Method for controlling combustion in an internal combustion engine and the internal combustion engine

A technology for internal combustion engines and control devices, applied in the direction of adding non-fuel substances to fuel, electrical control, engine control, etc., can solve the problems that parameters cannot be fully pre-controlled, high fluid consumption, etc., to improve exhaust gas temperature regulations and reduce fluid consumption , the effect of reducing the amount of fluid maintained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

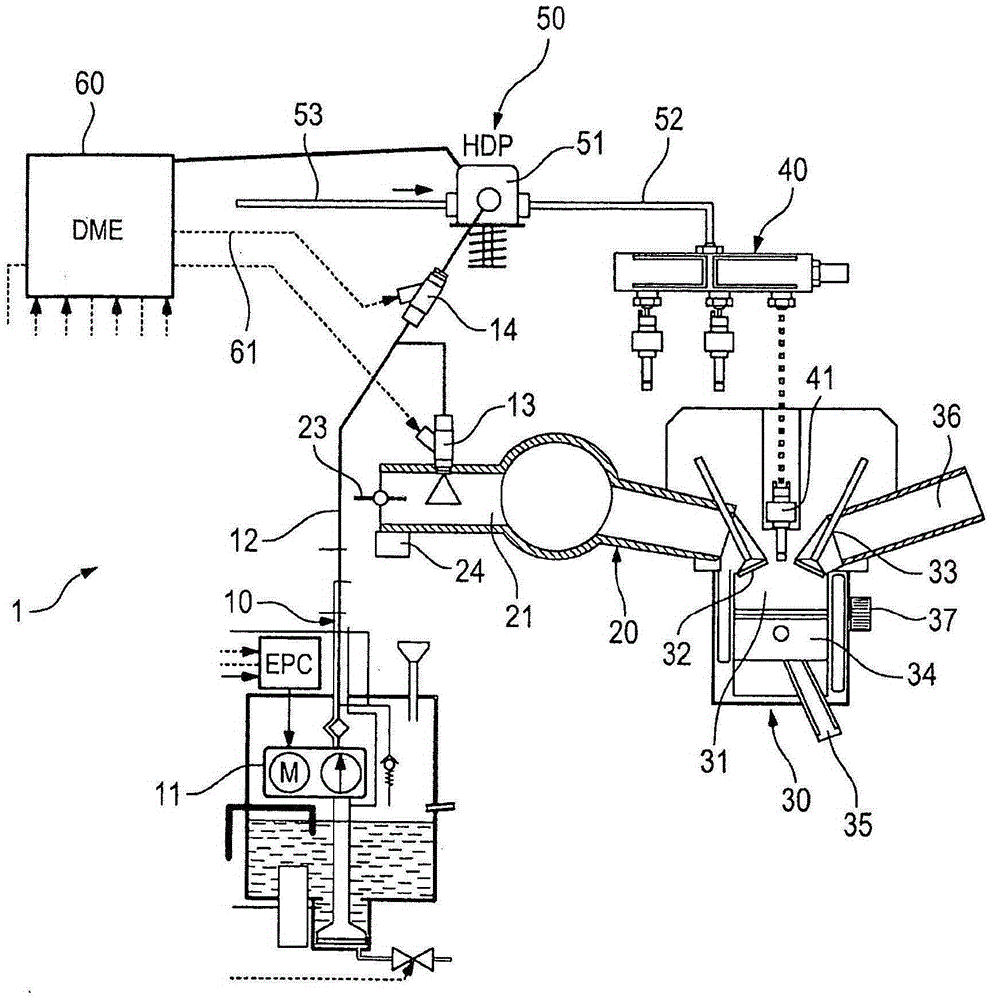

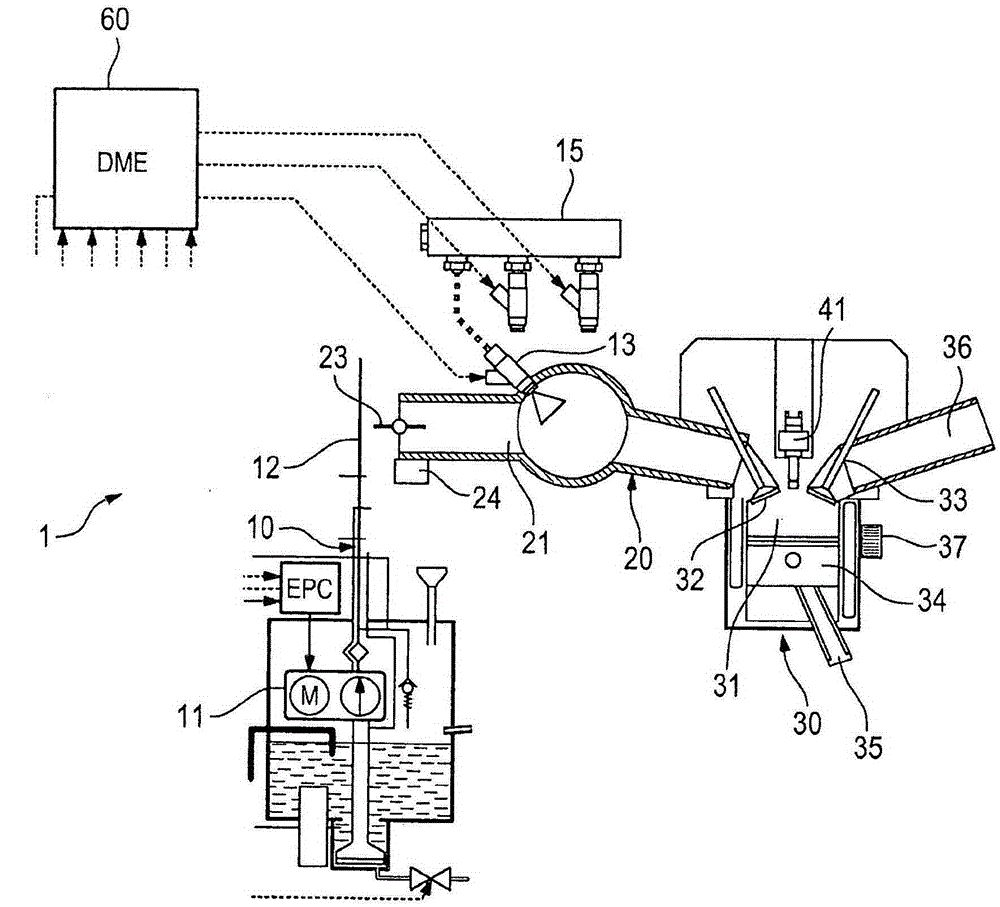

[0035] figure 1 A schematic diagram of a fluid ejection system 1 is shown. The fluid injection system 1 has a fluid system 10 . Fluid system 10 includes a fluid pump 11 , which maintains a fluid or delivers fluid at a predeterminable pressure into fluid system 10 . Furthermore, the fluid pump 11 may have a fluid reservoir (not shown) for storing a predeterminable amount of fluid. The fluid has been pressurized in the fluid system 10 at which pressure the fluid is injected into the fuel system 50 or directly into the cylinder 30 .

[0036] Fluid is directed in fluid system 10 through fluid tube 12 to fluid injector 13 . In particular, fluid injector 13 can be designed as a throttle valve. exist figure 1 In the embodiment shown, the fluid injector 13 connects the fluid system 10 to the intake line 21 of the intake system of the cylinder 30 . Here, in this embodiment, the intake manifold 21 is a common intake manifold or a community of an internal combustion engine, in part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com