Substrate drying device and method, and substrate producing method

A technology of a drying device and a drying method, which is applied in the field of substrate manufacturing and can solve the problems of low drying substrate capacity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

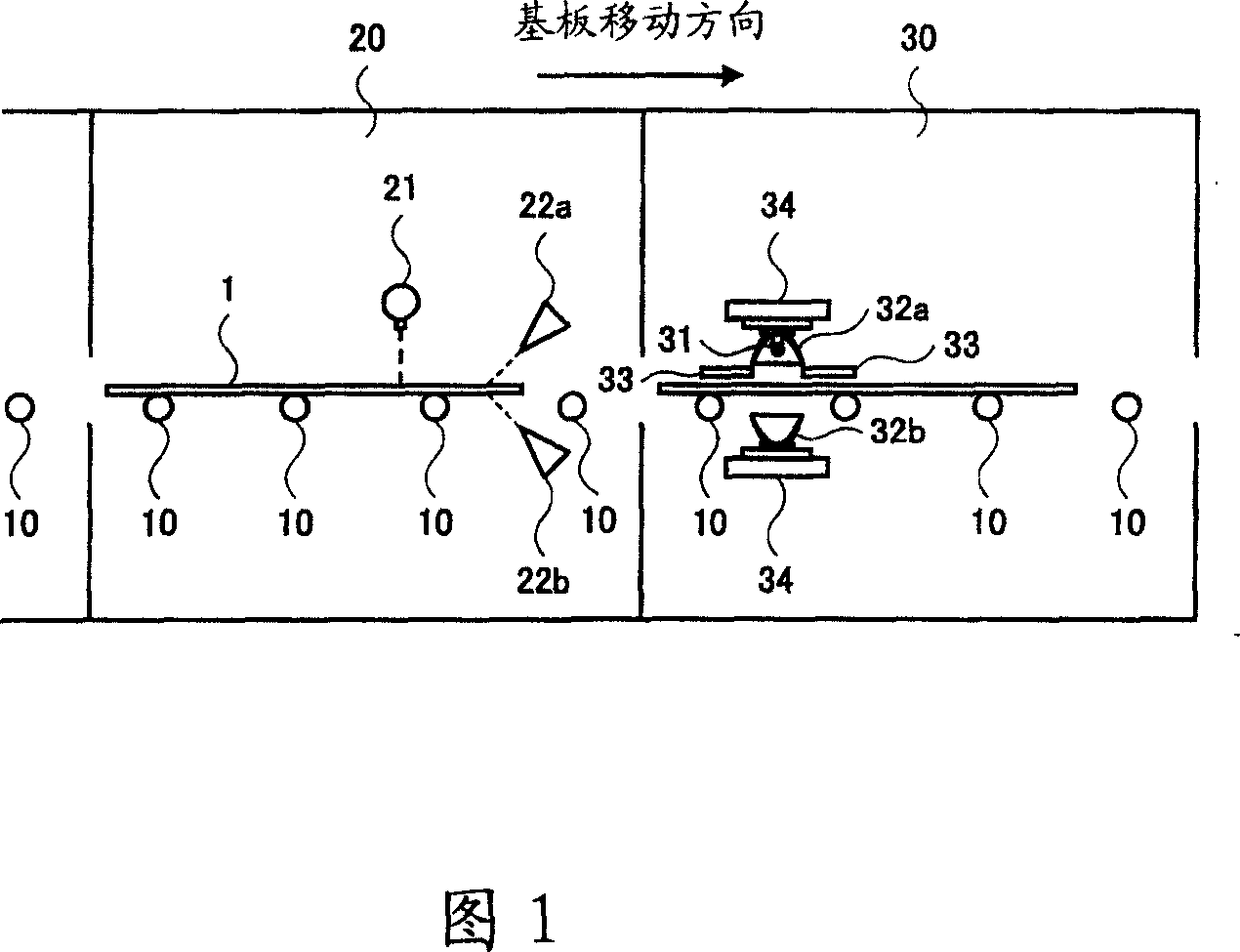

[0031] FIG. 1 is a diagram showing a schematic configuration of a substrate drying apparatus according to an embodiment of the present invention. The substrate drying device includes a liquid film forming chamber 20 and a liquid film removing chamber 30 . In the liquid film forming chamber 20 and the liquid film removing chamber 30 , a plurality of rollers 10 are provided at predetermined intervals, and the substrate 1 mounted on the rollers 10 moves in the substrate moving direction indicated by the arrow by the rotation of the rollers 10 .

[0032] Furthermore, in the present embodiment, the substrate 1 is moved in a horizontal state, but the present invention is not limited thereto, and may be in a direction perpendicular to the substrate moving direction or at a predetermined angle relative to the horizontal direction. In an inclined state, the substrate 1 is moved.

[0033] In the front stage of the liquid film forming chamber 20 , for example, a cleaning chamber is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com