Production line and production method for producing long-strip-shaped plastic parts

A long-strip, production line technology, applied in metal processing and other directions, can solve the problems of poor cooling effect, inability to achieve continuous operation of cooling and cutting, and reduce efficiency, and achieve the effects of good installation reliability, easy positioning, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

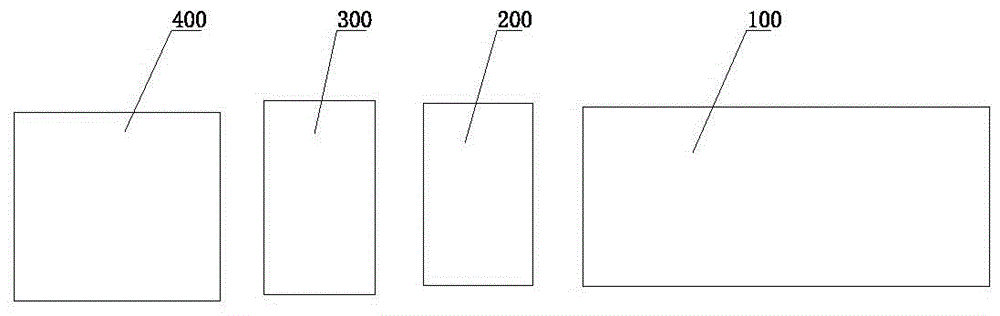

[0067] Such as figure 1 As shown, the production line for producing elongated plastic parts includes cooling equipment 100 , traction equipment 200 , cutting equipment 300 and collecting equipment 400 in sequence according to the conveying direction of elongated plastic parts.

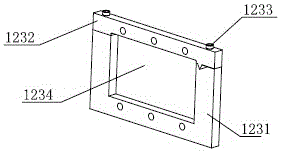

[0068] Such as Figure 2 to Figure 4 As shown, the cooling device 100 includes a first rack 10 , a collecting guide trough 11 , an adjustable cooling device 12 and a vacuum cooling system 13 .

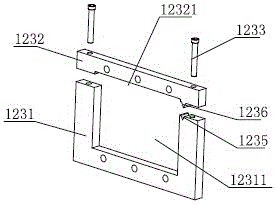

[0069] Such as Figure 5 As shown, the first frame 10 includes longitudinal beams 101, crossbeams 102 and columns 103; in the horizontal direction, crossbeams 102 are connected between adjacent longitudinal beams 101 except the top; in the vertical direction, adjacent longitudinal beams 102 Columns 103 are connected between the beams 101; a longitudinally extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com