Carrier conveying device

A technology for conveying devices and vehicles, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that it is difficult for vehicles to abut against vehicles, affect the accuracy of vehicles, the assembly accuracy of assembly machines, and the impact on stability, etc. , to achieve the effect of compact structure, convenient layout, stable and precise conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

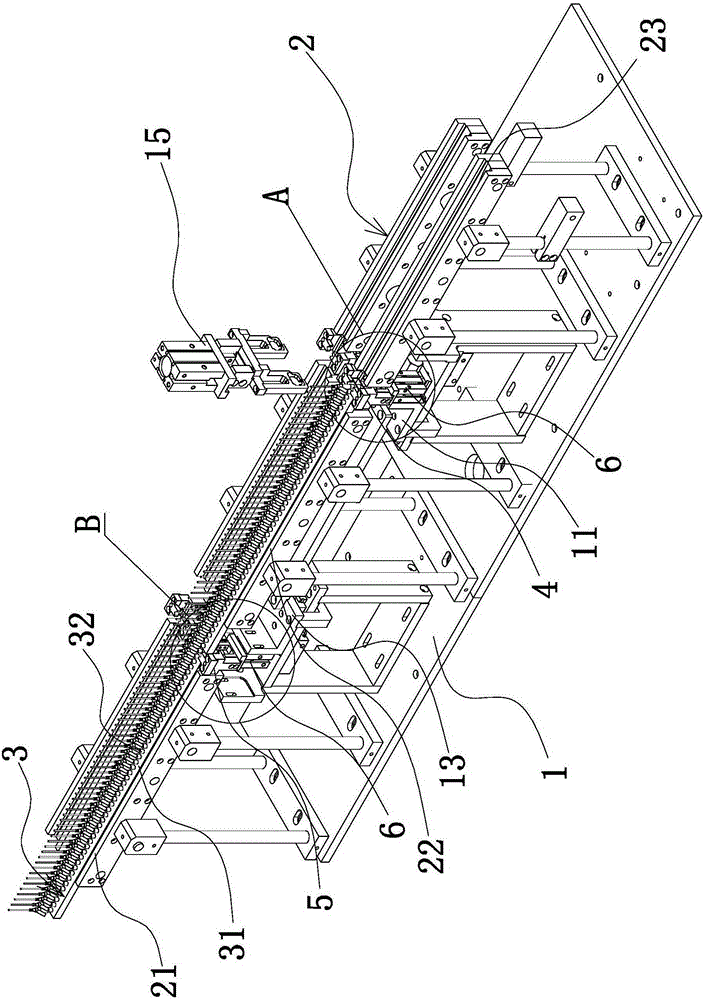

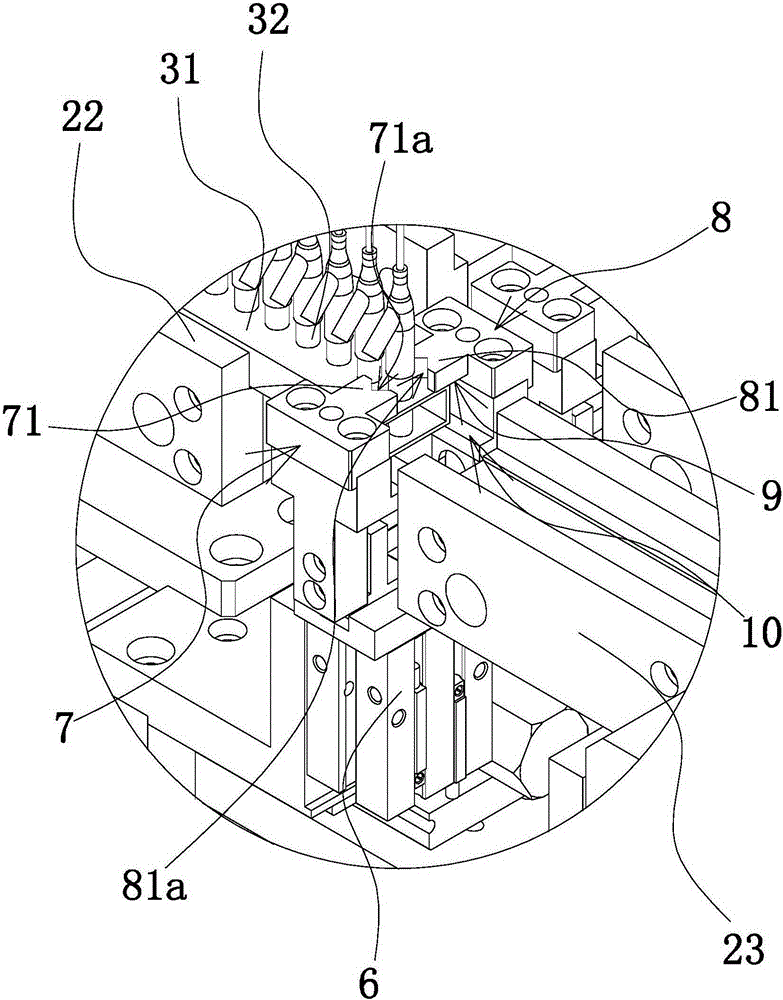

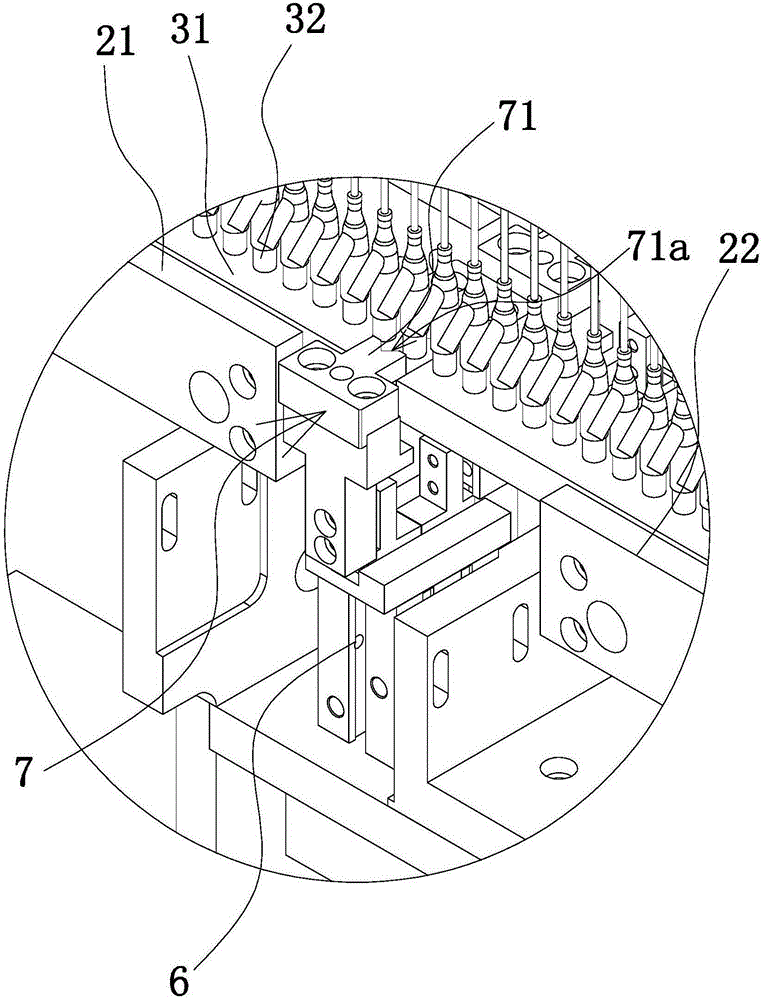

[0030] Such as figure 1 As shown, the conveying device of the carrier 3 includes a frame 1 and a guide rail 2 arranged on the frame 1 and extending in a straight line direction. The guide rail 2 is provided with a chute along its length direction, and several long rails are slidably arranged in the chute. Strip carrier 3. Of course, the carrier 3 can also be in other shapes. Several carriers 3 are arranged in sequence along the length direction of the guide rail 2 and can translate along the guide rail 2 . The carrier 3 includes a long slider 31, the cross section of the slider 31 is rectangular, the ends of the sliders 31 of two adjacent carriers 3 are against each other, and the upper surface of the slider 31 is uniform along the length direction of the slider 31. Several positioning columns 32 are arranged at intervals. The positioning post 32 can be used to sheath the needle sheath, sheath, etc. on it, so as to realize the delivery of the needle sheath, sheath, etc. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com