Full-automatic plastics rolling moulder capable of precise length control

A roll forming machine, fully automatic technology, applied in the direction of metal processing, etc., can solve the problems of large product length deviation, conveying slippage, low production efficiency, etc., and achieve the effect of stable product conveying, accurate length and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technology will be further described below in conjunction with the accompanying drawings.

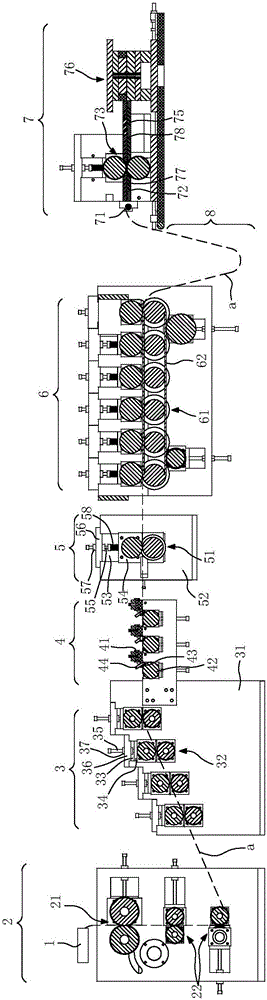

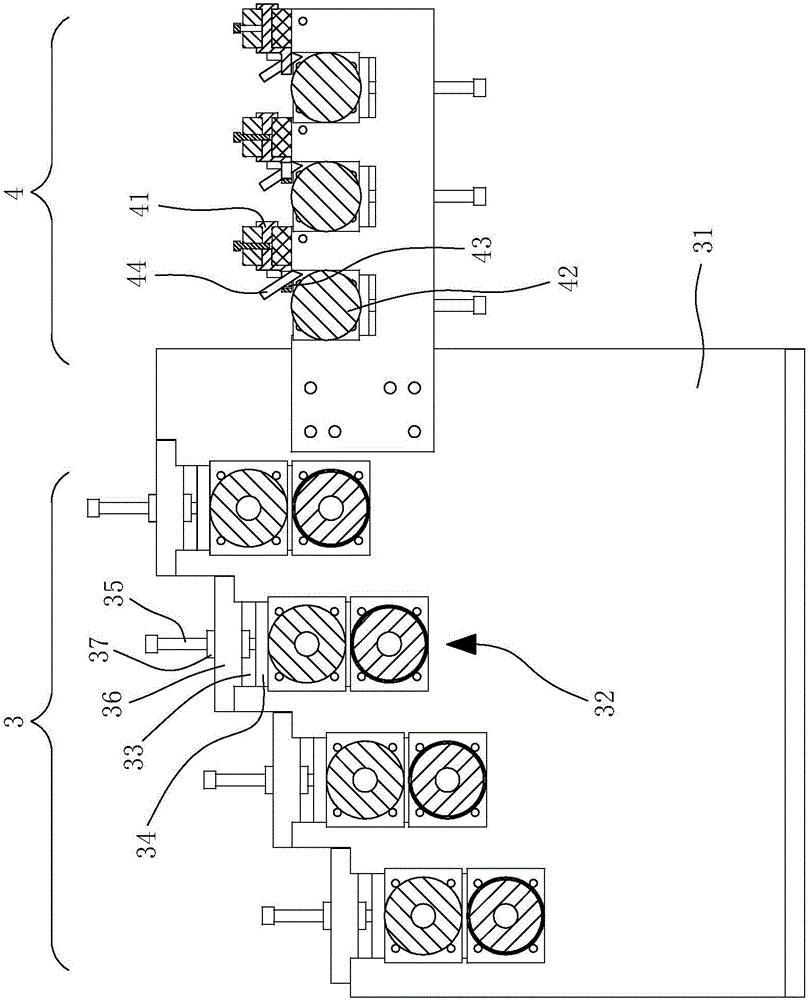

[0022] The fully automatic plastic roll forming machine that can be precisely fixed in length in this embodiment includes a discharge port 1 connected to the extruder, a forming unit 2, a cooling unit 3, a cutting unit 4, a primary traction unit 5, a belt type The traction unit 6 and the numerical control punching unit 7, the discharge port 1 is set above the forming unit 2, and the rear of the forming unit 2 is sequentially arranged with a cooling unit 3, a cutting unit 4, a primary traction unit 5, a belt traction unit 6 and a numerical control unit. Punching unit 7, space 8 for free falling of product a is reserved between belt traction unit 6 and numerical control punching unit 7.

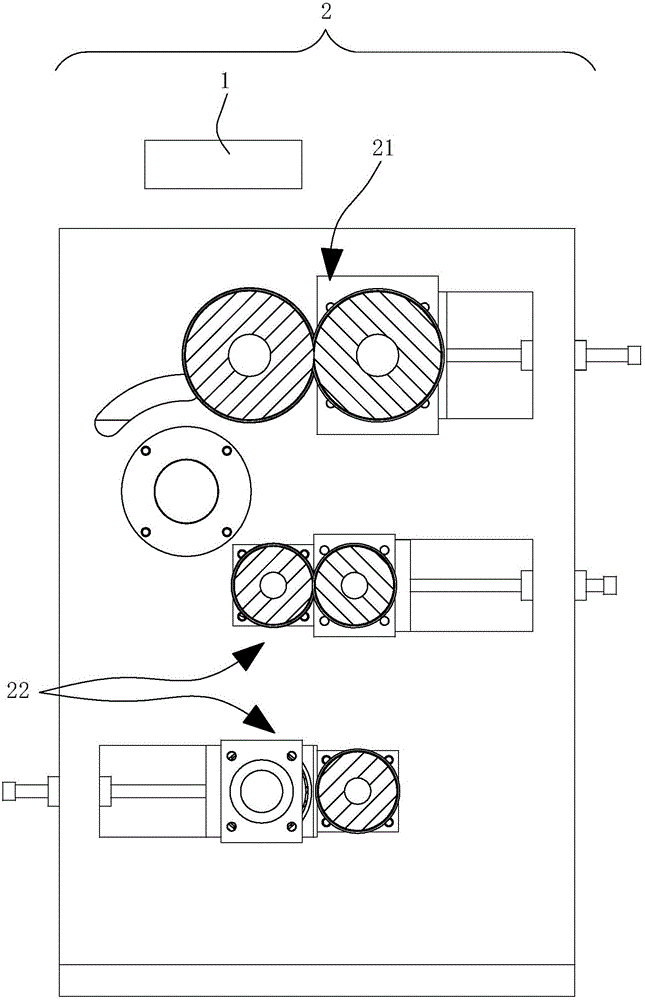

[0023] The molding unit 2 is composed of a pair of mold rollers 21 and a pair of primary cooling rollers 22. The pair of mold rollers 21 are combined with one left and one right. A set of pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com