Vibrating bunker

A technology of vibrating hopper and material area, applied in the direction of vibrating conveyor, conveyor, transportation and packaging, etc., can solve the problems of inability to guarantee the continuous conveying of the regulator shell, slow speed and low production efficiency, and achieve high practical value. , The effect of improving assembly speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

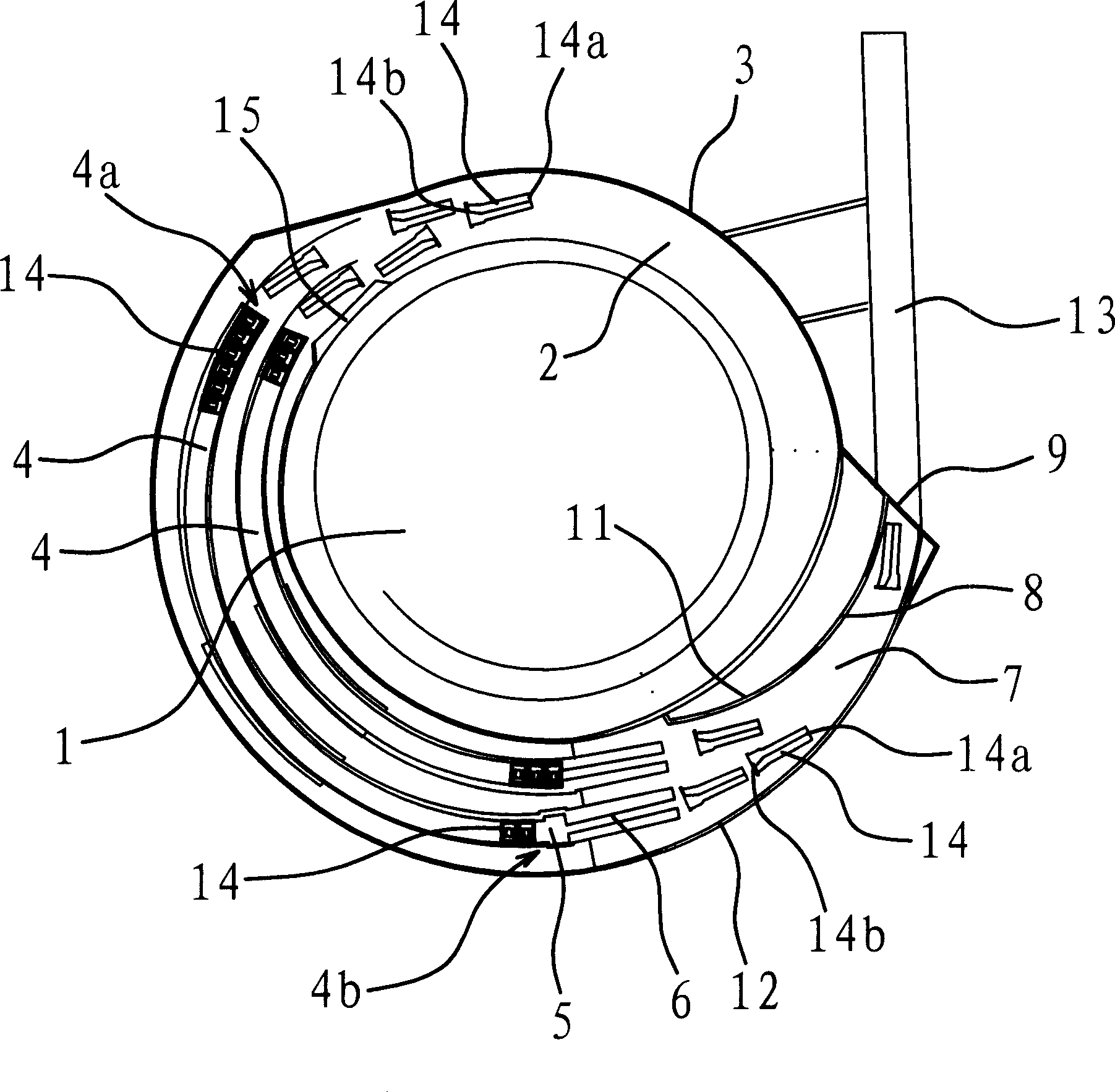

[0020] The following is an example of a vibrating hopper for monolithic processing of the regulator housing on the infusion set. Depend on figure 1 It can be seen from the figure that the main part of the vibrating hopper is mainly composed of a base 1 and a cylindrical side wall 3 fixed together, and a spiral slope 2 is provided on the base 1 along the side wall 3 .

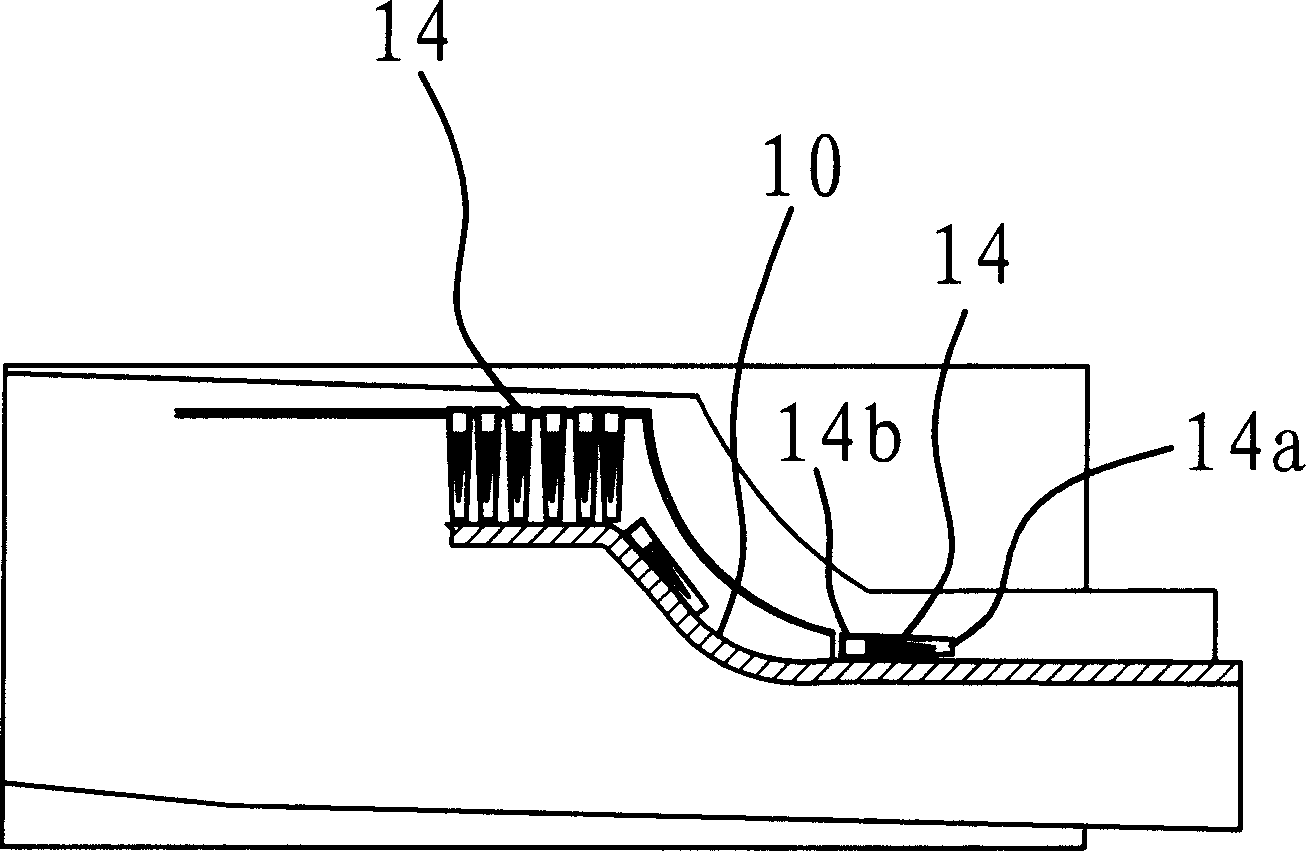

[0021] Such as figure 1 As shown, a discharge port 9 is also provided on the side wall 3, and at least two discharge troughs 4 arranged side by side are arranged between the discharge port 9 and the inclined surface 2, and the width of the discharge chute 4 is between the regulator shell The size of the housing head 14a of the body 14 is between the size of the housing and the size of the housing tail 14b. In this embodiment, considering the overall compact structure of the vibrating hopper and the actual requirement of the material delivery speed, the number of discharge troughs 4 is two. The two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com