Micro needle tip with orientation structure and method thereof for continuously conveying liquid

A micro-needle tip and orientation technology, applied in the field of micro-nano manufacturing, can solve problems such as difficulty in wide applicability, inability to transport large droplets, and inability to transfer droplets successfully, achieving high success rate and continuous transportation , the effect of transporting a small amount of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

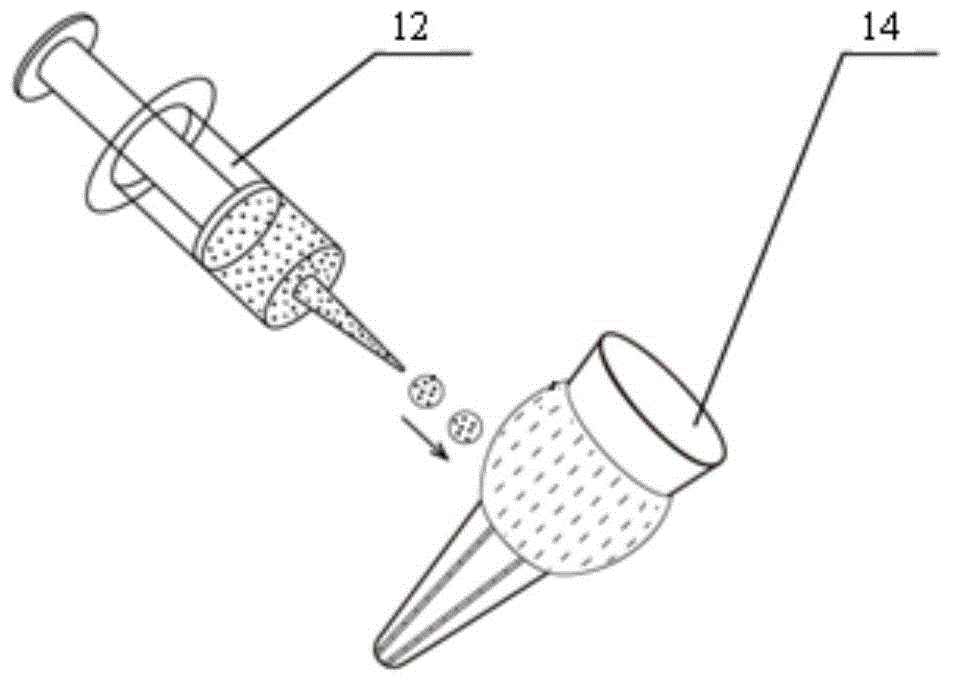

[0037] The present invention proposes a microneedle tip with an orientation structure and a method for continuously transporting liquid thereof. The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

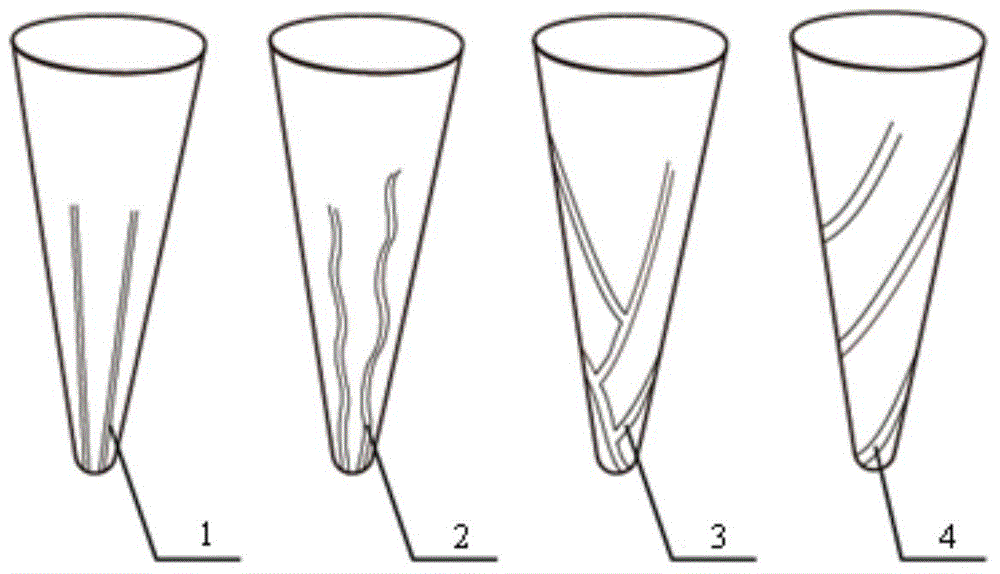

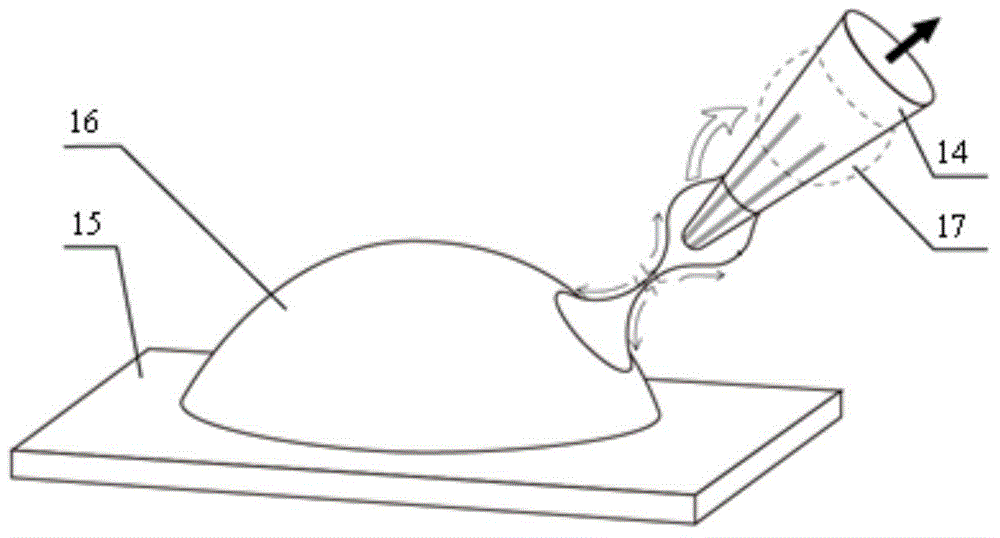

[0038] The present invention proposes a micro-needle tip with an orientation structure. The micro-needle tip is tapered with a thin tip and a thick root. The surface of the micro-needle tip is made with an oriented micro-nano groove-like structure. The micro-nano groove-like structure penetrates to the micro-nano The tip of the needle tip, the radius of the curvature circle of the tip of the micro-needle tip is not more than 20 microns, the average width and average depth of the micro-nano groove-like structure are between 20 nanometers and 5 microns, the micro-nano groove-like structure on the surface of the micro-needle tip The orientation is specifically that the axial direction of the micro-nano-groove-lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com