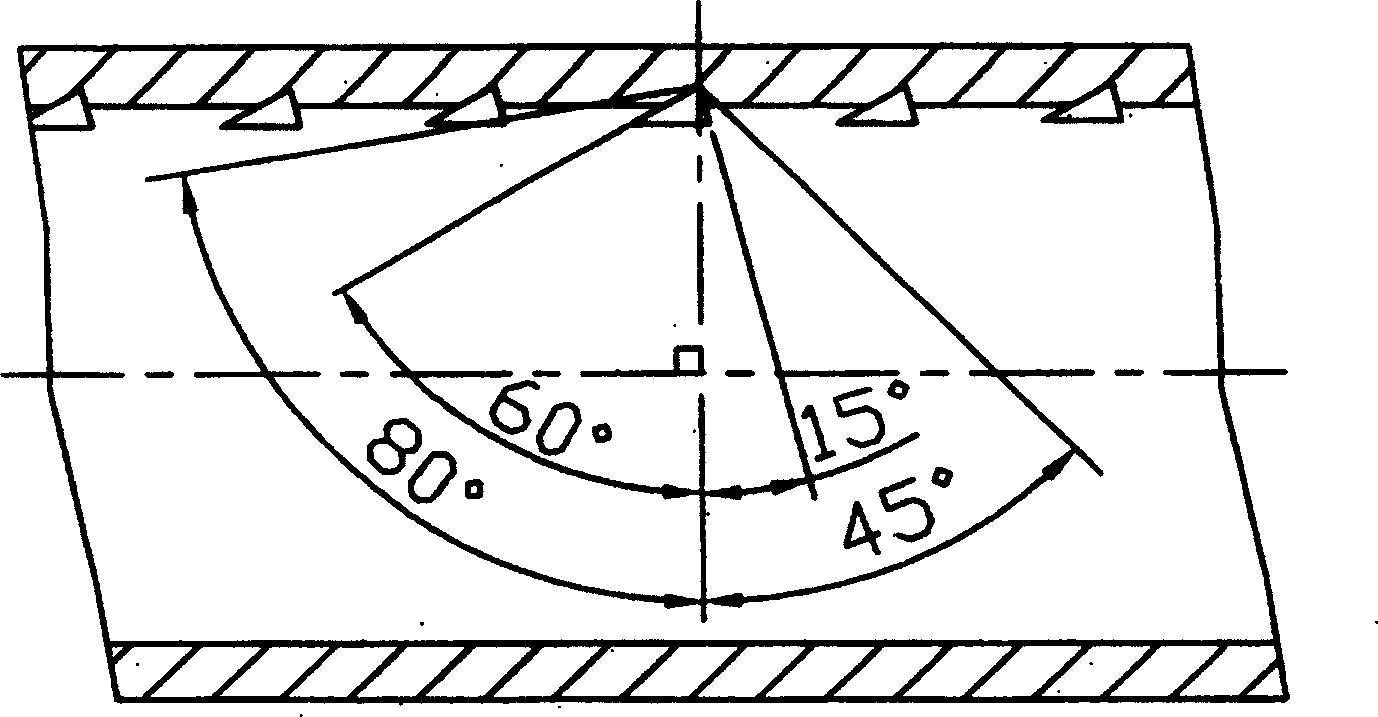

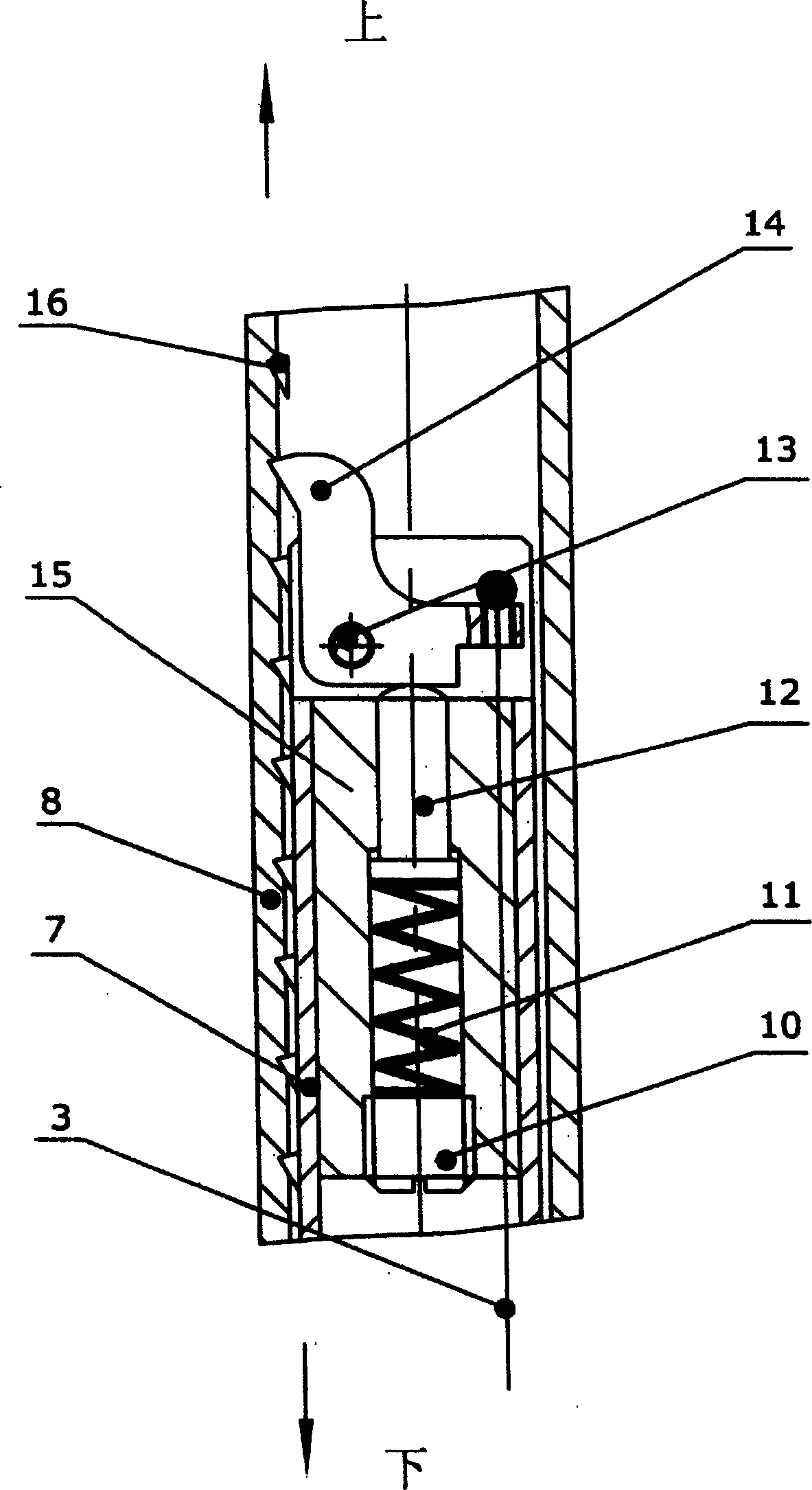

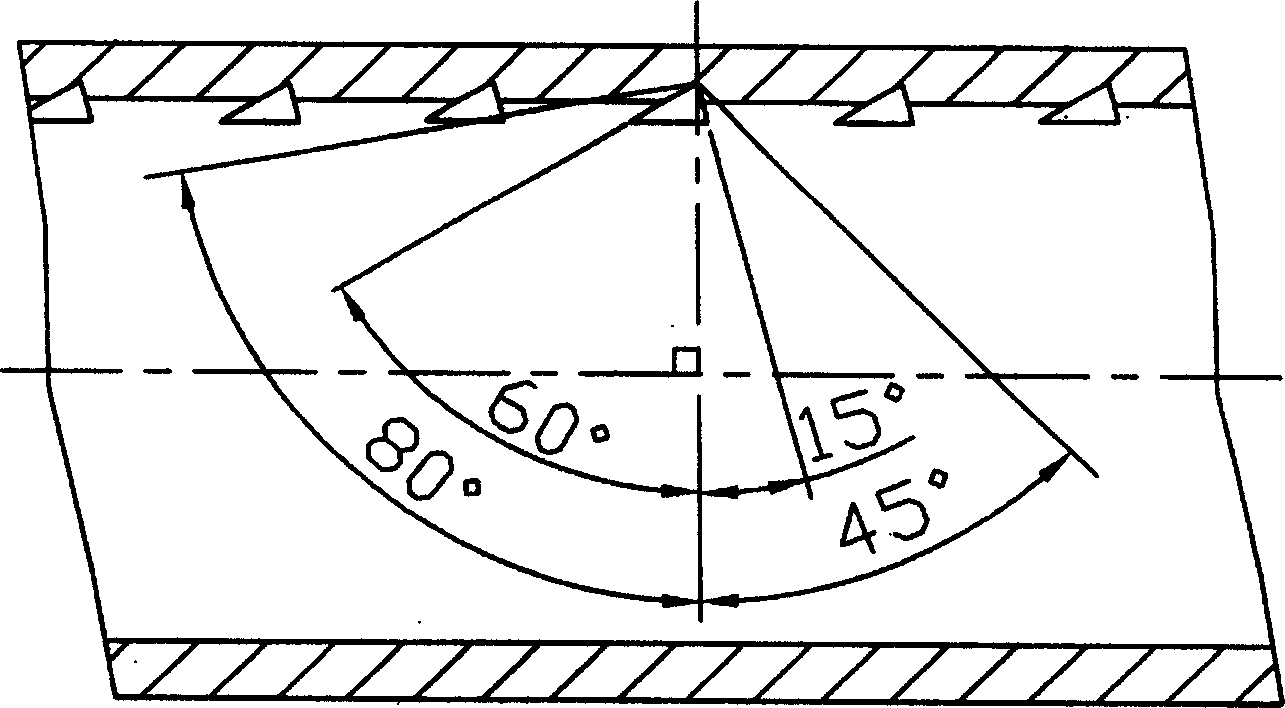

Portable lower limb fracture tractor

A portable lower limb fracture traction frame relates to a lower limb fracture traction device for orthopedic medical treatment. The traction frame mainly includes an outer tube, an inner tube arranged in the outer tube, a handle fixed at one end of the inner tube, a fixed support for feet, and a fixed support for thighs arranged at one end of the outer tube; There is a row of unidirectional force-bearing teeth on the inner wall. The self-locking angle of the teeth is 0-45 degrees, and the slip angle is 45-80 degrees; The fixedly connected pawl part is made up of a pawl, a pawl rotating shaft, an adjusting screw, a spring and a backguy. The invention can make lower limb fracture patients achieve the purpose of traction and reset without going to the hospital, and has the advantages of compact structure, quick adjustment, reliable traction, convenient carrying, etc., and is especially suitable for use on the battlefield or in catastrophic first aid.

Owner:TSINGHUA UNIV +1

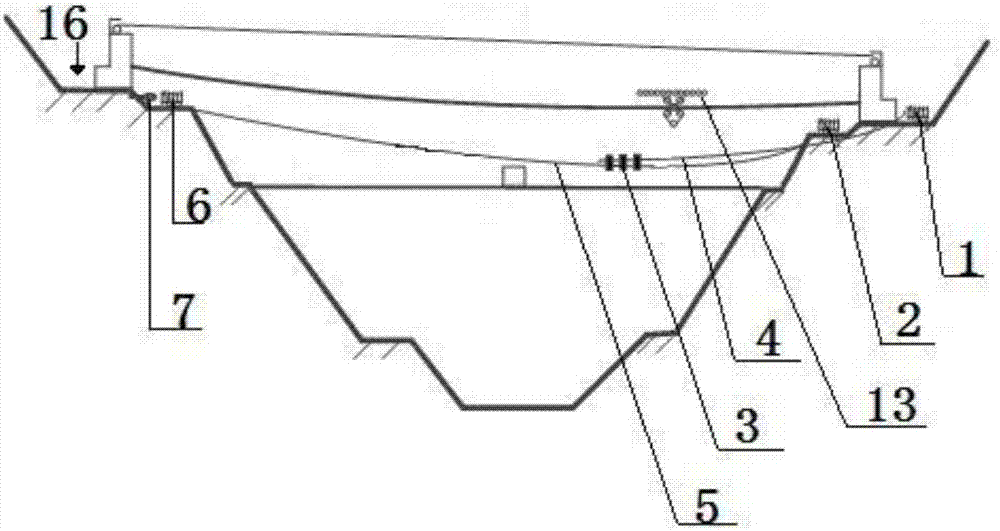

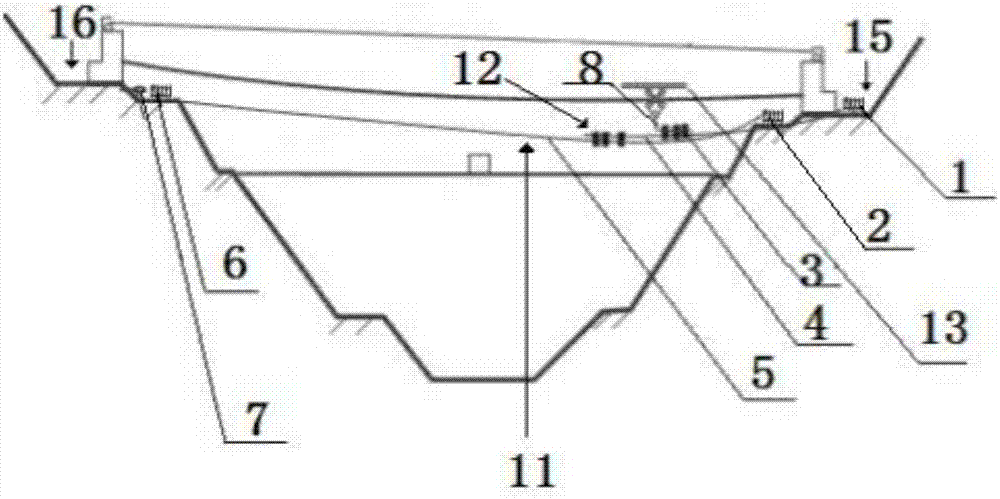

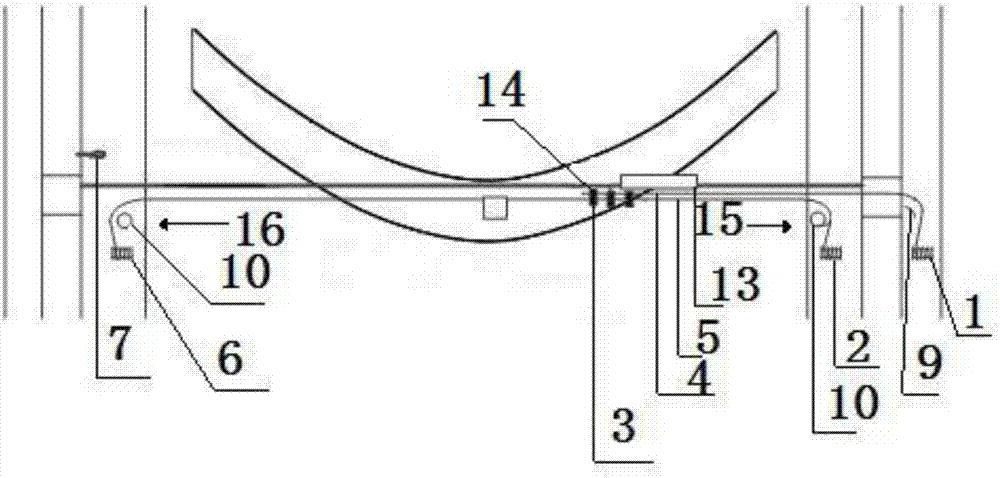

Structure and method for auxiliary traction of carrying cables across the river by trolley of cable machine

ActiveCN106044579BLess time to cross the riverReduce stressWinding mechanismsCable carsTraction systemEconomic benefits

The invention discloses a river-crossing structure for auxiliary traction of a carrying cable by a trolley of a cable machine. It includes a traction system, a connection system, a cable machine traveling trolley, and a lifting traction rope; the traction system includes a cable machine traveling trolley, a reciprocating rope, a load-bearing rope hoist, a reciprocating rope hoist on the releasing side, a reciprocating rope hoist on the non-releasing side, curved rails, guide wheel; the connection system includes rope clamps, filled steel wires, anchoring devices, and hoisting traction ropes; the hoisting traction ropes connect the carrying ropes and the trolley of the cable machine; The cable hoist releases the rope, the reciprocating rope hoist on the non-releasing side takes in the rope, and the cable hoist trolley moves to the non-releasing side under the drive of the traction mechanism. It overcomes the disadvantages of low efficiency, long construction period and potential safety hazards in the existing technology; it has the advantages of short construction period, stable traction process, high economic benefit and high safety factor for crossing the river. The invention also discloses a method for assisting the traction of the carrying cable by the trolley of the cable machine to cross the river.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Corrugated line automatic guiding and pasting edge banding equipment and its application method

ActiveCN107813546BReliable tractionEliminate potential safety hazardsMechanical working/deformationBox making operationsPaperboardEngineering

The invention discloses automatic guiding, sticking and edge sealing equipment for corrugated lines. The equipment comprises an adhesive tape unwinding device and a support; and a first limiting device, an adhesive tape guiding wheel, an automatic adhesive tape guiding and sticking device, an adhesive tape overturning and sticking device and a second limiting device are sequentially arranged on the support in the advancing direction of a corrugated paperboard production line. An upper rocker and a lower rocker which are arranged vertically symmetrically are used for performing adsorbing fixingon an adhesive tape guiding head, so that the adhesive tape guiding head can be pulled reliably; after the upper rocker and the lower rocker are closed, the adhesive tape guiding head and corrugatedpaperboards are clamped together in the upward direction and the downward direction, so that the adhesive tape guiding head is ensured to be stuck to the corrugated paperboards. After adhesive tapes are overturned by overturning clamping plates step by step, the overturned adhesive tapes are extruded onto the upper and lower surfaces of the corrugated paperboards by the aid of adhesive tape scraping plates, the structure is simple and reliable, and potential safety hazards caused by manual operations are eliminated.

Owner:ZHEJIANG GREAT SHENGDA PACKING CO LTD

Steel tube traction machine

The invention discloses a steel tube traction machine. The machine comprises a rack, a main drive shaft and a driven shaft, two chains which are arranged opposite to each other in front and at the back, a guide support, a chuck opening support and a plurality of chuck parts, wherein two horizontal guide blocks and two clamping guide plates are arranged opposite to each other in the front and at the back of the guide support; each of the chuck parts comprises a sliding plate, a first chuck base, a second chuck base and a chuck; two ends of the sliding plate are connected fixedly with chain plates of the chains and are provided with a guide roller assembly which is matched with the horizontal guide blocks; the first chuck base and the second chuck base are connected with the sliding plates in a sliding mode opposite to each other in the front and at the back and are provided with a chuck opening roller assembly which is matched with the chuck opening support, an opposite end is provided with a chuck installation portion respectively, and the other end is provided with a first clamping roller assembly and a second clamping roller assembly, which are matched with the clamping guide plates respectively, except the chuck which is matched with a pipe fitting with a maximum specification, a plurality of sub-chucks are overlapped to form the other chucks. The steel tube traction machine relates to the field of manufacture devices of steel-plastic composites pipes and has the advantages of being simple in structure, convenient in centering adjustment, high in accuracy, even in clamping force distribution and convenient in pipe fitting specification conversion.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

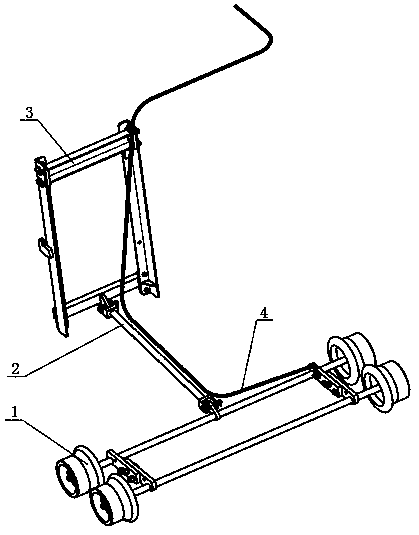

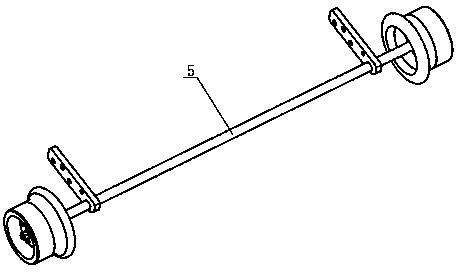

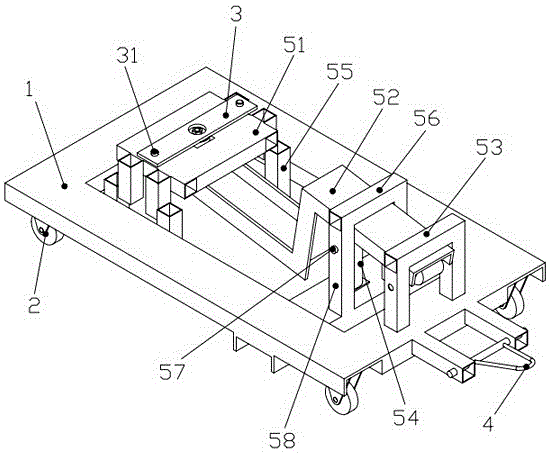

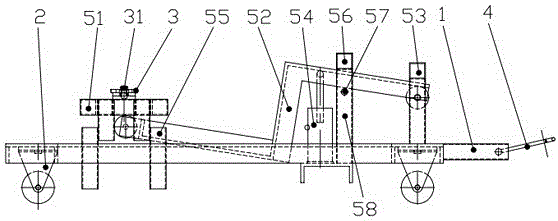

Towing devices for unpowered vehicles in the production process

The invention discloses a draft gear for unpowered vehicles in a production process. The draft gear for the unpowered vehicles in the production process comprises a rear connecting mechanism and a front connecting mechanism, wherein the rear connecting mechanism is connected to the vehicles to be pulled, and the front connecting mechanism is connected to a traction vehicle. The draft gear comprises a chassis and a wheel assembly arranged below the chassis, the rear connecting mechanism is arranged at the rear end of the chassis through a lifting device in a mode that the rear connecting mechanism can rise and fall, the front connecting mechanism is arranged at the front end of the chassis, and at least one of the rear connecting mechanism and the front connecting mechanism is in pivot connection with the chassis. Rigid traction connection is formed between the traction vehicle and the vehicles to be pulled through the rear connecting mechanism and the front connecting mechanism, the vehicles to be pulled are lifted simultaneously through the lifting device when traction connection is carried out on the vehicles to be pulled, and the problems that the unpowered vehicles in the production process are poor in braking, low in efficiency and poor in safety are solved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +2

Portable lower limb fracture tractor

A portable tractor for treating the bone fracture of lower extremity is composed of the external shaped tube with a line of unidirectional stressed teeth having a self-locking angle of 0-45 deg. and 45-80 deg of slide angle on its inner surface and the internal shaped tube in said external one. The handle and foot supporter is fixed to one end of said internal tube and the ratchet unit is fixed to thue other end. A leg supporter is fixed to one end of said external tube. Its advantages are compact structure, easy regulation, and high reliability.

Owner:TSINGHUA UNIV +1

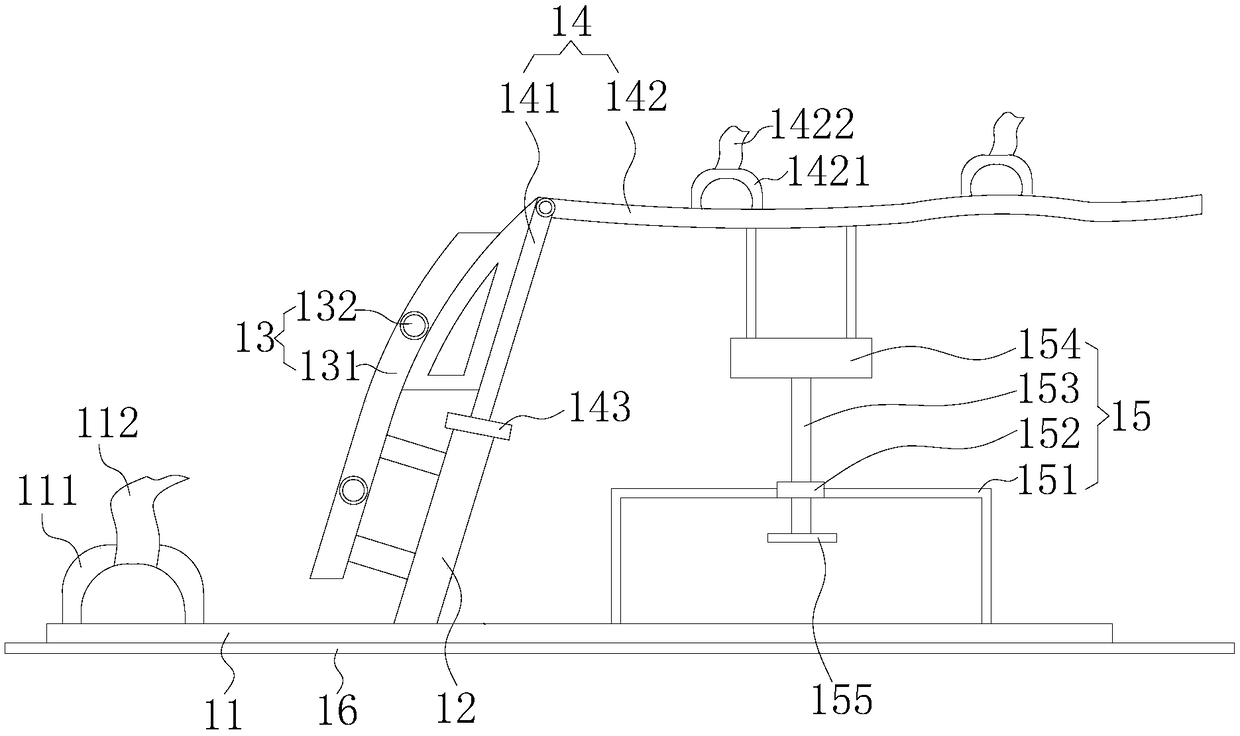

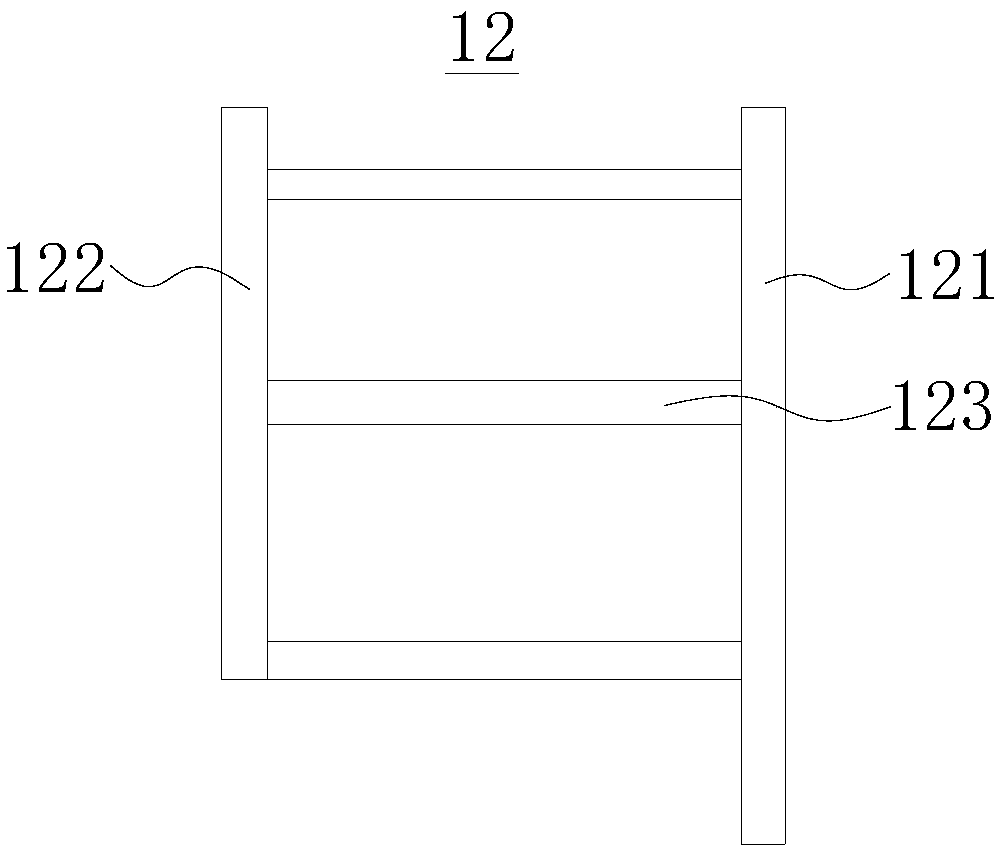

Child thighbone adjustable lever traction support

PendingCN108814790AEasy to correctDynamically understand the situationFractureEngineeringMedical device

The invention discloses a child thighbone adjustable lever traction support, and belongs to the technical field of medical equipment. The support comprises a base, an inclined supporting frame, a thighbone angulation adjusting mechanism, a thighbone traction mechanism and a pressure regulating mechanism; the inclined supporting frame is obliquely arranged on the base, the thighbone angulation adjusting mechanism is arranged at one side of the inclined supporting frame, the thighbone traction mechanism comprises a first traction support and a second traction support, one end of the first traction support is rotationally connected with one end of the second traction support, the end, away from the second traction support, of the first traction support is slidably connected with the inclinedsupporting frame, the pressure regulating mechanism is arranged on the base and located at the side, away from the thighbone angulation adjusting mechanism, of the inclined supporting frame, and the second traction support is connected with the pressure regulating mechanism. The support is simple in structure and convenient to use, the needed traction force can be provided by adjusting the thighbone traction mechanism, the fracture angulation can be corrected, the thighbone angulation can be further regulated through the thighbone angulation adjusting mechanism, and the reset angle can be obtained.

Owner:史青林

A kind of production method of perforated steel strip reinforced composite pipe

The invention discloses a production method of a perforated steel strip reinforced composite pipe, comprising the following steps: S1, unwinding the perforated steel strip from an unwinding machine; S2, obliquely winding the unrolled perforated steel strip on a welding support cylinder The steel strip welded pipe is welded on top; S3, the steel strip welded pipe rotates through the rotary composite molding die, and the plastic fluid extruded from the extruder enters the rotary composite molding mold to form an inner plastic layer and an outer plastic layer wrapping the steel strip welded pipe, and the rotary composite The front end of the forming mold is equipped with an outer sizing die that rotates in the same direction and at the same speed as the steel strip welded pipe, and the composite pipe passes through the inner hole of the outer sizing die to complete the outer sizing; S4, the composite pipe is sent into the cooling box for cooling; S5 1. The composite pipe is synchronously rotated and pulled by the rotating traction device; S6. The composite pipe is cut by an online synchronous cutting machine; S7. The cut composite pipe is folded and stored. The production method can produce a perforated mesh steel strip reinforced composite pipe with high surface quality on a continuous production line.

Owner:ZHANGJIAGANG XIEXIN MACHINERY

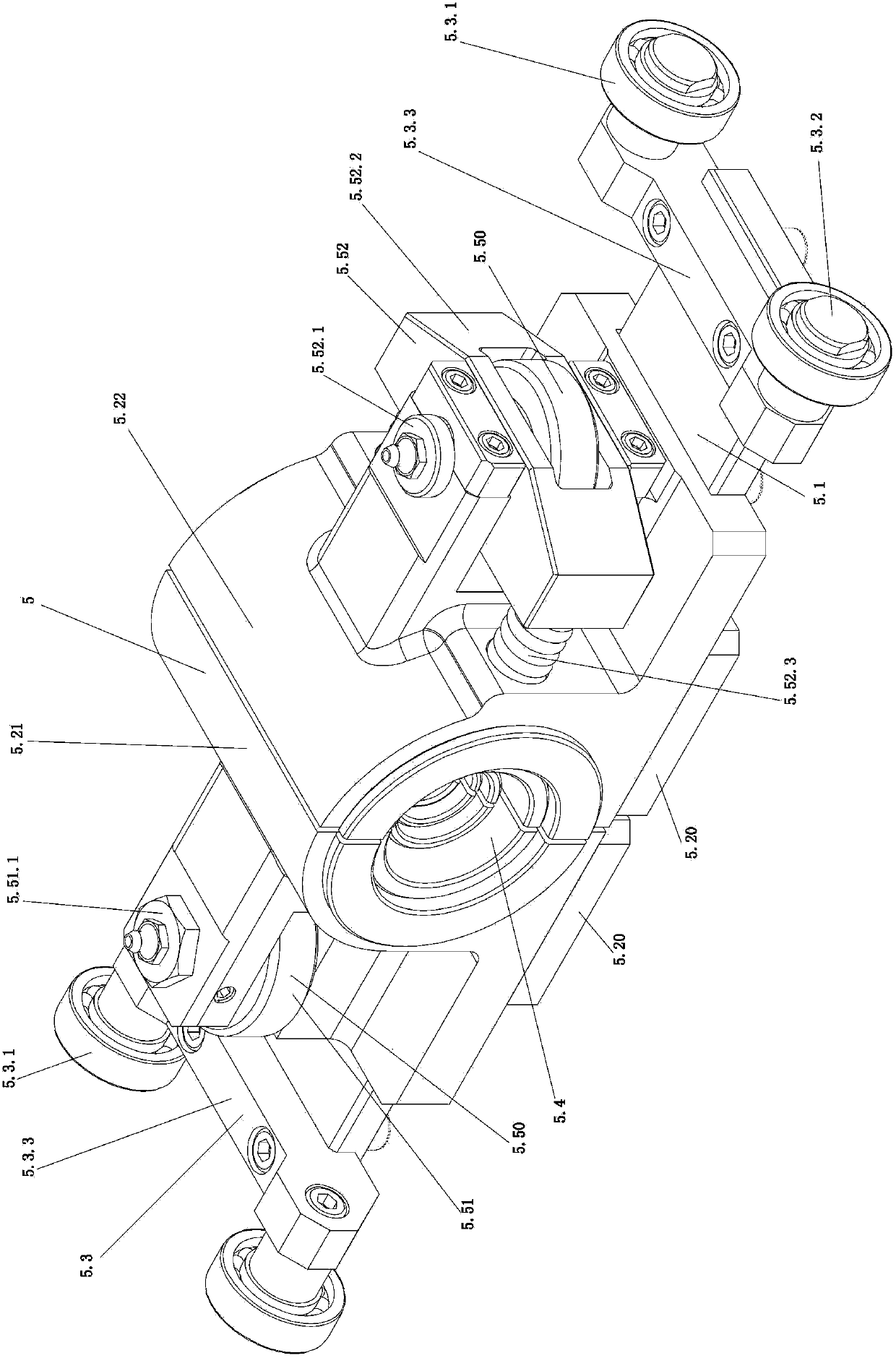

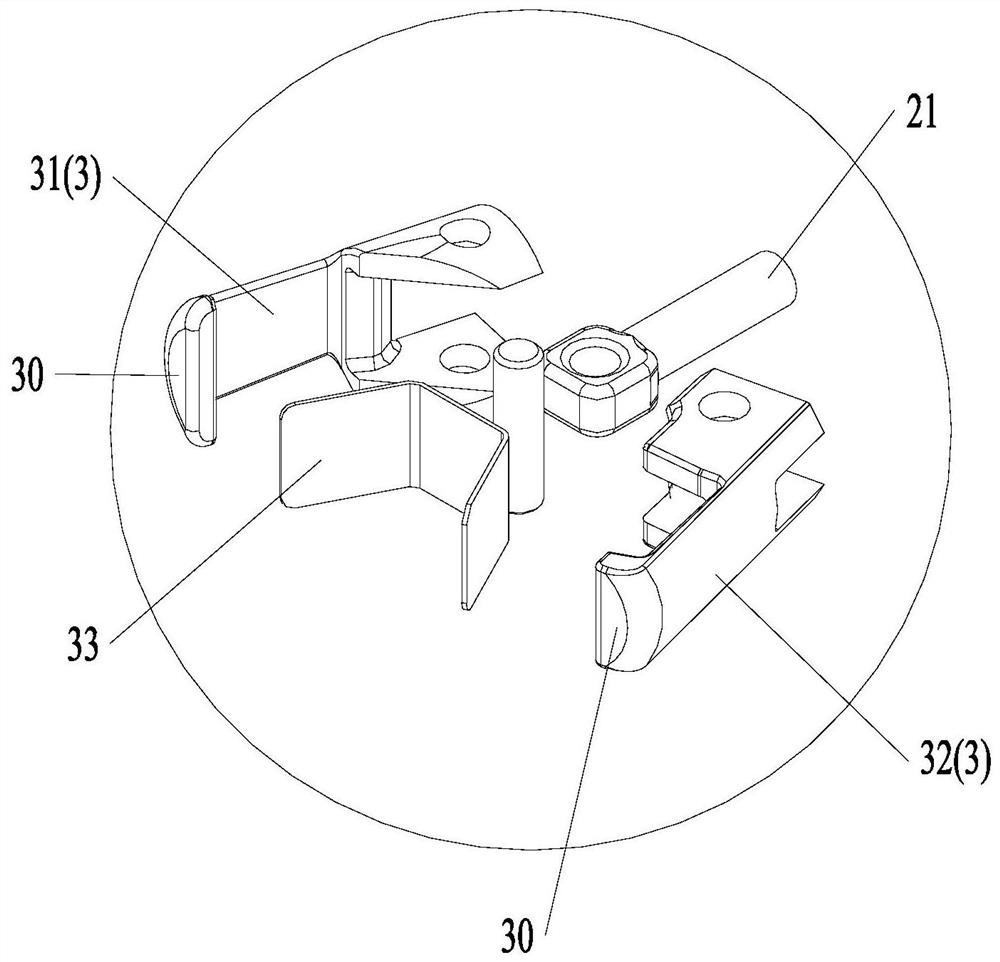

Surgical instrument connection joint and surgical instrument

The present application discloses a connection joint for surgical instruments, which includes a first connection assembly and a second connection assembly. The first connection assembly is provided with a plurality of transmission parts, and the second connection assembly is provided with a plurality of Traction parts, one end of each traction part is provided with a locking unit; during the docking process of the first connection component and the second connection component, the transmission part is connected with the locking unit; when the first connection component and the second connection component are in the setting In a fixed docking state, the transmission part is connected with the traction part through the locking unit, so that the transmission part can transmit power to the traction part matched with it. The surgical instrument connection joint disclosed in this application can realize quick transfer between power components and control components, has the advantages of simple structure, quick and convenient switching, etc., and can also realize quick connection between multiple transmission parts and multiple traction parts and separation. The present application also discloses a surgical instrument, which has the advantages of precise manipulation, simplicity, safe and reliable use, and the like.

Owner:APEIRON SURGICAL CO LTD

Surgical instrument connector and surgical instrument

The invention discloses a surgical instrument connector, and the connector comprises a first connecting assembly and a second connecting assembly; the first connecting assembly is provided with a plurality of transmission parts, the second connecting assembly is provided with a plurality of traction parts matched with the transmission parts, and one end of each traction part is provided with a locking unit; in the butt joint process of the first connecting assembly and the second connecting assembly, the transmission part is connected with the locking unit; when the first connecting assembly and the second connecting assembly are in a set butt joint state, the transmission piece is connected with the traction piece through the locking unit so that the transmission piece can transmit power to the traction piece matched with the transmission piece. The surgical instrument connector disclosed by the invention can realize quick switching between the power assembly and the control assembly, has the advantages of simple structure, quick and convenient switching and the like, and can also realize quick connection and separation between a plurality of transmission pieces and a plurality of traction pieces. The invention further discloses a surgical instrument which has the advantages of being accurate and easy to control, safe and reliable to use and the like.

Owner:APEIRON SURGICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com