Patents

Literature

252results about How to "Reduce fluid volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

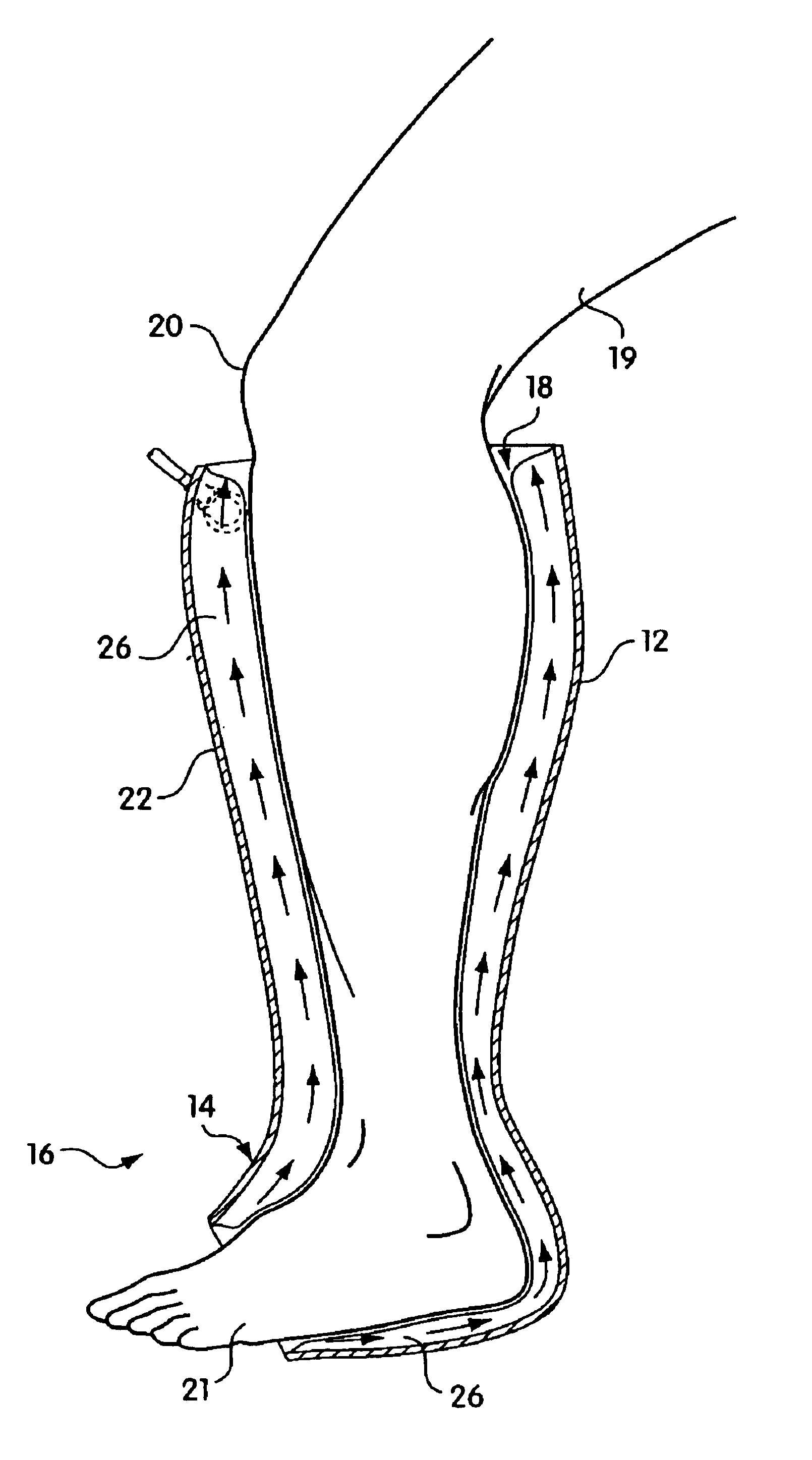

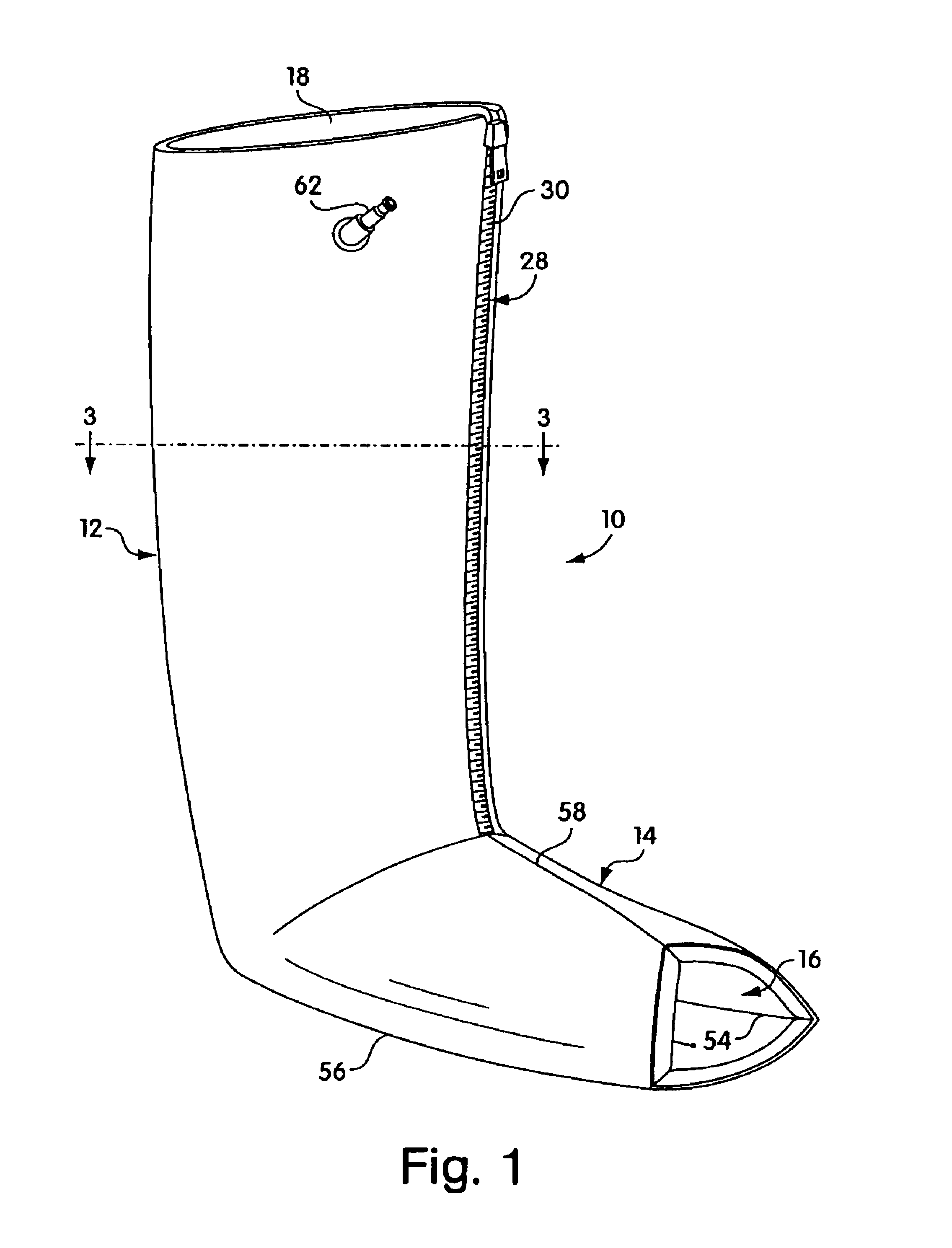

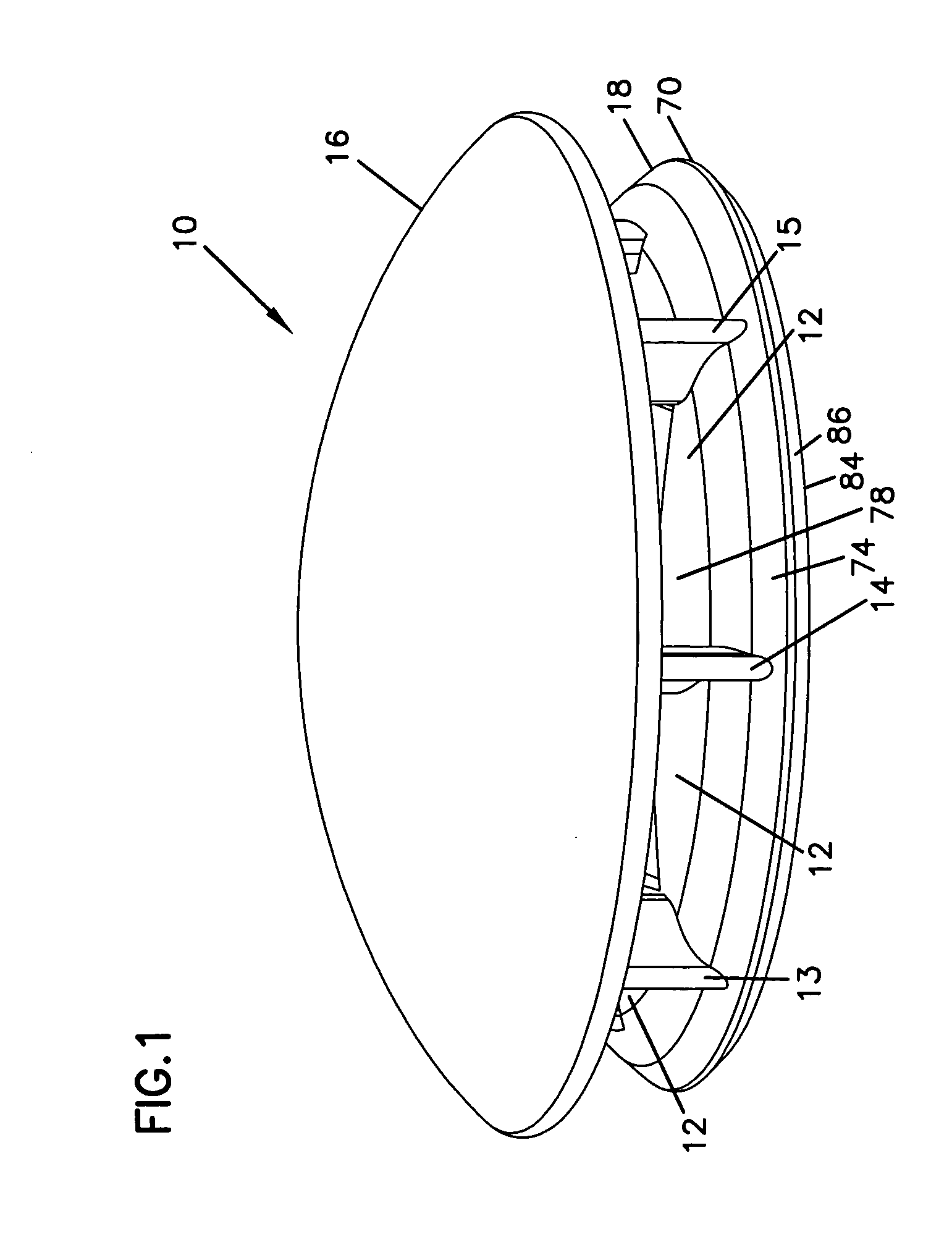

Therapeutic limb covering using hydrostatic pressure

InactiveUS6945944B2Easy to useEasy to wearPneumatic massageRestraining devicesLimb coverHydrostatic pressure

The present invention provides a therapeutic limb covering and an associated method of treating chronic swelling of a limb. The limb covering is uses hydrostatic pressure provided by liquid contained within the covering to apply pressure to the limb. The limb covering comprises a substantially non-distensible flexible outer layer, a distensible flexible inner layer joined together and a liquid tight bladder therebetween. The covering may be adapted for releasable securement about a limb such as an arm or a lower leg and foot of a patient. After placement on the limb, when the bladder is filled with a liquid, such as water, it expands to contact and apply pressure to the limb.

Owner:INCAPPE

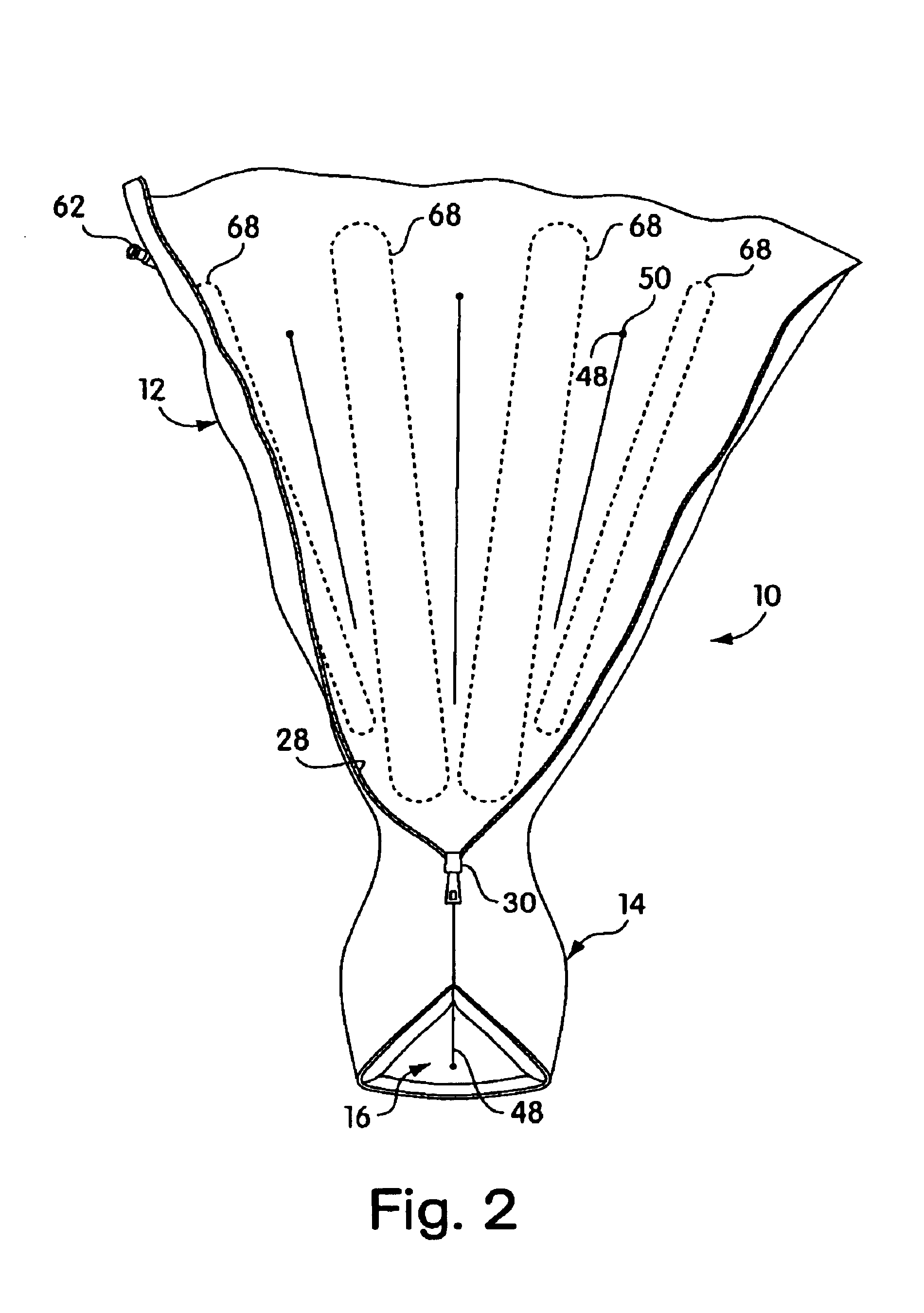

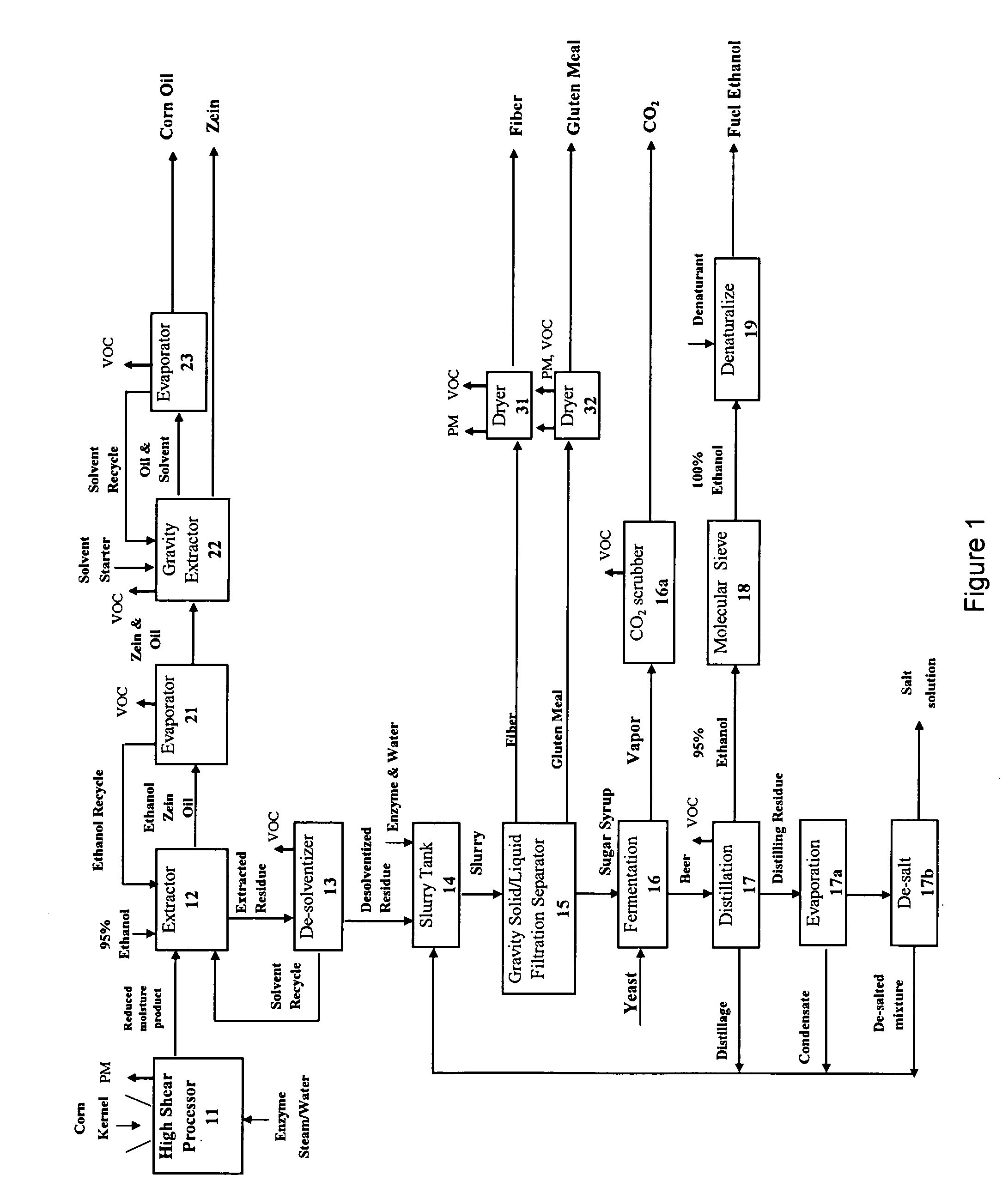

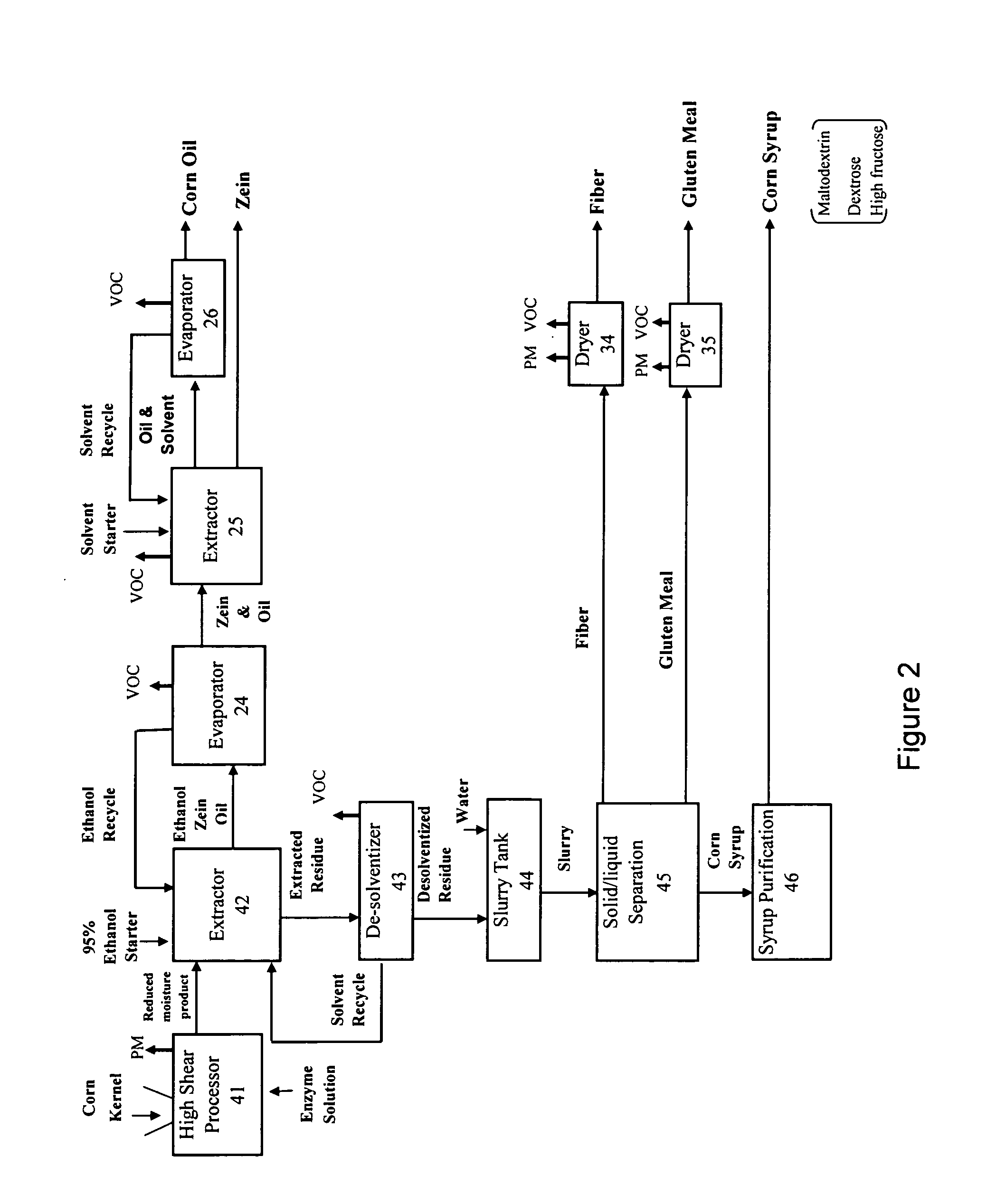

Starchy material processed to produce one or more products comprising starch, ethanol, sugar syrup, oil, protein, fiber, gluten meal, and mixtures thereof

InactiveUS20070014905A1Reduce processIncrease shearProtein composition from eggsConfectioneryFiberFood grade

The invention provides a method and system of processing a starchy material that can advantageously produce ethanol, sugar syrup, or starch as the chief products along with food-grade co-products such as, but not limited to oil, protein, fiber, and gluten meal. The invention can apply such a force to a starchy material that is at a superambient temperature with a high shear processor to mill, mix, and gelatinize some of the starch. A liquefaction enzyme can be introduced into the high shear processor to liquefy the processed product. The moisture content of the processed starchy material can be reduced, which preferably occurs in the high shear processor. Some of the co-products such as the oil, protein, fiber and gluten meal can be separated prior to the sugar syrup purification or ethanol fermentation steps.

Owner:PURDUE RES FOUND INC

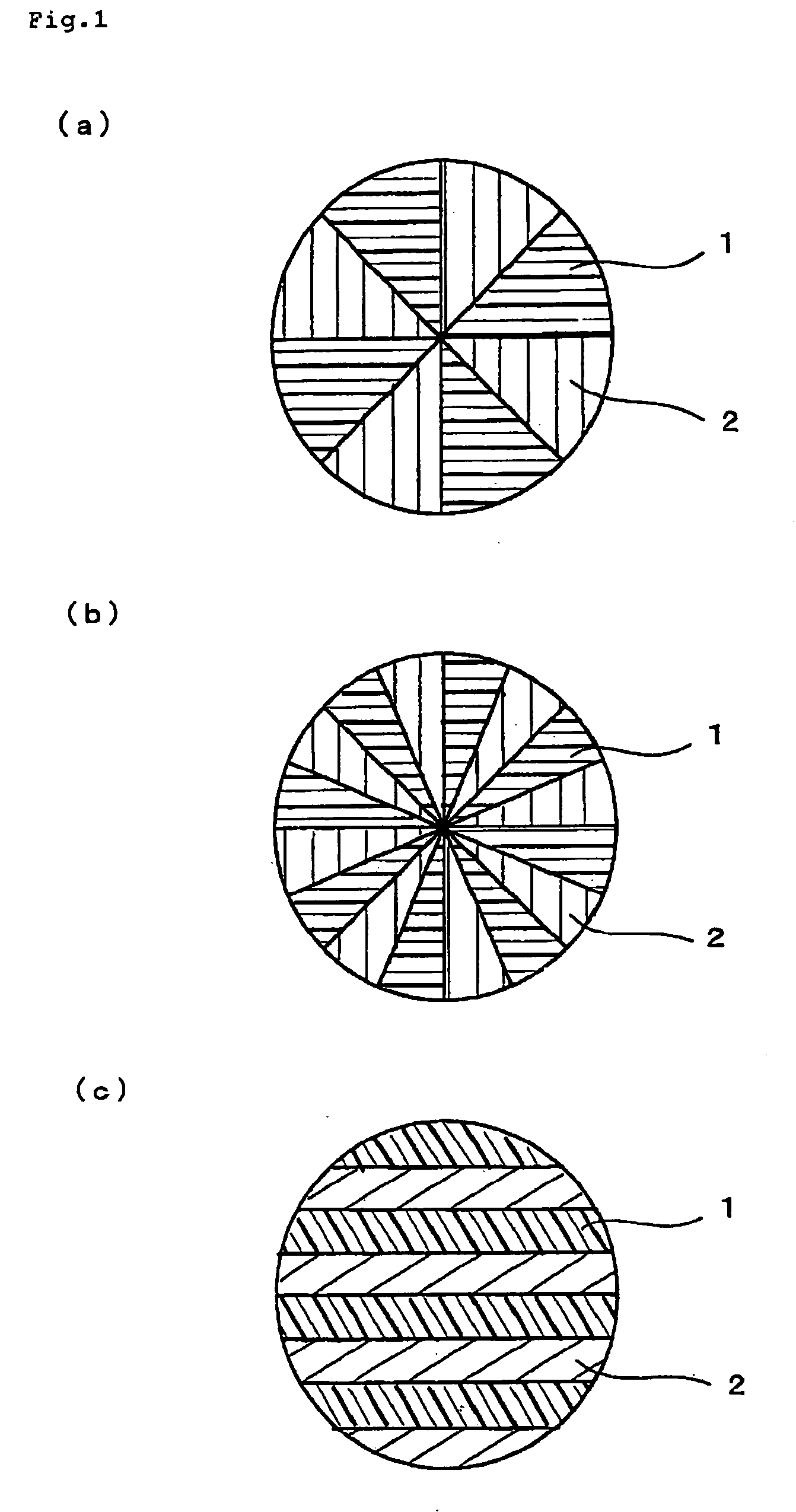

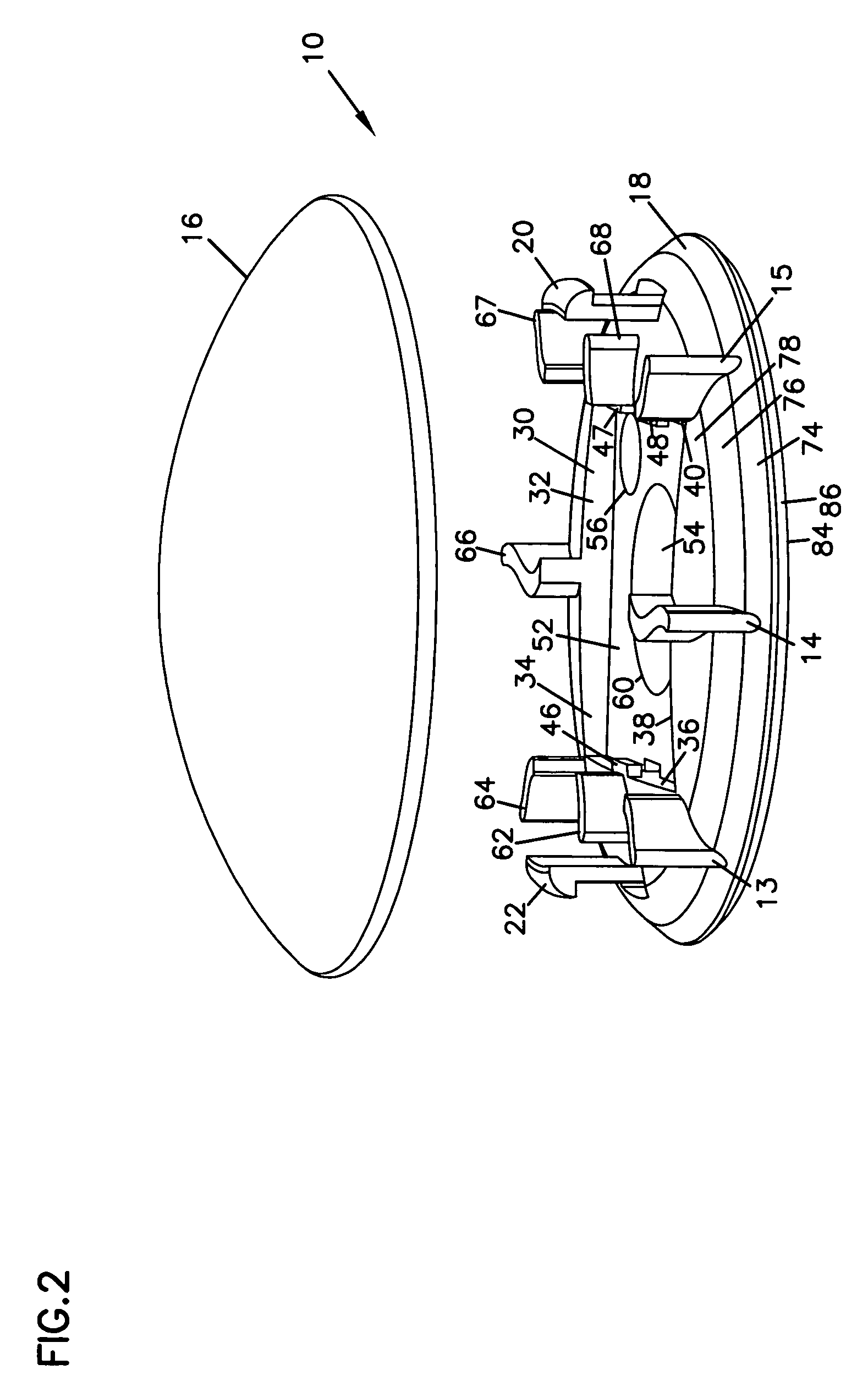

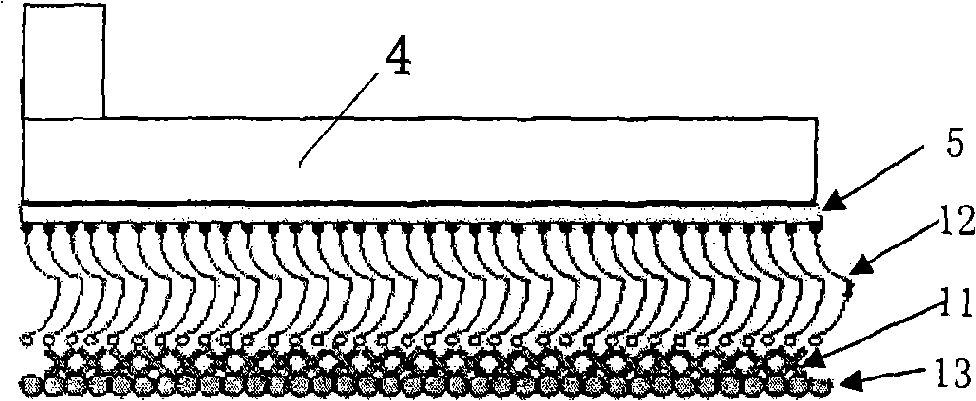

Wiping sheet

InactiveUS20060009106A1Improve wiping effectPromote stratificationCarpet cleanersFloor cleanersNonwoven fabricFiber structure

A wiping sheet is provided, which presents excellent in handling during wiping, high wiping ability for greasy dirt, and less liquid remains on an object after wiping. A wiping sheet having a fiber structure (such as a woven fabric, a knitted fabric and a nonwoven) is obtained, which includes an ultrafine fiber layer containing ultrafine fibers having a fineness of at most 0.9 dtex which result from at least two types of ultrafine fiber-generating conjugate fibers, at least one conjugate fiber giving ultrafine fibers containing a modified vinyl alcohol resin, and the other conjugate fibers giving ultrafine fibers containing another resin(s). The ultrafine fibers can be obtained by a first splittable conjugate fiber including a component containing the modified vinyl alcohol resin and a second splittable conjugate fiber composed of components of other resins. In the ultrafine fiber layer, the fibers are preferably bonded by thermoadhesive resin-containing ultrafine fibers.

Owner:DAIWABO HLDG +1

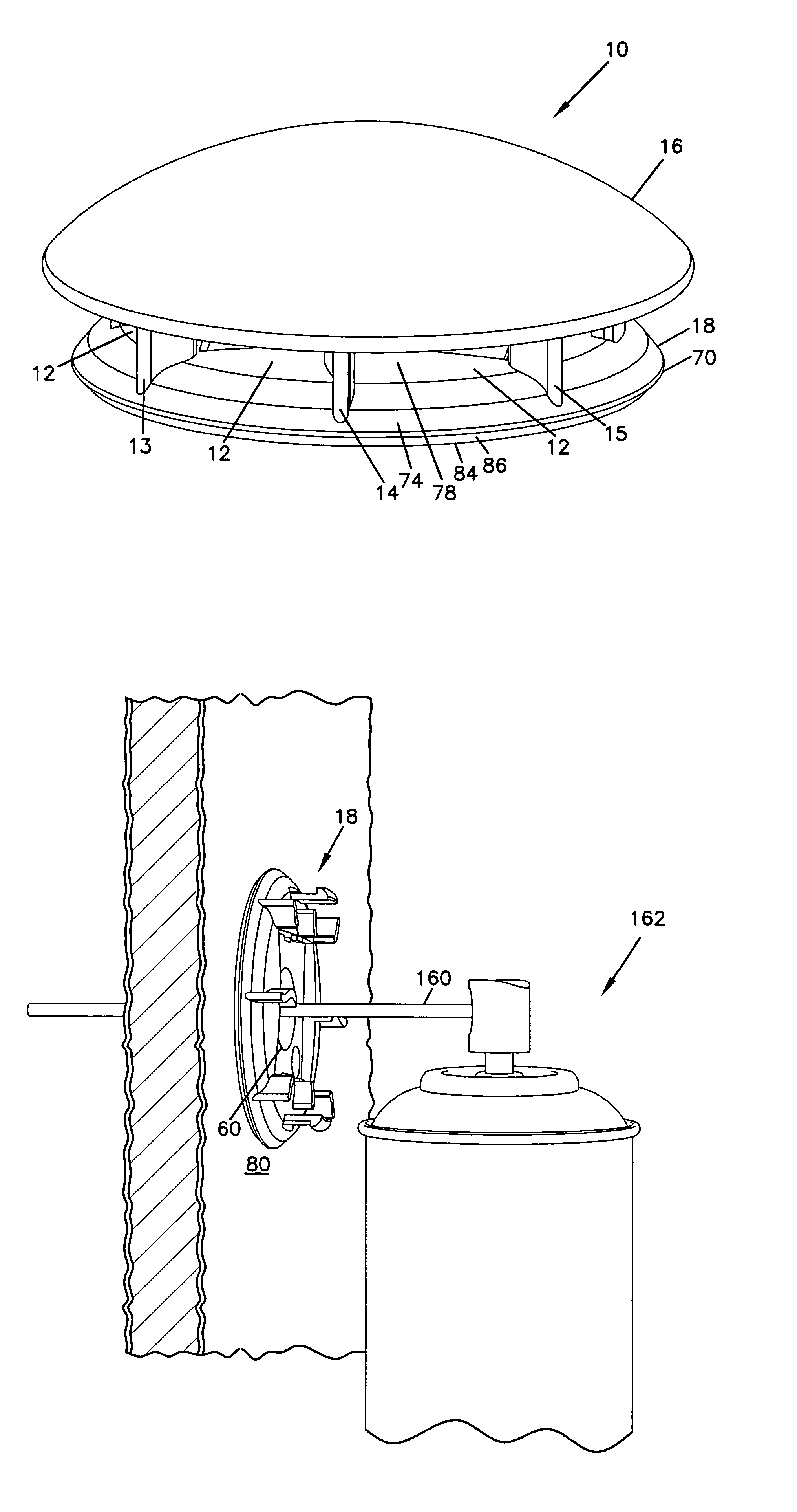

Insect suppression station

An insect station for luring insects, baiting insects, trapping insects, monitoring insects or any combination of these functions includes a cover that can be moved to provide access to selected insect suppression devices, such as glueboards or baited pads. The insect station may have two changeable pad areas situated facing each other to provide a compact design. In addition, a base portion of the station may have a wall access opening to facilitate applying insecticide behind a wall. The insect station of the present invention may be used with any combination of attractant pads, bait, and glueboards, as well as many other insect suppression devices.

Owner:ECOLAB USA INC

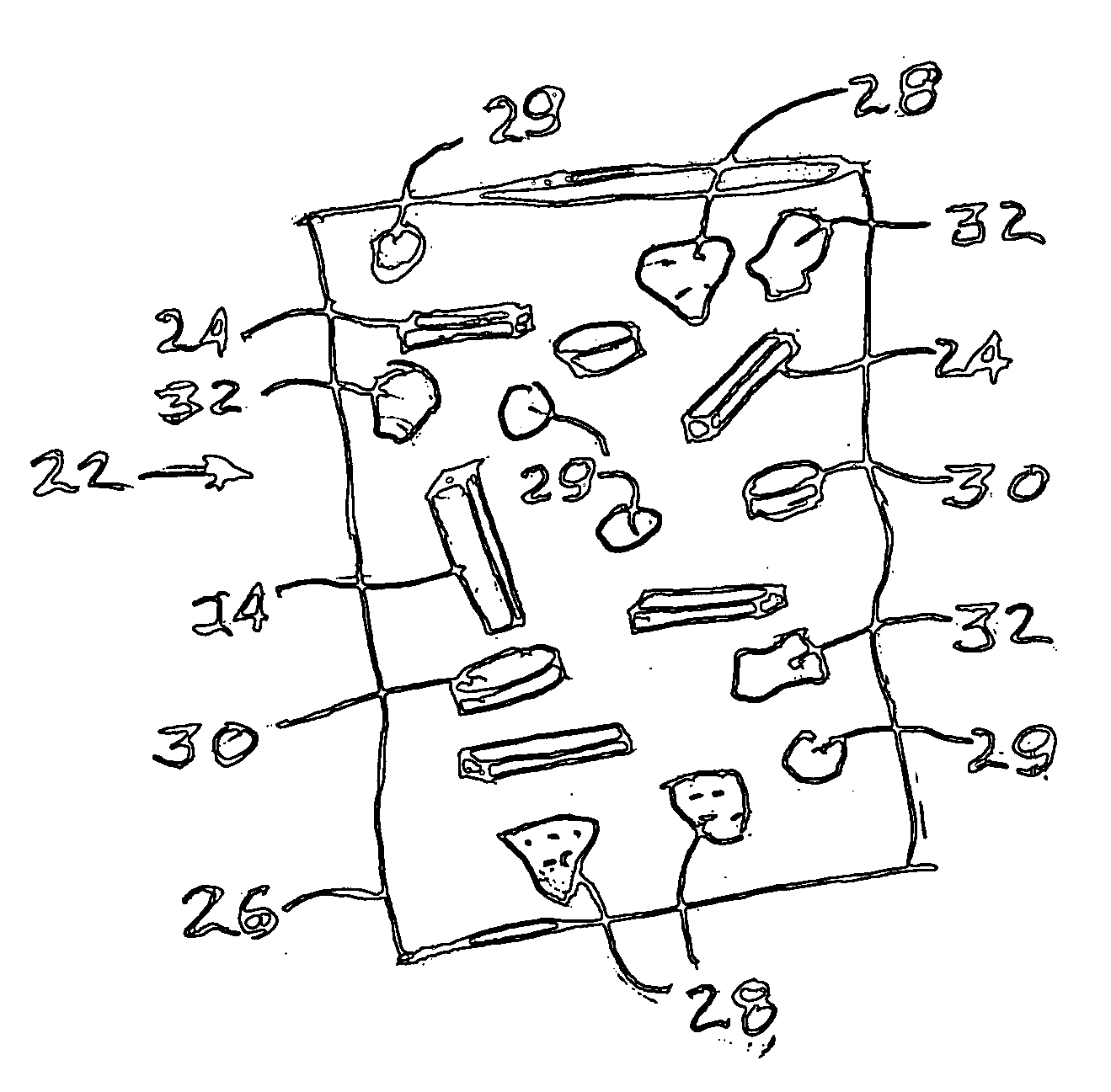

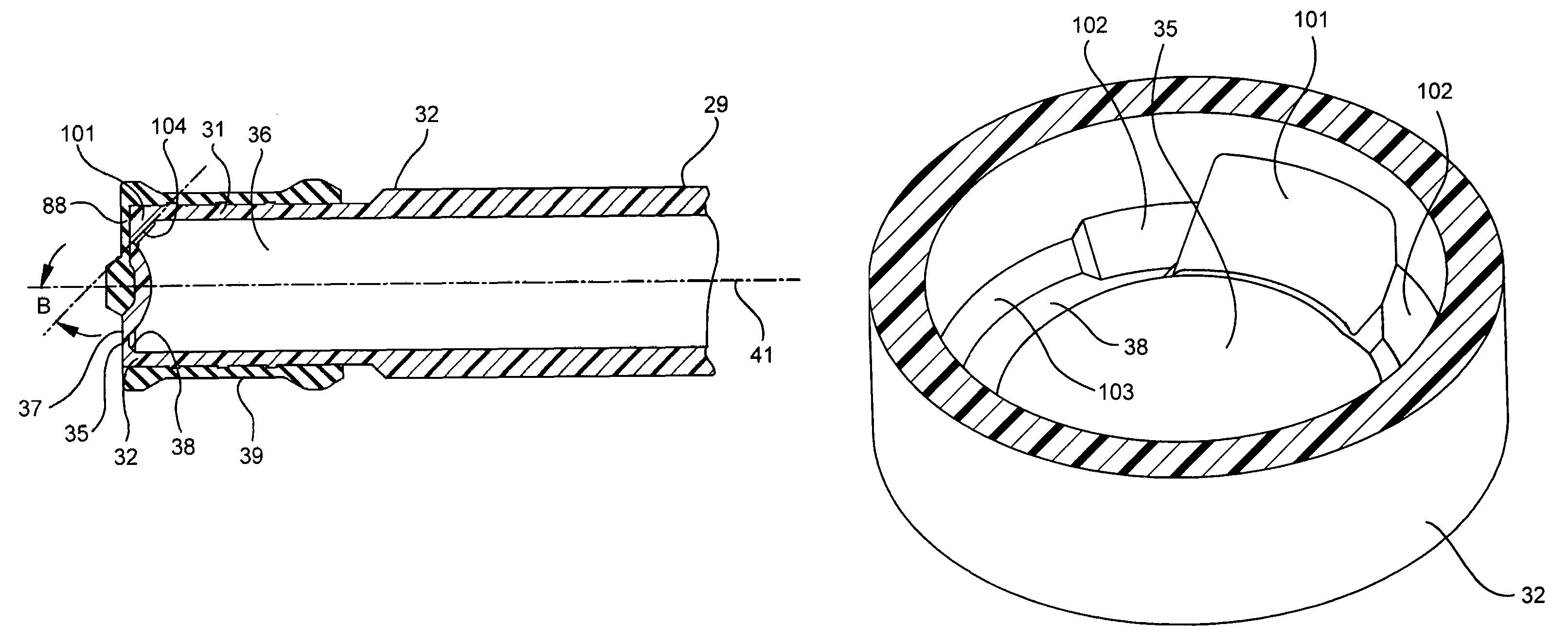

Reduced exothermic bone replacement cement

InactiveUS7138442B2High and substantially necrotic temperatureReduce amountImpression capsSurgical adhesivesBone replacementBone cement

A bone cement having a dry component including a large constituent and a small constituent. The small constituent fills a substantial volume of the interstitial spaces between the particles of the large constituent. Therefore, only a second or minor interstitial space is left remaining between the individual particles of the small constituent and the particles of the small constituent and the particles of the large constituent. Therefore, a reduced amount of a polymerizable component need be added to the dry component to form a bone cement. Such a bone cement formulation decreases the exothermic temperature of the bone cement and decreases the possibility of tissue necrosis in the implantation area.

Owner:BIOMET MFG CORP

Male member

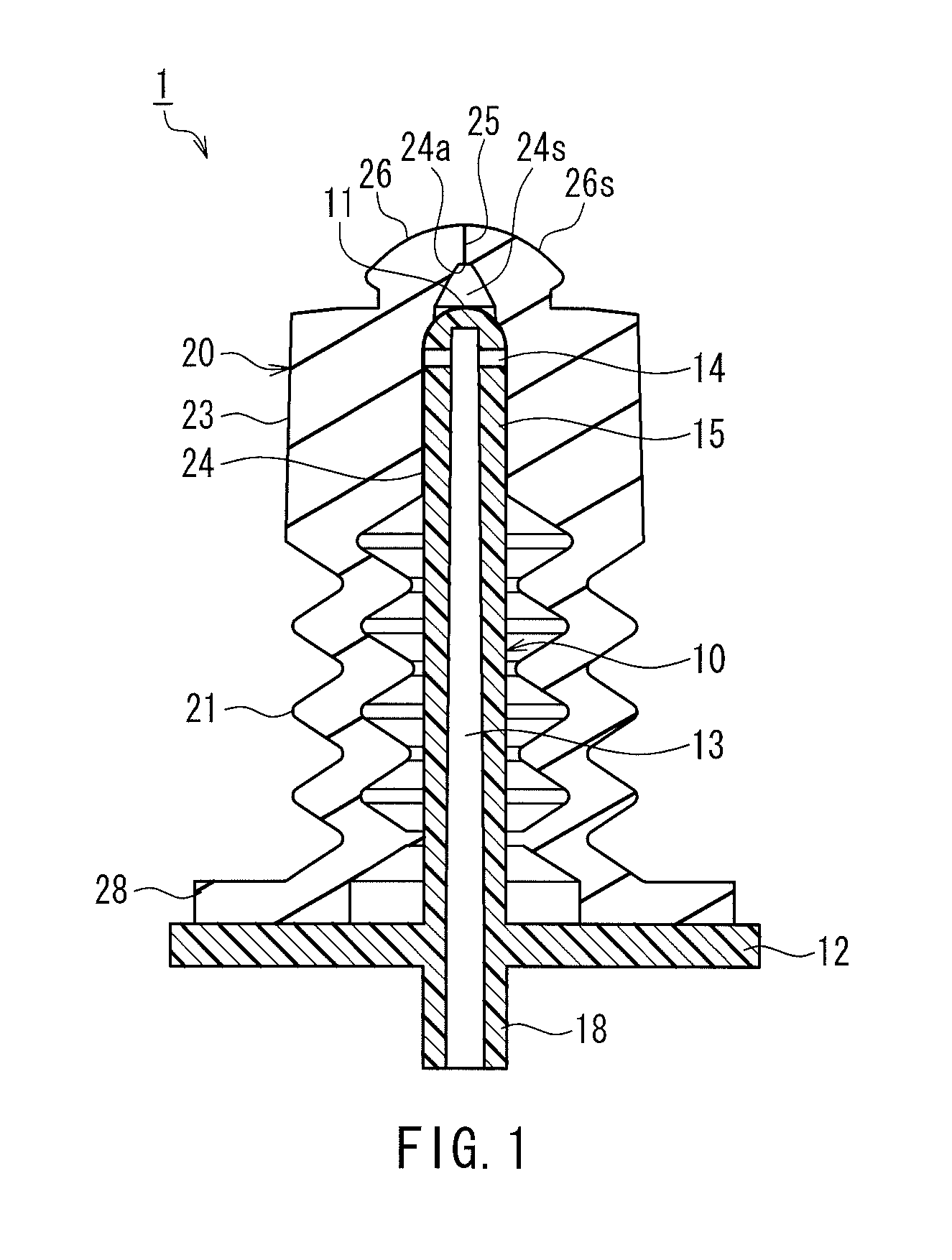

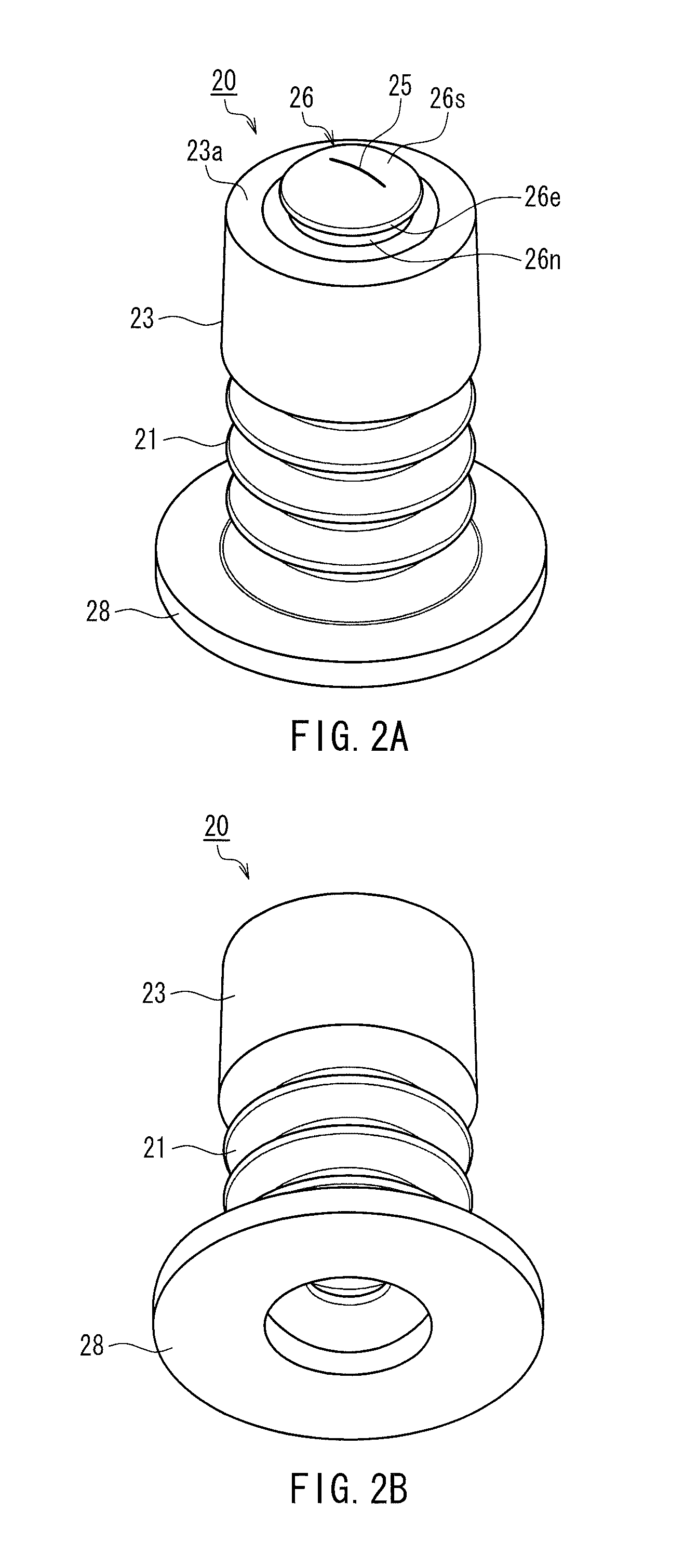

ActiveUS8974425B2Prevent liquid substance leakageIncrease capacityInfusion devicesSurgeryEngineeringMechanical engineering

A male member (1) includes a tubular member (10) and a cover (20) covering at least a tip (11) of the tubular member. A lateral hole (14) that communicates with a flow path (13) is formed in an outer peripheral surface of the tubular member. The cover includes an outer peripheral wall (21) that can be deformed elastically by compression and a head part (23) that is provided at one end of the outer peripheral wall. The head part includes an interior cavity (24) into which the tubular member is inserted, and a slit (25) is formed in an innermost part (24a) of the interior cavity. In a state where the outer peripheral wall is not deformed by compression, an inner peripheral surface of the interior cavity contacts closely with the outer peripheral surface of the tubular member so as to block the lateral hole, and the tip of the tubular member and the innermost part of the interior cavity are spaced apart from each other. Thereby, it is possible to reduce an amount of a liquid substance adhering to outer surfaces of the cover and a female member after separation from the female member.

Owner:JMS CO LTD

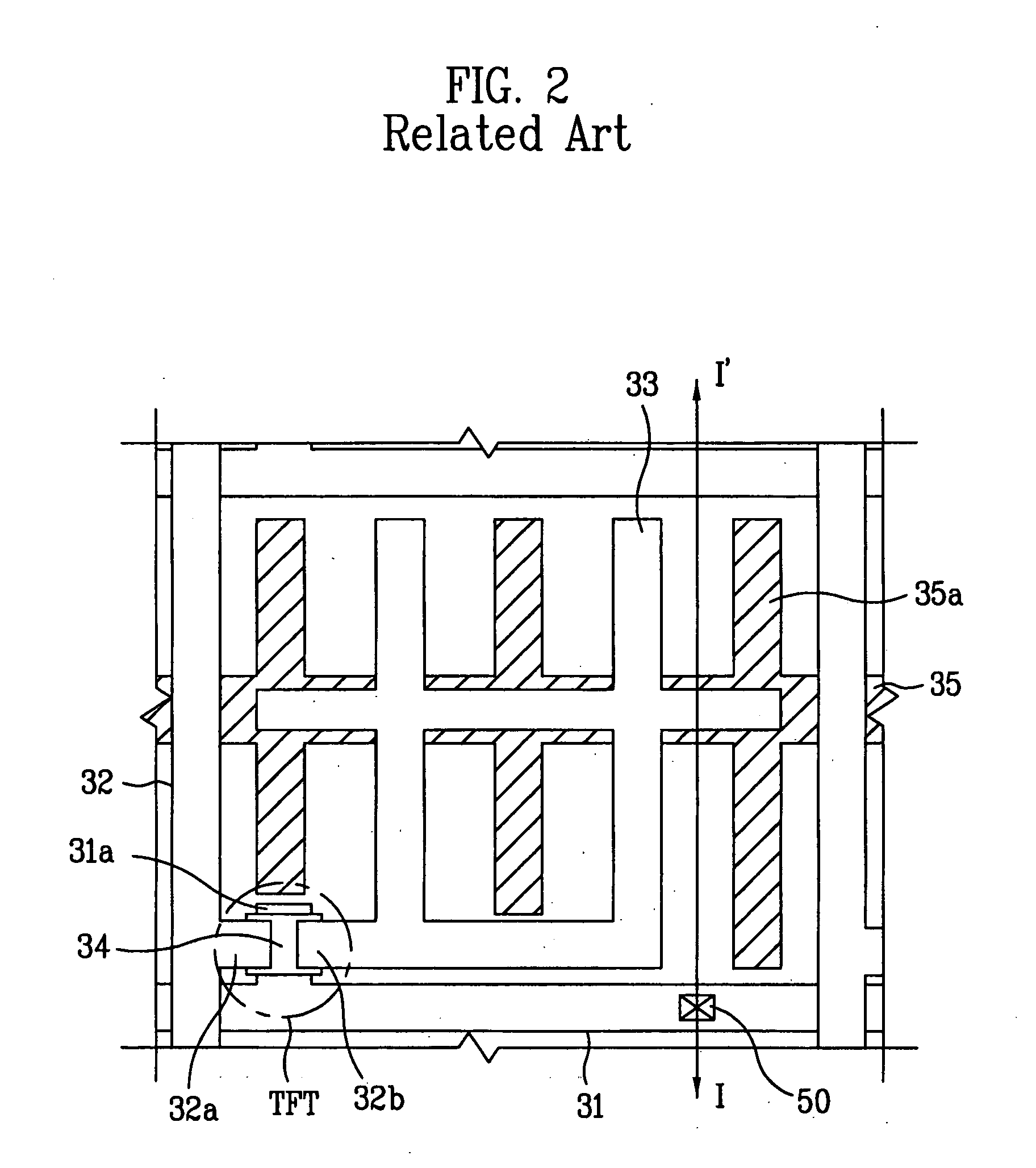

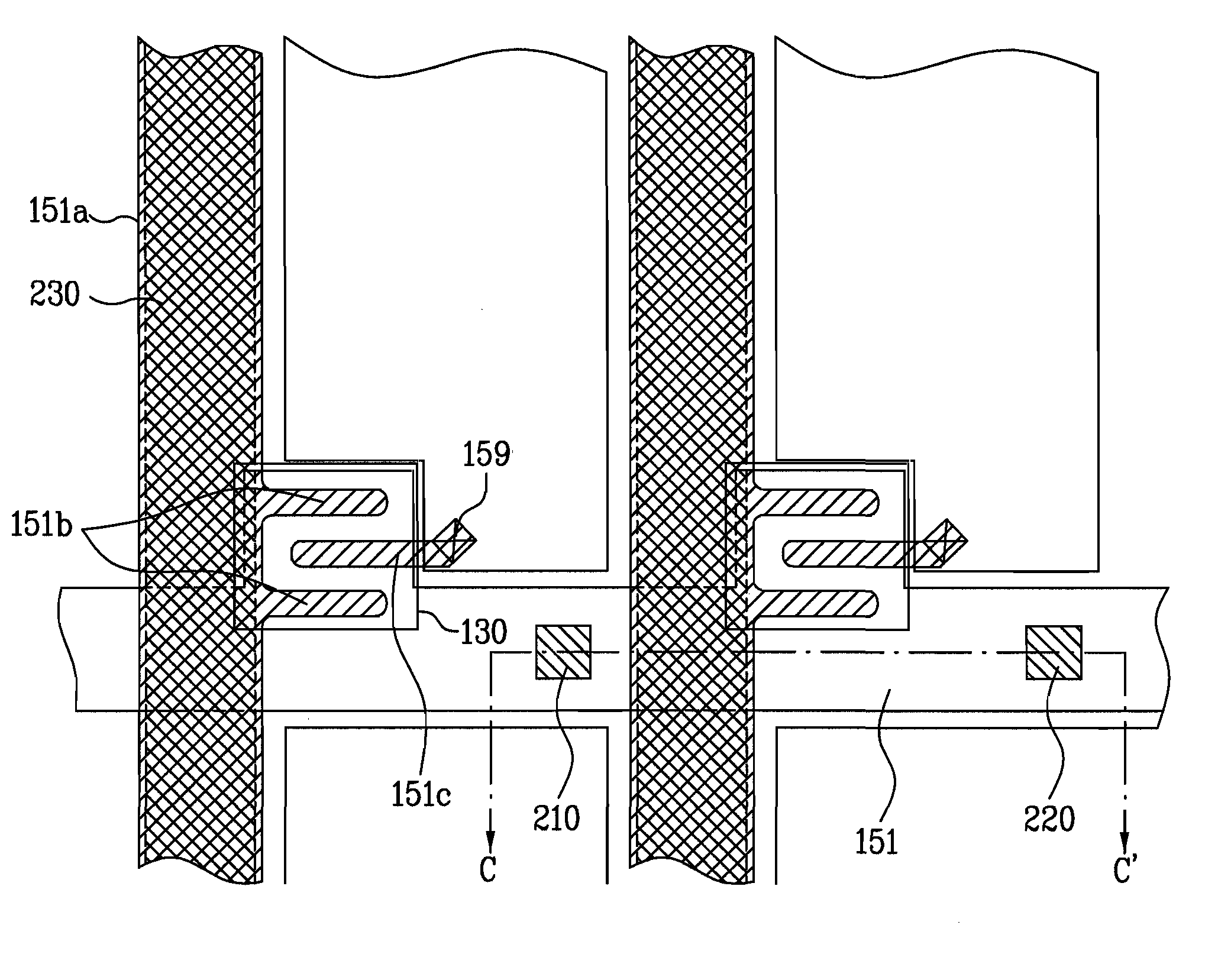

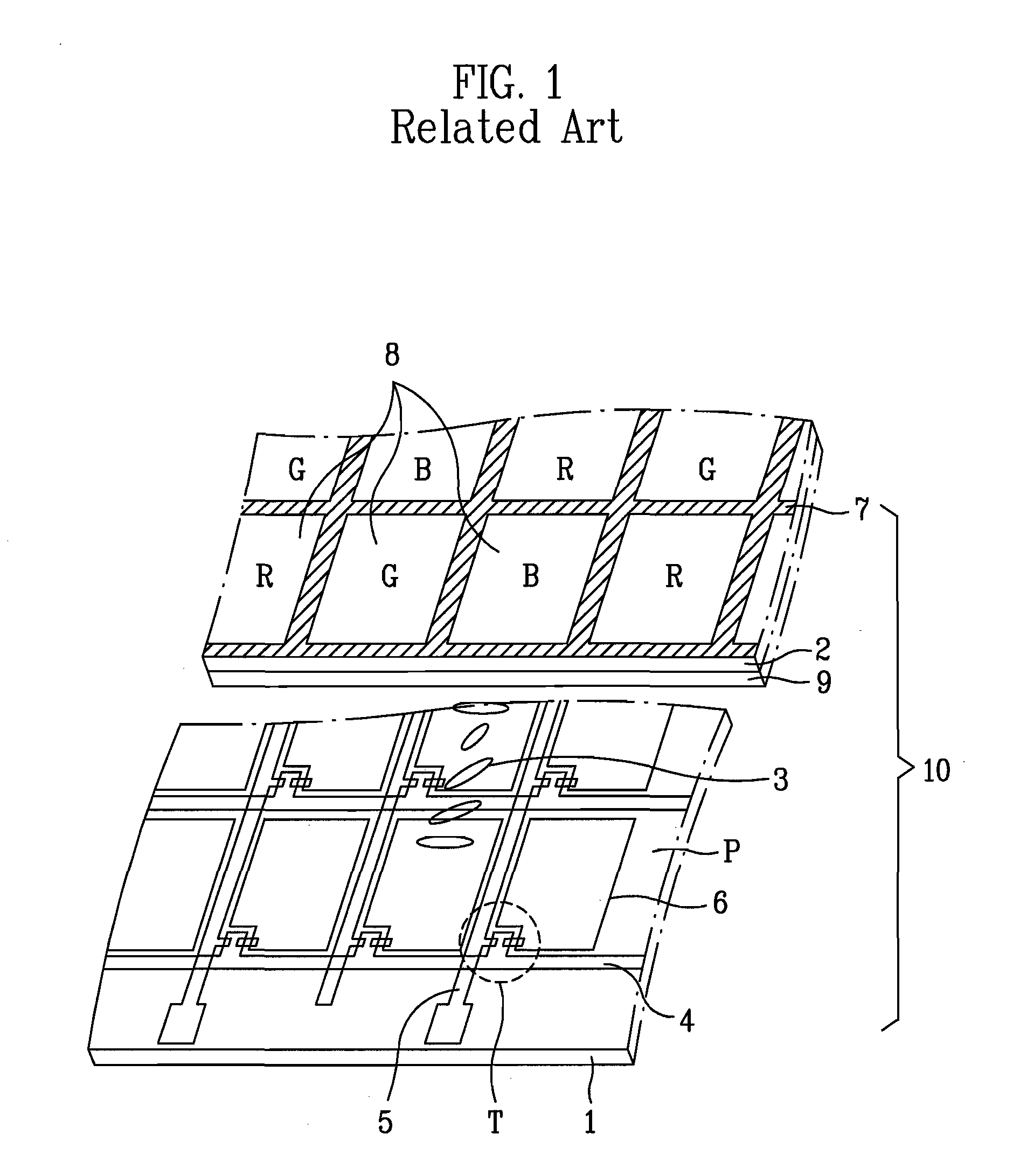

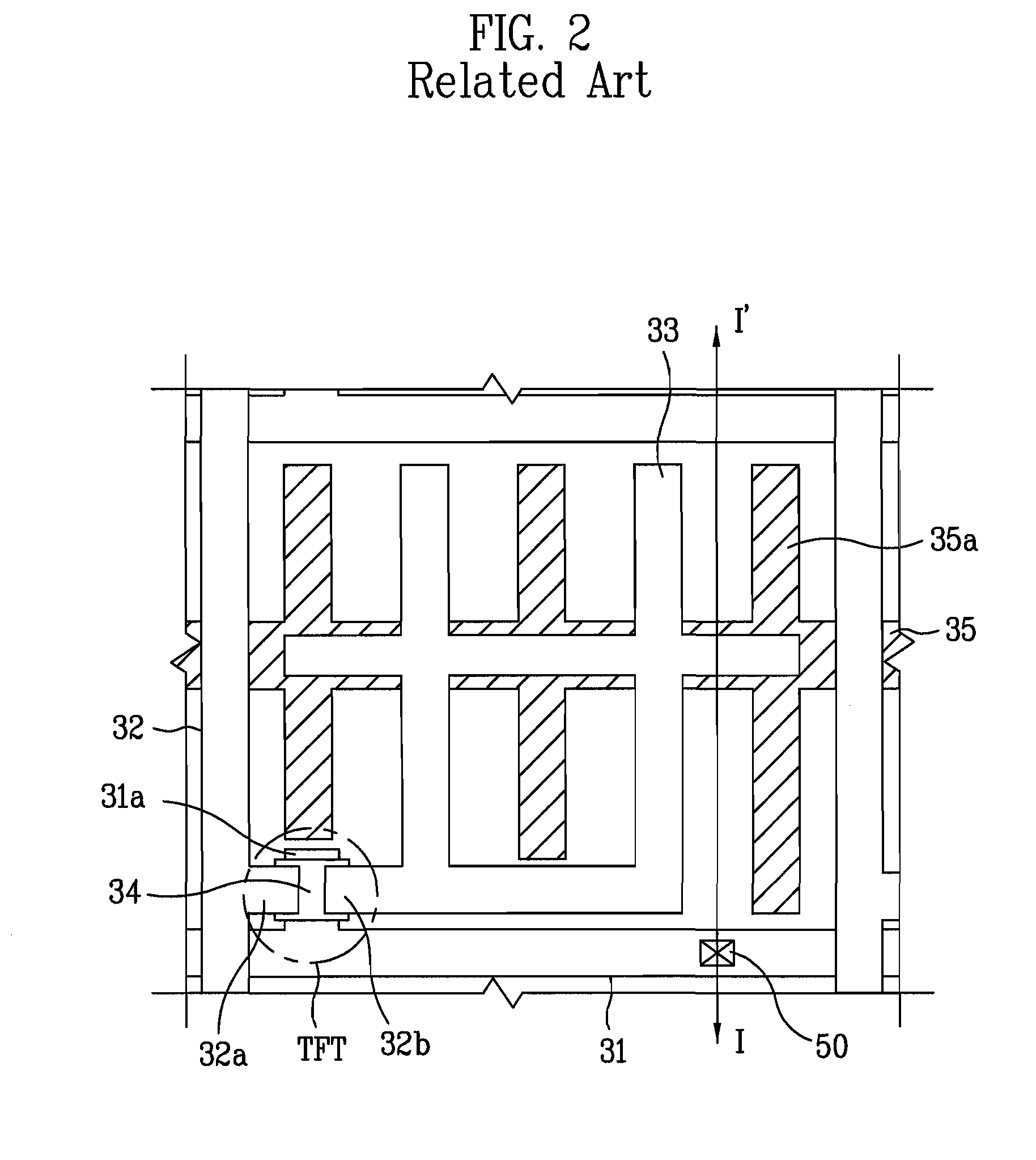

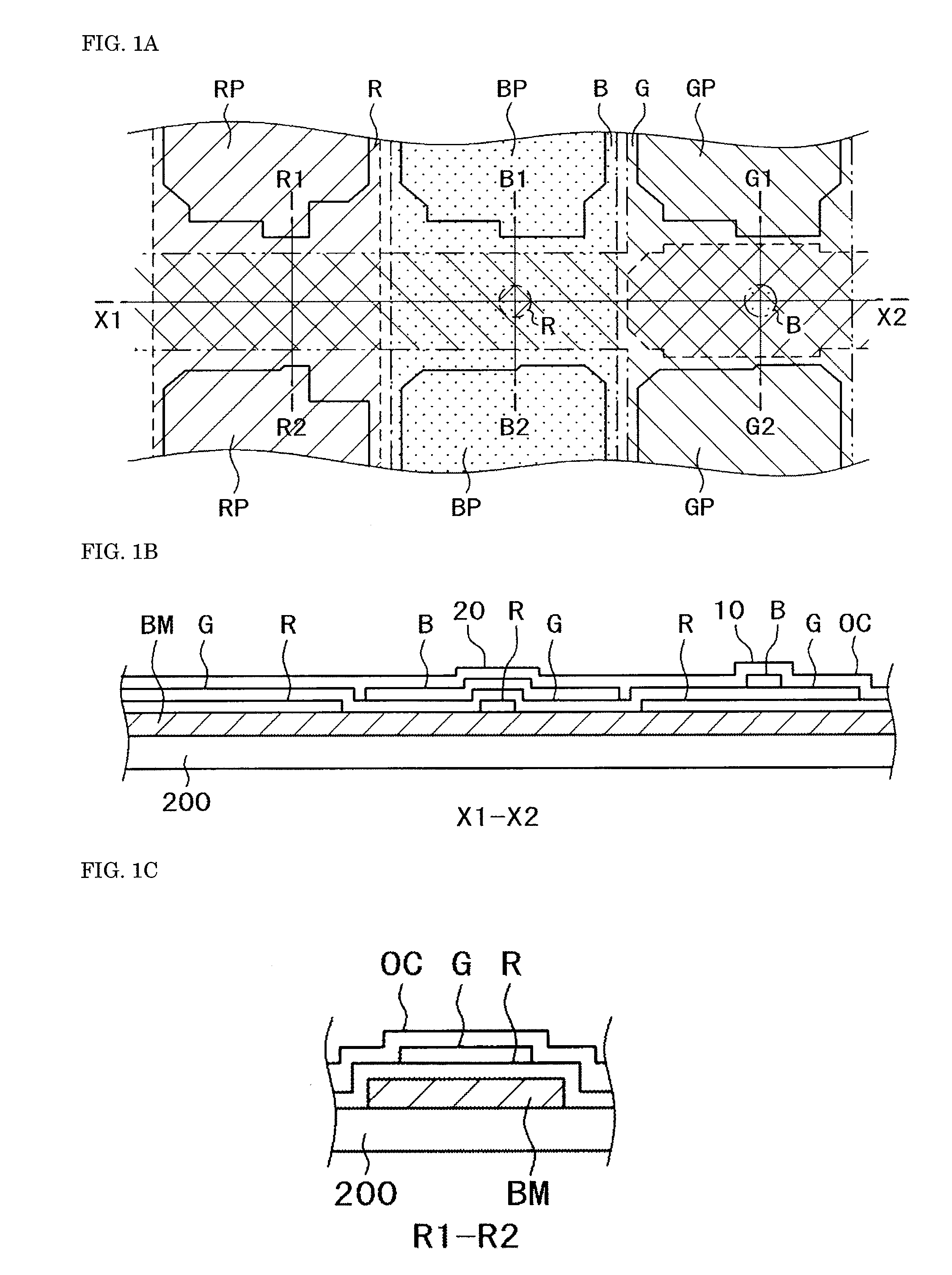

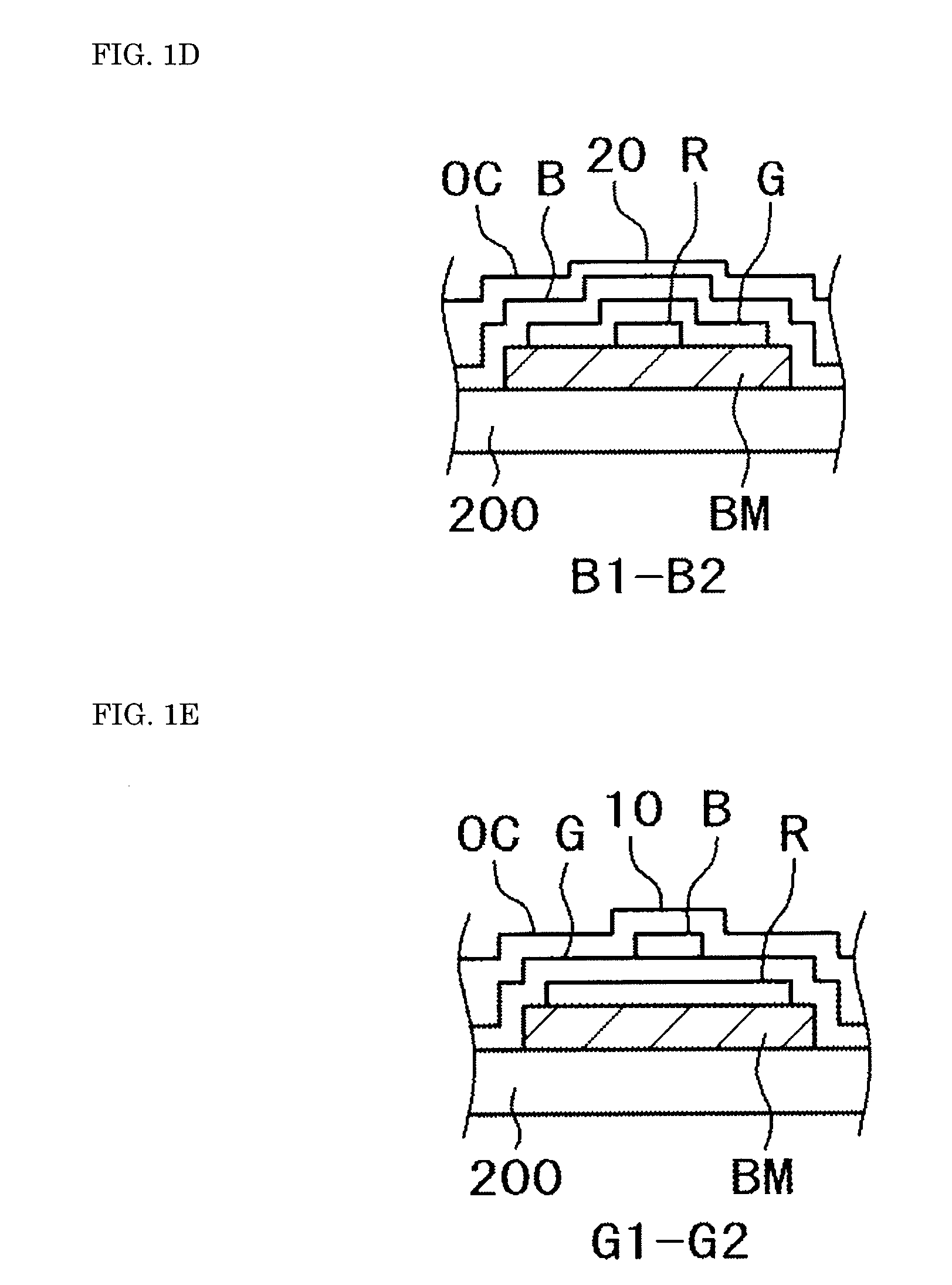

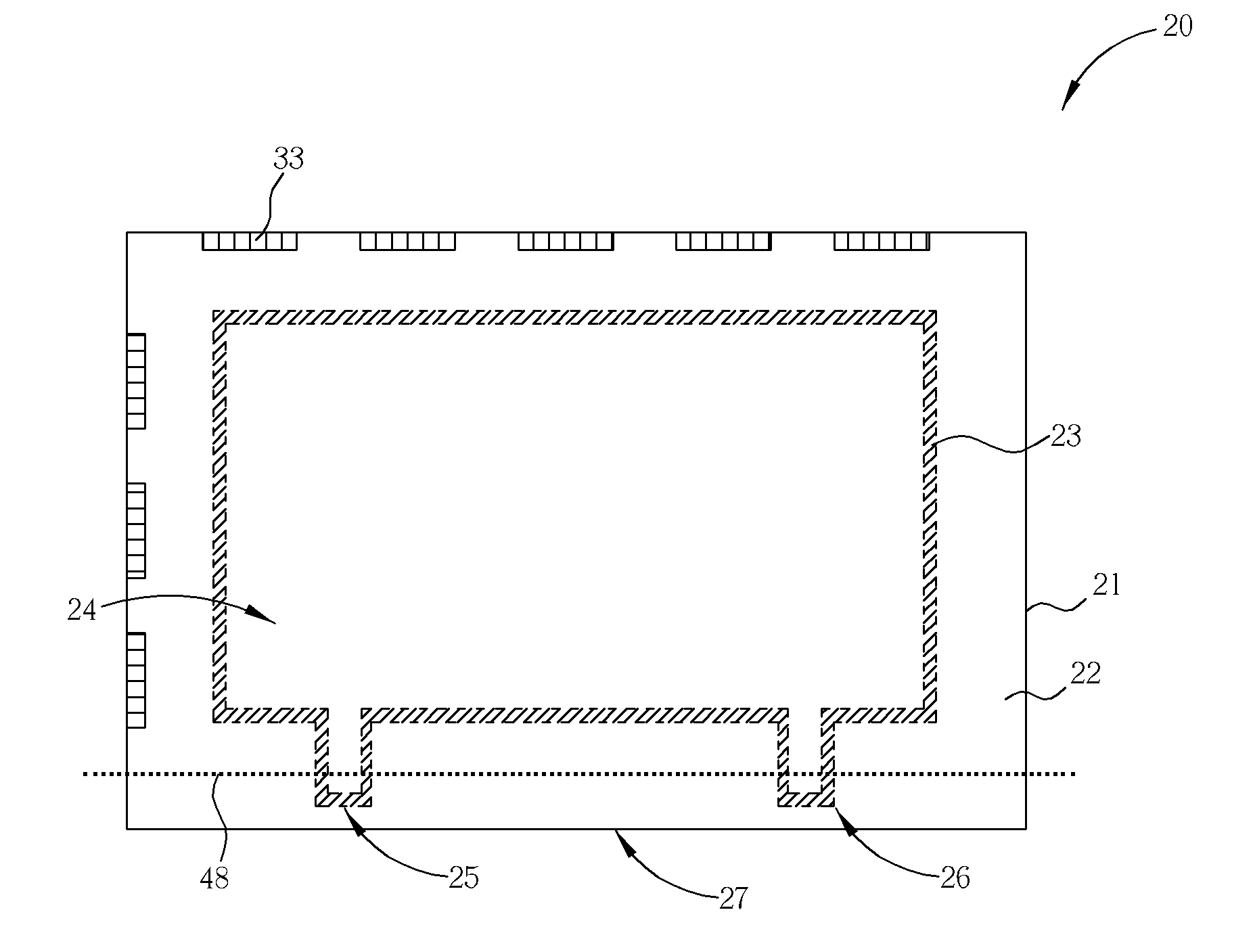

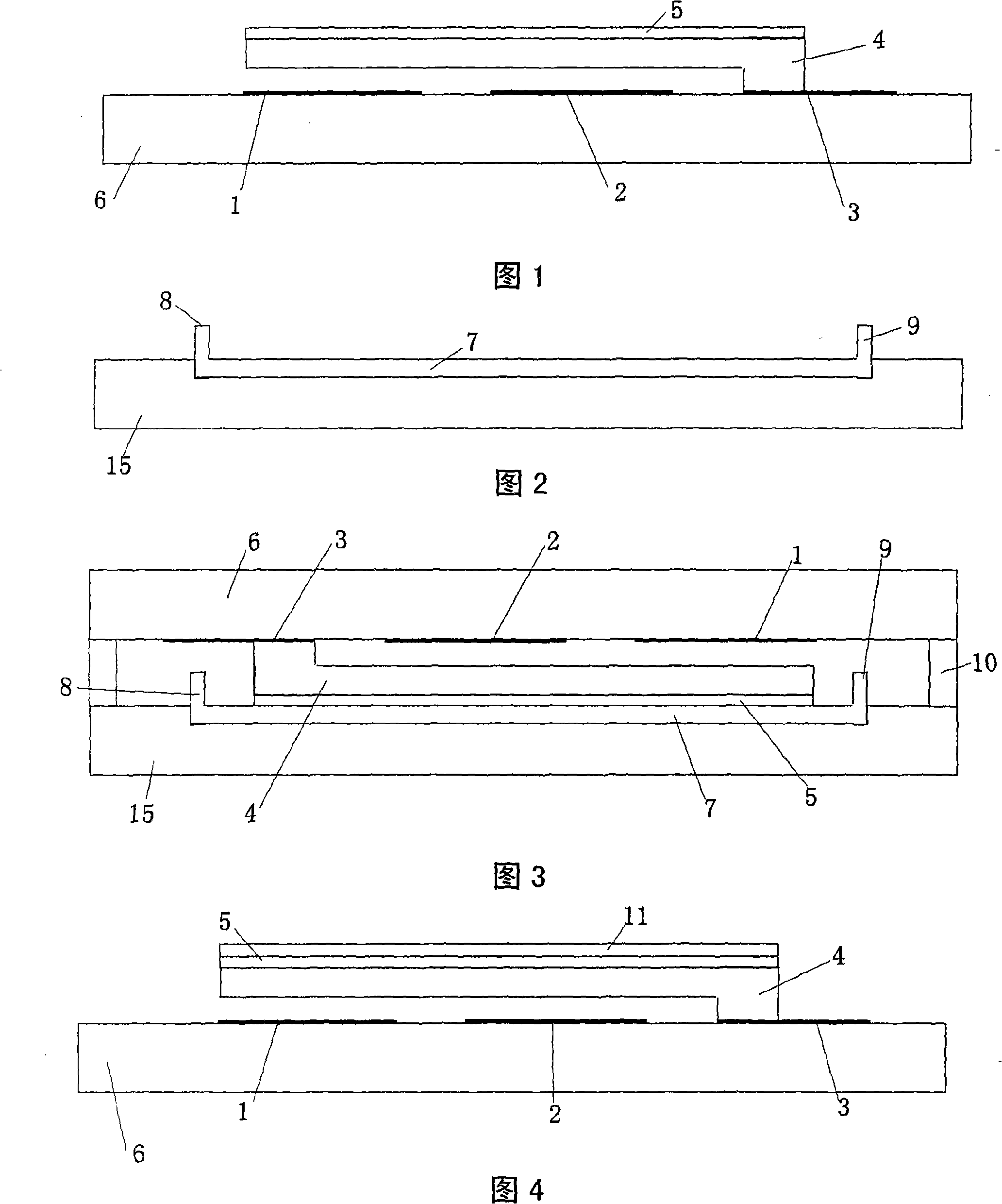

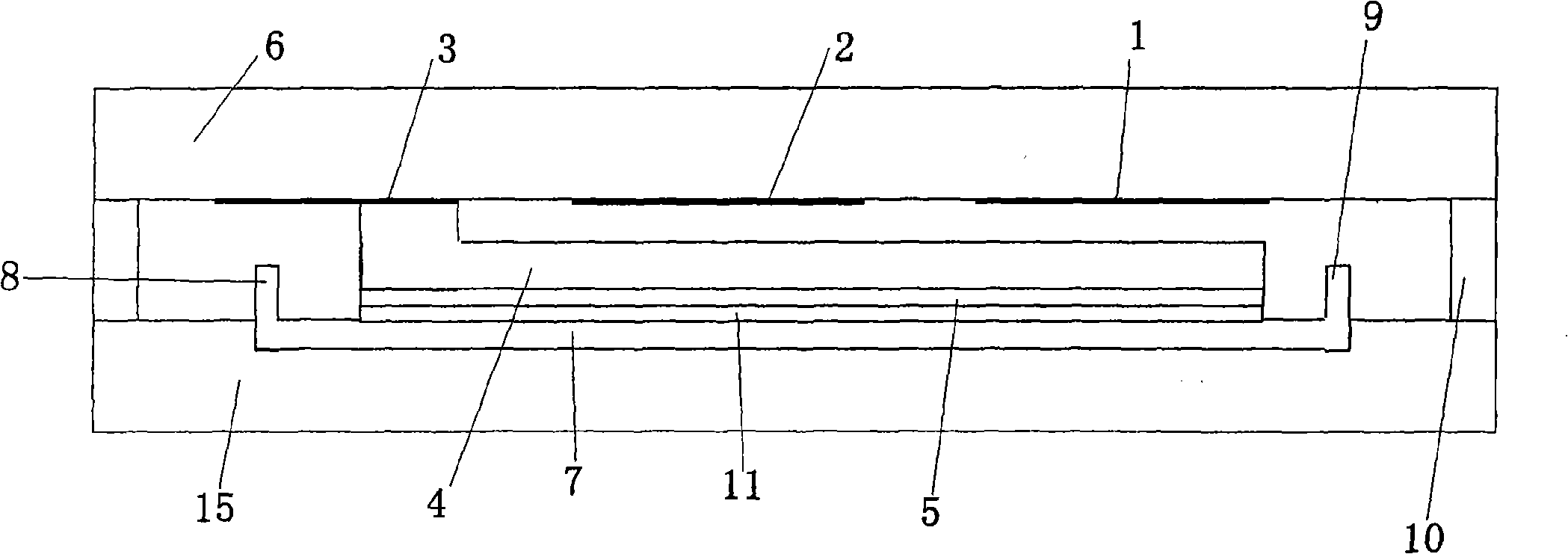

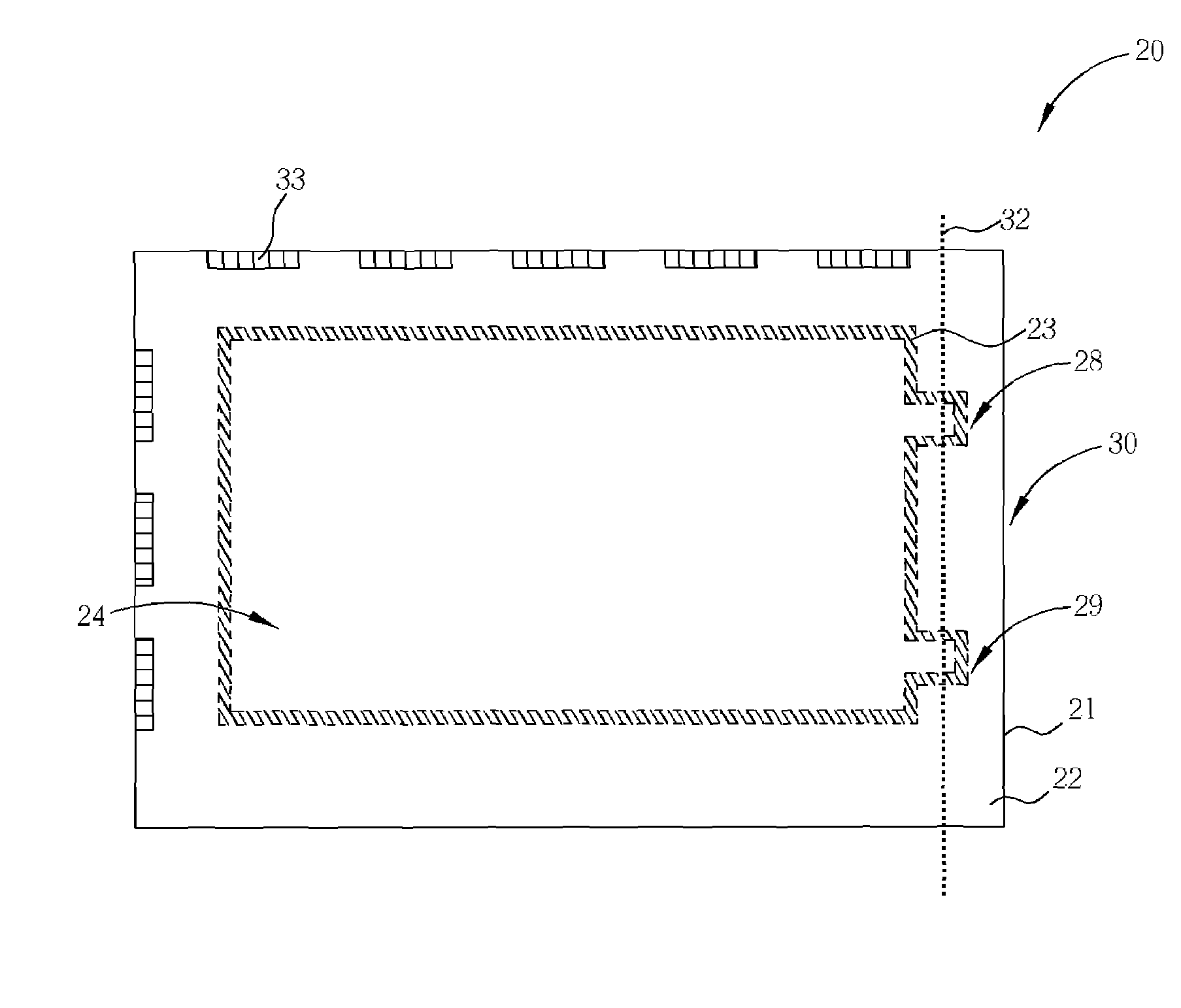

Liquid crystal display device and method for fabricating the same

ActiveUS20090015780A1Reduce fluid volumeReduce amountNon-linear opticsLiquid-crystal displayEngineering

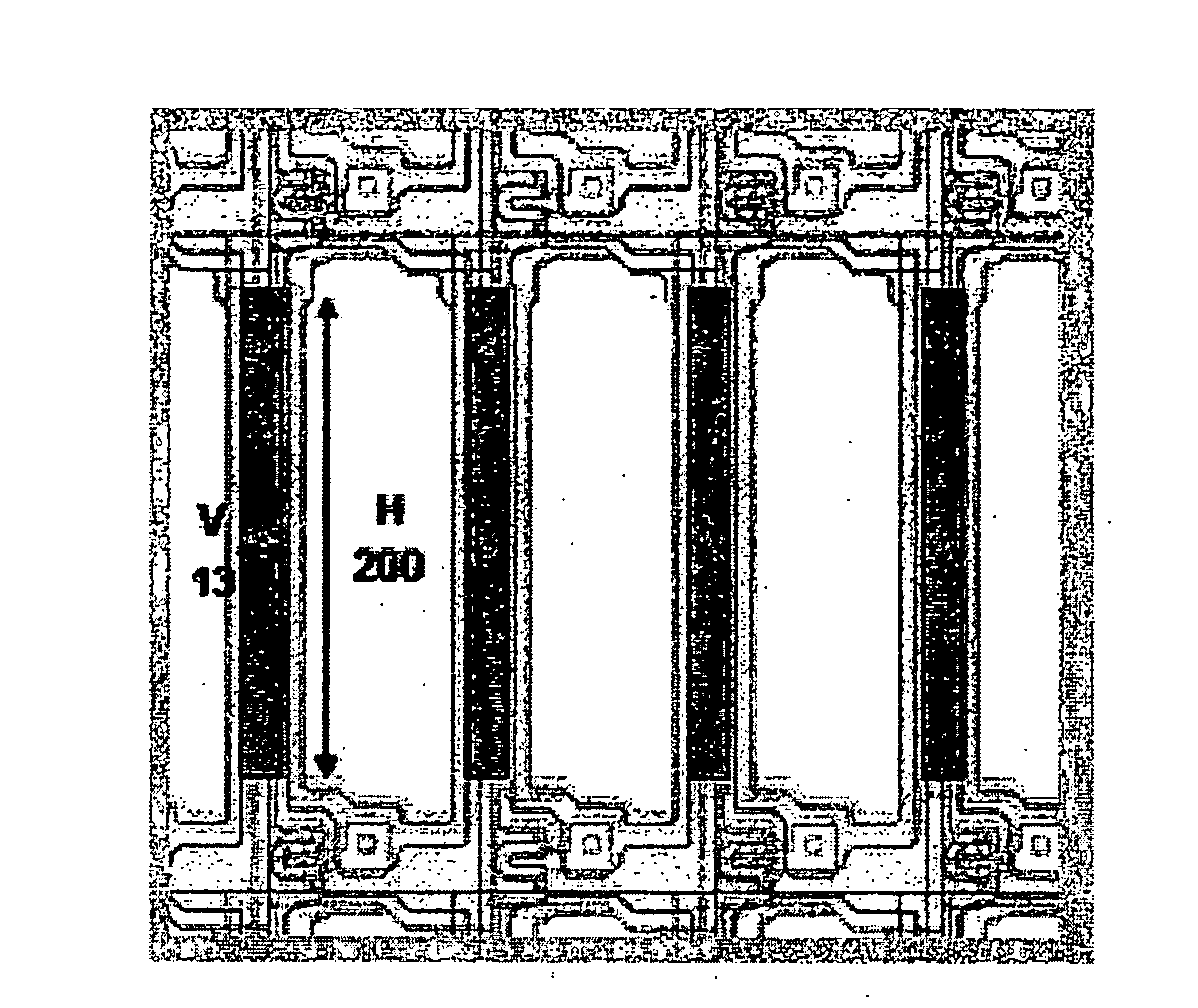

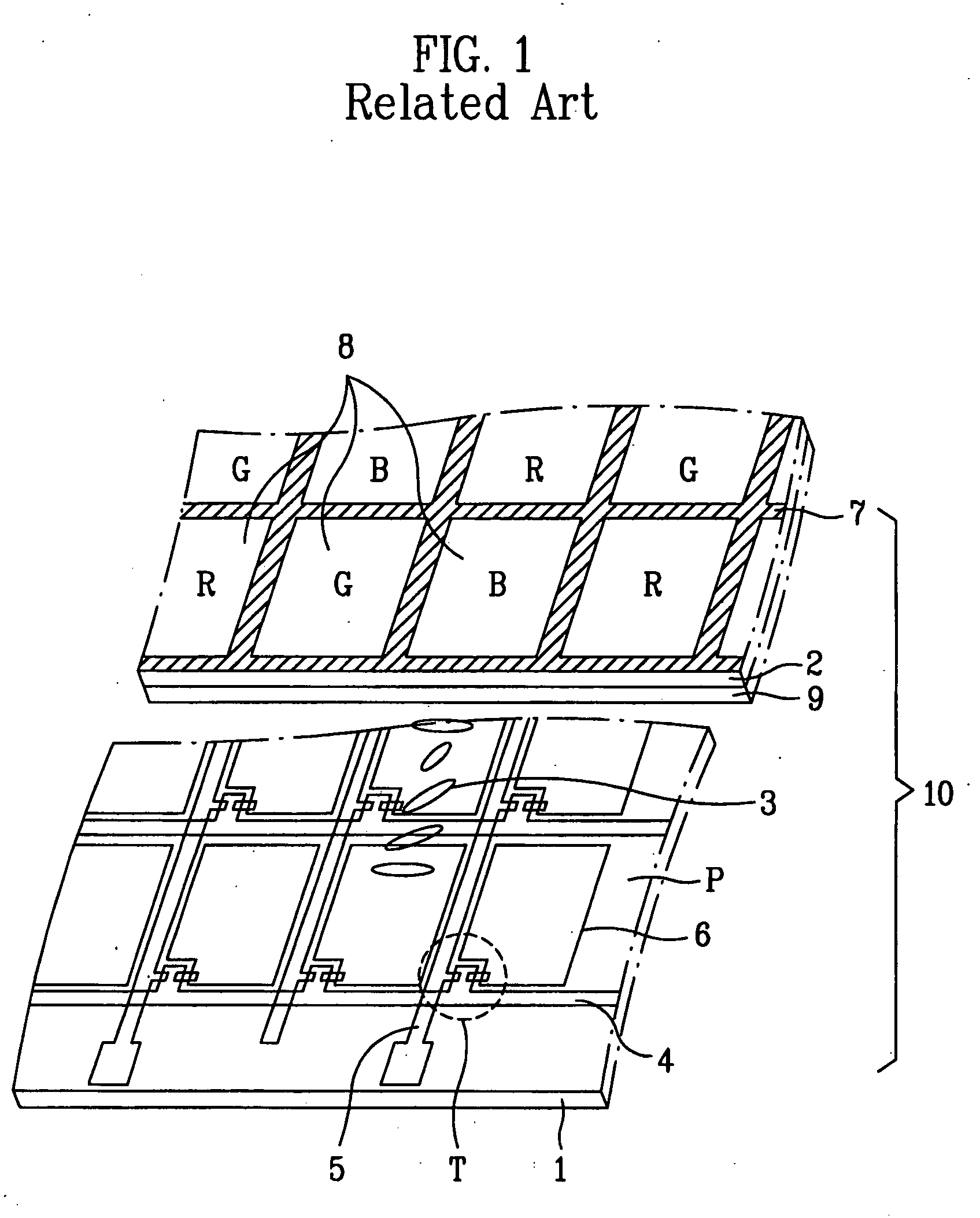

A liquid crystal display device includes first and second substrates facing each other; gate lines and data lines formed on the first substrate such that the gate lines and the data lines intersect each other to define pixel regions; thin film transistors formed at respective intersections of the gate lines and the data lines; a black matrix layer formed on the second substrate such that the black matrix layer corresponds to a region other than the pixel regions; color filter layers extending in an extension direction of the data lines in respective pixel regions; a liquid crystal layer interposed between the first and second substrates; first column spacers formed on one of the first and second substrates such that each first column spacer corresponds to an associated one of the gate lines or to a channel region of an associated one of the thin film transistors to maintain a cell gap between the first-and second substrate; and spacer patterns formed on one of the first and second substrates such that each spacer pattern corresponds to at least one of an associated one of the gate lines and an associated one of the data lines, thereby forming a first gap between the spacer pattern and the other substrate facing the spacer pattern, and reducing an amount of liquid crystals filled between the first and second substrates.

Owner:LG DISPLAY CO LTD

Liquid crystal display device and method for fabricating the same

InactiveUS20100103364A1Reduce amountAvoid generatingNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes first and second substrates facing each other; gate lines and data lines formed on the first substrate such that the gate lines and the data lines intersect each other to define pixel regions; thin film transistors formed at respective intersections of the gate lines and the data lines; a black matrix layer formed on the second substrate such that the black matrix layer corresponds to a region other than the pixel regions; color filter layers extending in an extension direction of the data lines in respective pixel regions; a liquid crystal layer interposed between the first and second substrates; first column spacers formed on one of the first and second substrates such that each first column spacer corresponds to an associated one of the gate lines or to a channel region of an associated one of the thin film transistors to maintain a cell gap between the first and second substrate; and spacer patterns formed on one of the first and second substrates such that each spacer pattern corresponds to at least one of an associated one of the gate lines and an associated one of the data lines, thereby forming a first gap between the spacer pattern and the other substrate facing the spacer pattern, and reducing an amount of liquid crystals filled between the first and second substrates.

Owner:LG DISPLAY CO LTD

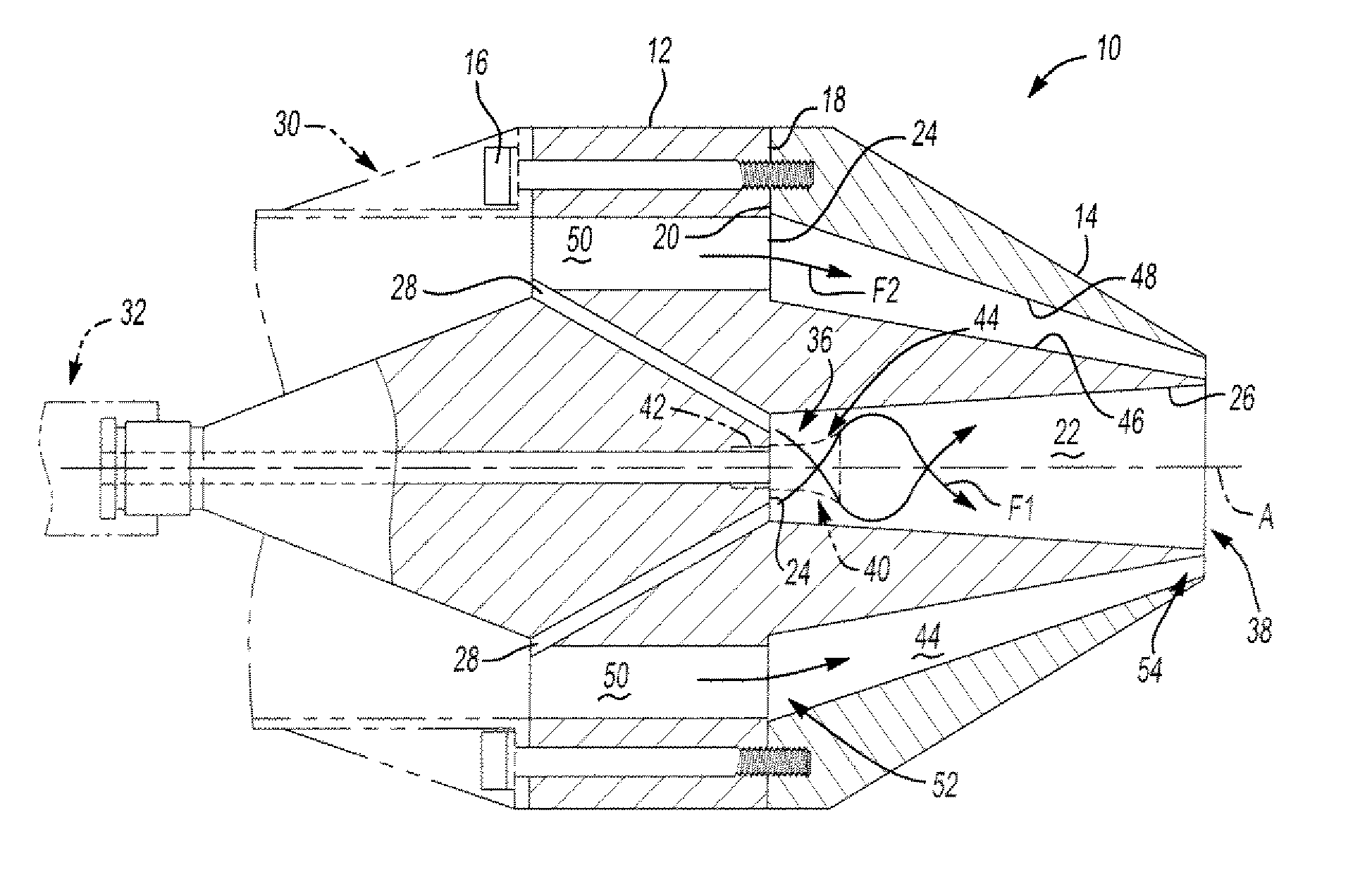

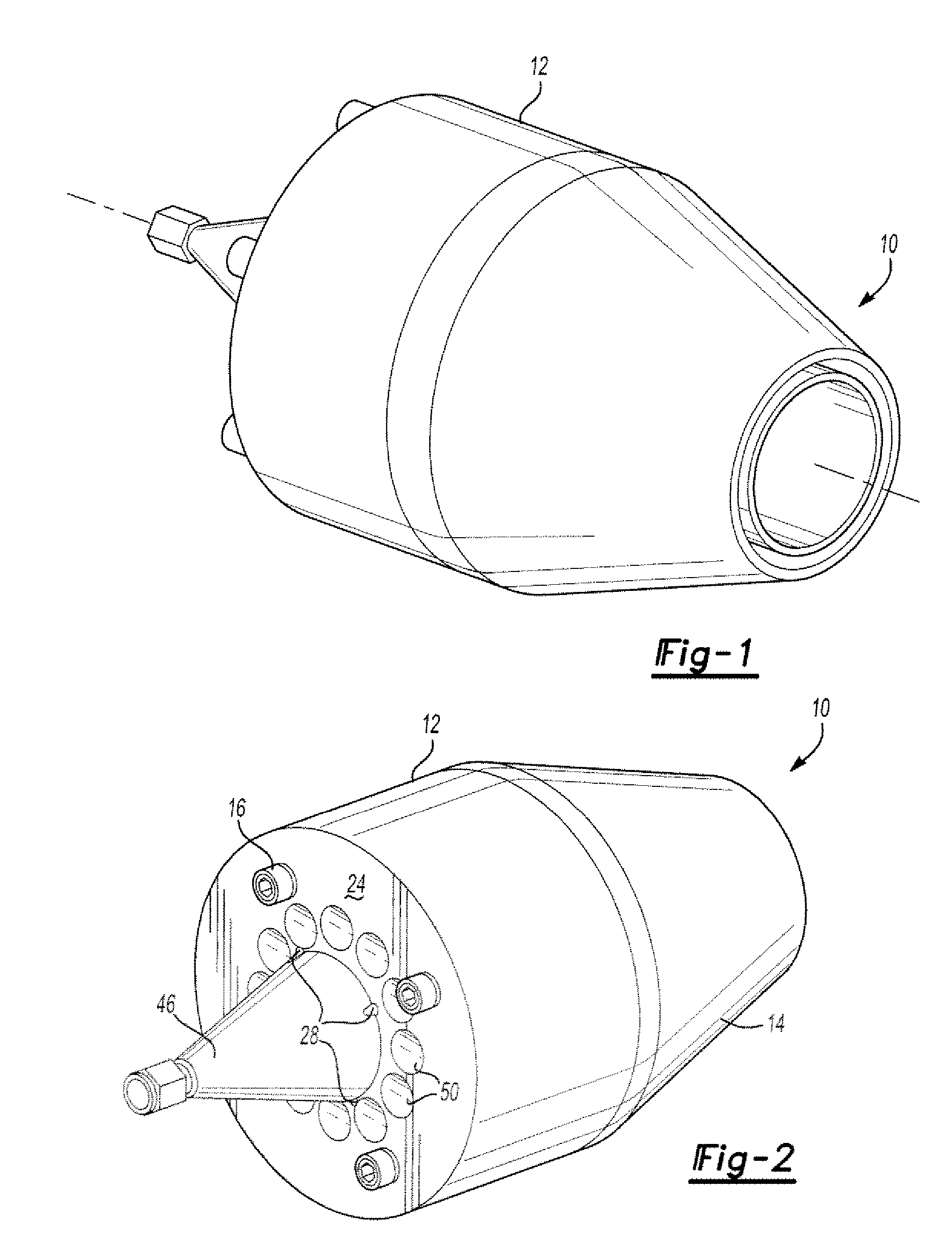

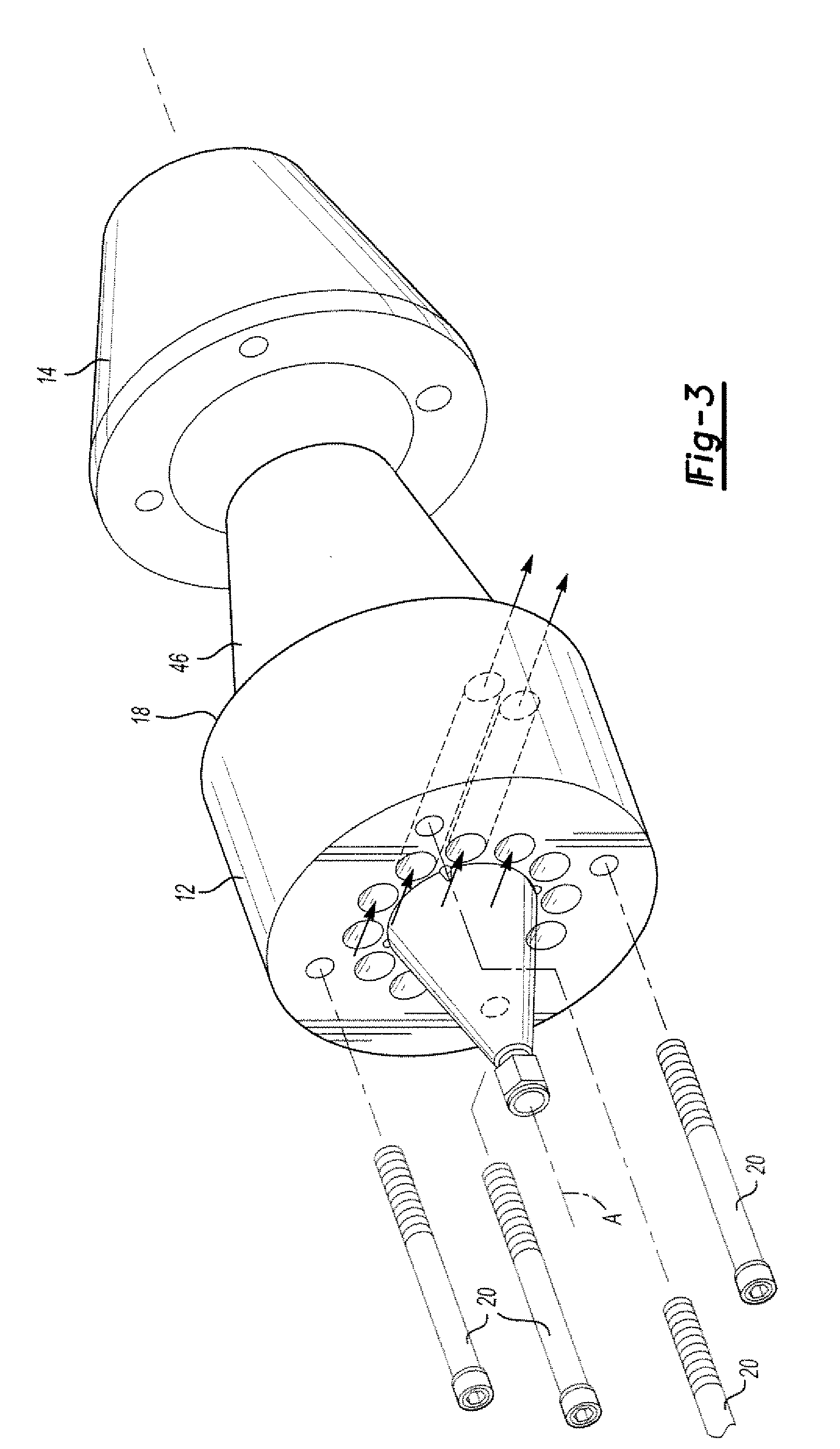

A liquid atomizing nozzle

InactiveUS20070194146A1Improved and simplifiedLow costSpray nozzlesLiquid spraying apparatusSpray nozzleCost savings

The present invention provides a nozzle capable of multiple atomizing steps of a liquid. In one configuration the nozzle provides atomization of a liquid fluid in a first direction and subsequent post atomization of the same liquid in a second direction to form a counter-flow nozzle. Accordingly, the liquid fluid to be dispensed is atomized in at least two separate stages causing improved atomization and the creation of particulate matter size of the liquid within a specified droplet spectrum. Furthermore, the present invention provides these features through an improved and simplified design providing potential cost savings to the end user due to the more effective operation of the nozzle and more efficient dispensing of fluid agents.

Owner:ADVANCED SPECIALIZED TECH

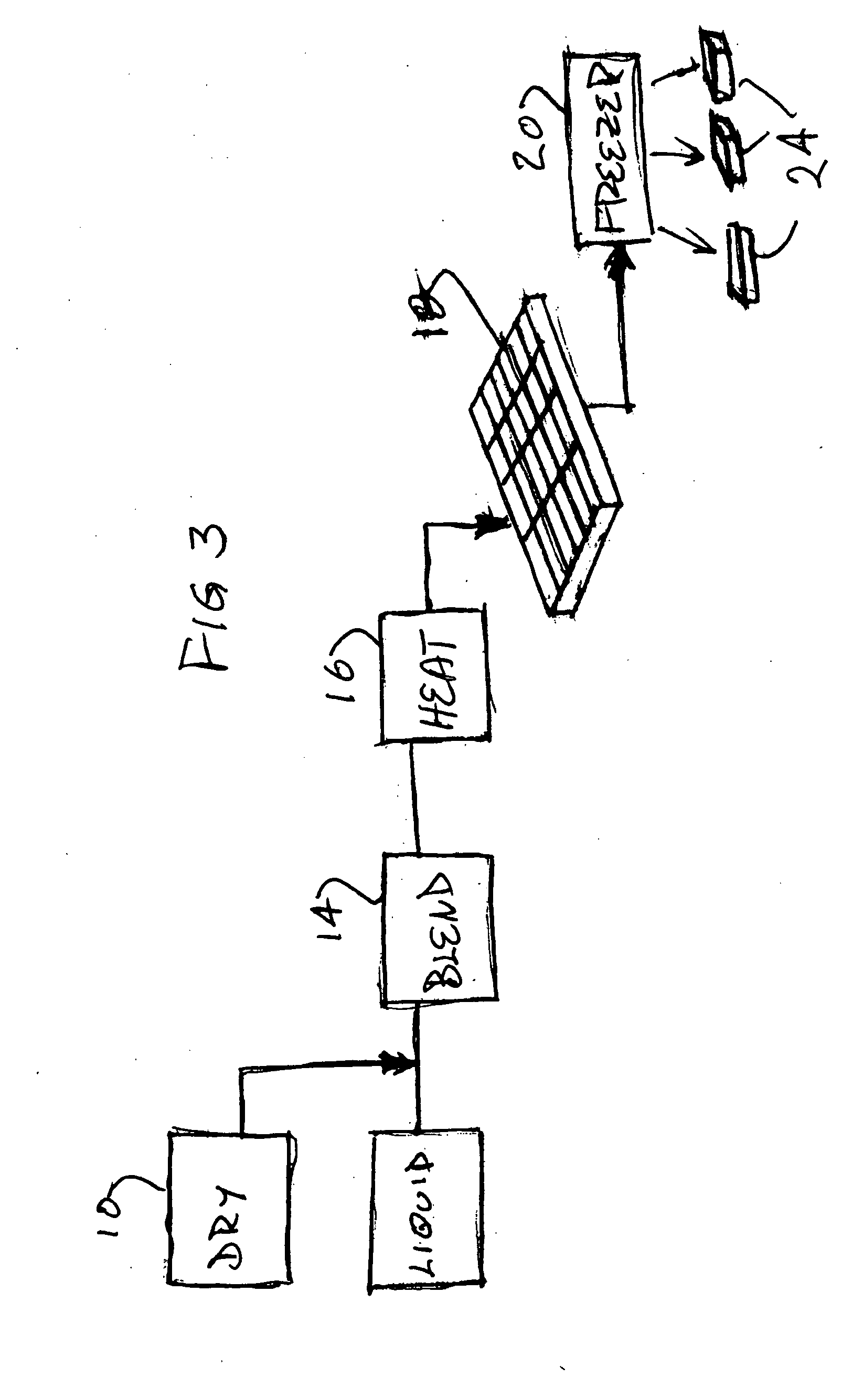

Frozen smoothie kit and method

InactiveUS20070042090A1Simple processReduce fluid volumeReady-for-oven doughsFrozen sweetsFruit juiceAdditive ingredient

A frozen pellet for blending with other ingredients to make a smoothie is formed of a sugar sweetened yogurt or yogurt formulation diluted with water and frozen solid at temperatures between 0° F. and 32° F. The frozen-solid yogurt pieces eliminate the need for the use of ice in the smoothie making process. Instead the frozen-solid yogurt pieces simply are blended together with fruits, preferably also frozen, and a liquid such as a juice, soda or milk to make a cold smoothie having a desirable thick consistency.

Owner:BIRDS EYE FOODS

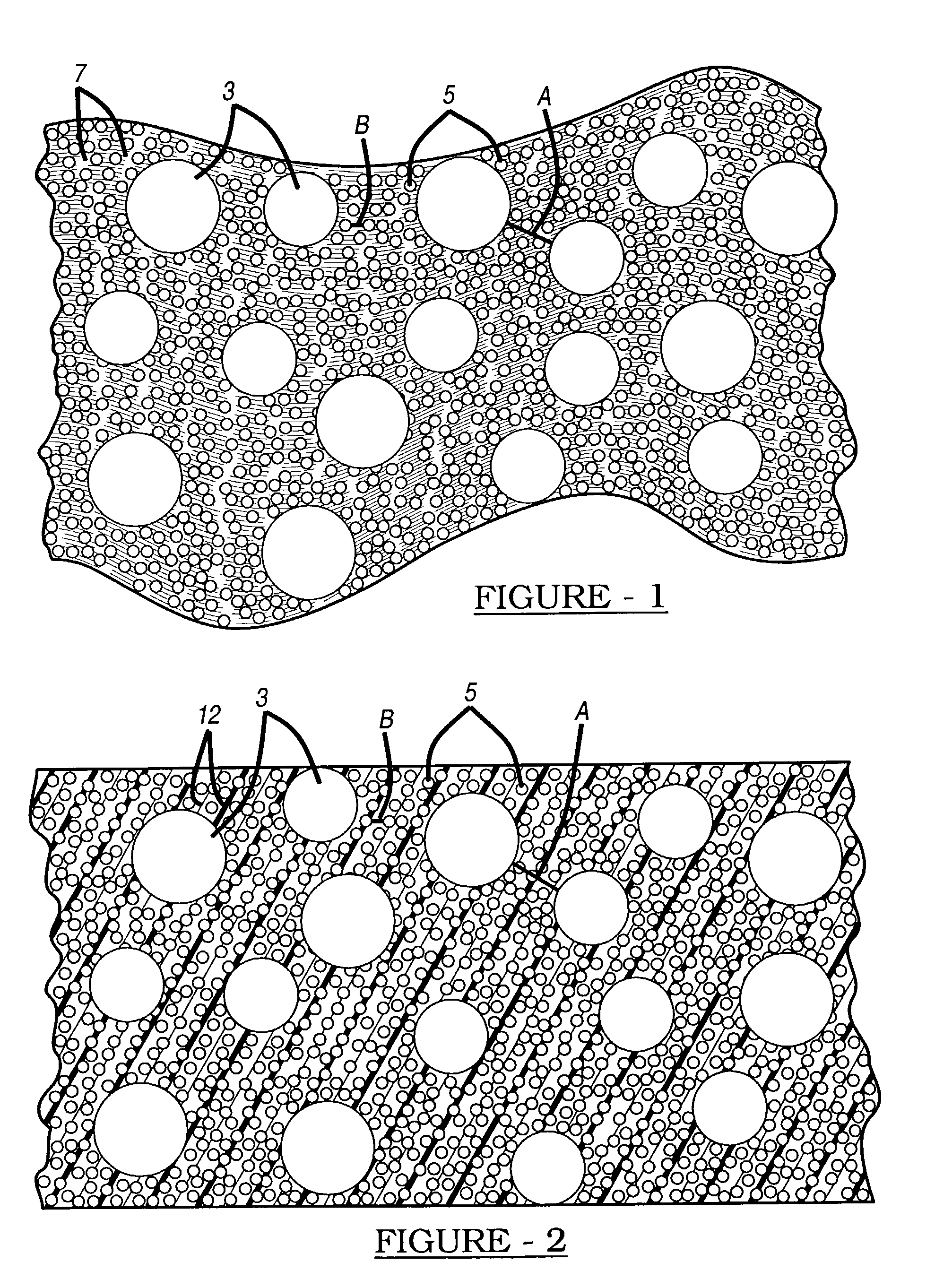

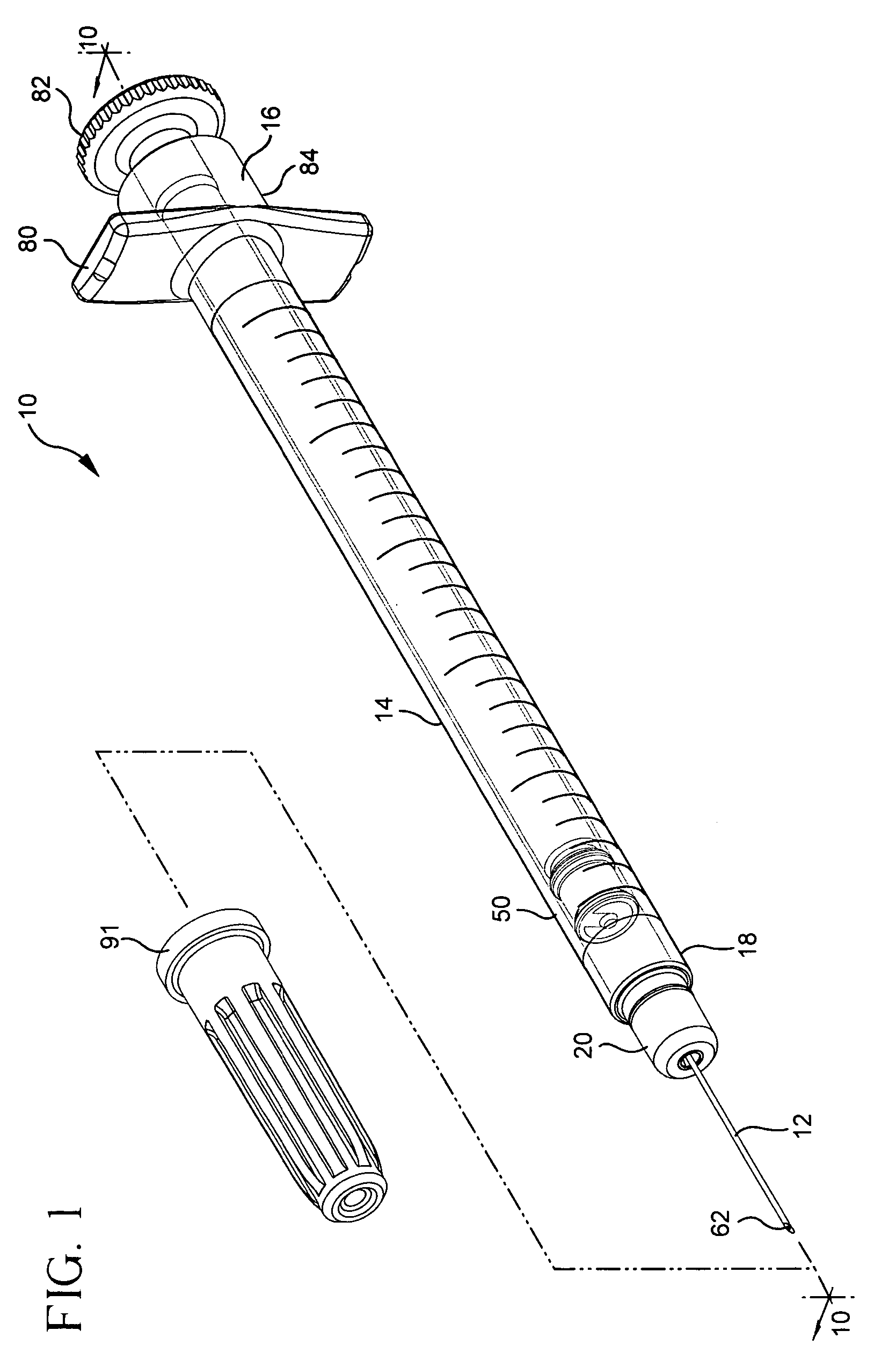

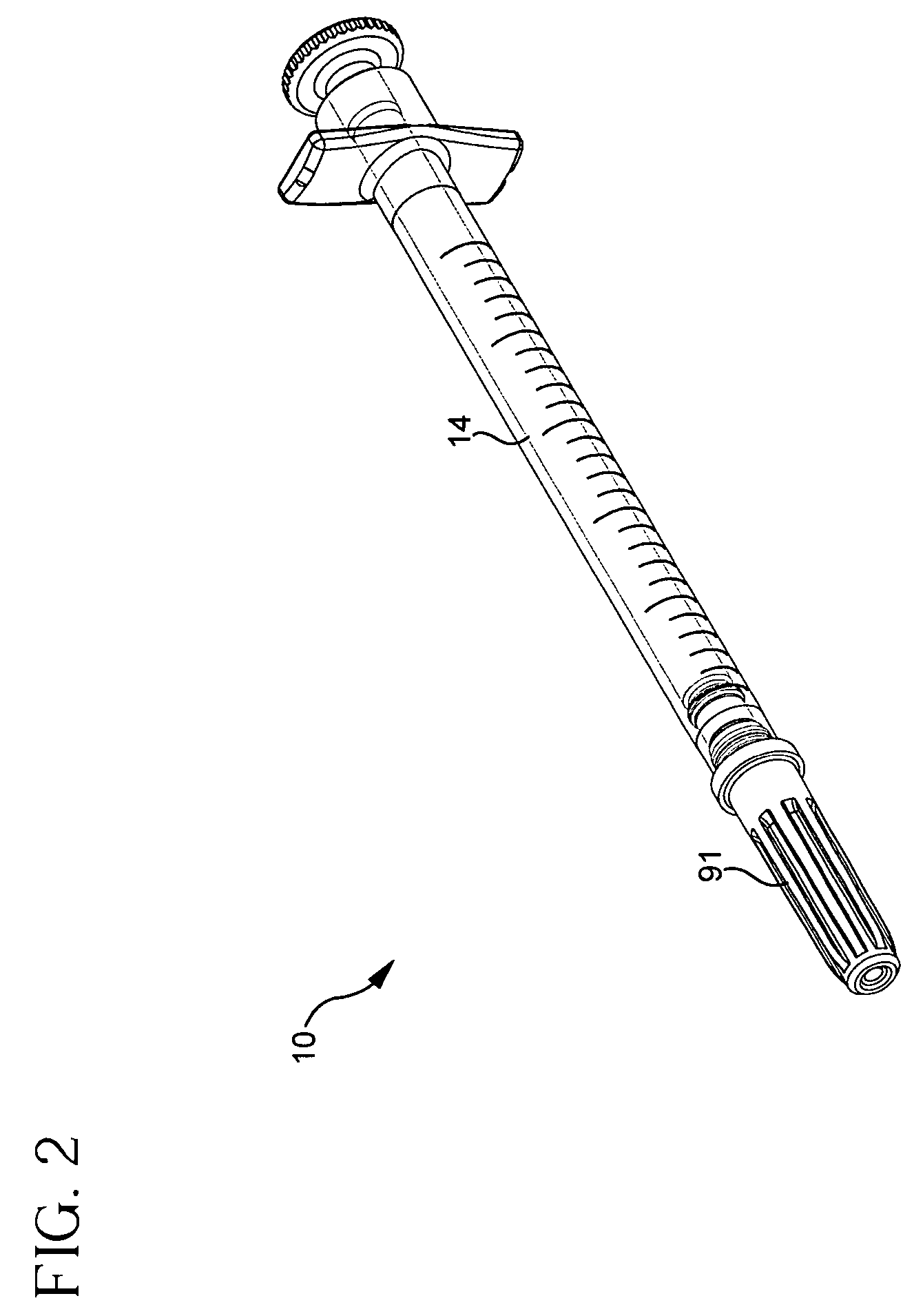

Plunger for retracting needle syringe

ActiveUS7713245B2Reduce fluid volumeInfusion syringesIntravenous devicesNEEDLE/SYRINGEBiomedical engineering

A plunger for a retracting needle syringe includes a hollow elongate body portion having a proximal end, a distal end, and a side wall therebetween defining a cavity. The distal end includes a distal wall having an inside surface and an outside surface. A stopper, at the distal end of the body portion, includes a peripheral portion performing a seal with the inside surface of a syringe barrel and at least one radial element extending from about a center of the outside surface of the distal wall to the peripheral portion. The distal end of the body portion includes at least one primary chamfer in the cavity at an intersection of the inside surface of the distal wall and the side wall. The chamfer is positioned under the at least one radial element for supporting the distal wall and the radial element when a hollow sleeve in the syringe barrel cuts through the end wall plunger. A secondary, smaller chamfer on each side of the primary chamfer is also provided.

Owner:BECTON DICKINSON & CO

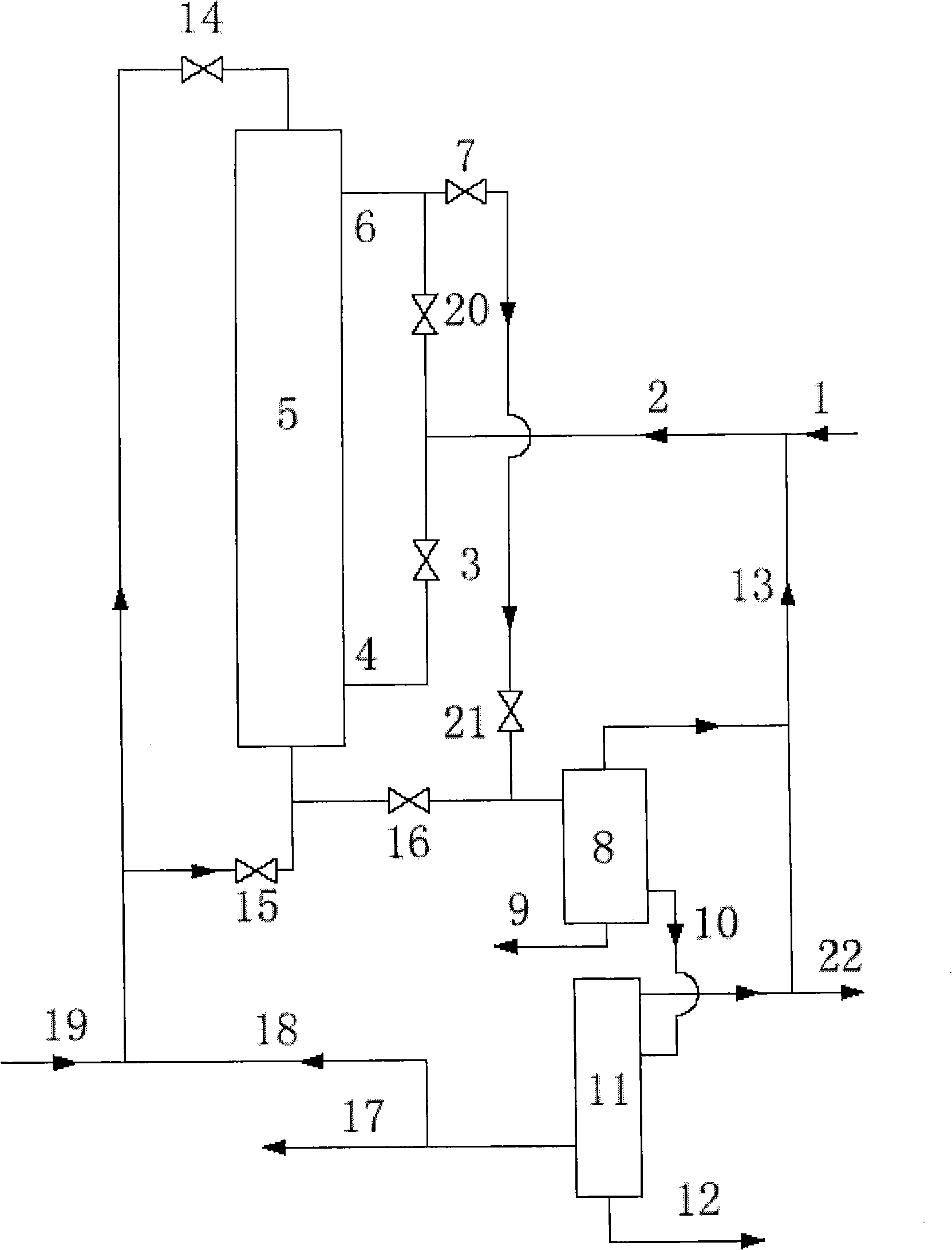

Liquid-liquid phase change absorbent for separating acid gas

ActiveCN105536434AReduce fluid volumeReduce sensible heatGas treatmentDispersed particle separationChemistryWater soluble

The invention relates to a liquid-liquid phase change absorbent for separating acid gas. The absorbent comprises the following components in percentages by mass: 10-60% of ethanolamine, 20-60% of other water-soluble organic compounds and 10-70% of water. Before the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent is a homogeneous-phase body, and after the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent forms into liquid-liquid phase spontaneously; the upper liquid phase is a barren liquor phase which loads acid gas, the lower liquid phase is a rich liquor phase which loads acid gas, and only the rich liquor phase enters a desorption unit, so that desorption energy consumption is reduced. After the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent forms into liquid-liquid phase for facilitating separation; according to characteristics of the absorbed acid gas, ratio of the absorbent can be adjusted for adapting to optimal volume ratio of the upper liquid phase and the lower liquid phase and load capacity of the absorbent in the process, so that amount of the rich liquor phase which enters the desorption unit in industrial environment is reduced, and energy consumption in the desorption process is reduced as possible.

Owner:BEIJING UNIV OF CHEM TECH

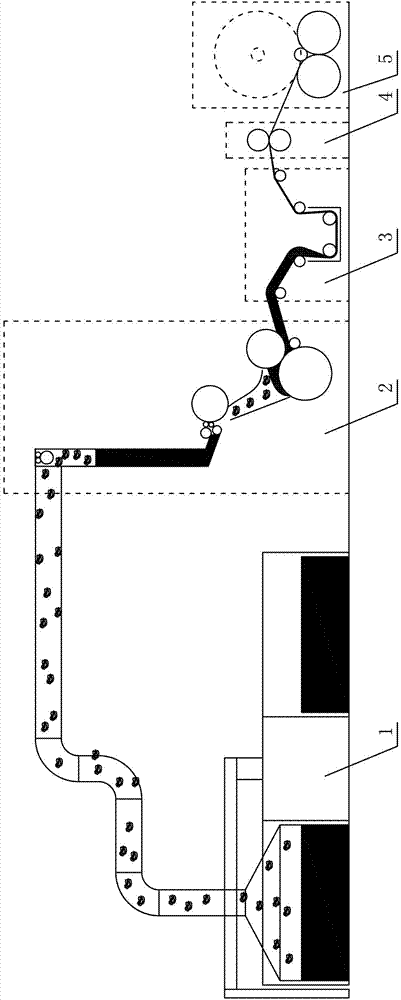

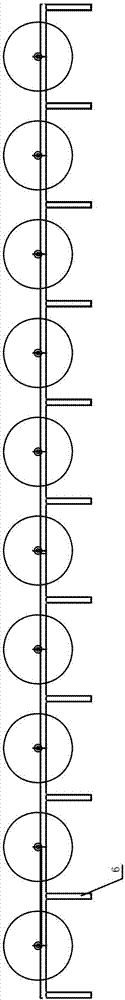

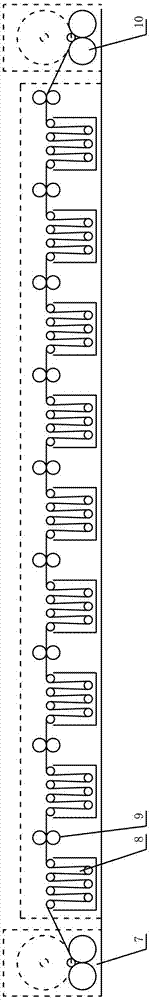

Cold-pad batch dyeing process for bulk fiber

InactiveCN102817192AReduce fluid volumeReduce laborLiquid/gas/vapor removalTextile treatment machine arrangementsBleachMaterials science

The invention relates to the field of bulk fiber dyeing, in particular to a cold-pad batch dyeing process for bulk fibers, which comprises the steps of: (1) bulk fiber web formation: forming a uniform fiber layer with bulk fibers by an automatic bale plucker and a web forming machine; (2) padding: controlling a bleaching mangle expression to be 100-120 percent and a dyeing mangle expression to be 120-140 percent, only adding a refining agent and a bleaching agent for pretreatment into an immersion solution tank during bleaching, and adding dyes, a penetrant and an alkaline agent into the immersion solution tank during dyeing; (3) stacking after uniform padding and rolling: performing stacking on a cold-pad batch unit after the fiber layer is rolled so as to complete bleaching or dyeing; and (4): washing and drying: making the fibers treated by a washing machine and a soaping tank after dying and then treated by a drying machine. The cold-pad batch dyeing process has the advantages of little pollution and low energy consumption.

Owner:ZHEJIANG CHUNLANFANG TRADE

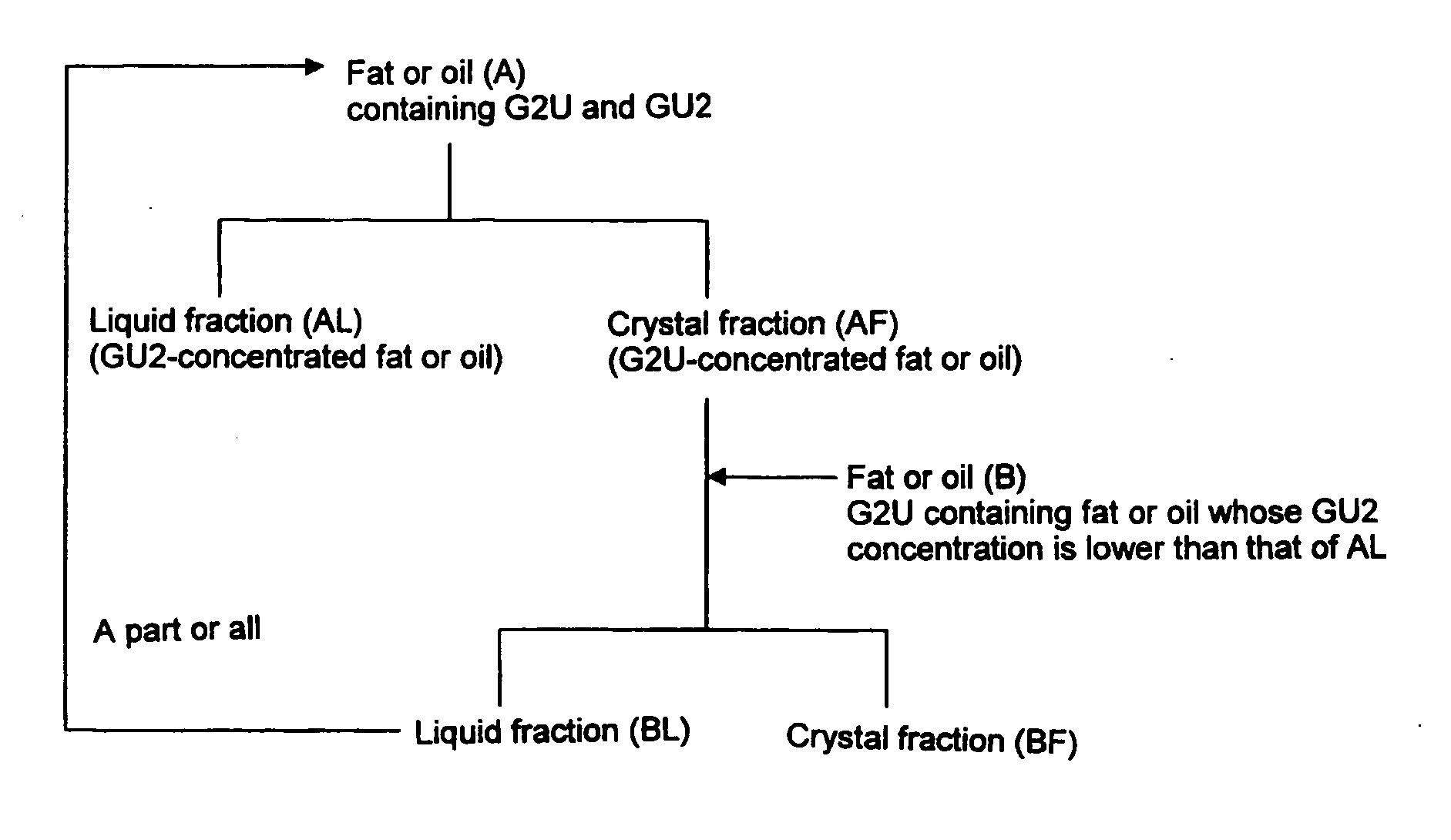

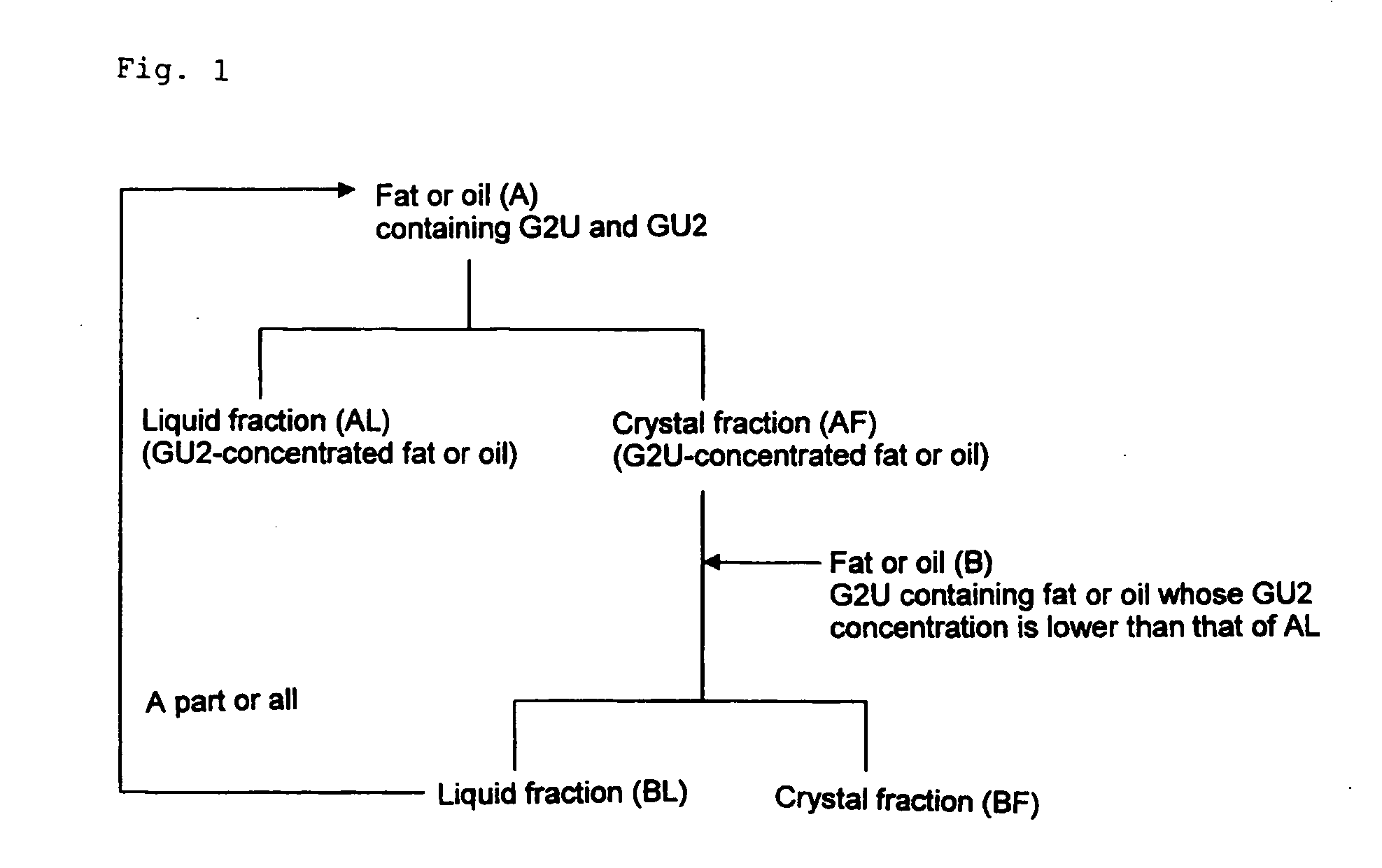

Method of dry fractionation of fat or oil

InactiveUS20070160739A1Residue reductionQuality improvementFatty oils/acids recovery from wasteFatty acid isomerisationUnsaturated fatty acidSolvent

It is intended to provide a procedure for, in the fractionation of vegetable butter, transesterified fat or oil, isomerized hydrogenated fat or oil, etc. without the use of solvents, obtaining high-concentration component G2U (defined below) by concentrating operation through reduction of the amount of liquid component residue in crystal portion. There is provided a method of dry fractionation of fat or oil characterized in that fat or oil (A) containing components G2U and GU2 is fractionated through crystallization / solid-liquid separation into crystal fraction of concentrated G2U (AF) and liquid fraction of concentrated GU2 (AL), subsequently this crystal fraction (AF) is mixed with liquid G2U-containing fat or oil (B) whose GU2 concentration is lower than that of the liquid fraction (AL) and thereafter the mixture is separated into crystal fraction (BF) and liquid fraction (BL). Provided that G represents a saturated or trans acid form fatty acid residue; U a cis form unsaturated fatty acid residue; and G2U a triglyceride of G2-residue and U1-residue bonded together.

Owner:FUJI OIL CO LTD

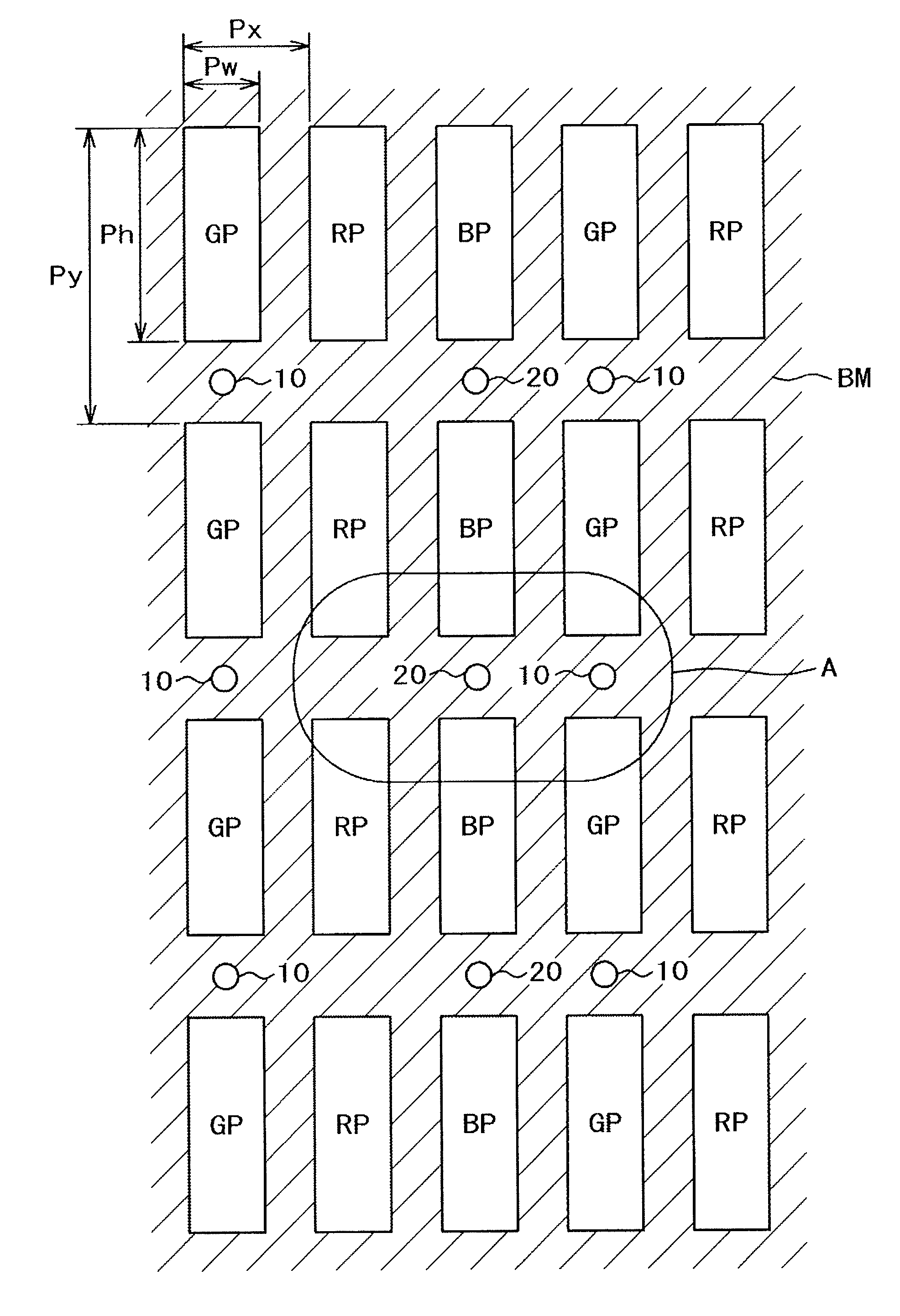

Liquid Crystal Display Device

ActiveUS20090153785A1Meet the height limit requirementsReduce fluid volumeNon-linear opticsPattern recognitionLeveling effect

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD

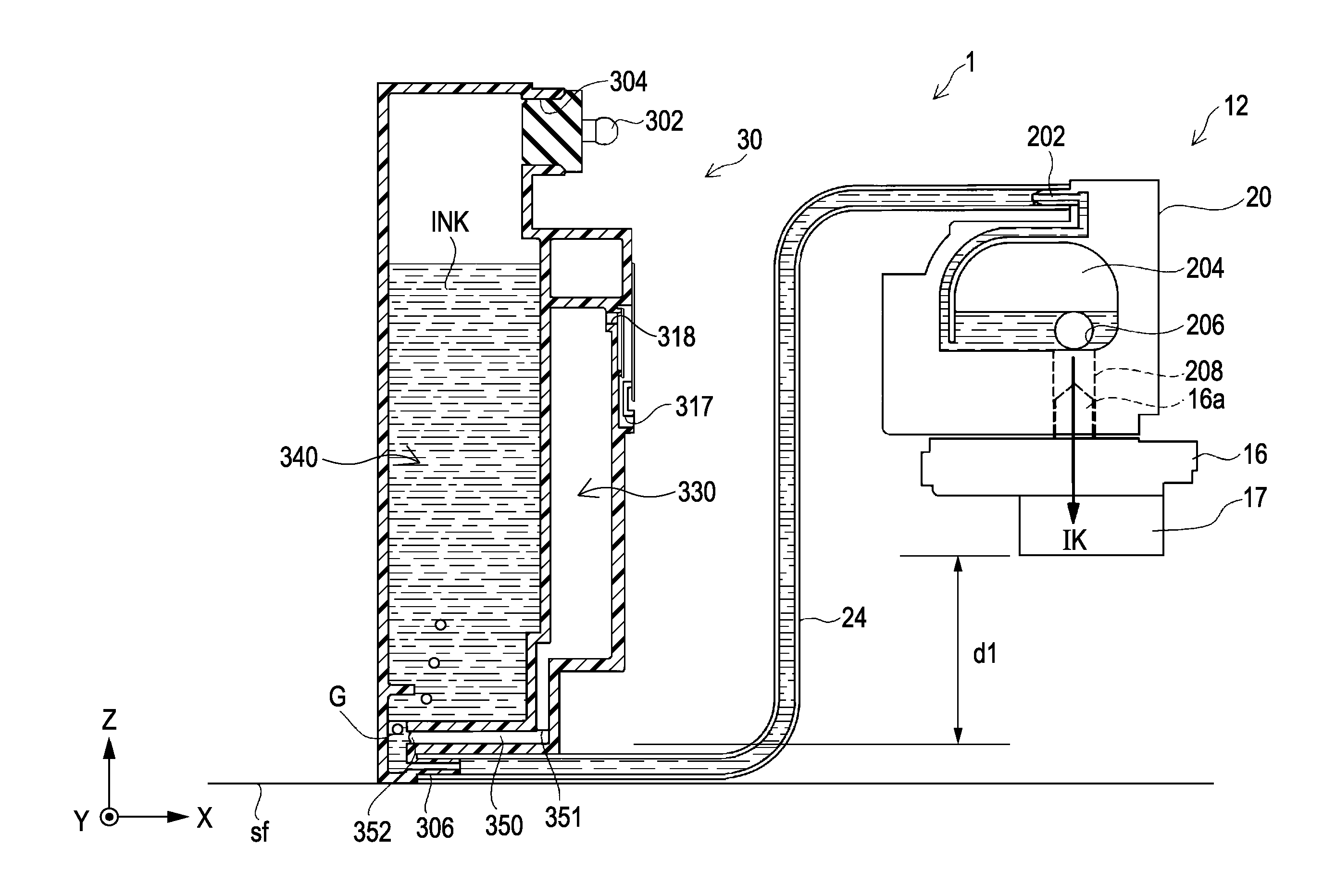

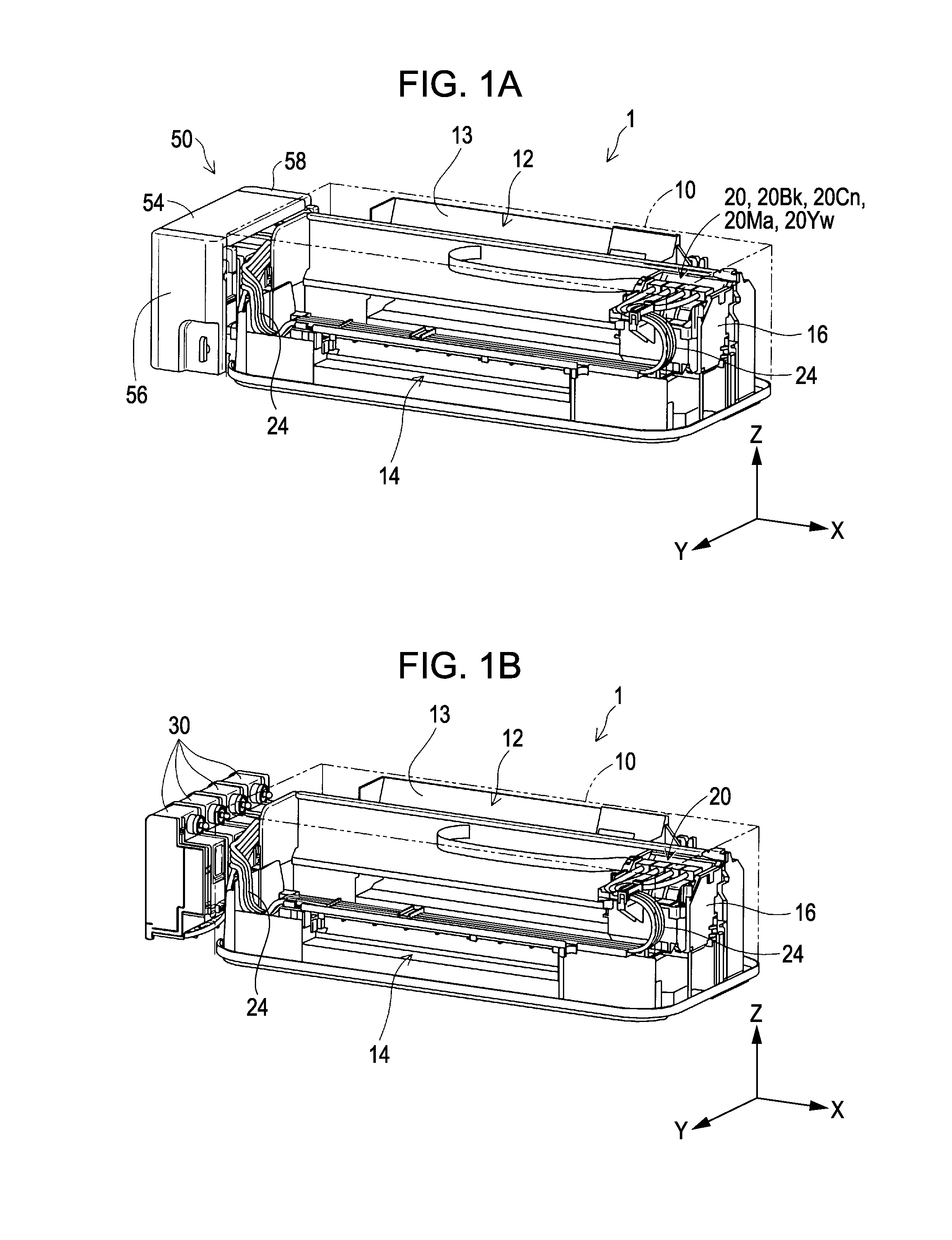

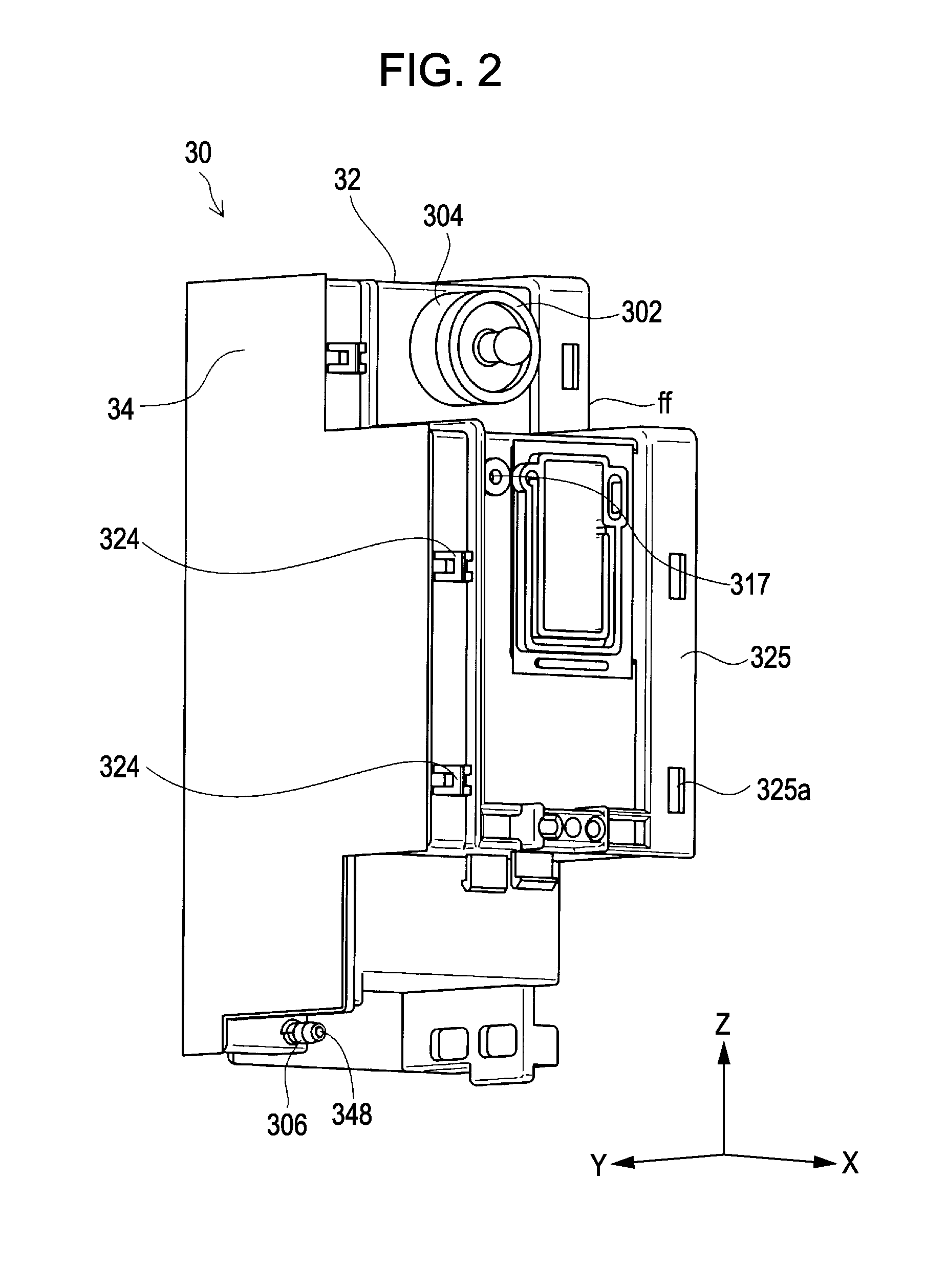

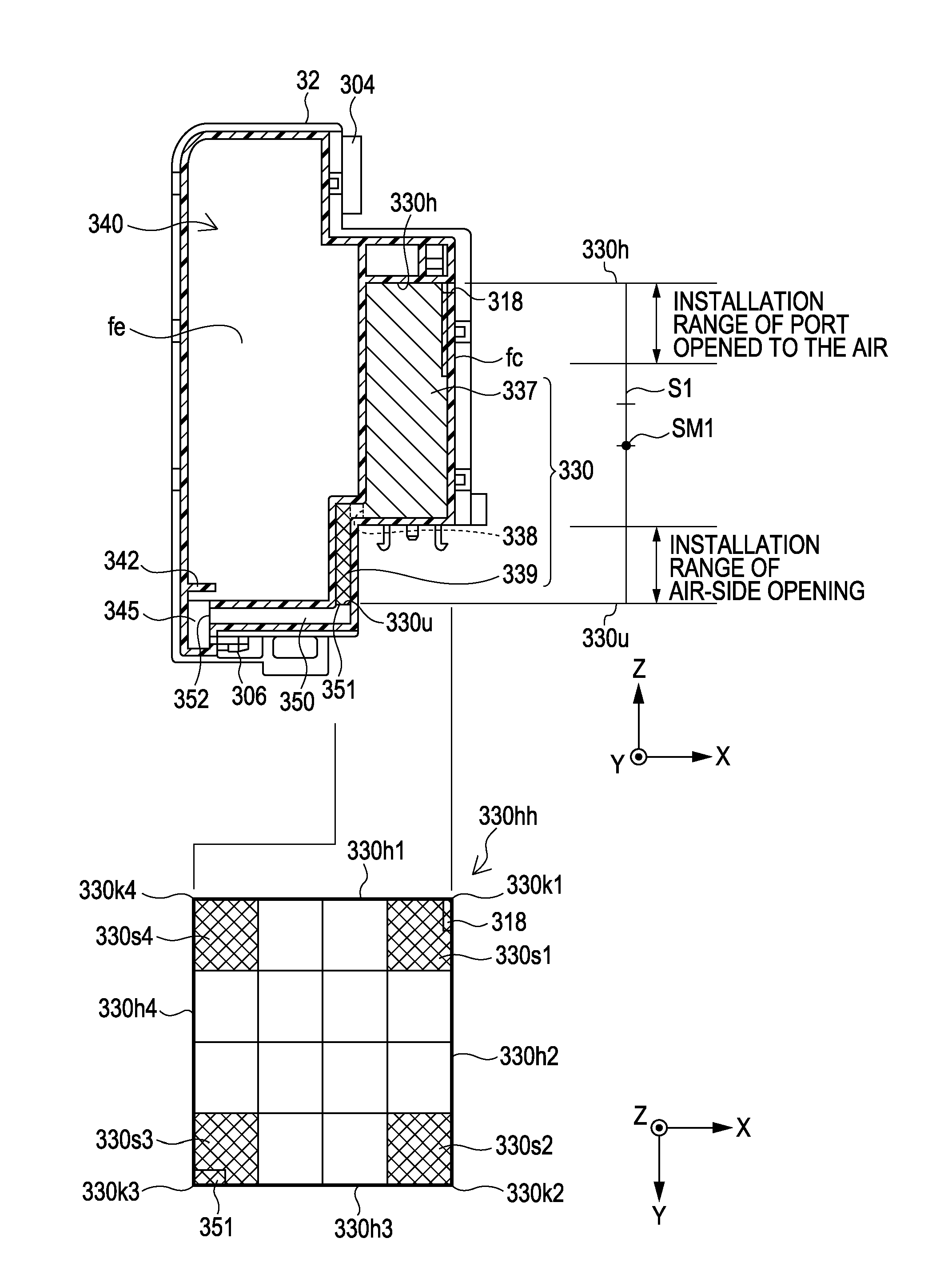

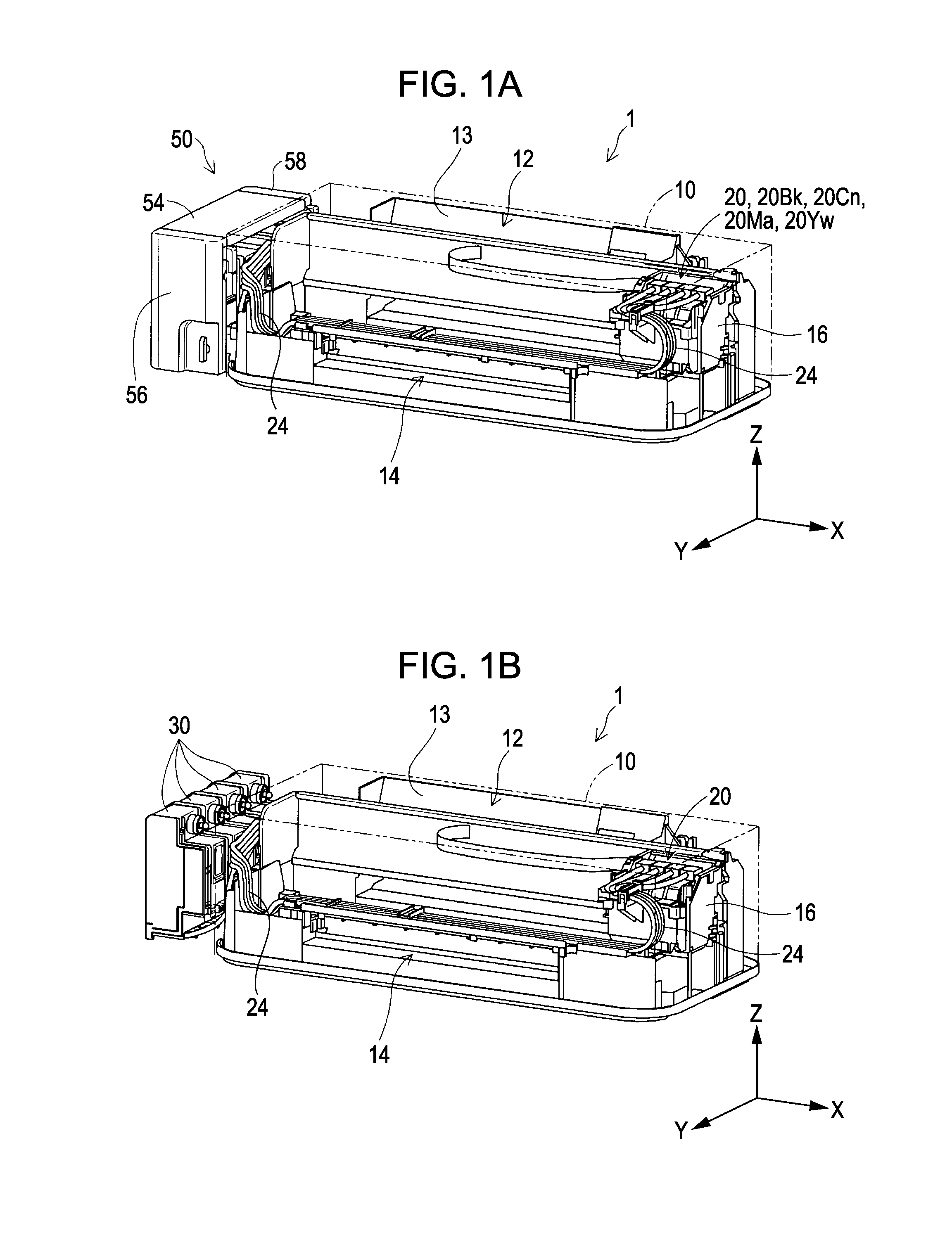

Liquid accommodating container, tank unit, and liquid ejecting system

A liquid accommodating container in which in a use position, a port opened to the air is provided at a position that is closer to an air chamber uppermost surface and is included in a first corner portion, an air-side opening is provided at a position that is closer to an air chamber lowermost surface and is included in a second corner portion which is at a diagonal position to the first corner portion, and a liquid-side opening is provided at a position satisfying the following conditions (a) and (b), (a) a position closer to a liquid chamber lowermost surface with respect to the vertical direction in the use position and (b) a position which is included in the second corner portion that is at a position equivalent to a diagonal position to the first corner portion.

Owner:SEIKO EPSON CORP

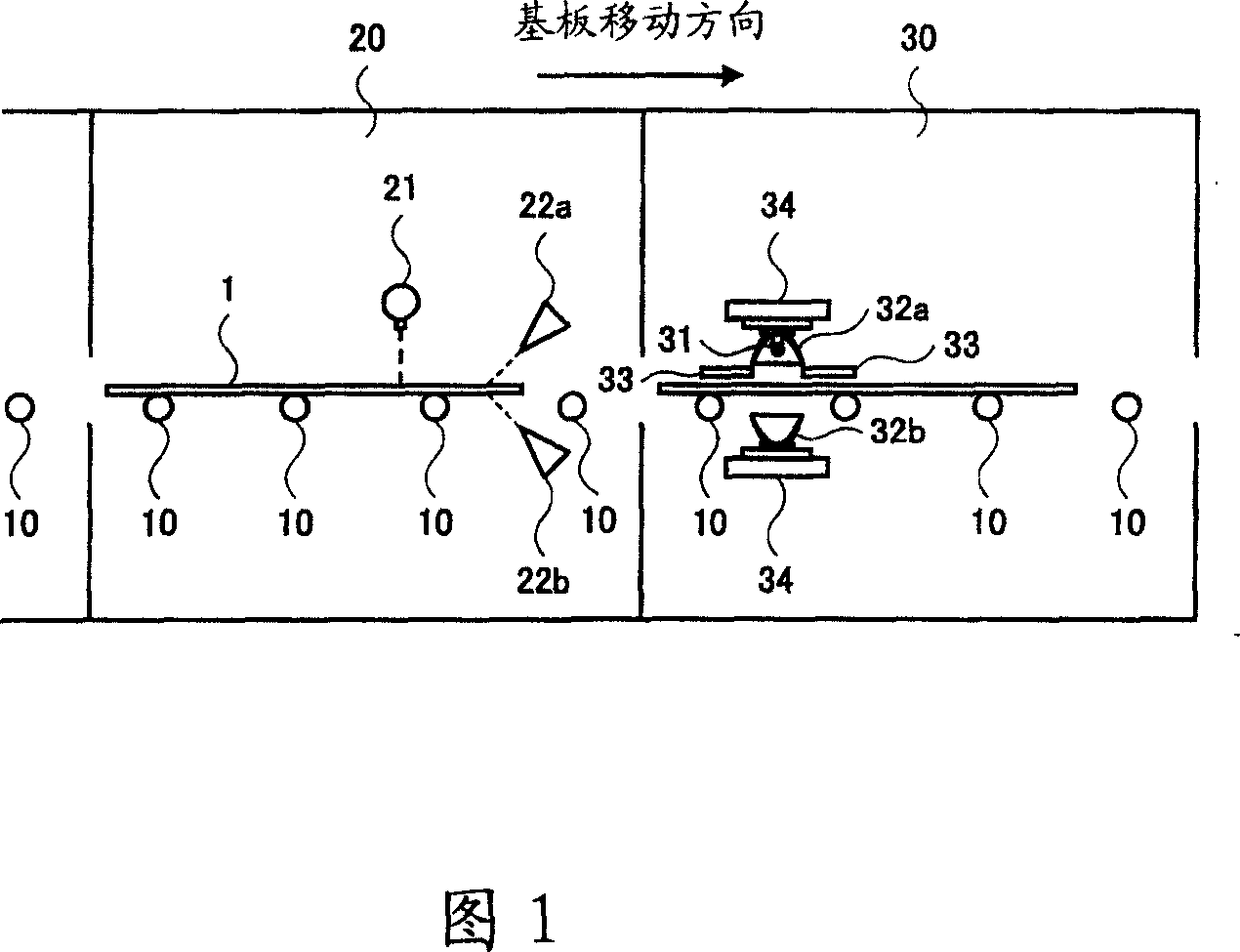

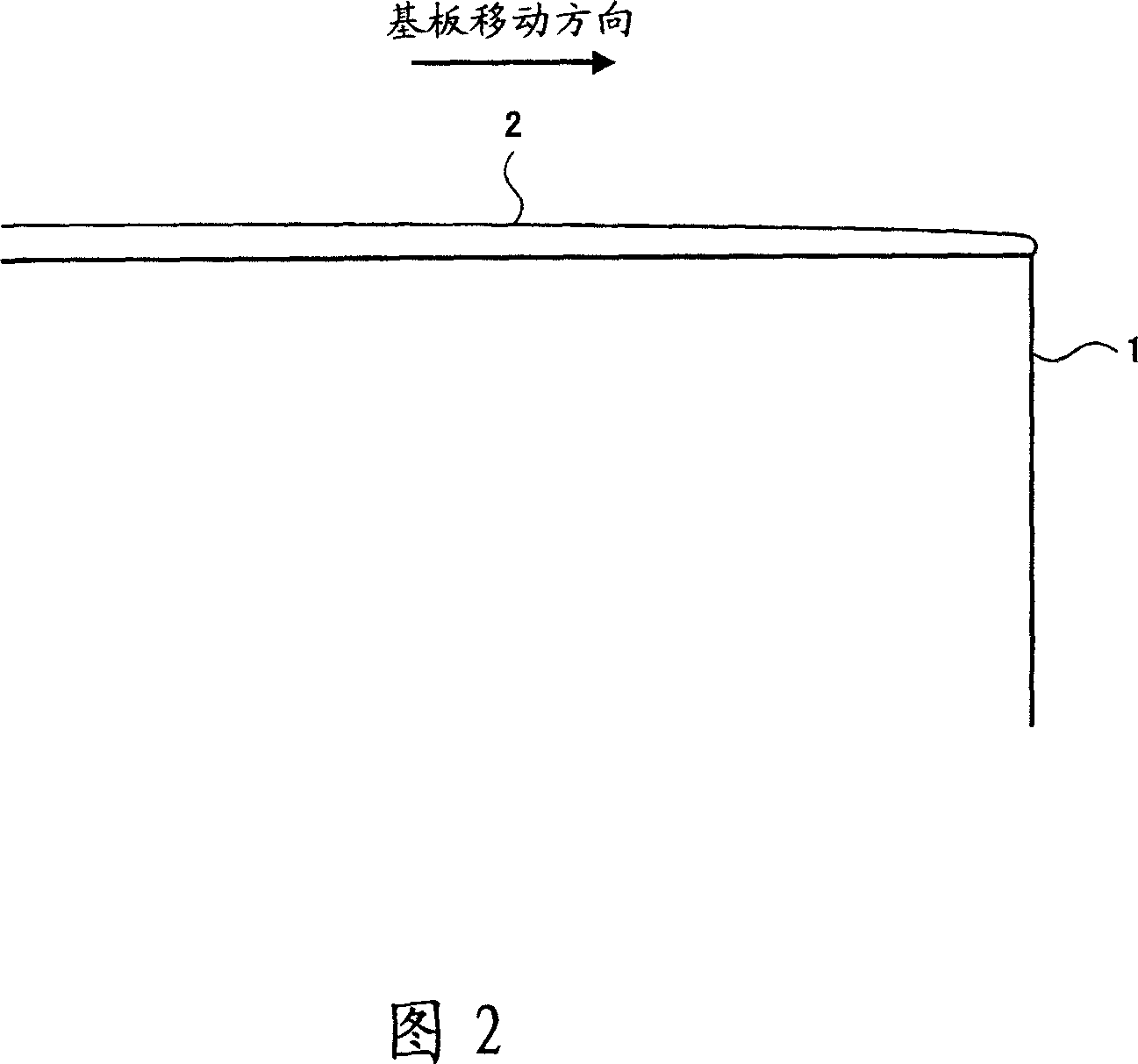

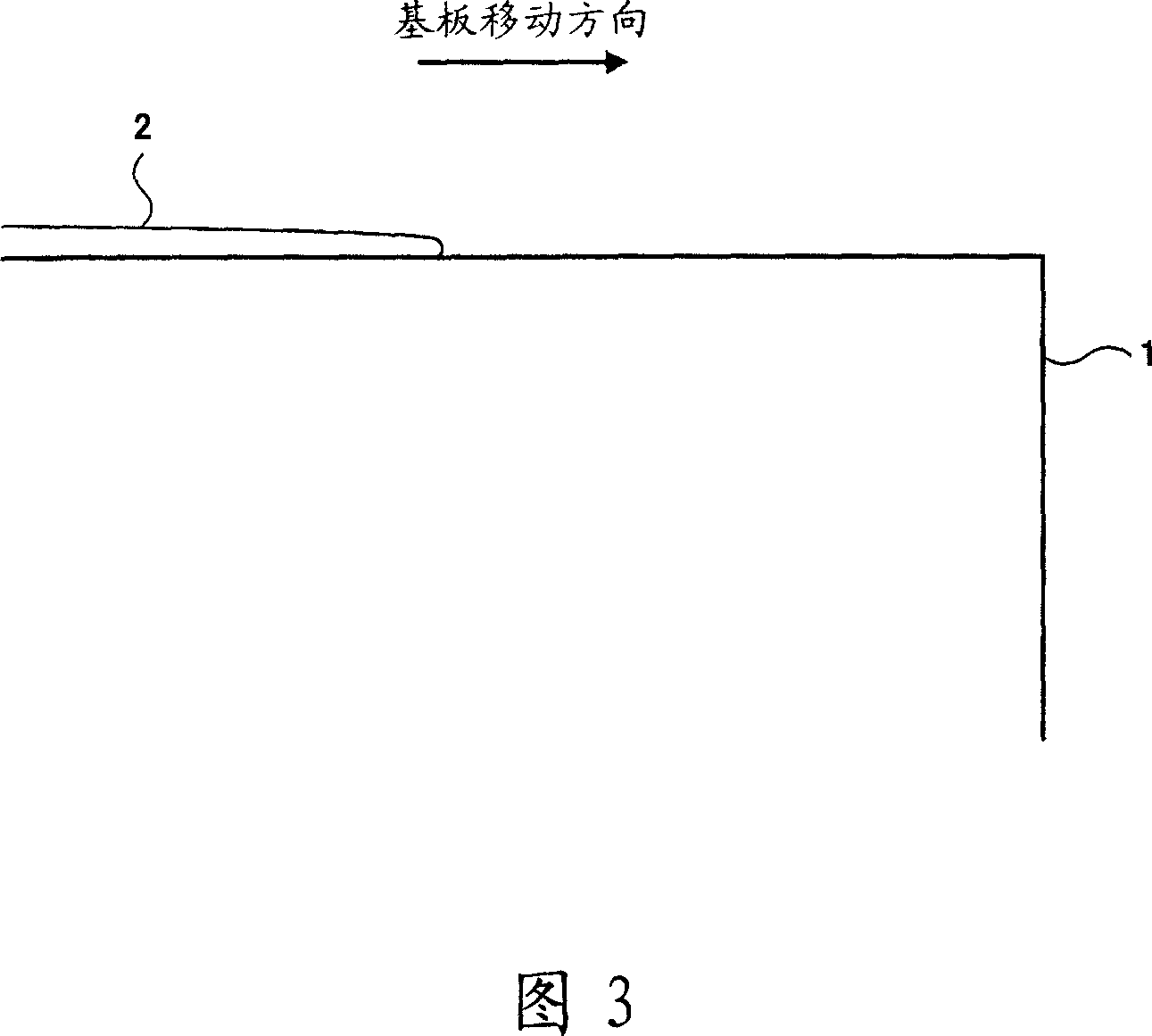

Substrate drying device and method, and substrate producing method

InactiveCN1941282ADry evenlyReduce air usageDrying using combination processesSemiconductor/solid-state device manufacturingAir knifeMoving speed

The present invention can move substrates with high speed, at the same time equably dry substrates. Nozzle (21) supplies cleaning liquid to the surface of the substrate 1, air knives (22a, 22b) eject air to the surface of back of the substrate (1). The air ejected from air knife (22a) makes the cleaning liquid supplied by nozzle (21) move toward the opposite direction of the substrate moving direction on the substrate (1). Adjusting the quantity of the cleaning liquid supplied by nozzle (21) and the quantity and speed of the air ejected from air knife (22a) in order to make the cleaning liquid moving speed slower than the substrate moving speed. Therefore, forming the continuous and thin liquid film of cleaning liquid on the whole surface of the substrate (1) under the air knife (22a). The liquid film forming on the surface of the substrate (1) is vaporized when it through the lower part of the halogen lamp (31), and is wiped off from one end of the substrate (1) continuously.

Owner:HITACHI HIGH-TECH CORP

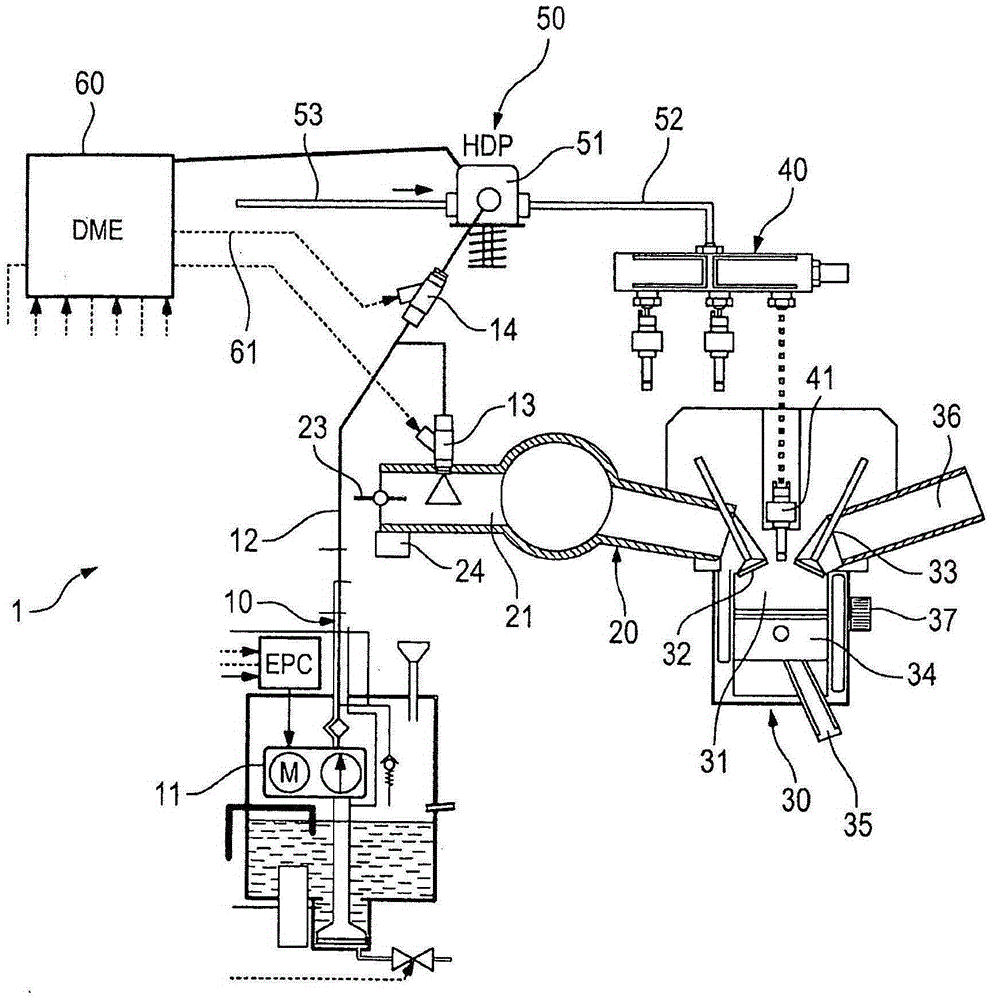

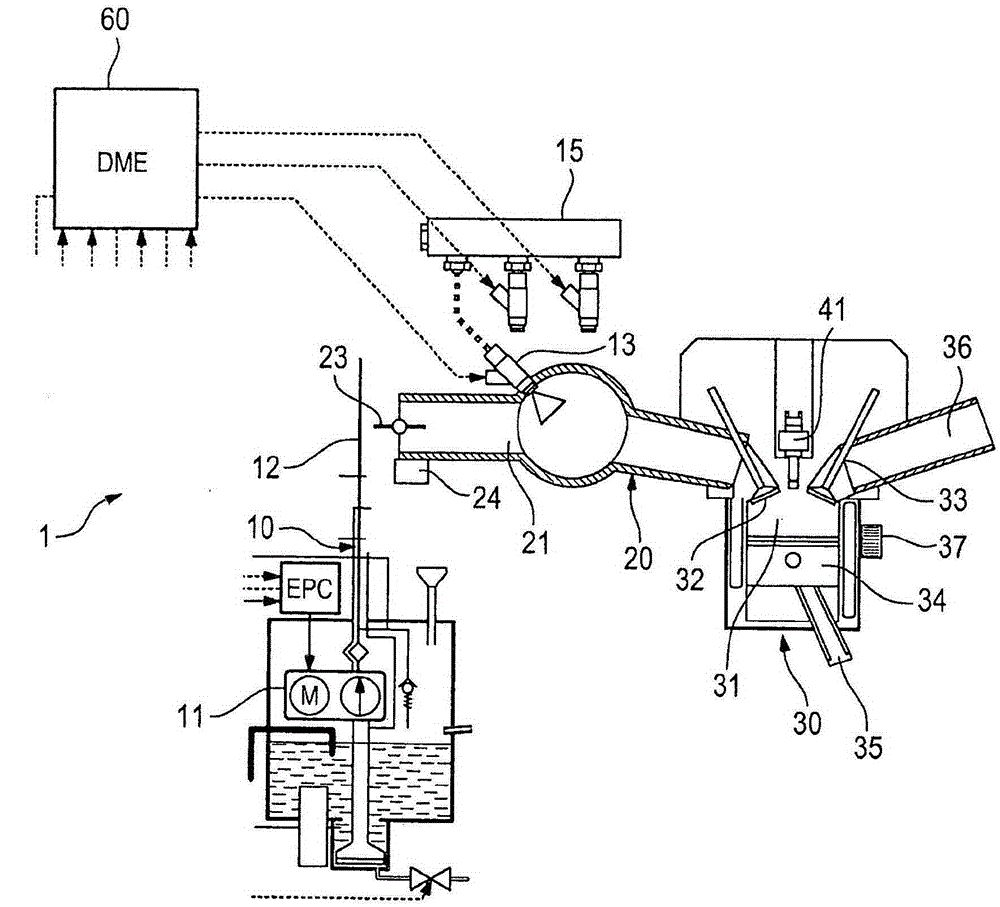

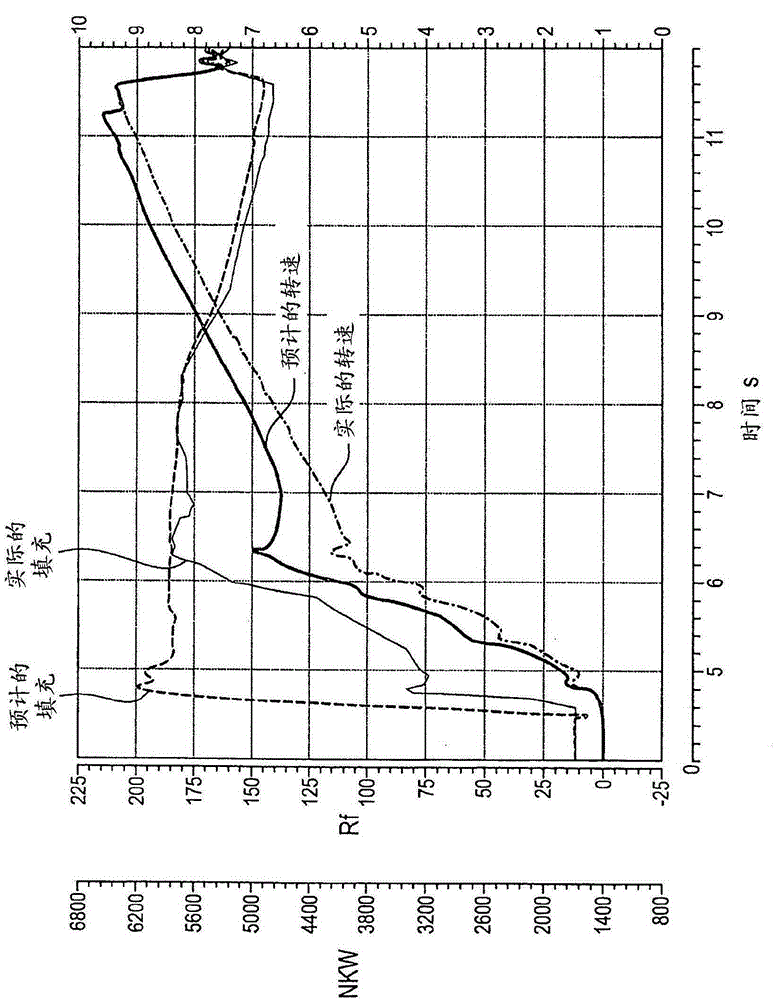

Method for controlling combustion in an internal combustion engine and the internal combustion engine

ActiveCN105569864AReduce consumptionCompliance improvementElectrical controlNon-fuel substance addition to fuelExternal combustion engineUltimate tensile strength

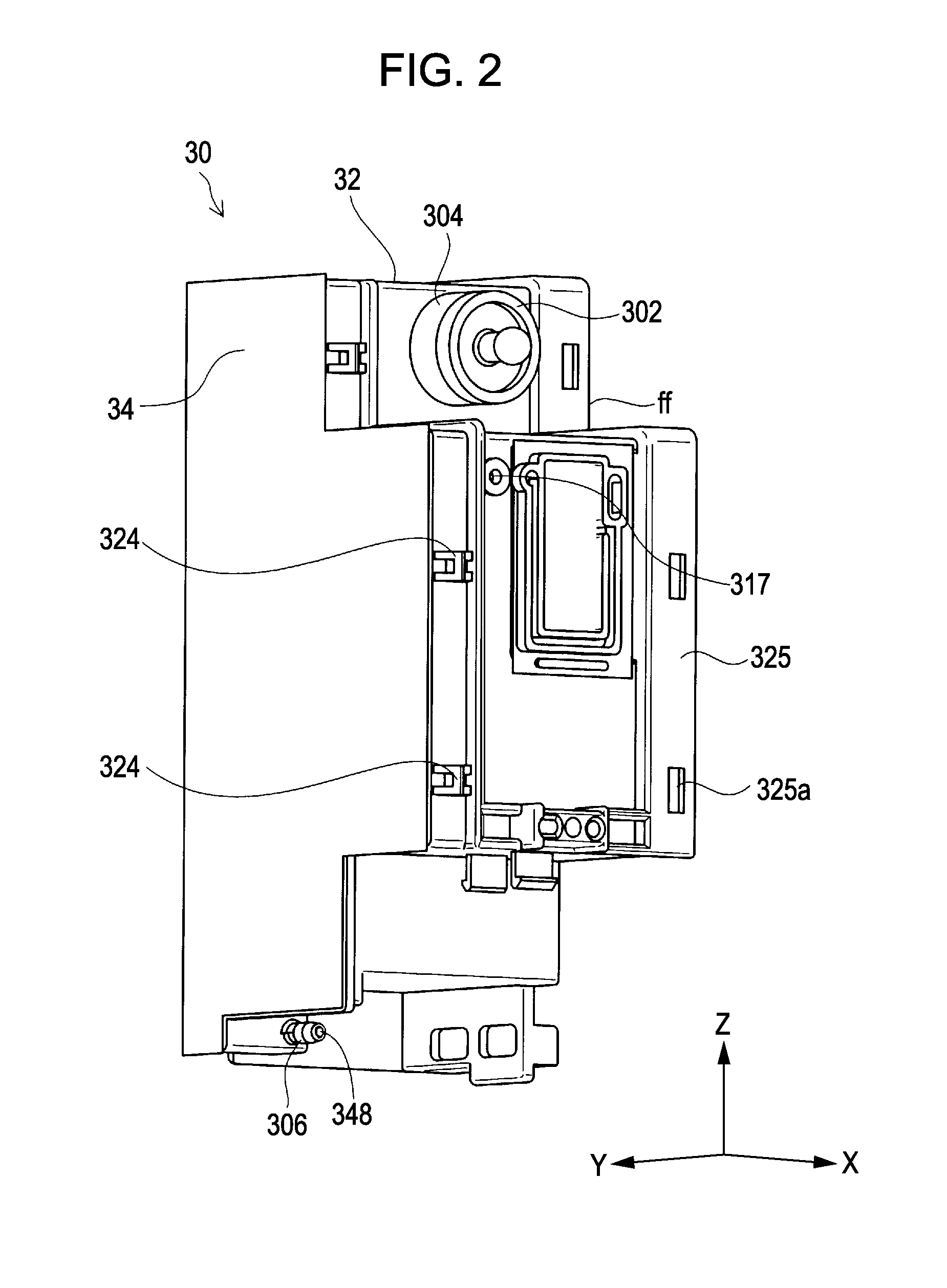

In a method for controlling combustion in an internal combustion engine with at least one cylinder (30), knock intensity in the cylinder (30) by means of a knock sensor (37) is detected. A predetermined setpoint ignition angle of the cylinder (30) corresponding to a target exhaust gas temperature is adjusted, and a fluid admixture in the cylinder (30) is controlled in dependence on the detected knock intensity.

Owner:BAYERISCHE MOTOREN WERKE AG

Liquid accommodating container, tank unit, and liquid ejecting system

A liquid accommodating container in which in a use position, a port opened to the air is provided at a position that is closer to an air chamber uppermost surface and is included in a first corner portion, an air-side opening is provided at a position that is closer to an air chamber lowermost surface and is included in a second corner portion which is at a diagonal position to the first corner portion, and a liquid-side opening is provided at a position satisfying the following conditions (a) and (b), (a) a position closer to a liquid chamber lowermost surface with respect to the vertical direction in the use position and (b) a position which is included in the second corner portion that is at a position equivalent to a diagonal position to the first corner portion.

Owner:SEIKO EPSON CORP

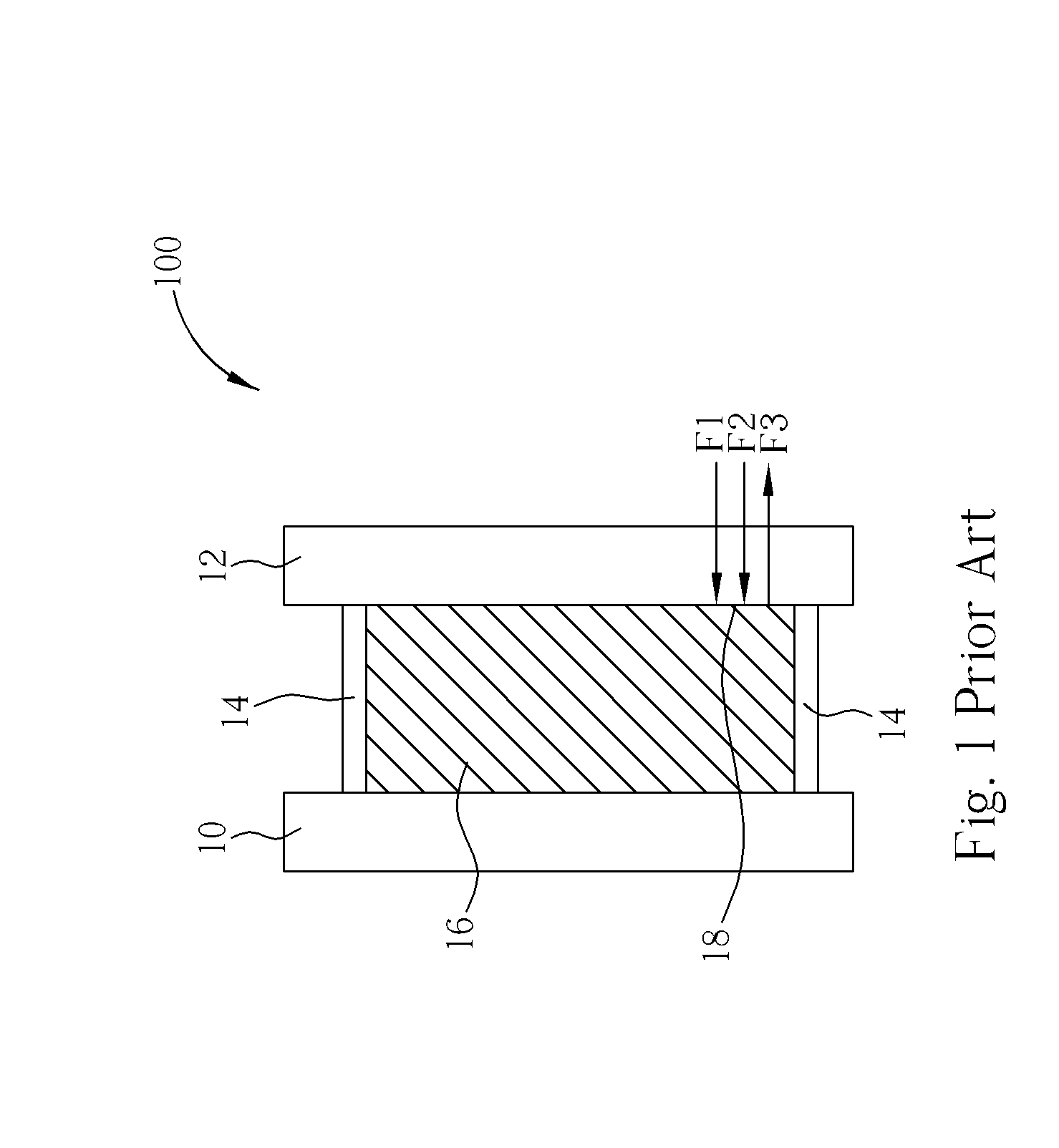

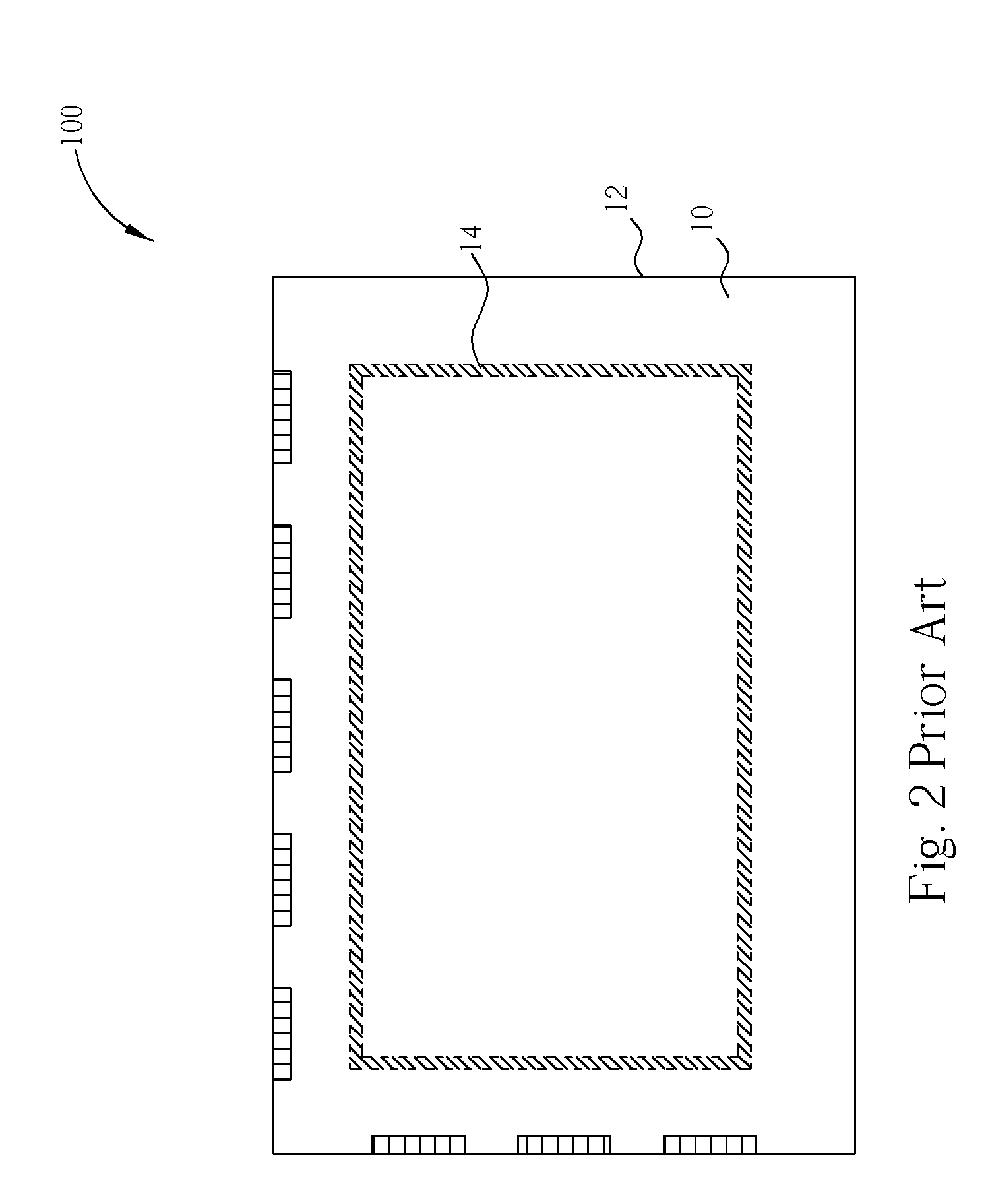

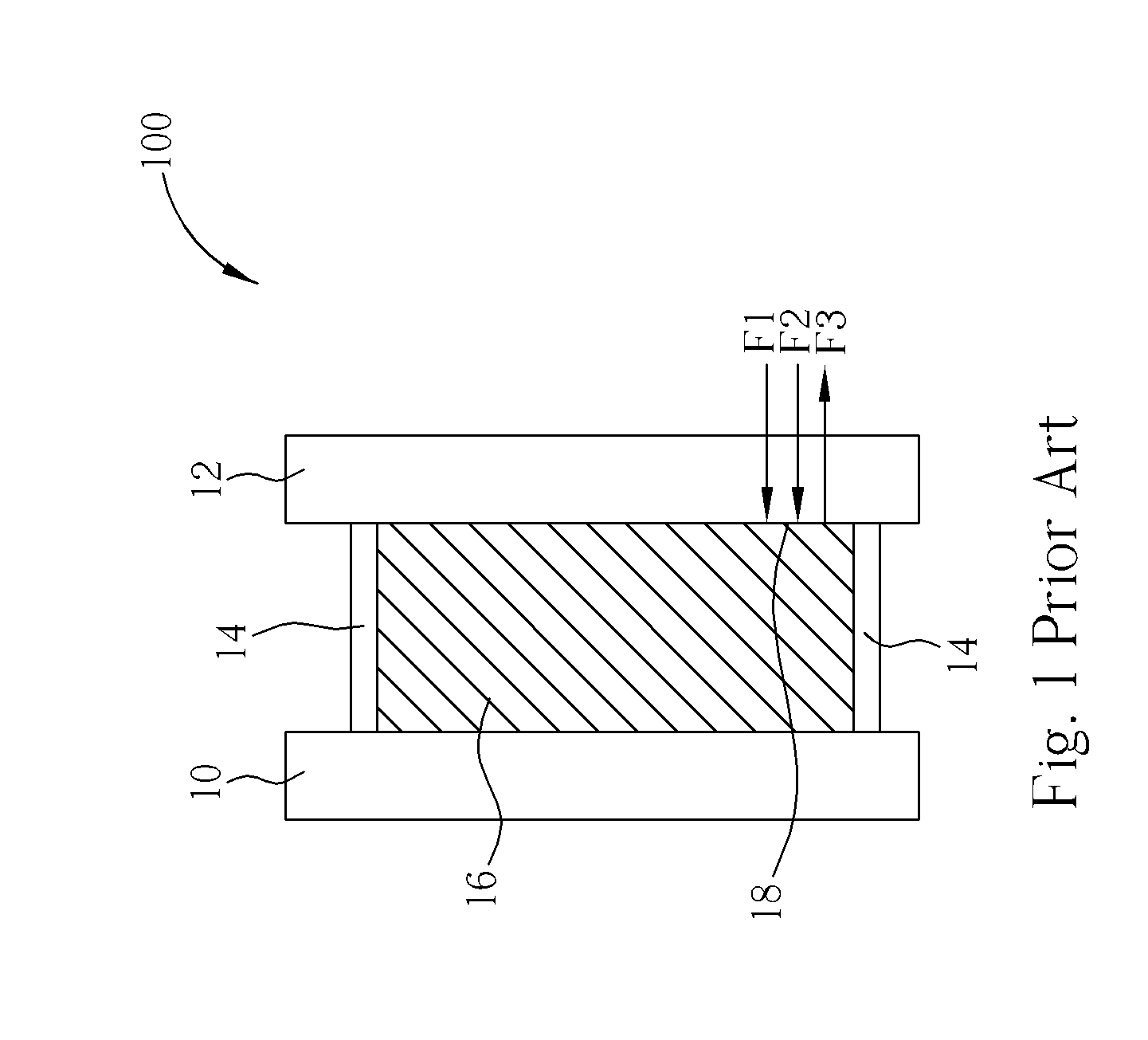

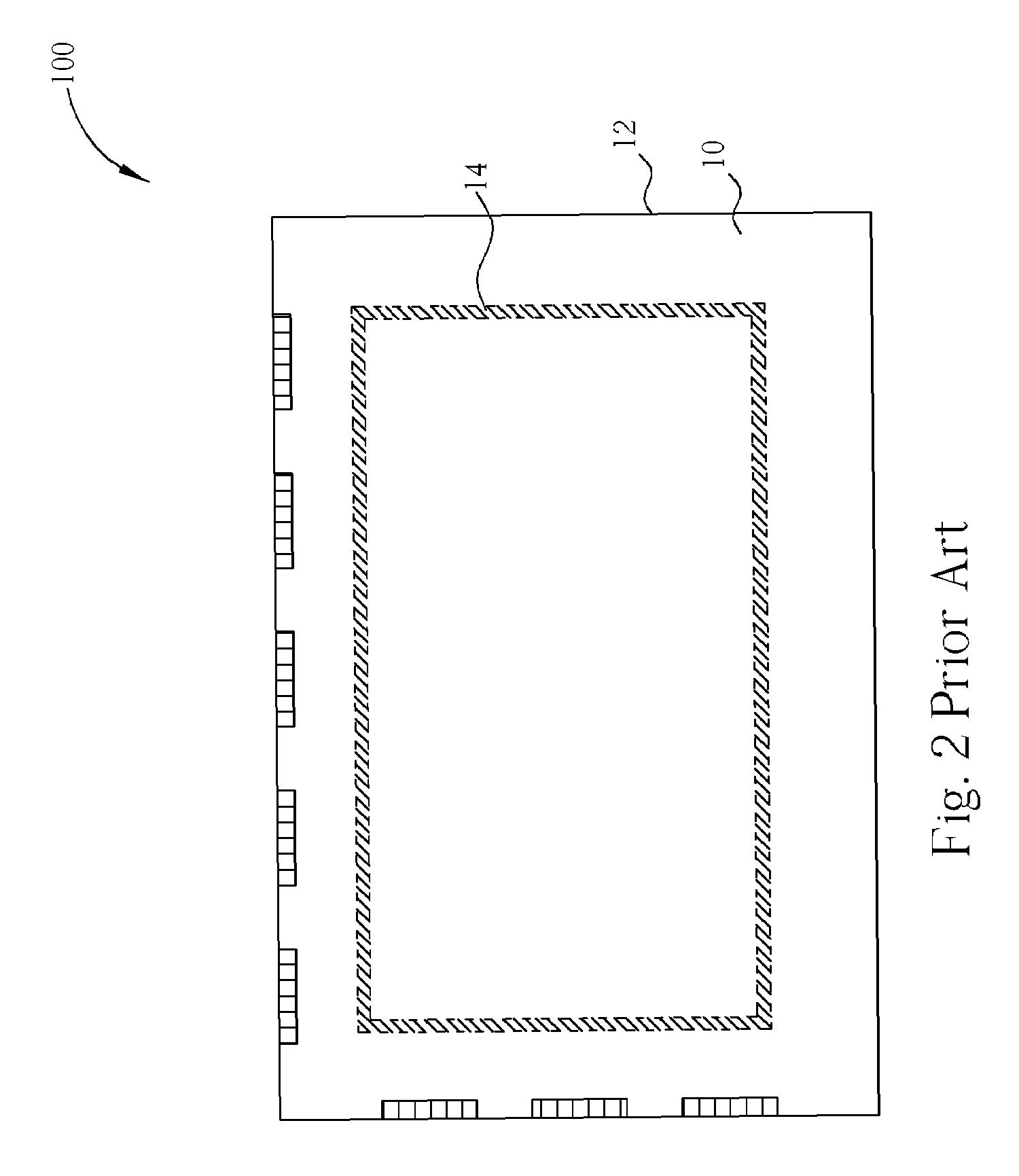

Method of repairing a liquid crystal display panel

ActiveUS20060164590A1Promote repairReduce fluid volumeNon-linear opticsLiquid-crystal displayEngineering

A method of repairing an LCD panel having a mura defect is disclosed. The closed seal pattern of the LCD panel has a shape of frame with at least one jut portion directing to a peripheral side of the two substrates. Thus, when a mura defect occurs, a peripheral portion on one side of the two substrates is cut off, wherein the cutting passes across the jut portion of the closed seal pattern to form an opening with respect to the sealed region. An extra amount of liquid crystal can be pressed out through the opening. Then the opening is sealed using a sealant, such that the LCD panel having a mura defect is repaired.

Owner:HANNSTAR DISPLAY CORPORATION

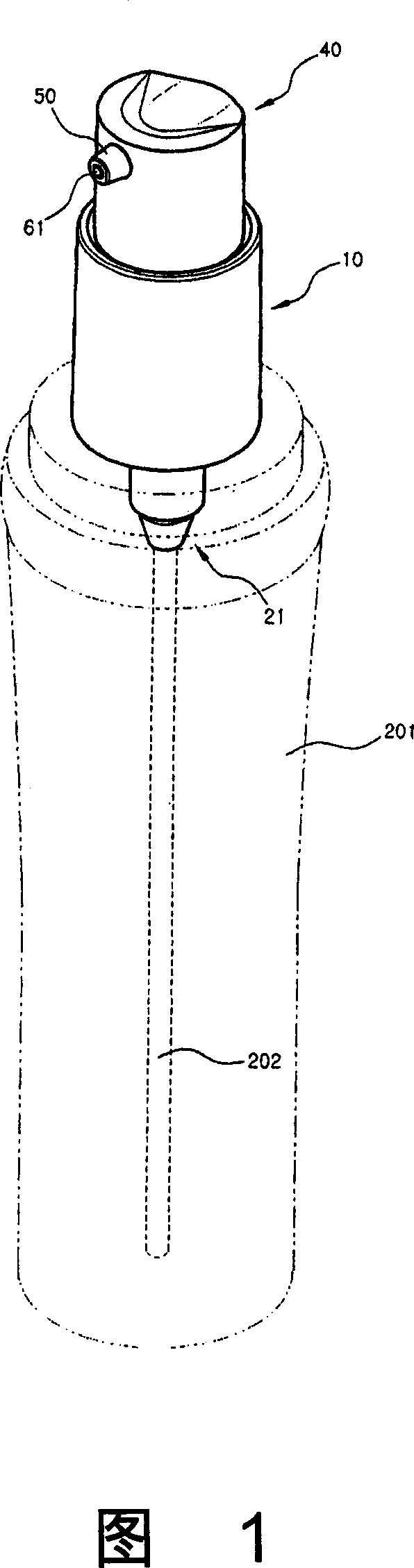

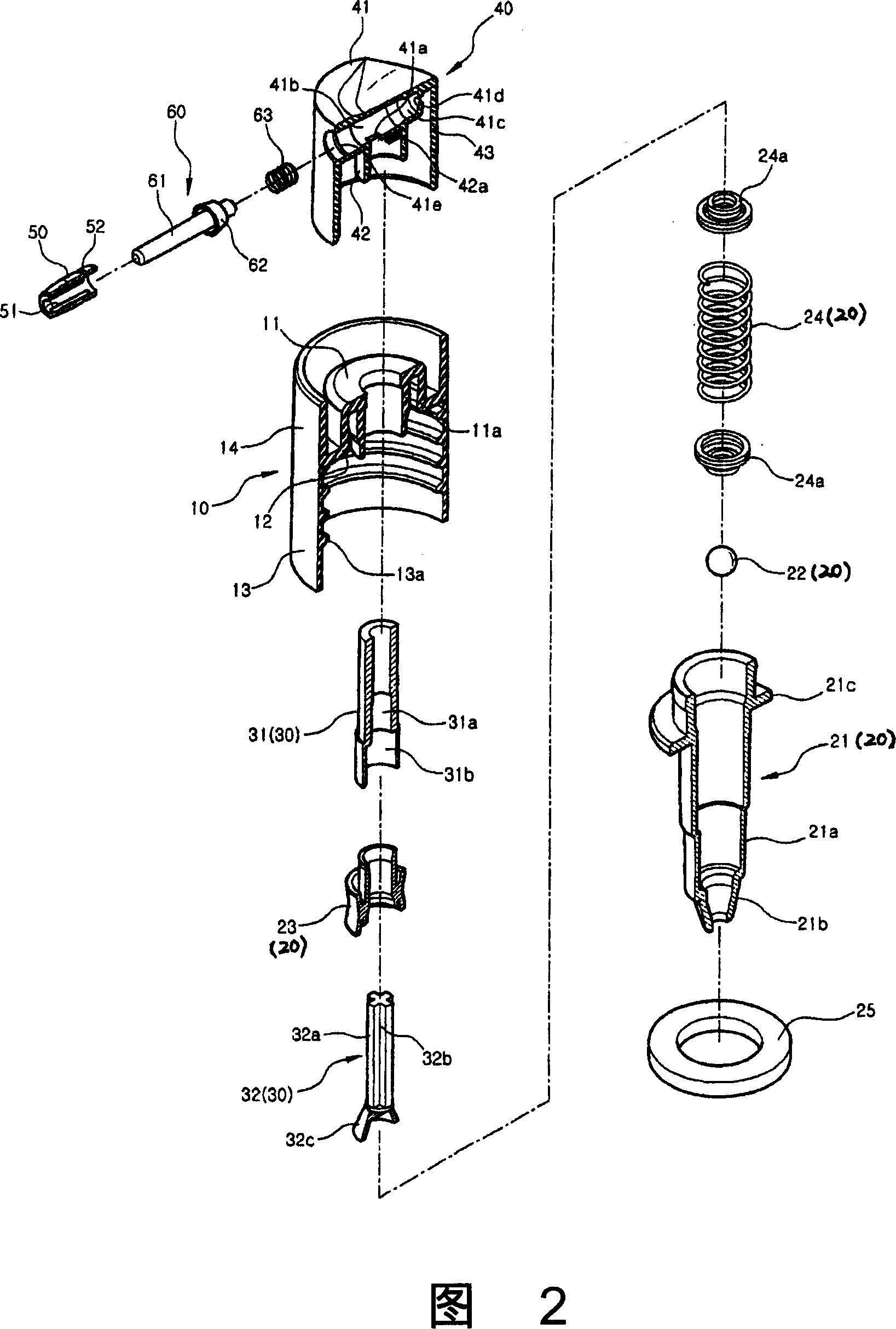

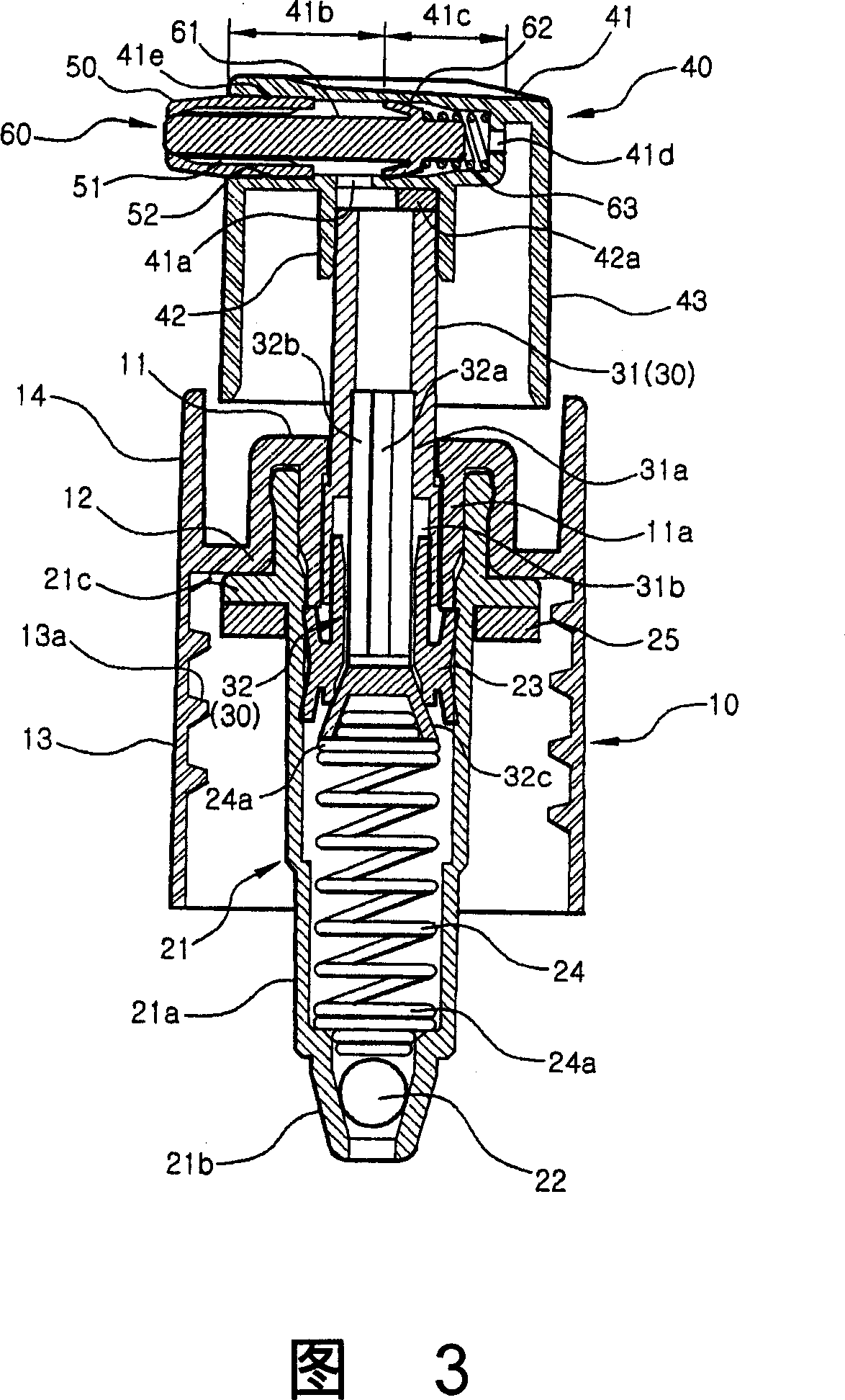

Diffuseur of liquid pump

InactiveCN101045226AReduce fluid volumePackaging toiletriesSingle-unit apparatusEngineeringClose contact

Disclosed is A liquid pump dispenser. A fluid path opening and closing section has a rod-shaped body part which is installed in a discharge guide path and a sliding guide groove of a push button, a wing part which is formed around the body part to be brought into close contact with an inner surface of the sliding guide groove, and a return spring which is disposed in the sliding guide groove to bias the wing part toward the discharge guide path. The body part is retracted to an opening position for opening the discharge guide path with respect to the outside by pressure applied from pumped liquid entering the discharge guide path to the wing part and is extended to a closing position for closing the discharge guide path with respect to the outside by pressure applied from the return spring to the wing part.

Owner:TAESUNG IND

Sensor for sensing contents of components to be measured in human tissue fluid, fluid channel unit and method for measuring contents of components to be measured in human tissue fluid

ActiveCN101514990AExtended service lifeTo overcome the lack of service lifeMaterial analysis using sonic/ultrasonic/infrasonic wavesBiological testingHuman bodyCantilevered beam

Owner:TIANJIN SUNRISE TECH DEV

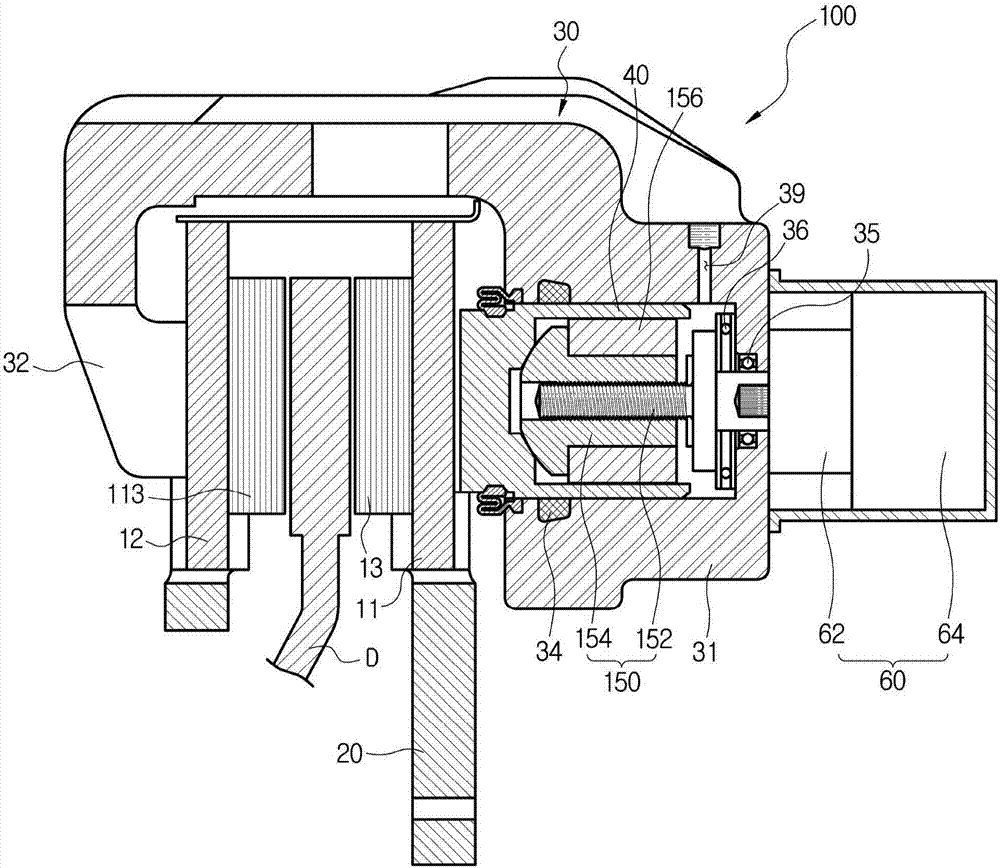

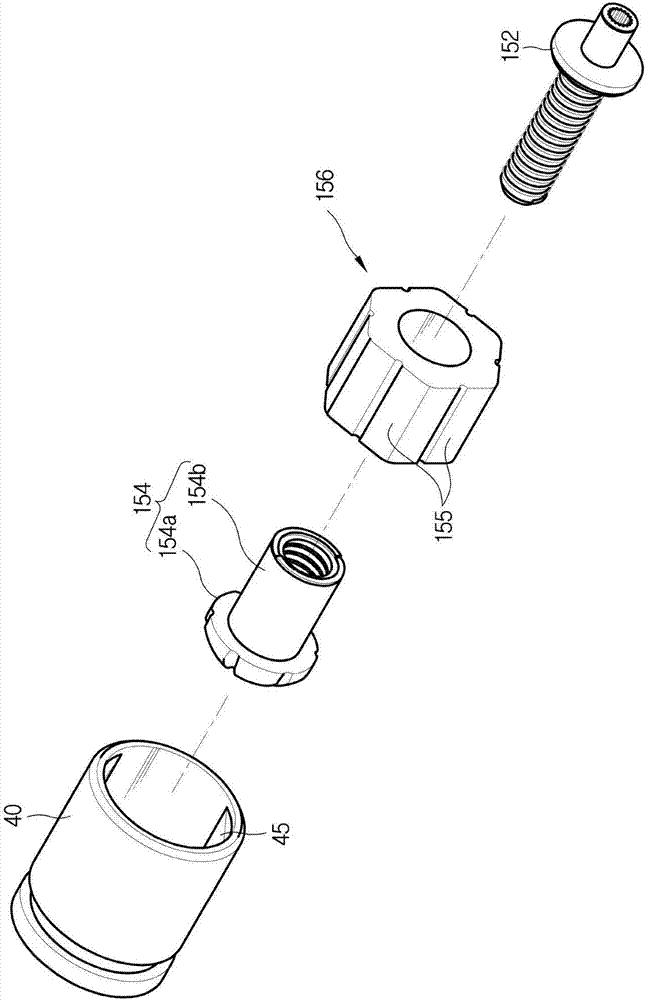

Electric caliper brake

ActiveCN107489714APrevent bearing forceIncreased durabilityAxially engaging brakesGearingCalipersActuator

Disclosed herein is an electric caliper brake. Then electric caliper brake which includes a carrier provided with a pair of pad plates movably with respect to a disk, and a caliper housing slidably installed on the carrier and provided with a cylinder in which a piston is movably provided by braking oil pressure, includes a spindle member which is installed to penetrate a rear portion of the cylinder and rotates by receiving a rotational force from an actuator, and a power converting unit including a nut member which is screwed with the spindle member and is disposed in the piston, moves forward and backward in accordance with the rotation of the spindle member so as to press the piston; a filling member coupled to the nut member in the piston; and an anti-rotation surface provided on at least one plane on an outer circumferential surface of the filling member so that the filling member is coupled to the piston in a limited rotation state.

Owner:HL MANDO CORP

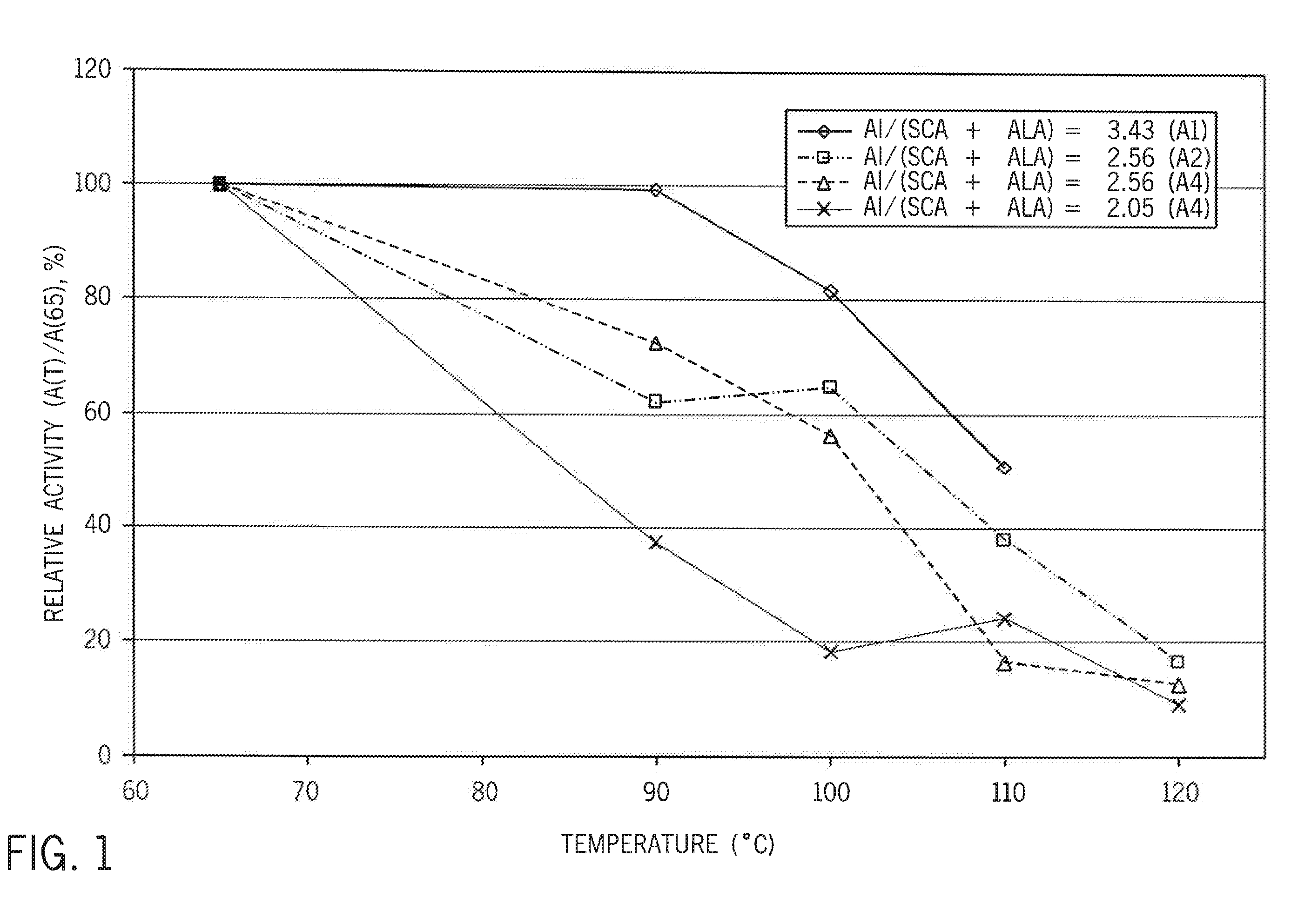

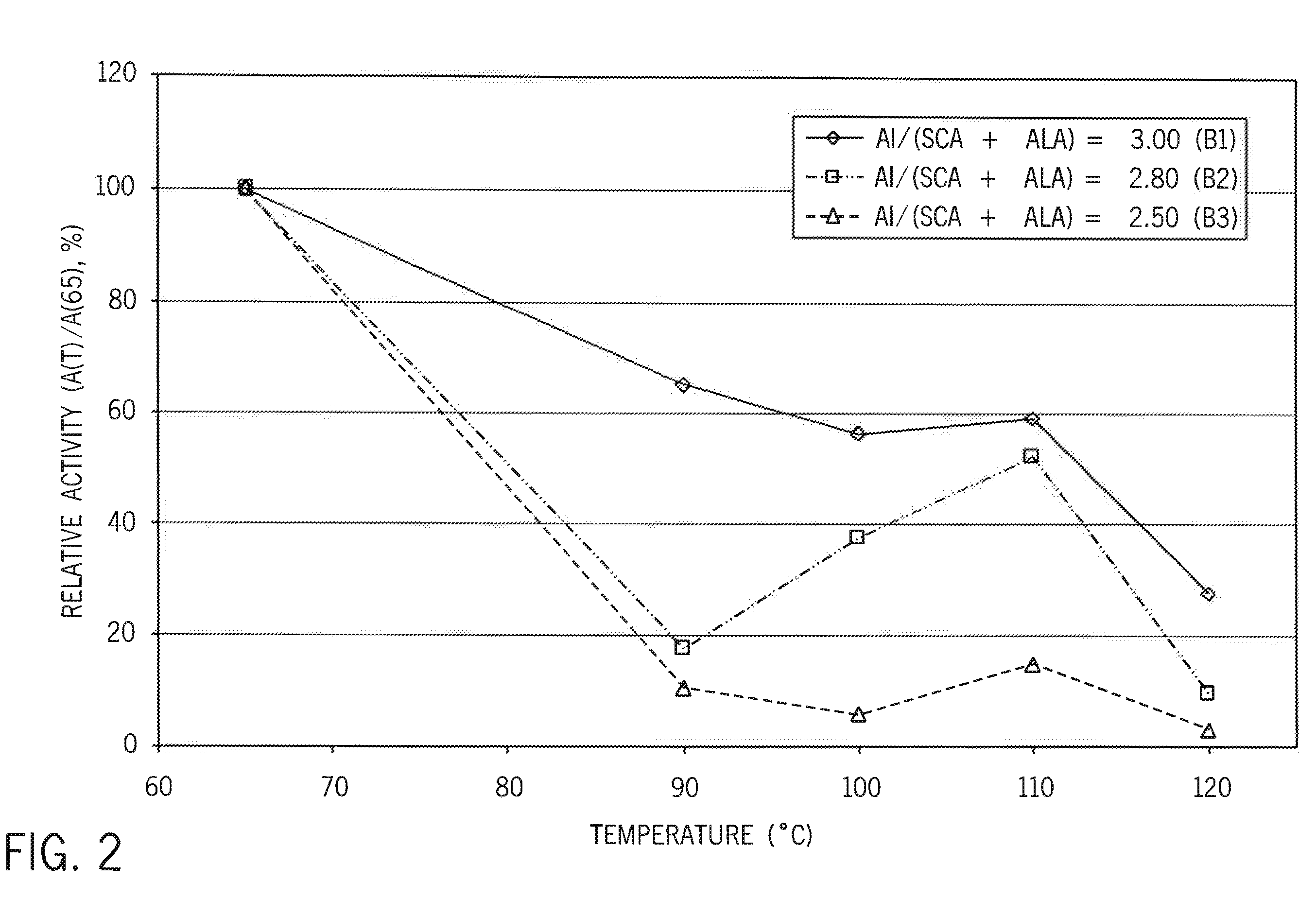

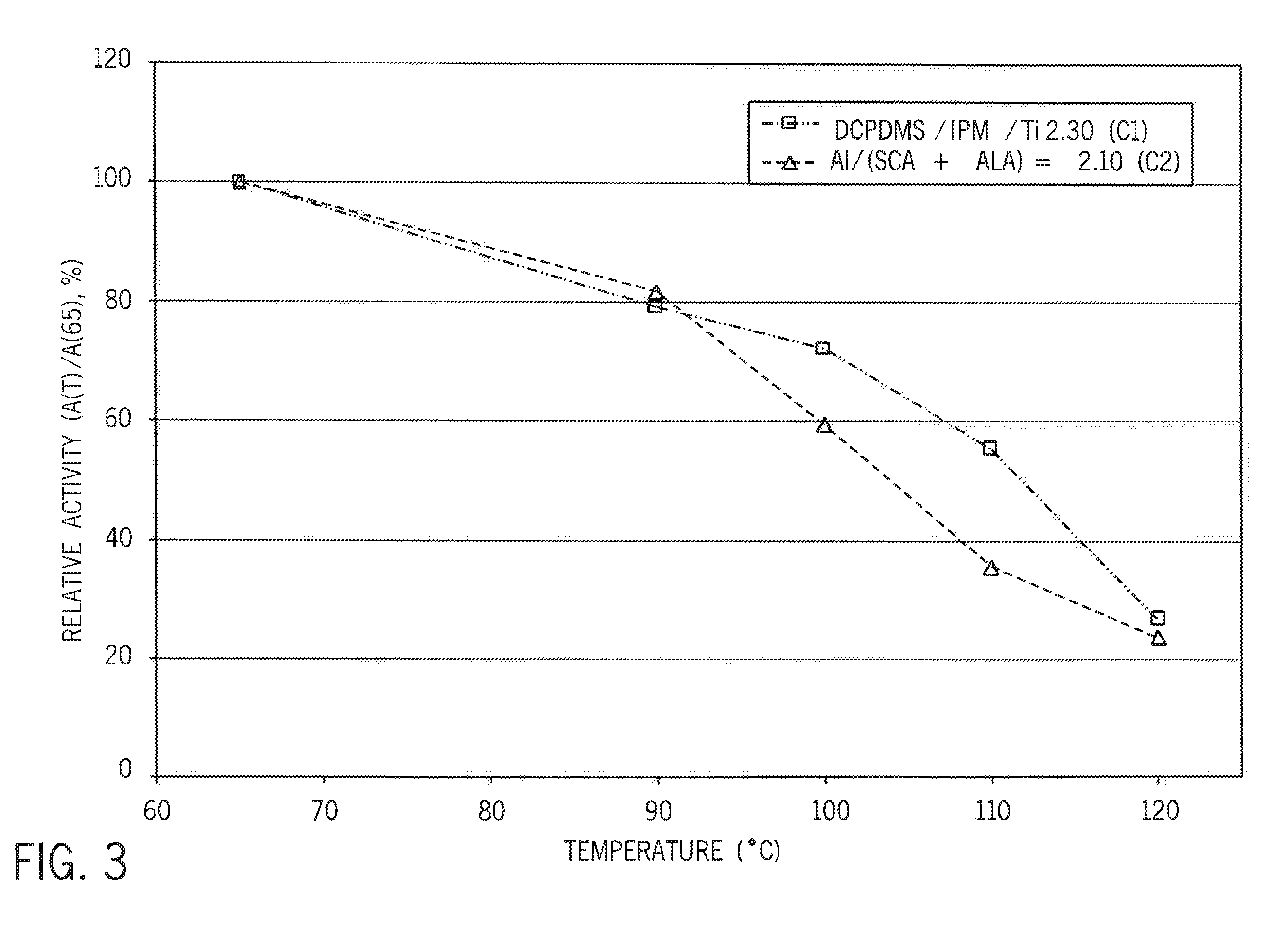

Self-Limiting Catalyst System with Controlled Aluminum to SCA Ratio and Method

ActiveUS20110152067A1Improved catalyst compositionReduced polymer agglomerationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSelf limitingProduction rate

A catalyst composition for the polymerization of propylene is provided. The catalyst composition includes one or more Ziegler-Natta procatalyst compositions having one or more transition metal compounds and one or more esters of aromatic dicarboxylic acid internal electron donors, one or more aluminum containing cocatalysts and a selectivity control agent (SCA). The SCA is a mixture of an activity limiting agent and a silane composition. The catalyst composition has a molar ratio of aluminum to total SCA from 0.5:1 to 4:1. This aluminum / SCA ratio improves polymerization productivity and the polymer production rate. The catalyst composition is self-extinguishing.

Owner:WR GRACE & CO CONN

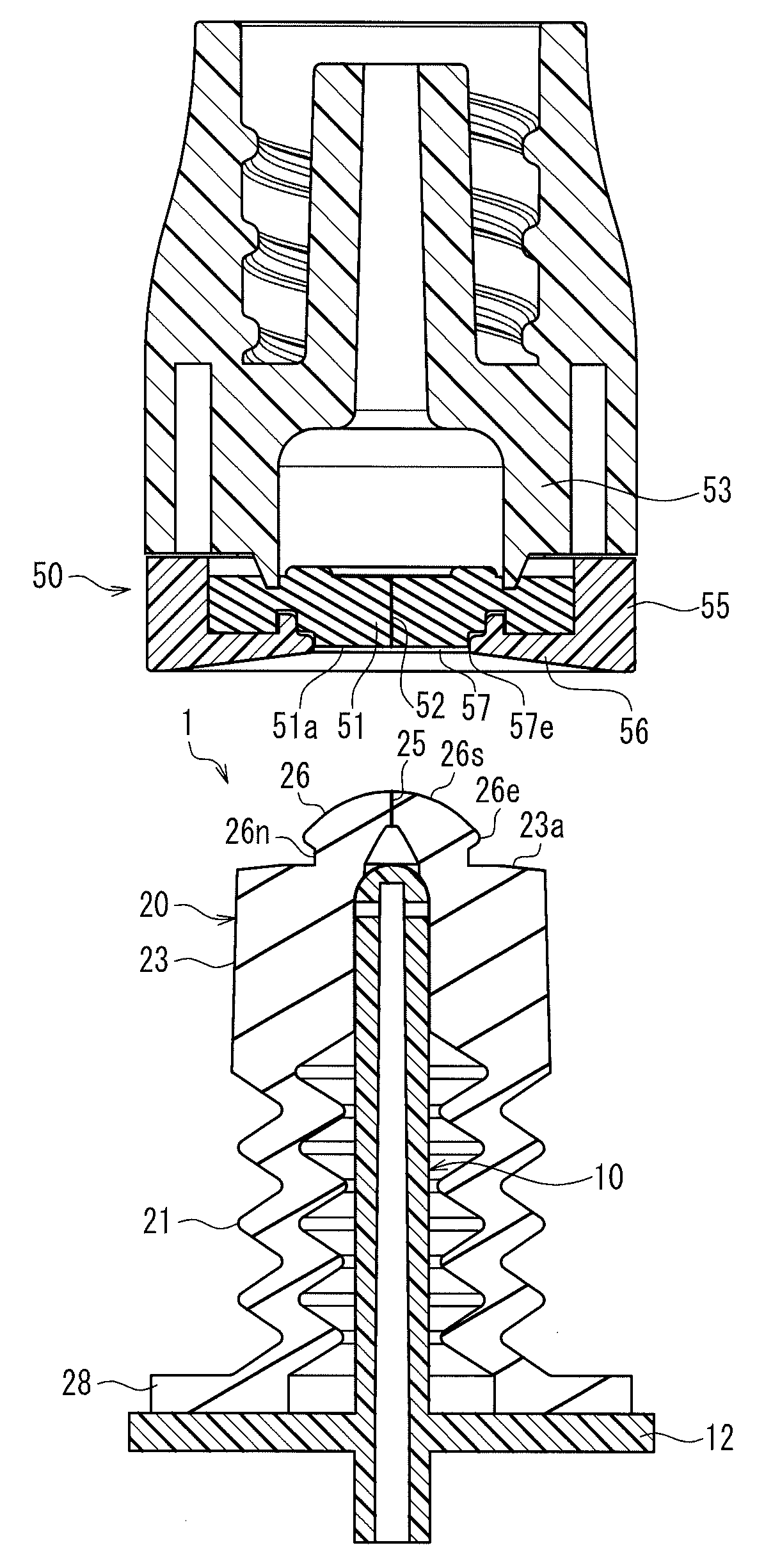

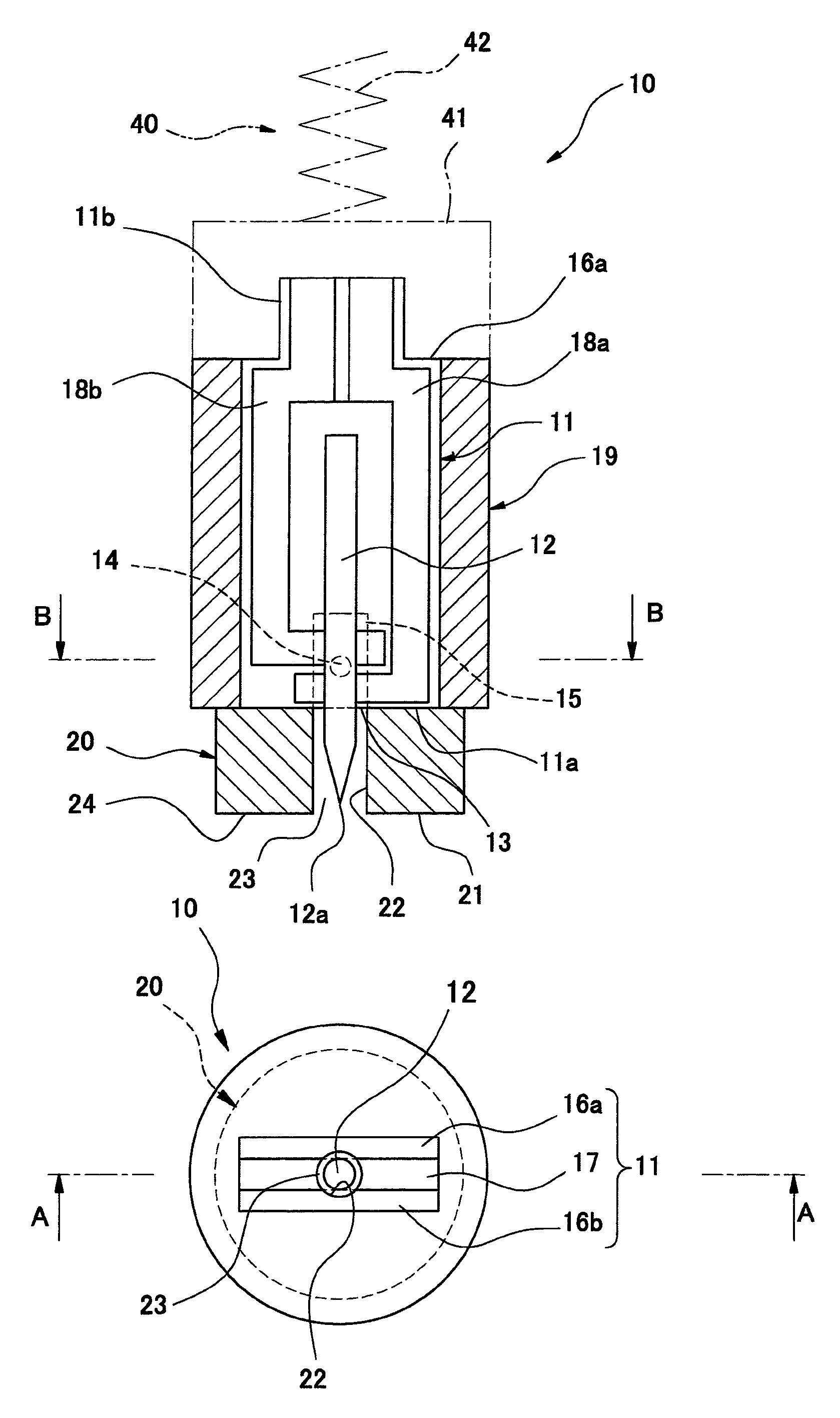

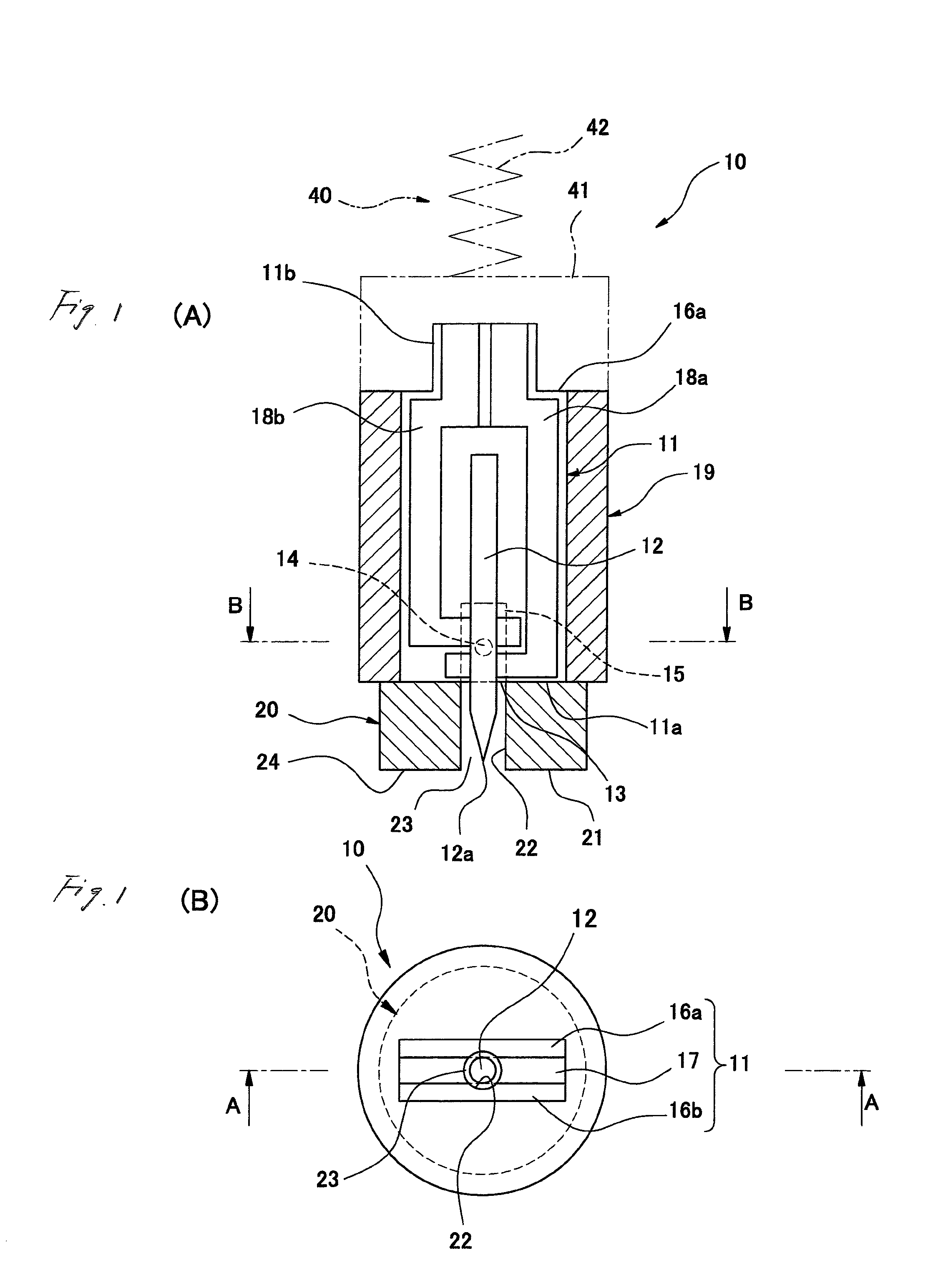

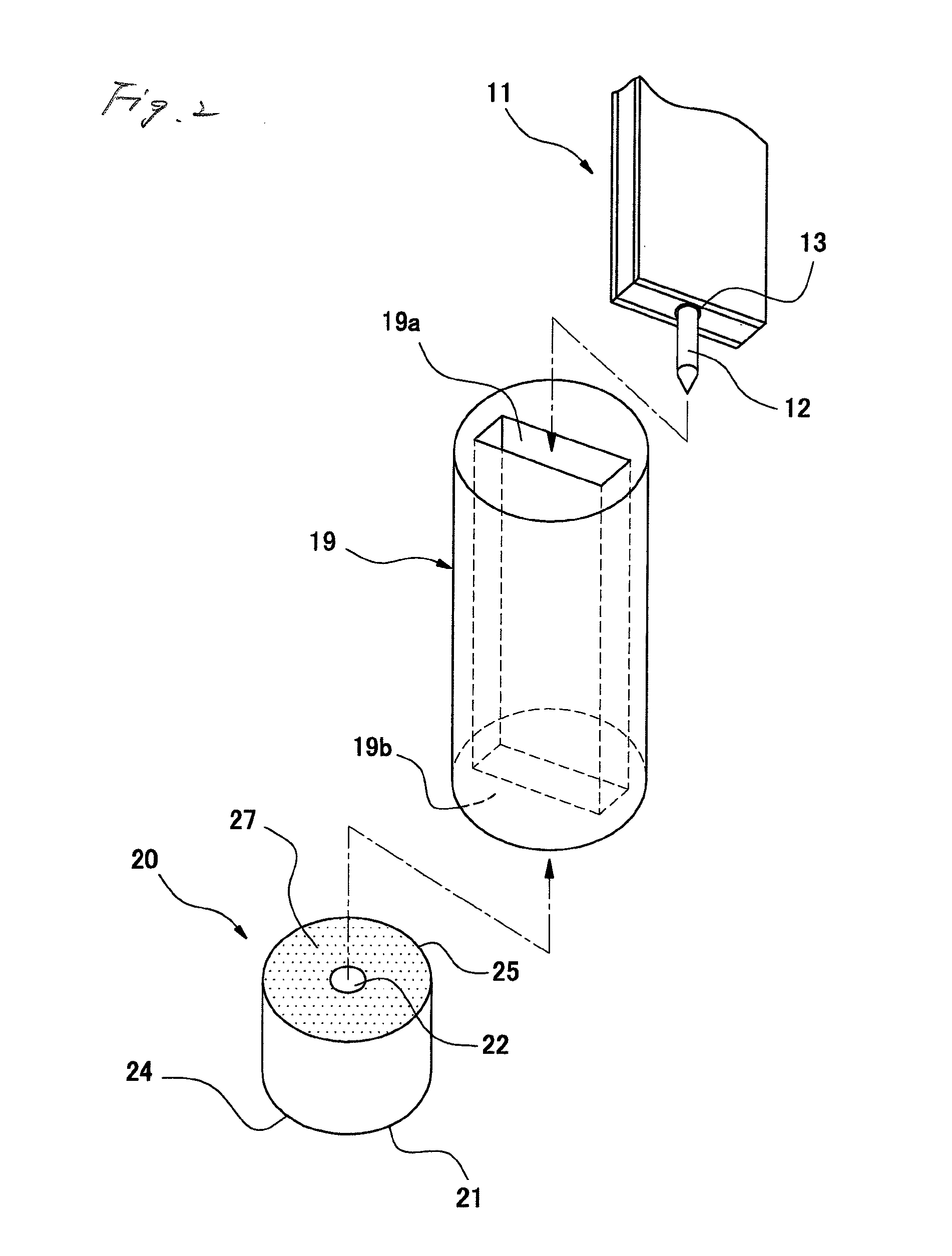

Biosensor cartridge, biosensor device, sample collecting method, manufacturing method of biosensor cartridge, and needle integral sensor

InactiveUS20100069792A1Ensure correct executionIncrease contact areaLine/current collector detailsWave amplification devicesEngineeringRestoring force

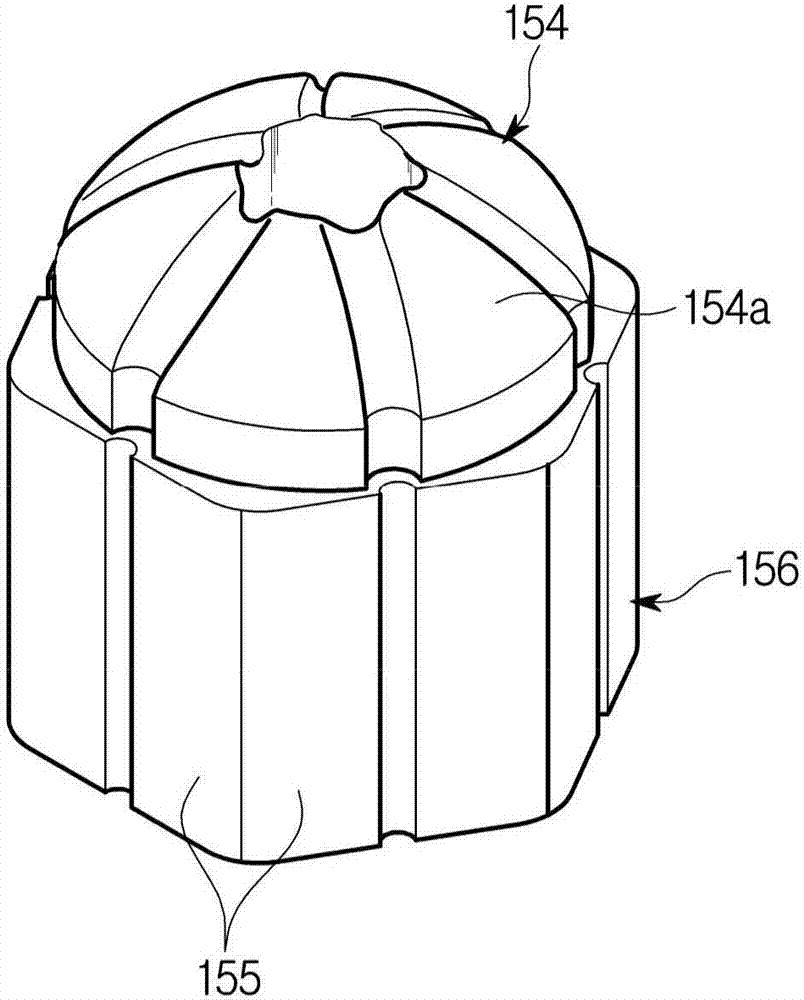

A biosensor cartridge capable of performing puncturing in an exact position, and easily collecting and measuring a sample of a puncture hole without requiring the operation of bringing a sample collection opening close to the puncture hole is provided. When tip portion 11a of biosensor chip body 11 is pushed against a subject M, elastic body 20 protruding from a tip portion 11a of biosensor chip body 11 is compressed, and puncturing tool 12 for puncturing protrudes. Thus, the subject M can be punctured. Additionally, if a pushing force is weakened, puncturing tool 12 is extracted from the subject M by the restoring force of elastic body 20, and the sample R flows out of the puncture hole. Additionally, cover member 19 is provided around biosensor chip body 11. Thus, when puncturing is performed by thin plate-shaped biosensor cartridge 10, biosensor chip body 11 can be prevented from deforming, and puncturing can be accurately performed in a desired puncturing position.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

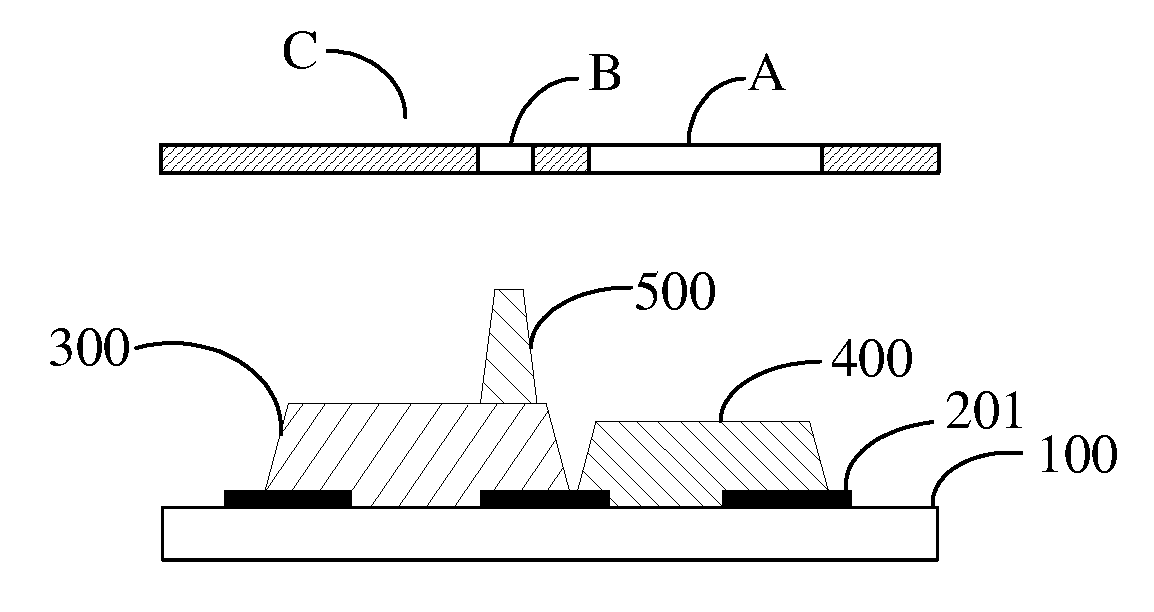

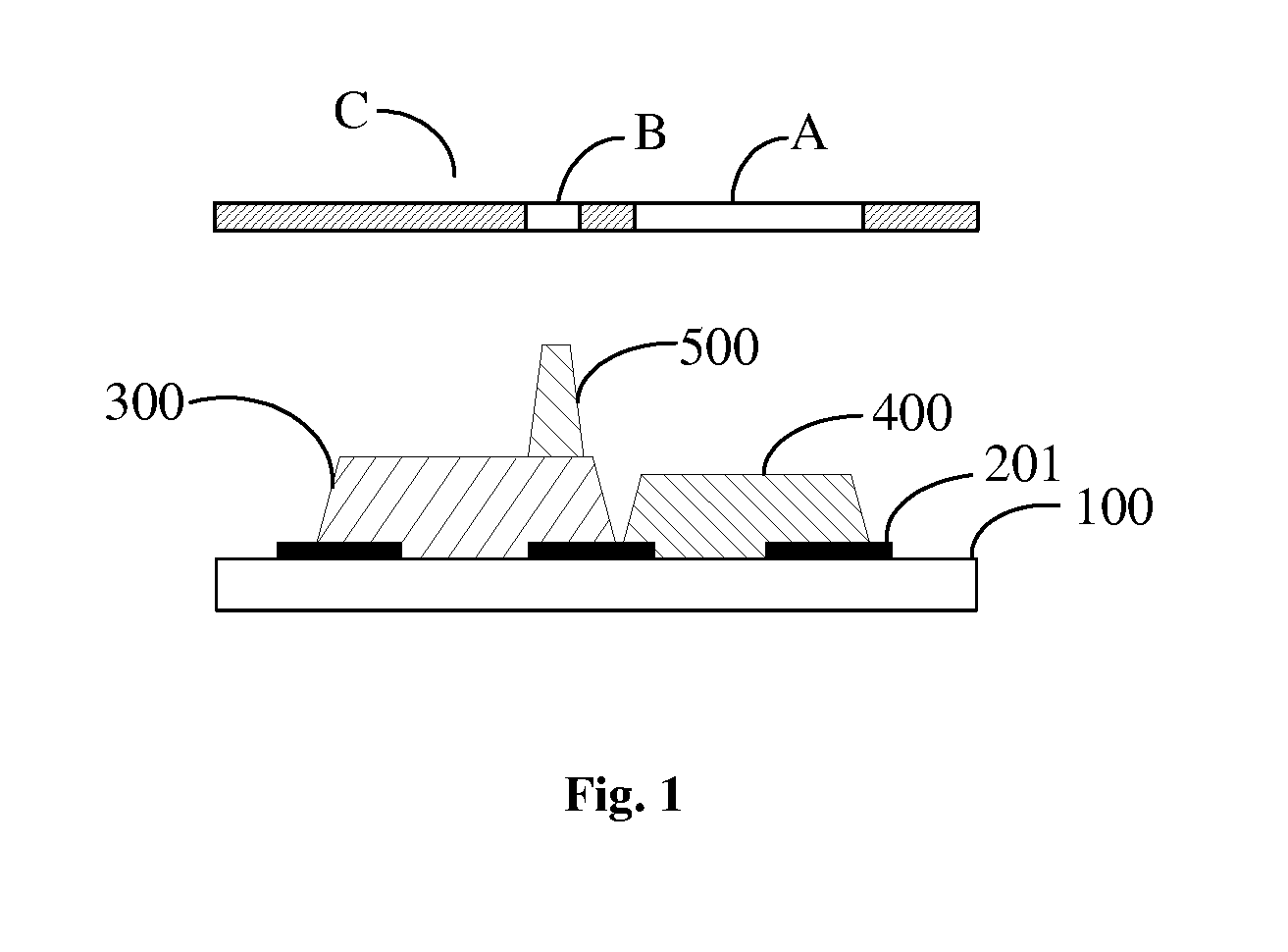

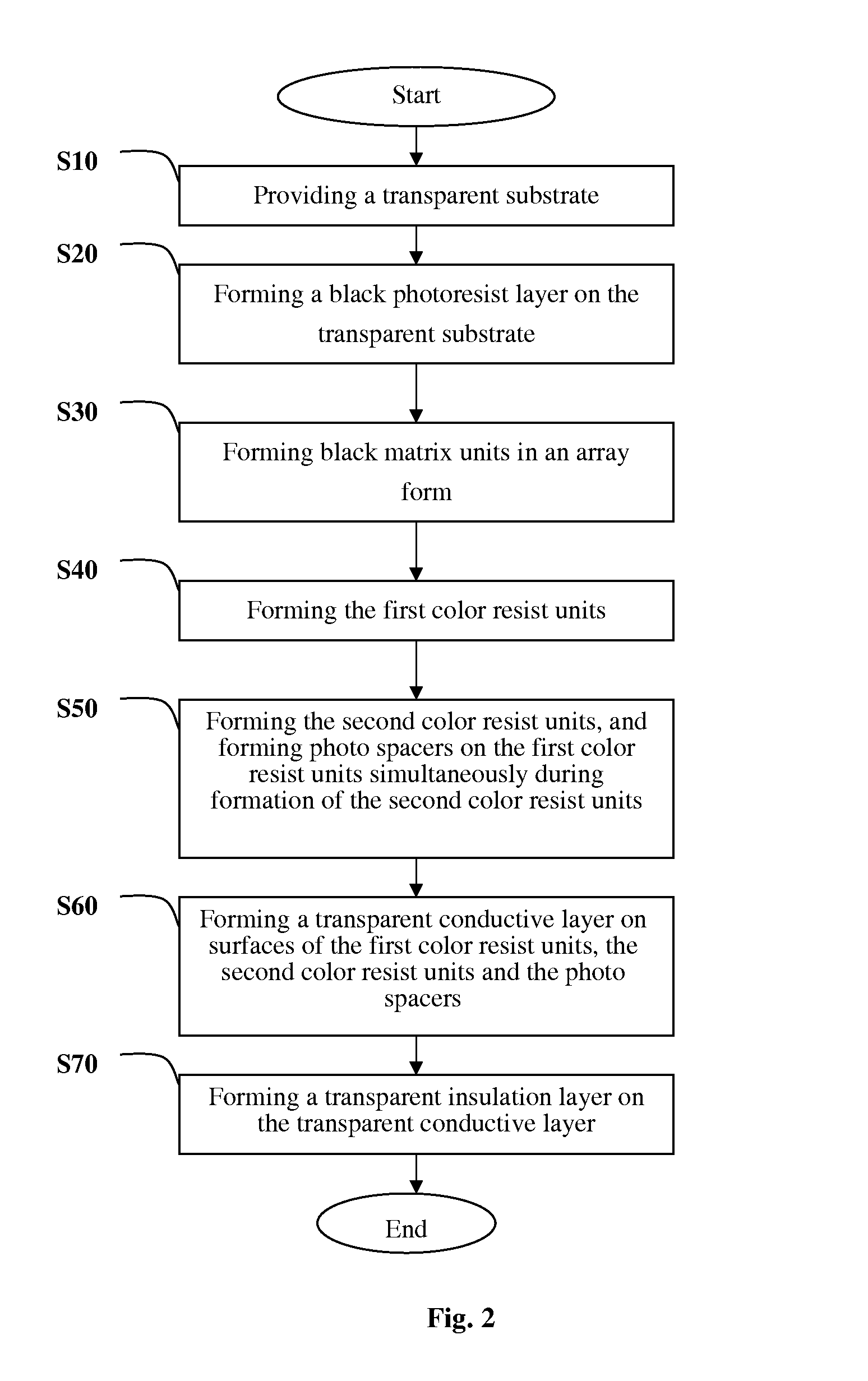

Color filter and manufacturing method thereof

InactiveUS20130021688A1Simple manufacturing processIncrease productivityPhotomechanical exposure apparatusMicrolithography exposure apparatusResistColor gel

The present invention provides a color filter and a manufacturing method of the color filter. The color filter comprises first color resist units and second color resist units, and a pixel layer is formed by the first color resist units and the second color resist units. The manufacturing method comprises the following step of: after the first color resist units are formed, forming photo spacers for controlling a gap between an array substrate and a color filter substrate simultaneously when the second color resist units are formed. The present invention can reduce the number of manufacturing processes and effectively reduce the manufacturing cost of liquid crystal displays (LCDs).

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

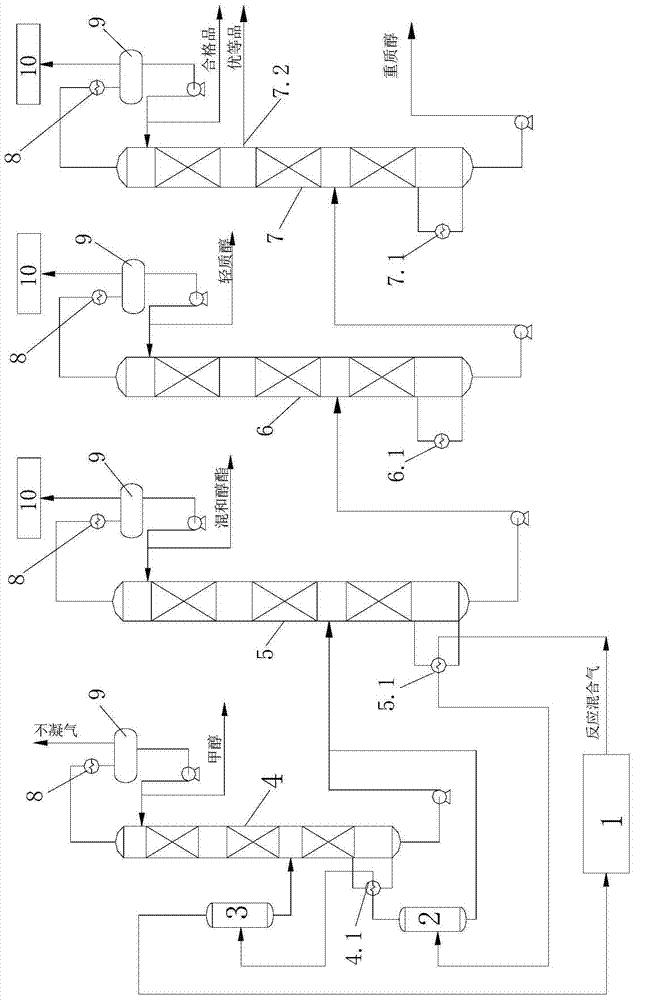

Ethylene glycol refining and separating method and system

InactiveCN104725191AImprove recycling efficiencyDistillation method is simpleOrganic compound preparationHydroxy compound separation/purificationGas phaseMixed gas

The invention discloses an ethylene glycol refining and separating method and system, solving the problems of complex process, difficult separation and high equipment investment and energy consumption existing in the prior art. Reaction mixed gas from an ethylene glycol synthetic system is cooled and then is separated by a first gas-liquid separator, the gas phase is fed into the ethylene glycol synthetic system as hydrogen-containing circulating gas, and the liquid phase is fed into a methanol recovering tower to product methanol from the top of the tower; the reaction mixed gas is fed into the second gas-liquid separator after cooling, the gas phase is cooled further and then is fed into the first gas-liquid separator, the liquid phase is mixed with a tower bottom liquid from the methanol recovering tower and then is fed into a degreasing tower, mixed ethanol ester is produced from the top of the degreasing tower, the tower bottom liquid is fed into a hydrogen removing tower, light alcohol is produced from the top of the hydrogen removing tower, the tower bottom liquid is fed into a refining tower, and qualified ethylene glycol is produced from the top of the refining tower, a side-draw is arranged at the same time to extract high-quality ethylene glycol. The process is simple, the operation is simple and convenient, the equipment investment and running cost are low, the impurity separation effect is favorable, and the yield is high.

Owner:WUHUAN ENG +1

Fischer-Tropsch synthesis process based on fixed bed reactor

ActiveCN101275080AImprove heat transfer phenomenonEliminate hot spotsHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasExhaust gas

The present invention provides a ft synthesis reaction process based on the fixed bed reactor is that the cycling medium enters from the top of the fixed bed reactor after preheated, the feed gas formed by mixing the syngas with the tail gas enters from the lower of the fixed bed reactor to contact with the catalyst to process ft synthesis , the product is fully collected to process the separation of water, a long chain hydrocarbon and a gas phase component; the long chain hydrocarbon processes C5-C18 middle distillate, the separation of C18+hydrocarbon and gaseous low carbon hydrocarbon, one part C5-C18 middle distillate is mixed with the cycling liquid medium, the other part is processed oil product process, C18+hydrocarbon fully enters in the oil product process, the gaseous low carbon hydrocarbon mixing with the gas phase component forms the tail gas, the water component is used as a gas agent to return in the gasification system. The invention has high heat exchange efficiency, high syngas throughput, lower cycling gas quantity, lower energy consumption, stable operation.

Owner:中科潞安能源技术有限公司

Elastic gel temporary plugging well killing fluid used in combination with gas well and construction process

ActiveCN111205839AHigh cross-linking reactivityHigh local compressive strengthDrilling compositionSealing/packingEnvironmental engineeringCross linker

The invention relates to an elastic gel temporary plugging well killing fluid used in combination with a gas well and a construction process. The elastic gel temporary plugging well killing fluid comprises 1 # elastic gel and 2 # elastic gel, wherein the 1 # elastic gel comprises the following components in parts by weight: 1.5-3 parts of a temperature-resistant and salt-resistant polymer, 1.0-1.5parts of an organic cross-linking agent, 4-6 parts of an inorganic toughening agent, 0.2-0.5 parts of a stabilizer and 100 parts of water, and the 2 # elastic gel comprises the following components in parts by weight: 2-5 parts of a temperature-resistant and salt-resistant polymer, 1.0-1.5 parts of an organic cross-linking agent, 0.2-0.5 parts of a stabilizer and 100 parts of water. After the combined elastic gel temporary plugging well killing fluid is gelatinized, the pressure resistance is greater than or equal to 20MPa, and the theoretical filtration loss is less than 200mL / h, the performance stabilization time is longer than 30 days, the adsorption retention in places such as stratums and wellbores is effectively reduced while the high pressure bearing capacity is ensured, and the technical requirements for temporary plugging leakage prevention and reservoir protection of gas wells with relatively low stratum pressure coefficients are met.

Owner:PETROCHINA CO LTD

Method of repairing a liquid crystal display panel

ActiveUS7319504B2Promote repairReduce fluid volumeNon-linear opticsLiquid-crystal displayEngineering

A method of repairing an LCD panel having a mura defect is disclosed. The closed seal pattern of the LCD panel has a shape of frame with at least one jut portion directing to a peripheral side of the two substrates. Thus, when a mura defect occurs, a peripheral portion on one side of the two substrates is cut off, wherein the cutting passes across the jut portion of the closed seal pattern to form an opening with respect to the sealed region. An extra amount of liquid crystal can be pressed out through the opening. Then the opening is sealed using a sealant, such that the LCD panel having a mura defect is repaired.

Owner:HANNSTAR DISPLAY CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com