Patents

Literature

39results about How to "Reduce sensible heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

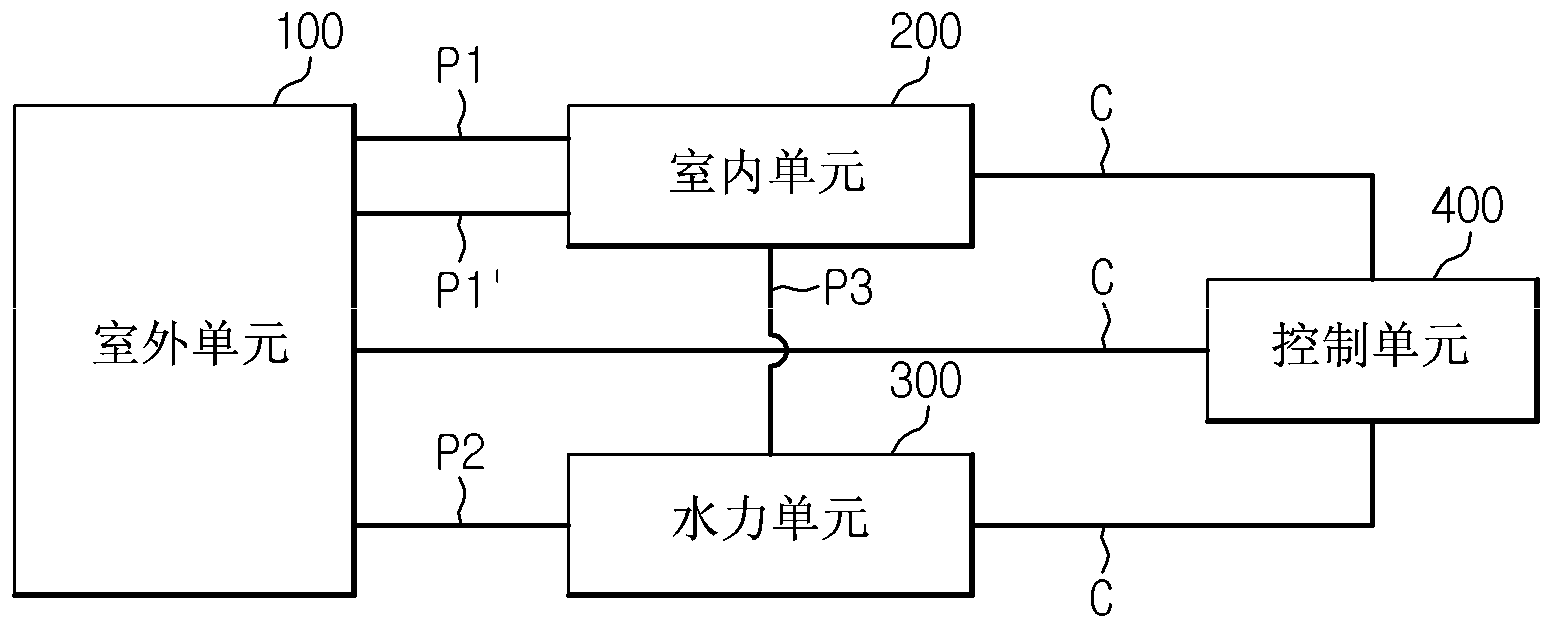

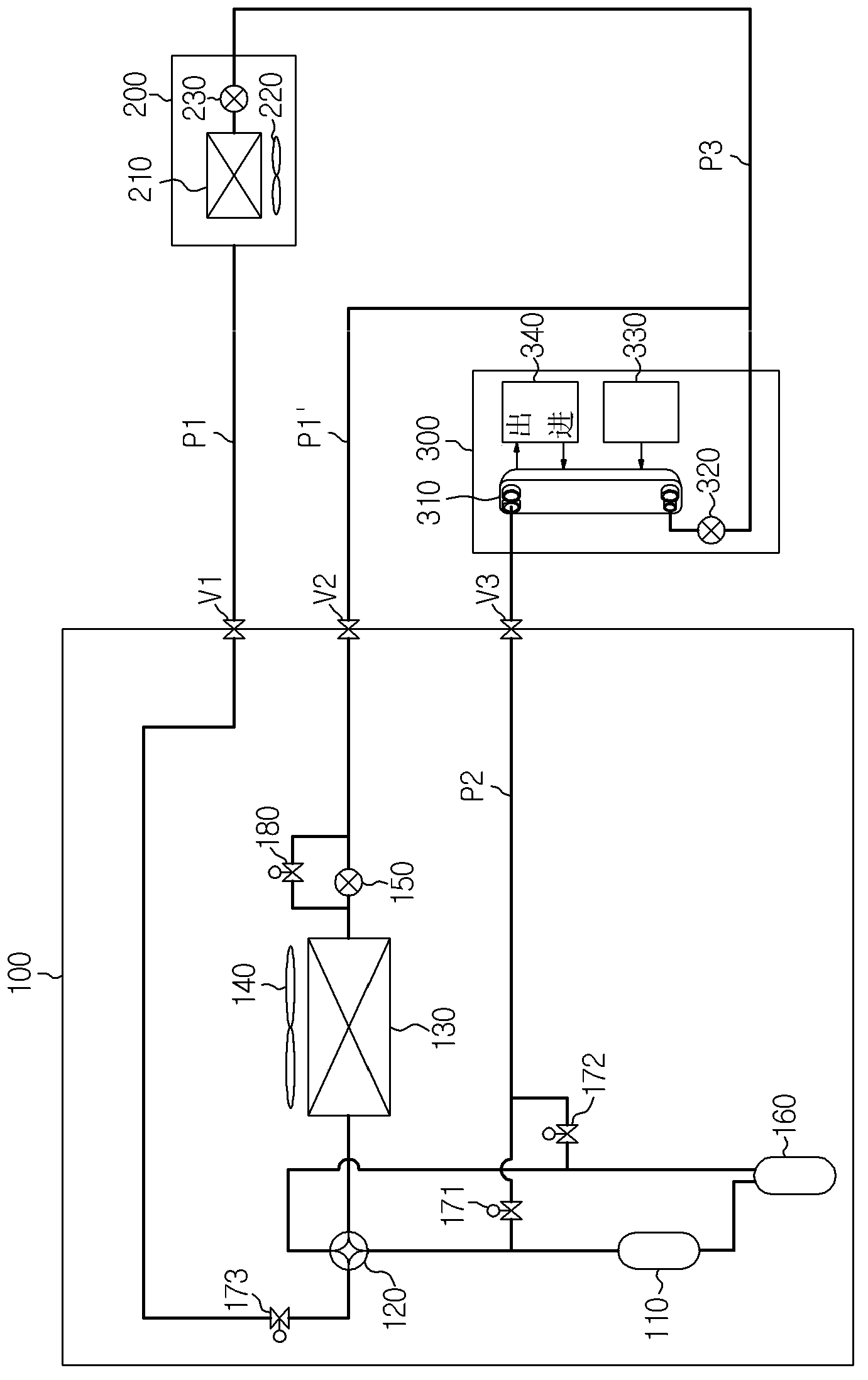

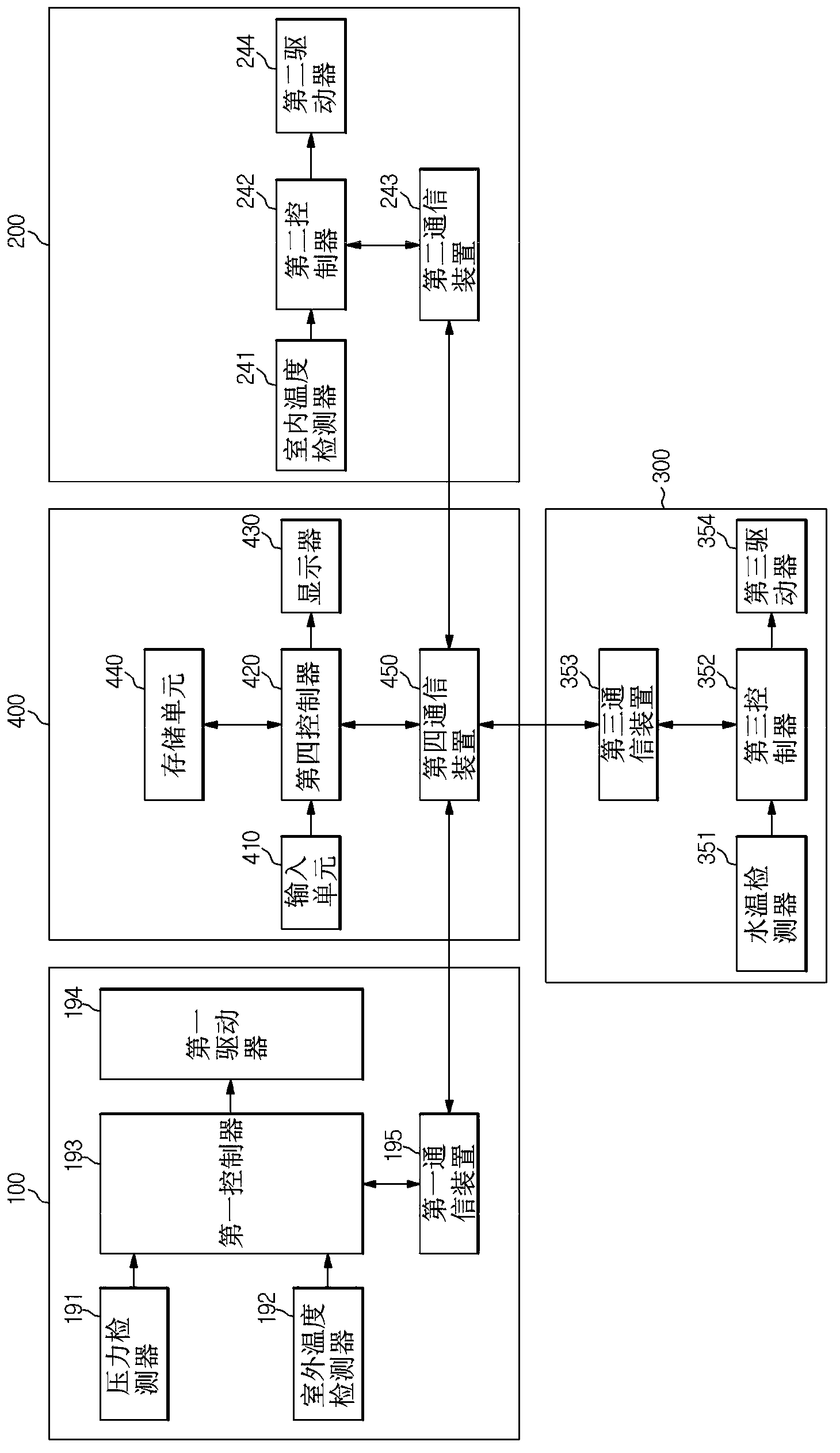

Heat pump and method for controlling the same

InactiveCN102840726AImprove general performanceNot affected by the seasonHeat pumpsSpace heating and ventilation detailsRecuperatorProcess engineering

The invention provides a heat pump and a method for controlling the same. The method for controlling a heat pump including an outdoor unit including a compressor and a first heat exchanger, an indoor unit including a second heat exchanger and an expansion valve to perform air stream cooling and heating operations, and a hydro unit connected among the compressor, the first heat exchanger, and the expansion valve, to change a flow direction of refrigerant in accordance with cold water and hot water operations. In the control method, it is determined whether the hot water operation and the air stream heating operation are simultaneously selected. When the hot water operation and the air stream heating operation are simultaneously selected, an opening degree of a valve included in the hydro unit is adjusted, to adjust amounts of refrigerant respectively supplied from the compressor to the hydro unit and the indoor unit.

Owner:SAMSUNG ELECTRONICS CO LTD

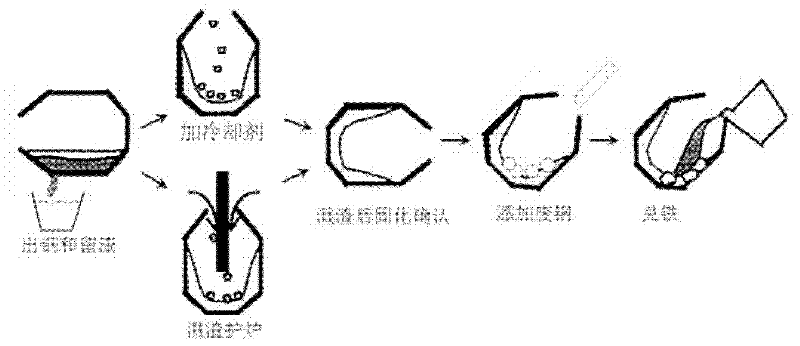

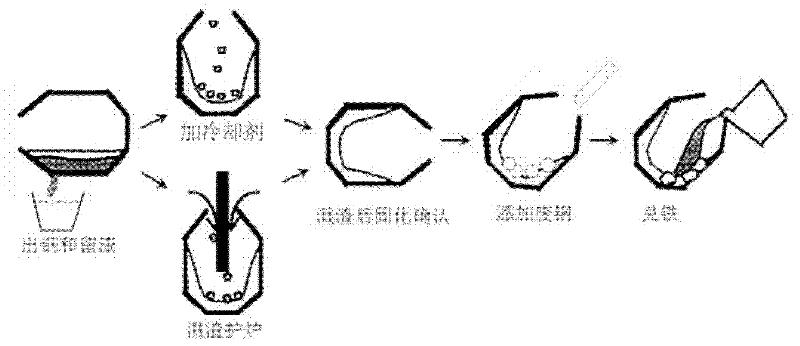

Cooling solidification recycling method for high-temperature liquid-state slag in steelmaking furnace

InactiveCN102337372AExtended reaction timeGood reaction kineticsManufacturing convertersProcess efficiency improvementSteelmakingLiquid state

The invention discloses a cooling solidification recycling method for a high-temperature liquid-state slag in a steelmaking furnace. The method comprises the following steps of: remaining slag, namely performing slag remaining operation after tapping, wherein the slag remaining amount in a converter is 5 to 40t; adding a coolant into residual slag according to the content of end point carbon in the converter and the slag remaining amount after the tapping, wherein the coolant comprises 1 to 3.0t of lime, 0 to 3.0t of magnesium carbon ball and 0.2 to 3.0t of dolomite; splashing the slag, namely splashing the slag and jetting N2 by using a gun under the pressure of between 1.2 and 1.5MPa at the temperature of between 25 and 35 DEG C for 3 to 7min, wherein the flow is 30,000 to 50,000Nm<3> / h; after the slag splashing is finished, lifting the gun, shaking the furnace to observe a slag splashing effect that whether the slag is solidified or not, and adding scrap steel together with iron after the high-temperature liquid-state slag in the furnace is cooled and solidified; and otherwise, adding 0 to 3.0t of coolant into the converter, wherein the coolant is lime. In the method, a tapping and slag remaining process, a slag splashing and furnace protecting process and a coolant adding process are combined, and the high-temperature liquid-state slag is recycled; and the slag is simply and effectively recycled, so that a good steel slag reaction condition is provided for subsequent smelting of the converter.

Owner:UNIV OF SCI & TECH BEIJING

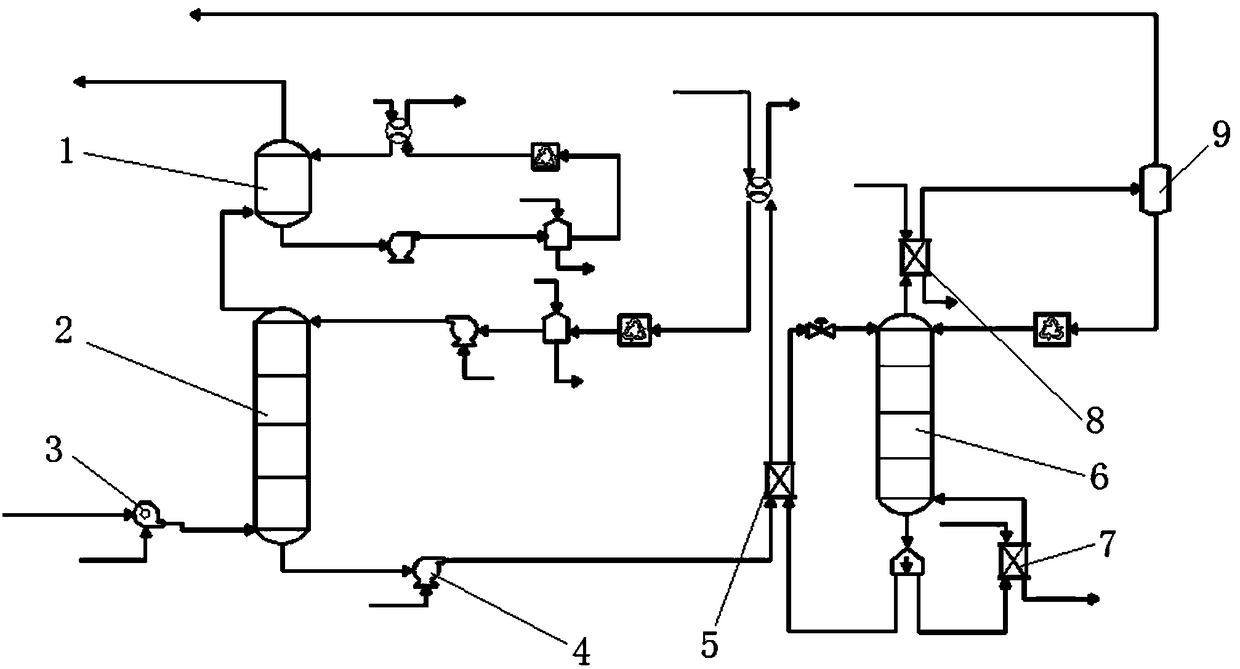

Liquid-liquid phase change absorbent for separating acid gas

ActiveCN105536434AReduce fluid volumeReduce sensible heatGas treatmentDispersed particle separationChemistryWater soluble

The invention relates to a liquid-liquid phase change absorbent for separating acid gas. The absorbent comprises the following components in percentages by mass: 10-60% of ethanolamine, 20-60% of other water-soluble organic compounds and 10-70% of water. Before the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent is a homogeneous-phase body, and after the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent forms into liquid-liquid phase spontaneously; the upper liquid phase is a barren liquor phase which loads acid gas, the lower liquid phase is a rich liquor phase which loads acid gas, and only the rich liquor phase enters a desorption unit, so that desorption energy consumption is reduced. After the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent forms into liquid-liquid phase for facilitating separation; according to characteristics of the absorbed acid gas, ratio of the absorbent can be adjusted for adapting to optimal volume ratio of the upper liquid phase and the lower liquid phase and load capacity of the absorbent in the process, so that amount of the rich liquor phase which enters the desorption unit in industrial environment is reduced, and energy consumption in the desorption process is reduced as possible.

Owner:BEIJING UNIV OF CHEM TECH

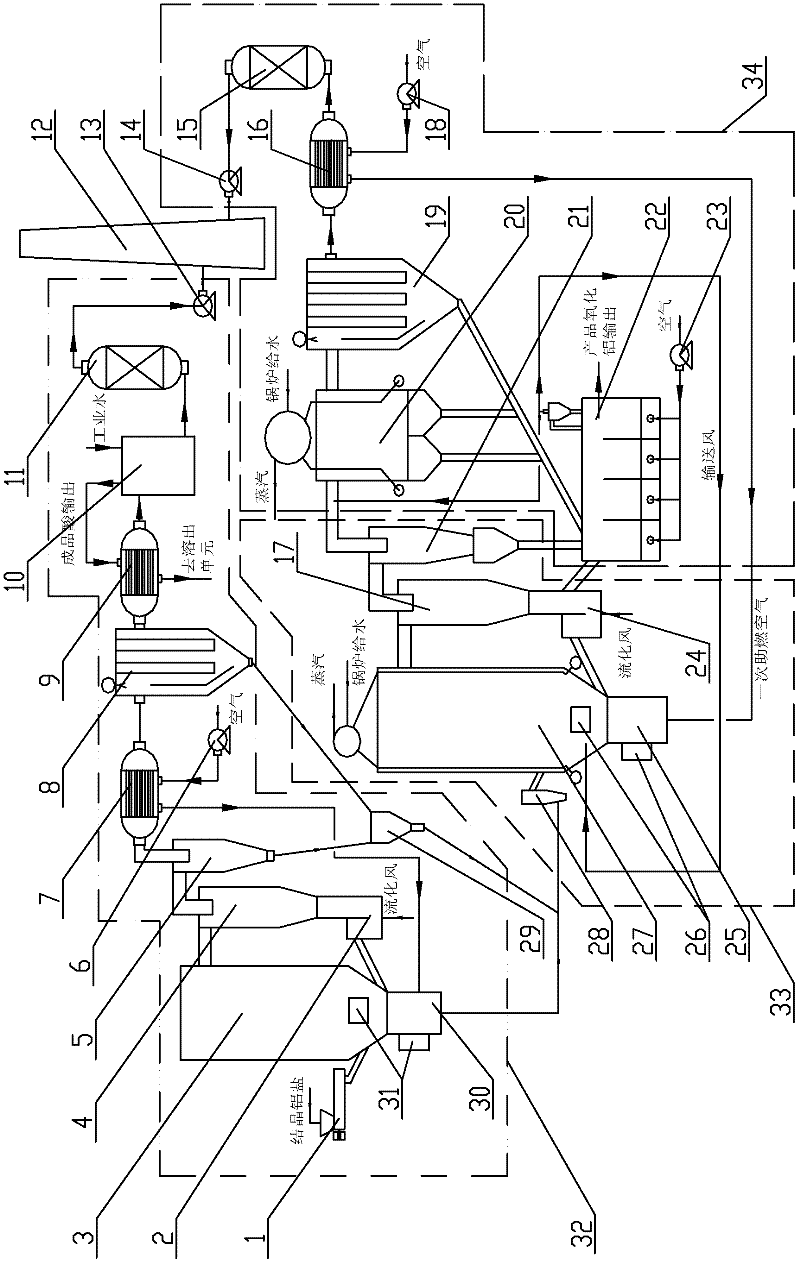

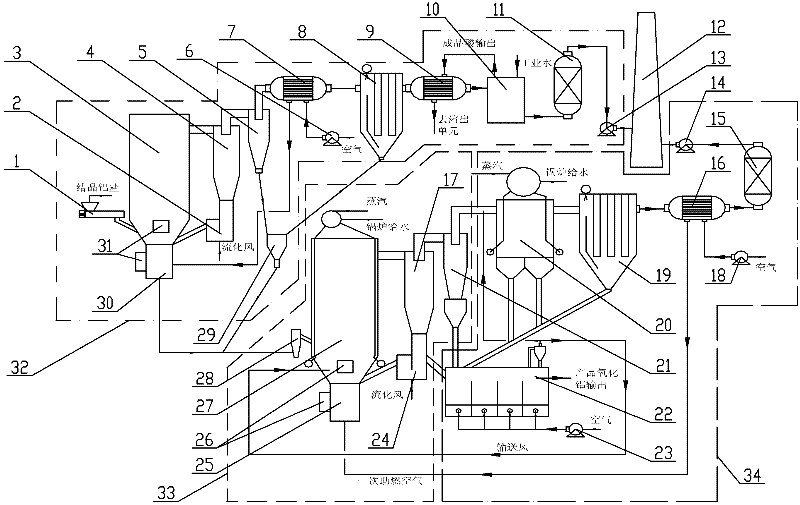

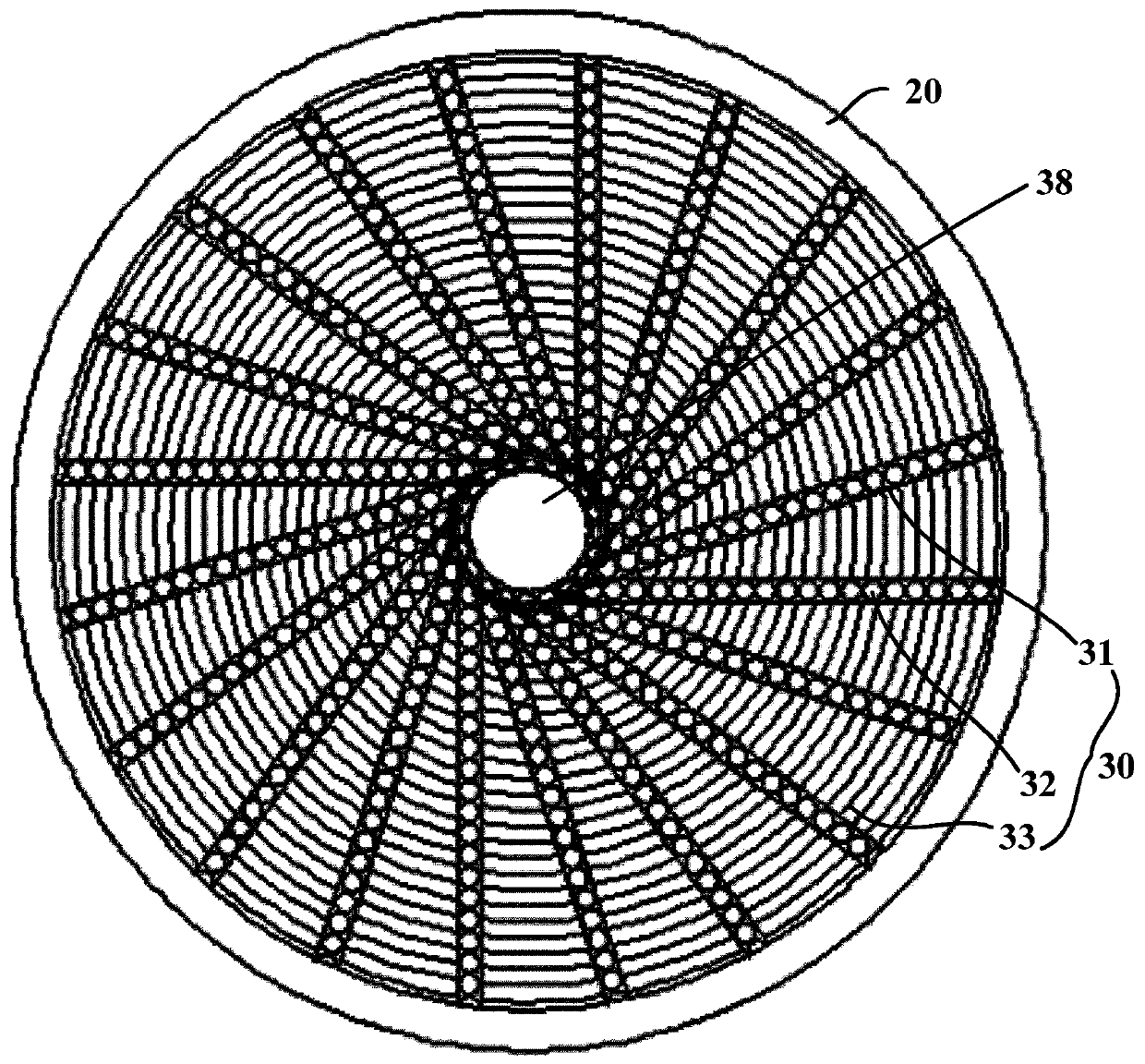

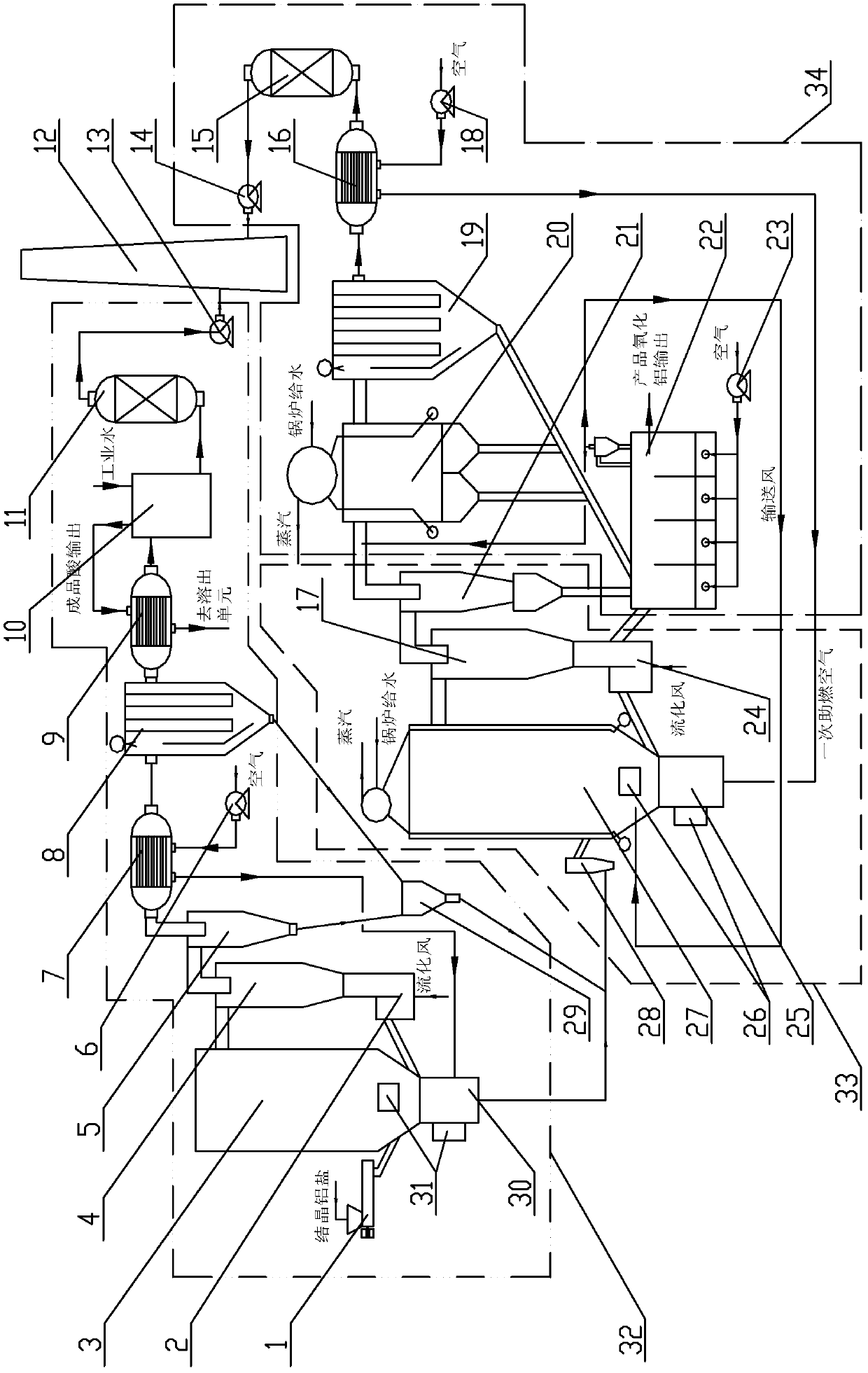

Slagging-free type and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and method thereof

ActiveCN102502744ASolve the problem of large initial investmentReduce energy consumptionEnergy inputAluminium oxide/hydroxide preparationFlue gasProcess engineering

The invention provides a slagging-free type, low-energy consumption and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and a method thereof. The system comprises a crystallized aluminum salt low-temperature roasting system, an aluminum oxide high-temperature finished product roasting system, a high-temperature aluminum oxide multilevel fluidized cooling and heat recovery system and a chimney. The method comprises the following steps of: reducing the outlet temperature of low-temperature roasting flue gas with large gas production rate by adopting a differential temperature multiple roasting method, so that sensible heat carried by the flue gas is greatly reduced; and carrying out reasonable cascade utilization on energy and converting fuel chemical energy inputted by a process system into effective heat of the system to a greatest extent. The slagging-free type and multilevel differential temperature fluidized roasting system has the remarkable advantages of strong adaptability to the content of attached water of the crystallized aluminum salt, good adjustment and stability, high product purity, low energy consumption, low investment, small floor area and the like.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent

InactiveCN110052117AAchieve enrichmentReduce total fluid volumeDispersed particle separationAir quality improvementFluid phaseEnvironmental engineering

The invention provides a liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent. The liquid-liquid phase-change absorbent for capturing the carbon dioxidecomprises, by mass, 20%-60% of synergist, 10%-50% of organic amine, 0%-5% of auxiliary agent and the balance water. The liquid-liquid phase-change absorbent for capturing the carbon dioxide has the advantages that the liquid-liquid phase-change absorbent can be automatically layered into liquid-liquid phases when loading a certain amount of CO2 in the absence of energy consumption, wherein CO2 gathers in a rich phase layer, and a lean phase layer hardly loads CO2, so that CO2 can be effectively concentrated in the rich phase, the total amount of liquid entering a regenerating column is decreased through desorption of the CO2 rich phase, and energy consumption for regeneration and capture cost are reduced.

Owner:HUANENG POWER INT INC +1

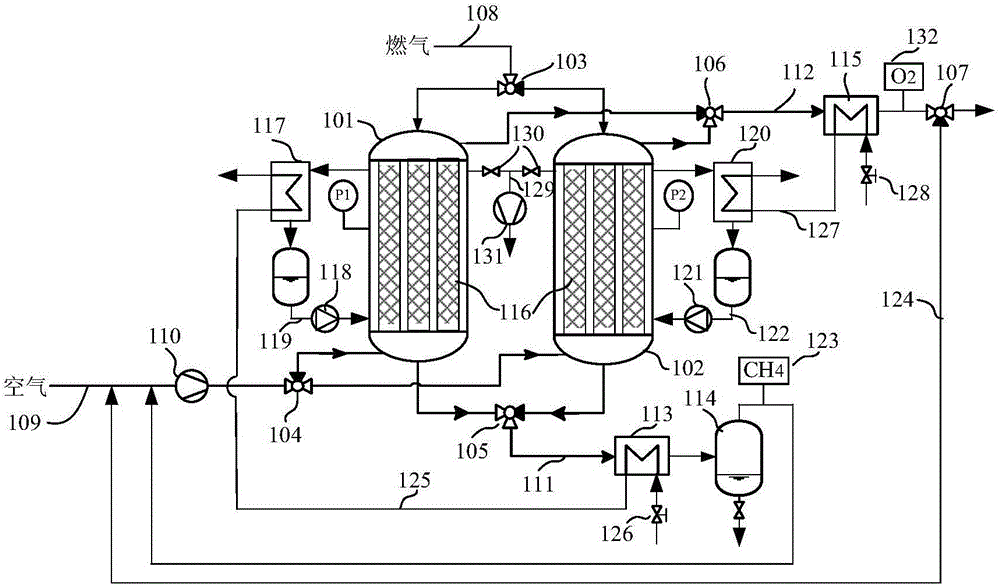

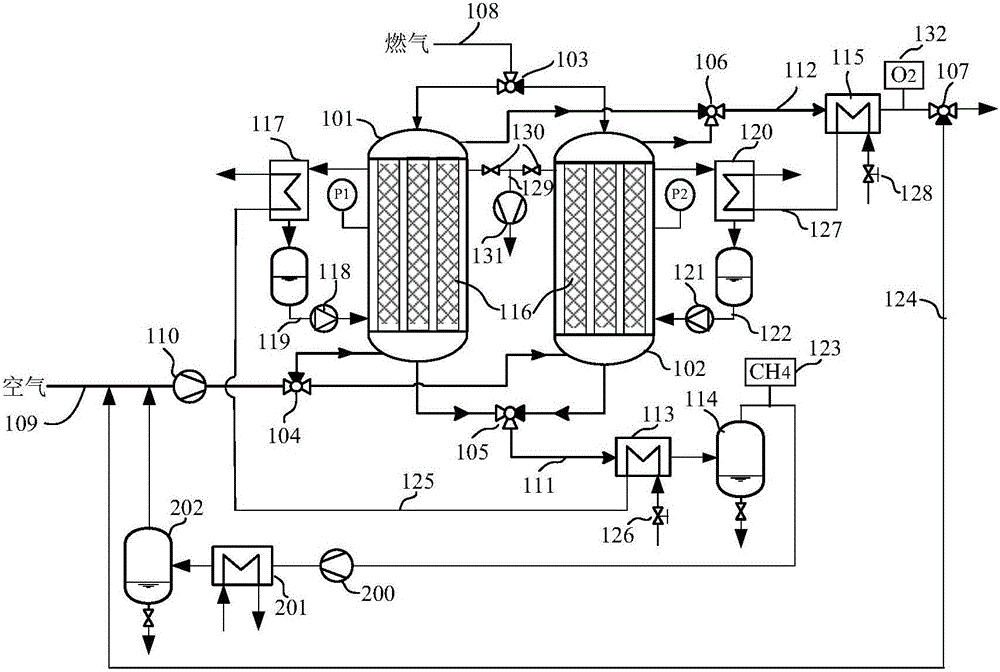

Gas-fired boiler system and operation method thereof

ActiveCN105757641ACaptureReduce the excess air factorSolidificationLiquefactionEngineeringProcess engineering

The invention discloses a gas-fired boiler system and an operation method thereof, wherein the gas-fired boiler system comprises a first chemical chain combustion reactor and a second chemical chain combustion reactor, wherein the first chemical chain combustion reactor and the second chemical chain combustion reactor are filled with oxygen carriers; when fuel gas is introduced into either the first chemical chain combustion reactor or the second chemical chain combustion reactor for reducing the oxygen carriers, air is introduced into the other chemical chain combustion reactor for oxidizing the oxygen carriers; through switching a fuel gas pipeline and an air pipeline, the oxygen carriers in the first chemical chain combustion reactor and the second chemical chain combustion reactor are alternately oxidized and reduced; during the oxidization and reduction reaction, heat is provided for a heat supply medium. The gas-fired boiler system has high heat energy utilization rate.

Owner:UNIV OF SCI & TECH BEIJING +1

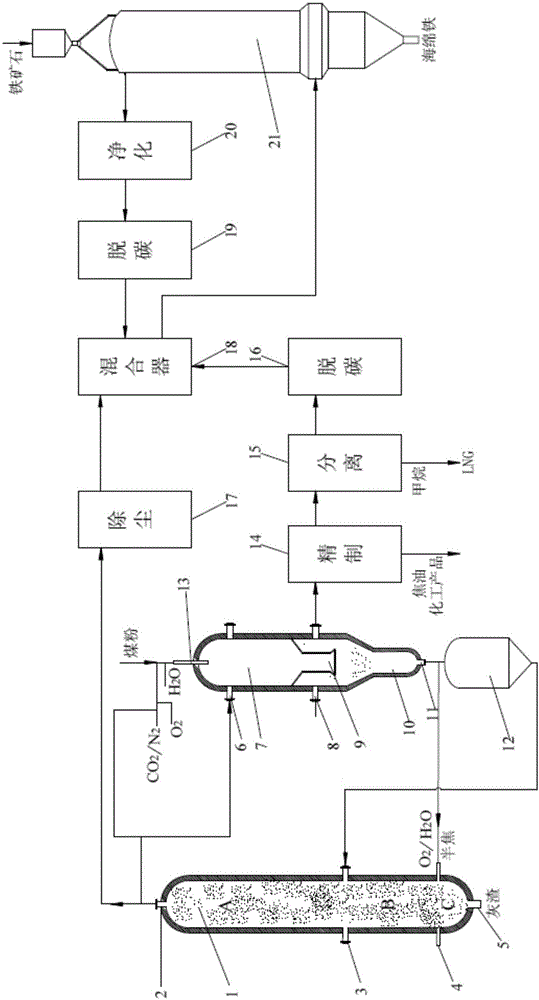

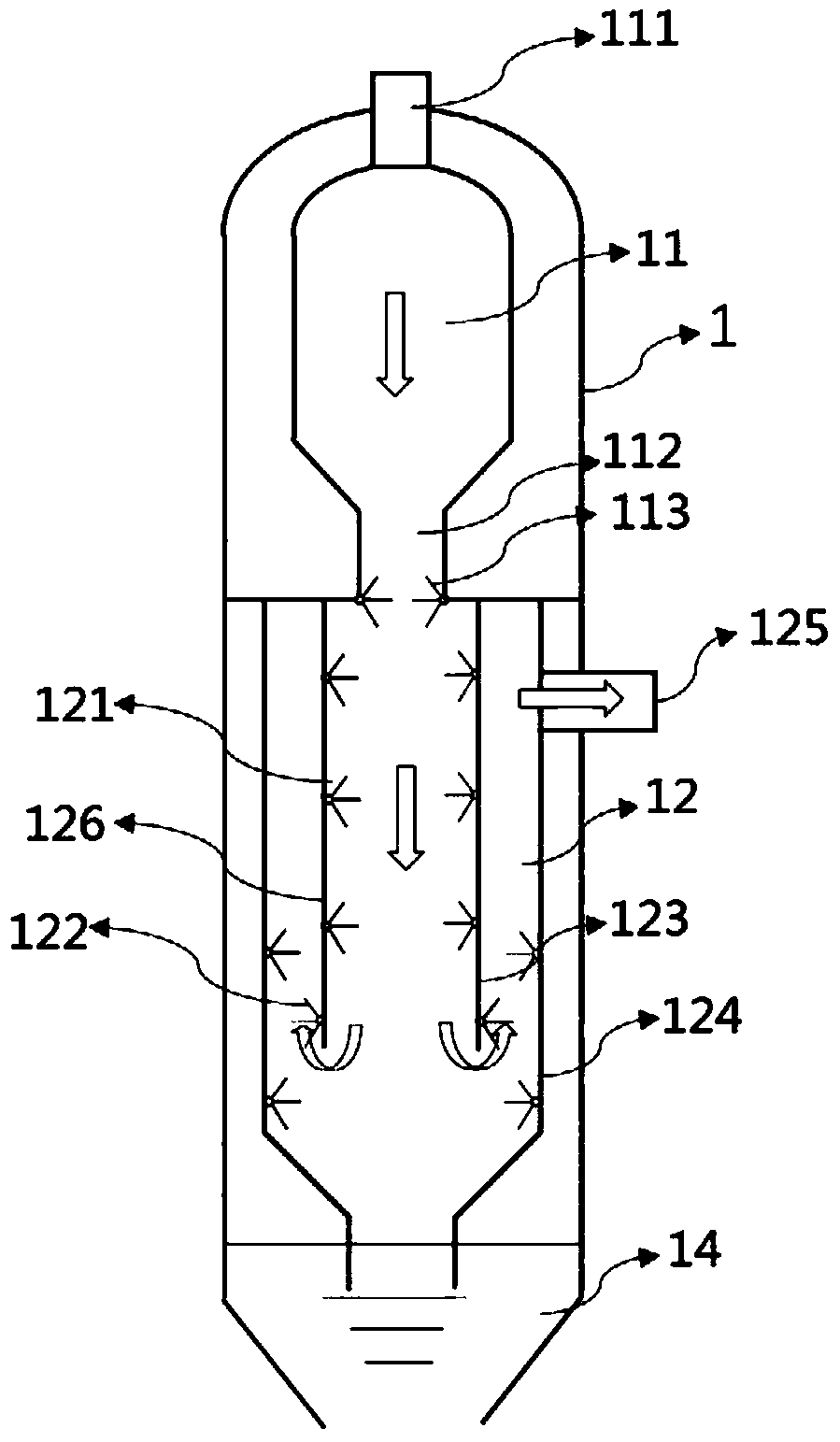

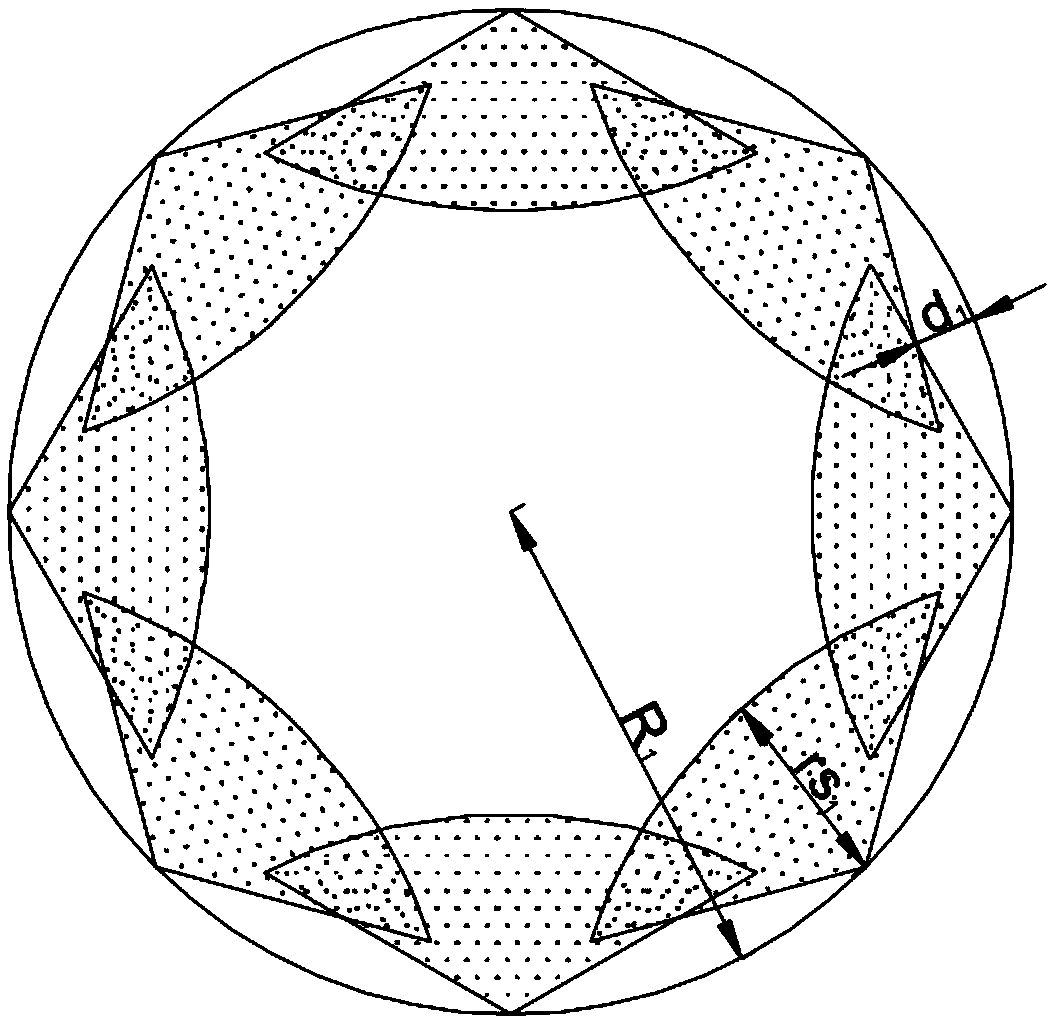

Device and method for preparing reducing gas through lignite gasification poly-generation

ActiveCN105885953ALow costImprove thermal efficiencyChemical industryGasification processes detailsHeat carrierSlag

The invention provides a device and method for preparing reducing gas through lignite gasification poly-generation. The device comprises a gasification furnace, a pyrolysis or partial gasification furnace, a semi-coke storage tank, a dust removal unit and a mixer; the gasification furnace is divided into a first area, a second area and a third area, a catalyst inlet is formed between the first area and the second area, a semi-coke or gasification agent inlet is formed between the second area and the third area, and the top end and the bottom end of the gasification furnace are provided with a synthesis gas outlet and an ash slag outlet respectively; a guide cylinder is arranged in the pyrolysis or partial gasification furnace, the top end and the bottom end of the pyrolysis or partial gasification furnace are provided with a nozzle and a semi-coke outlet respectively, the portion, close to the top end, of the pyrolysis or partial gasification furnace is provided with a heat carrier inlet, and a volatile matter outlet is formed in a semi-coke storage bin; the semi-coke outlet is connected with an inlet of the semi-coke storage tank and the semi-coke or gasification agent inlet; the synthesis gas outlet is connected with the heat carrier inlet and further connected with a mixer inlet through the dust removal unit; the volatile matter outlet is connected with the mixer inlet; the mixer inlet is further sequentially connected with a top gas decarbonization unit and a top gas purification unit. The method is achieved through the device, lignite can be transformed in a classifying mode to produce the reducing gas, the cost is low, the heat efficiency is high, and environment friendliness is achieved.

Owner:CERI ENERGY & AIR PROTECTION TECH CO LTD +1

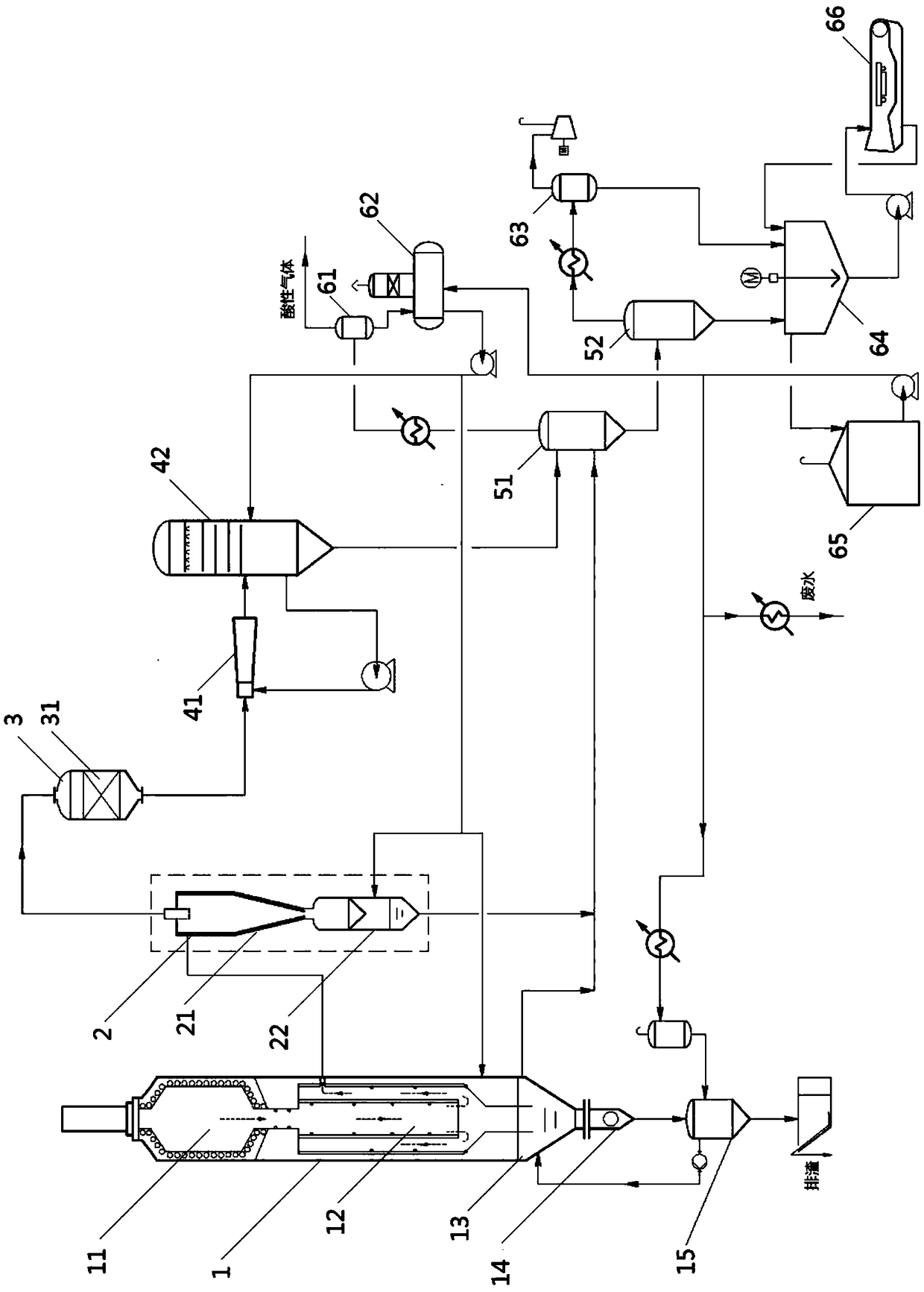

Gasification system and process for high-efficiency recovery of heat energy via wet ash cooling method

PendingCN108913208AImprove heat recovery efficiencyIncrease productionChemical industryGasification processes detailsScrubberDistillation

The invention provides a gasification system for high-efficiency recovery of heat energy via a wet ash cooling method. The gasification system comprises: a gasification furnace, wherein an injection device is arranged on a heat exchange surface in a radiant heat exchange chamber of the gasification furnace, thereby forming a low-temperature zone close to the heat exchange surface and a core high-temperature zone located at the side, away from the heat exchange surface, of the low-temperature zone; a gas-solid separation and wet ash cooling device, which is configured to communicate with the synthesis gas outlet of the gasification furnace; a convection heat exchange device, which is used for recycling the sensible heat of synthesis gas and produces power steam; a gas scrubbing equipment, which comprises a venturi scrubber and a scrubbing tower in series connection; and a black water treatment system, which comprises a primary flash distillation unit and a secondary flash distillation unit in series connection. The invention also provides a gasification process for high-efficiency recovery of heat energy. According to the invention, the radiant heat exchange chamber using a border area temperature control technology can ensure the safety of heat exchange tubes, higher heat recovery efficiency under high radiation intensity, higher saturated steam yield and smaller equipment size.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

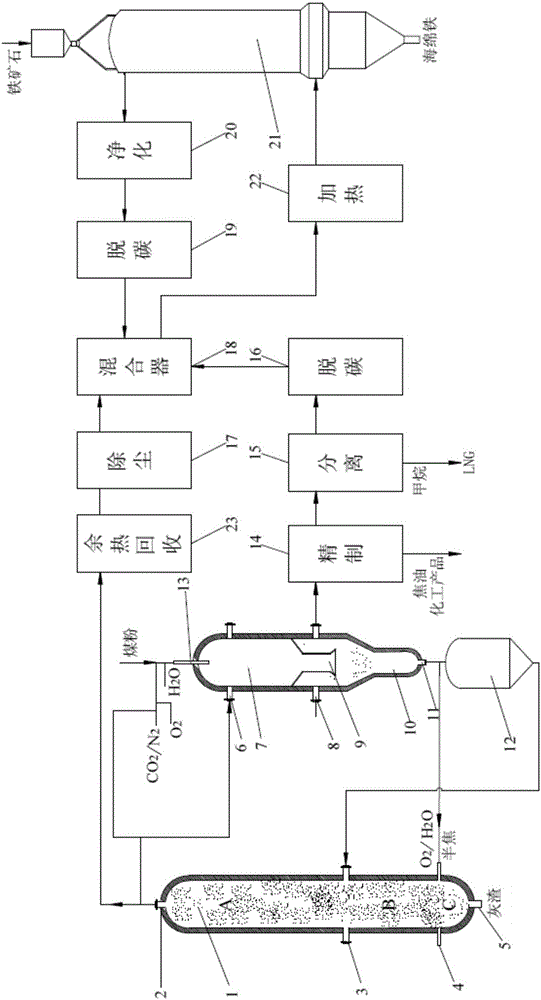

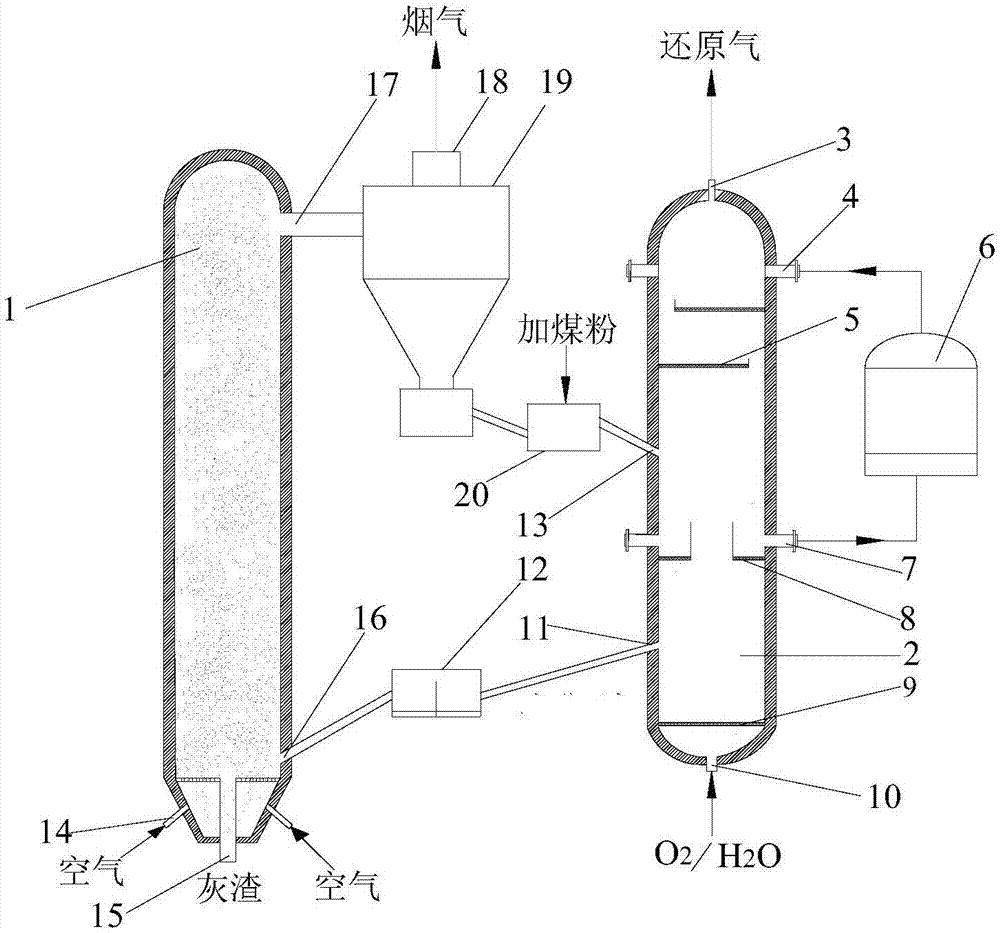

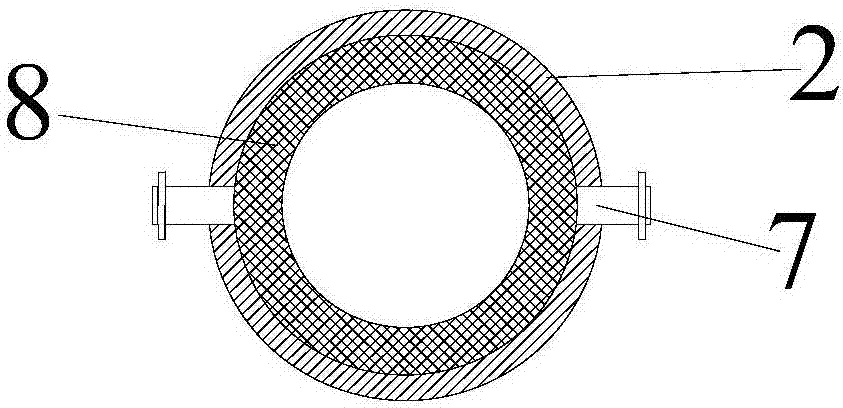

System and method for preparing reducing gas through lignite double-bed gasification

ActiveCN107118807ARich reservesGood catalytic propertiesGasification processes detailsGranular/pulverulent flues gasificationCombustionFlue gas

The invention provides a system and a method for preparing reducing gas through lignite double-bed gasification. The system comprises a combustion furnace, a gasification furnace, a gas solid separator, a material return device, a catalyst tank and a pulverized coal mixing device; the combustion furnace is provided with a flue gas outlet, a semi-coke / ash inlet, an ash residue outlet and an air inlet; a gasifying agent distribution plate, a semi-coke collecting plate and a catalyst supporting plate are arranged in the gasification furnace; a semi-coke / ash outlet, a semi-coke outlet, a catalyst inlet and a feeding port are formed in the side wall of the gasification furnace; the semi-coke / ash outlet is connected with the semi-coke / ash inlet through the material return device; the semi-coke outlet is connected with a catalyst inlet of the catalyst tank; the catalyst inlet is connected with a catalyst outlet of the catalyst tank; and the feeding port is connected with a discharging port of the pulverized coal mixing device. By utilization of the system, the reducing gas can be prepared from the lignite, and the reducing gas can be applied to a gas-based shaft furnace to perform direct reduction iron making without needing a conversion device to adjust gas components.

Owner:CERI ENERGY & AIR PROTECTION TECH CO LTD +1

Control method of intelligent comfortable cooling and heating household air conditioning system

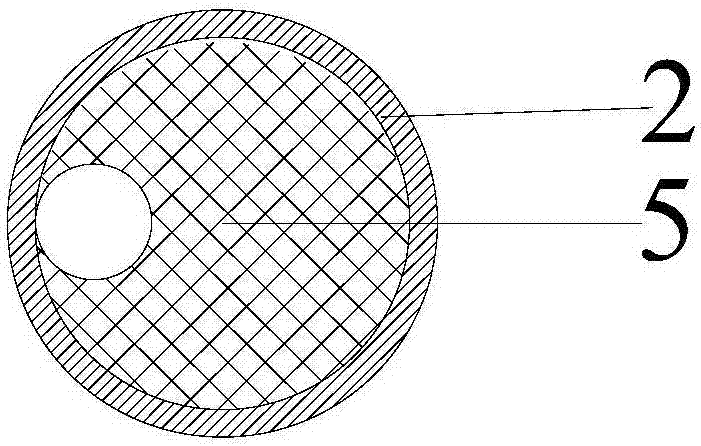

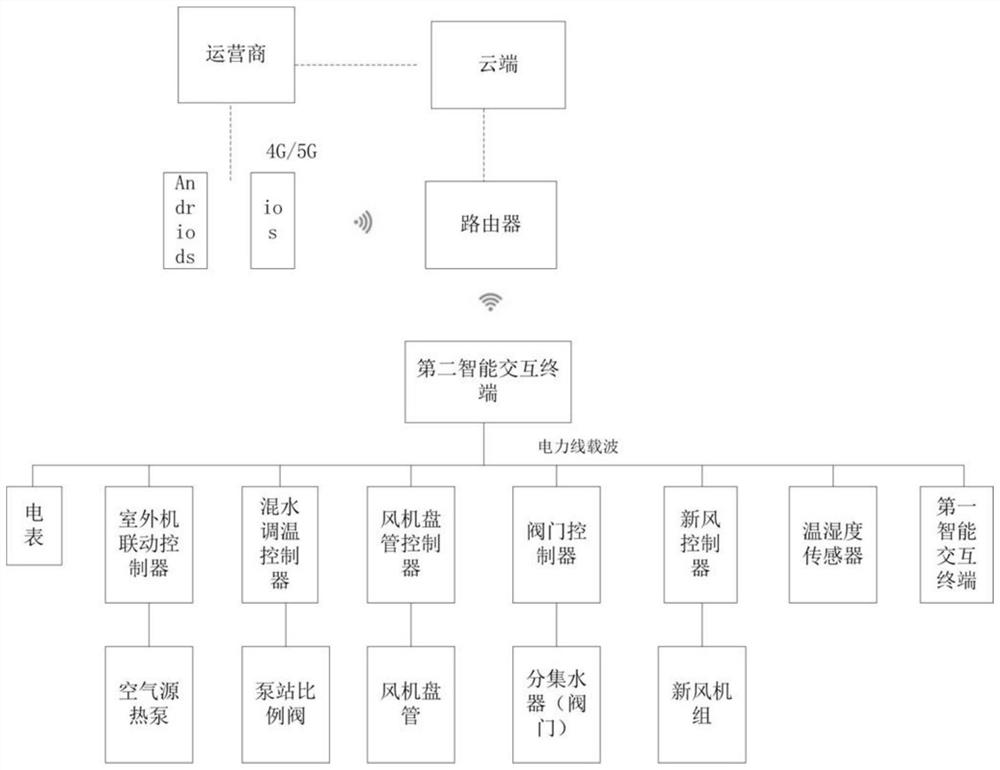

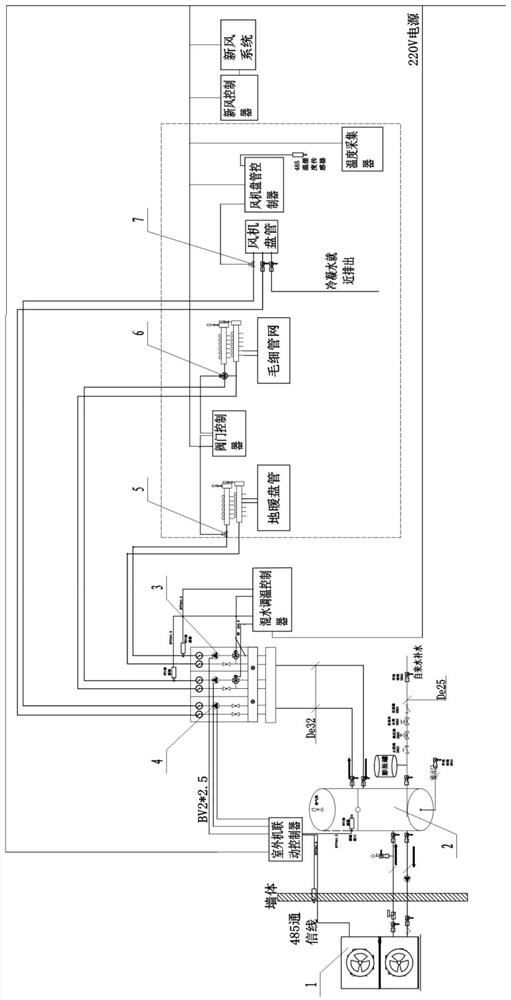

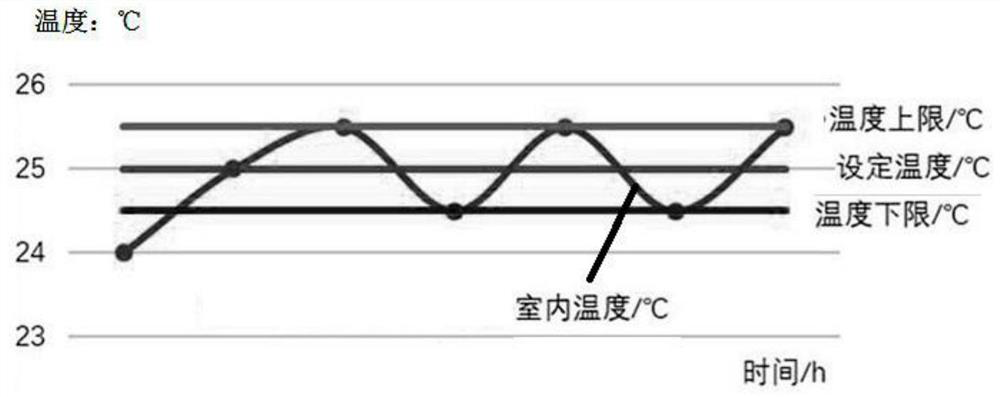

ActiveCN112880162AEasy to adjustReduce the feeling of windMechanical apparatusSpace heating and ventilation safety systemsCapillary networkCapillary Tubing

The invention relates to the technical field of indoor heating and ventilation, in particular to a control method of an intelligent comfortable cooling and heating household air conditioning system. The control method comprises the following steps: in a heating mode, valves of a capillary network and a ground temperature adjusting pipe network are controlled to be opened through a valve controller for heating; in a refrigerating mode, the valves of the capillary network and the ground temperature adjusting pipe network are controlled to be opened, meanwhile, water supply at the set temperature is controlled and provided through a water mixing temperature adjusting controller for cooling; when the control result of the capillary network and the ground temperature adjusting pipe network cannot meet the set requirement, a fan coil is opened in a linkage mode; and when the control result of the capillary network and the ground temperature adjusting pipe network can meet the set requirement, the temperature is controlled by controlling a proportional integral valve through the water mixing temperature adjusting controller in the heating mode, and the temperature is controlled by opening and closing the valves of the capillary network and the ground temperature adjusting pipe network in the refrigerating mode. Radiation temperature adjustment is mainly adopted, the temperature can be rapidly adjusted, the blowing feeling is reduced, and the comfort degree is improved.

Owner:QINGDAO DONGRUAN ZAIBO INTELLIGENT ELECTRONICS

Liquid-solid phase change absorbent used for carbon dioxide capture and application of absorbent

InactiveCN109701362AStrong toleranceReduce volatilityDispersed particle separationAir quality improvementHigh concentrationSolubility

The invention provides a liquid-solid phase change absorbent used for carbon dioxide capture and an application of the absorbent. The absorbent comprises the following components, in percentages by mass: 10%-60% of a carbonate, 2%-40% of a bicarbonate, 1%-20% of an absorption activator, 0.01%-10% of an absorption auxiliary agent, and the balance of water. According to the absorbent provided by theinvention, precipitation of the bicarbonate is realized by utilizing solubility difference of the carbonate and the bicarbonate in an aqueous solution and using a chemical exchange or cooling crystallization manner, then the high-concentration bicarbonate crystal slurry is subjected to pyrolysis regeneration, so that participation of water during regeneration can be reduced, solvent heating sensible heat during the enriched-liquid regeneration and water gasification latent heat can be reduced, and CO2 regeneration heat consumption and capture costs can be reduced.

Owner:HUANENG POWER INTERNATIONAL +1

Ternary double liquid phase absorbent for treating carbon dioxide in flue gas

ActiveCN110124448AReduce fluid volumeExcellent phase separation characteristicsGas treatmentDispersed particle separationFlue gasDesorption

The invention discloses a ternary double-liquid absorbent for treating carbon dioxide in flue gas. The ternary double-liquid absorbent is a mixed aqueous solution prepared from triethylenetetramine, diethylaminoethanol, inert solvent and water, wherein the mass fraction of the triethylenetetramine is 10%-30%, the mass fraction of the diethylaminoethanol is 30%-40%, the mass fraction of the inert solvent is 20%-35%, and the mass fraction of the water is 20%-35%. The carbon dioxide load of the ternary double liquid phase absorbent of the invention is about 1.23 to 1.40 times that of the traditional absorbent ethanolamine, most carbon dioxide is enriched in the lower liquid phase, the lower phase is used for desorption, the regeneration heat is 0.61 to 0.64 of ethanolamine, and the energy consumption is greatly reduced.

Owner:ZHEJIANG UNIV OF TECH

Gasification system and technology for efficient heat recovery

PendingCN108795500AImprove heat recoveryEnsure safetyChemical industryGasification processes detailsThermal energyDistillation

The invention provides a gasification system for efficient heat recovery. The system comprises a gasification furnace, gas-solid separation and ash cooling equipment, a convective heat exchange device, gas scrubbing equipment and a black water treatment system, wherein a spraying device is arranged on a heat transfer surface in a radiation heat transfer chamber of the gasification furnace, so as to form a lower temperature zone close to the heat transfer surface and a core high temperature zone on one side, far from the heat transfer surface, of the lower temperature zone; the gas-solid separation and ash cooling equipment is communicated with a synthesis gas outlet of the gasification furnace; the convective heat exchange is used for recycling sensible heat of synthesis gas and producingpower steam; the gas scrubbing equipment comprises a venturi scrubber and a scrubbing tower which are connected in series; the black water treatment system comprises a primary flash distillation device and a secondary flash distillation device. The invention further provides a gasification technology for efficient heat recovery. The scheme adopts a radiation heat exchange chamber adopting a borderland temperature control technology, not only guarantees the safety of a heat exchange tube, but also guarantee high heat recovery efficiency, higher yield of saturated steam and smaller equipment volume under high radiation intensity.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Flue gas waste heat recovery system for gas thermal equipment

InactiveCN105509083AImprove exhaust heat recovery rateIncreased turbulenceCombustion processIndirect carbon-dioxide mitigationThermal energyFeedwater heater

The invention discloses a flue gas waste heat recovery system for gas thermal equipment. A discharge flue of the gas thermal equipment is communicated to a gas inlet of a heat pipe air heater; an exhaust port of the heat pipe air heater is communicated to a gas inlet of a condensation type feed water heater; an exhaust port of the condensation type feed water heater is communicated to a chimney; an air supply outlet of a variable frequency air feeder is communicated to an air inlet of the heat pipe air heater; an air outlet of the heat pipe air heater is communicated to an inlet of combustion equipment; a water inlet of a variable frequency pulsing water feeding pump is communicated to a water feeding tank; a drainage port of the variable frequency pulsing water feeding pump is communicated to a water inlet of the condensation type feed water heater; a water outlet of the condensation type feed water heater is communicated with heat using equipment; a programmable controller periodically changes a Hedstrom number of the variable frequency pulsing water feeding pump by a program, so that a flow velocity in the condensation type feed water heater is periodically mutated, and thus, the technical problem of low energy-saving rate of an existing gas thermal equipment heat energy recovery mode is solved, and energy saving efficiency of the system is effectively improved.

Owner:CHONGQING SOUTH THERMAL ENG TECH CO

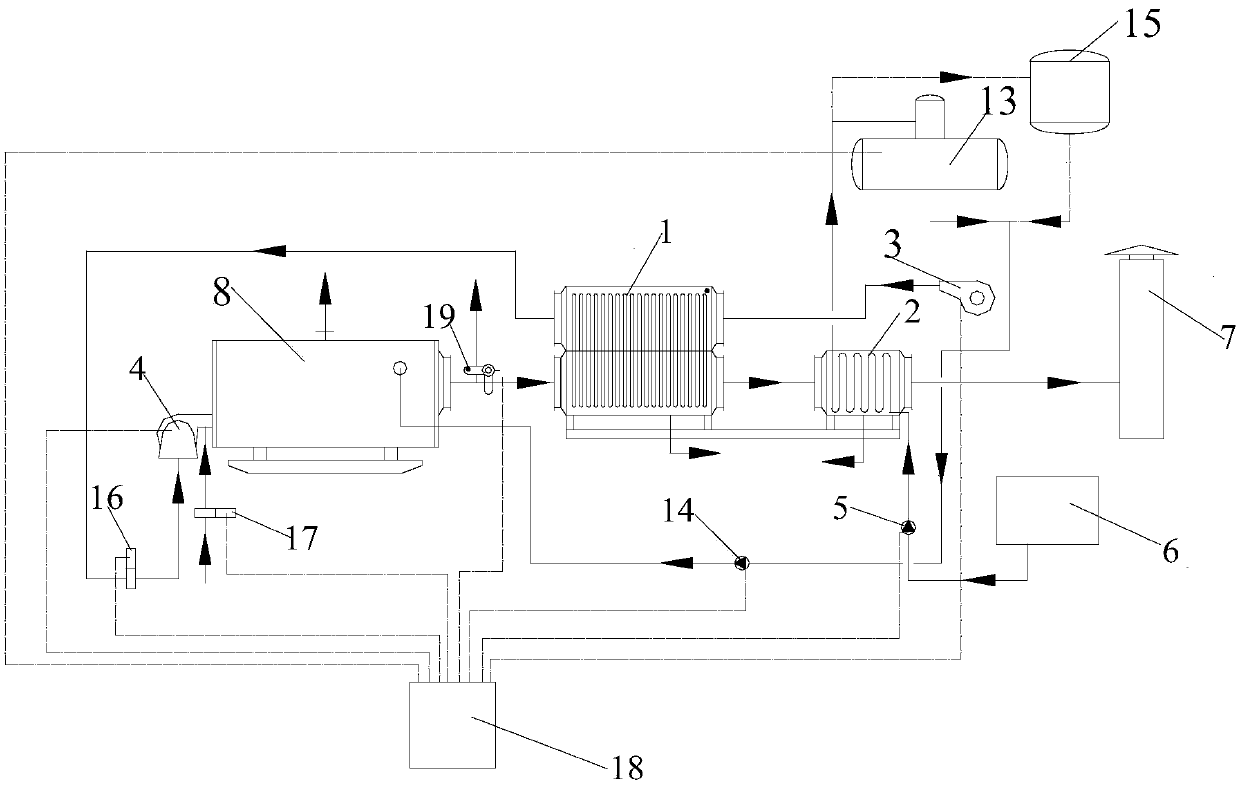

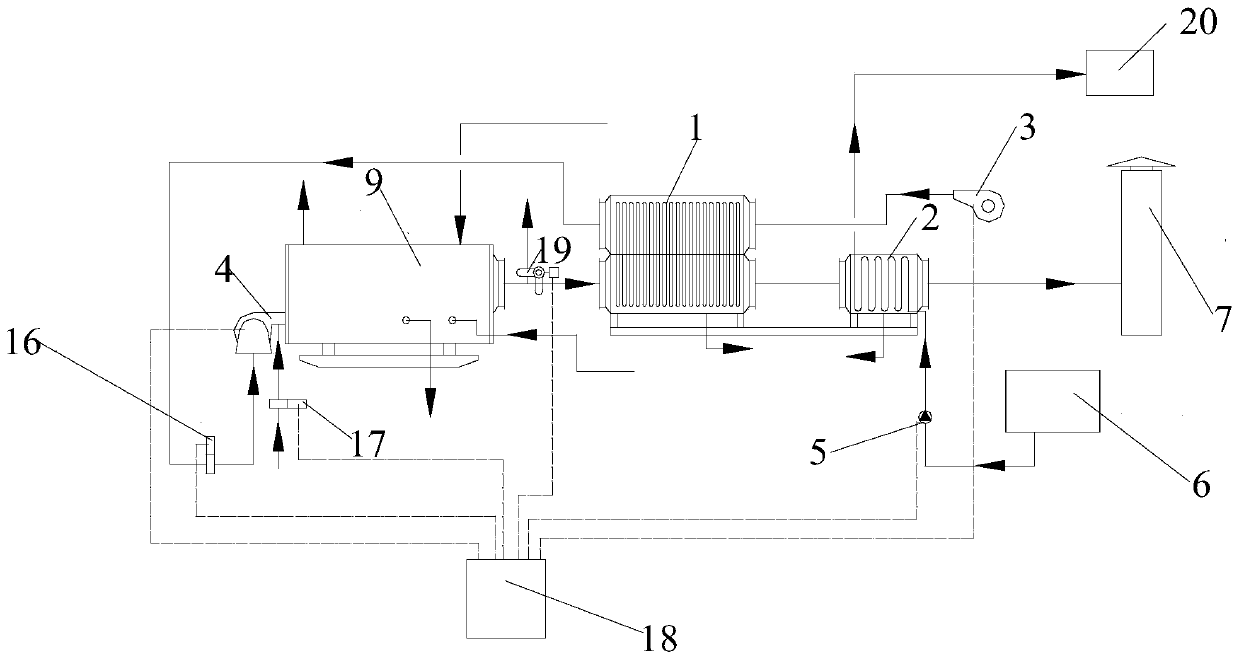

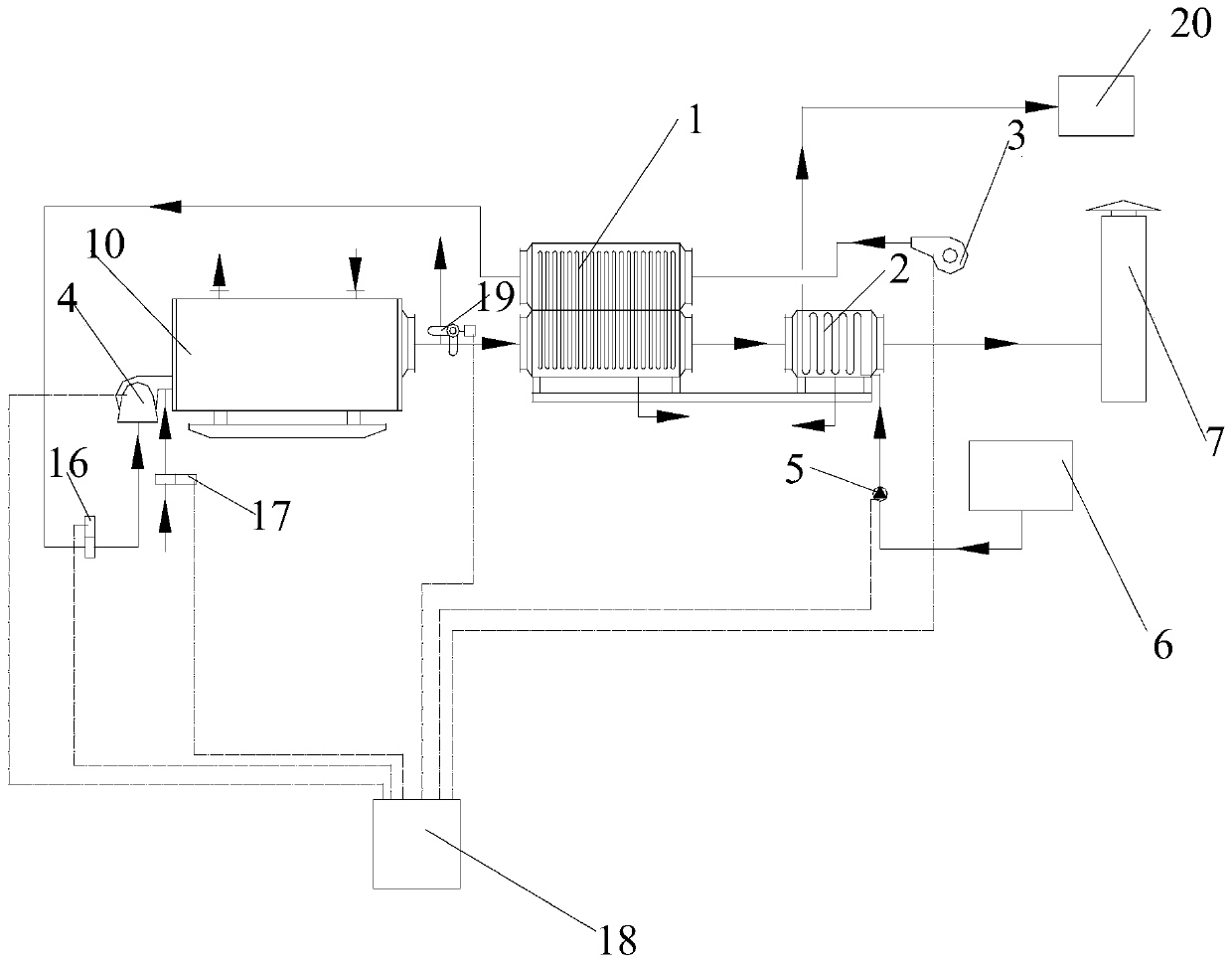

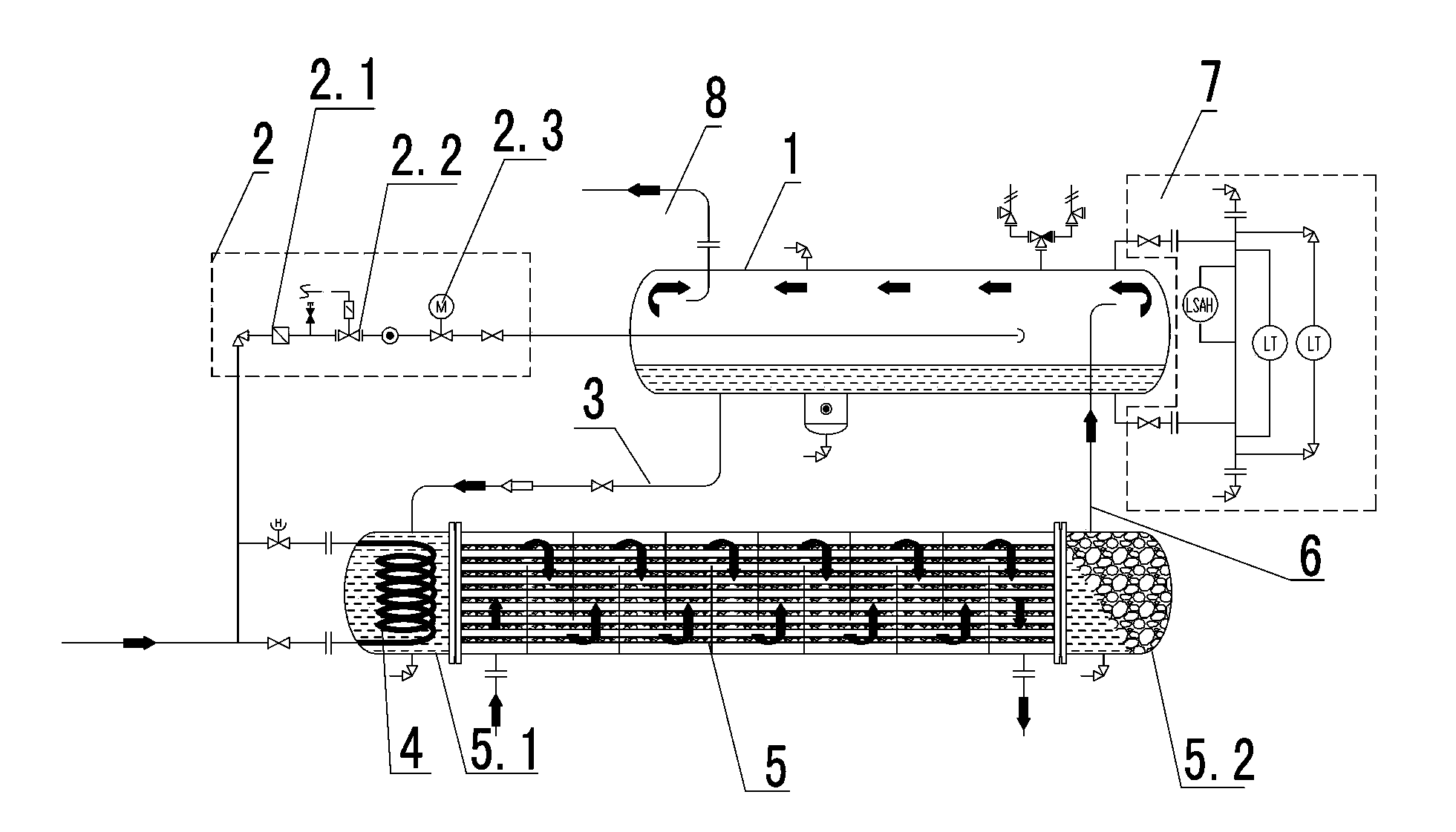

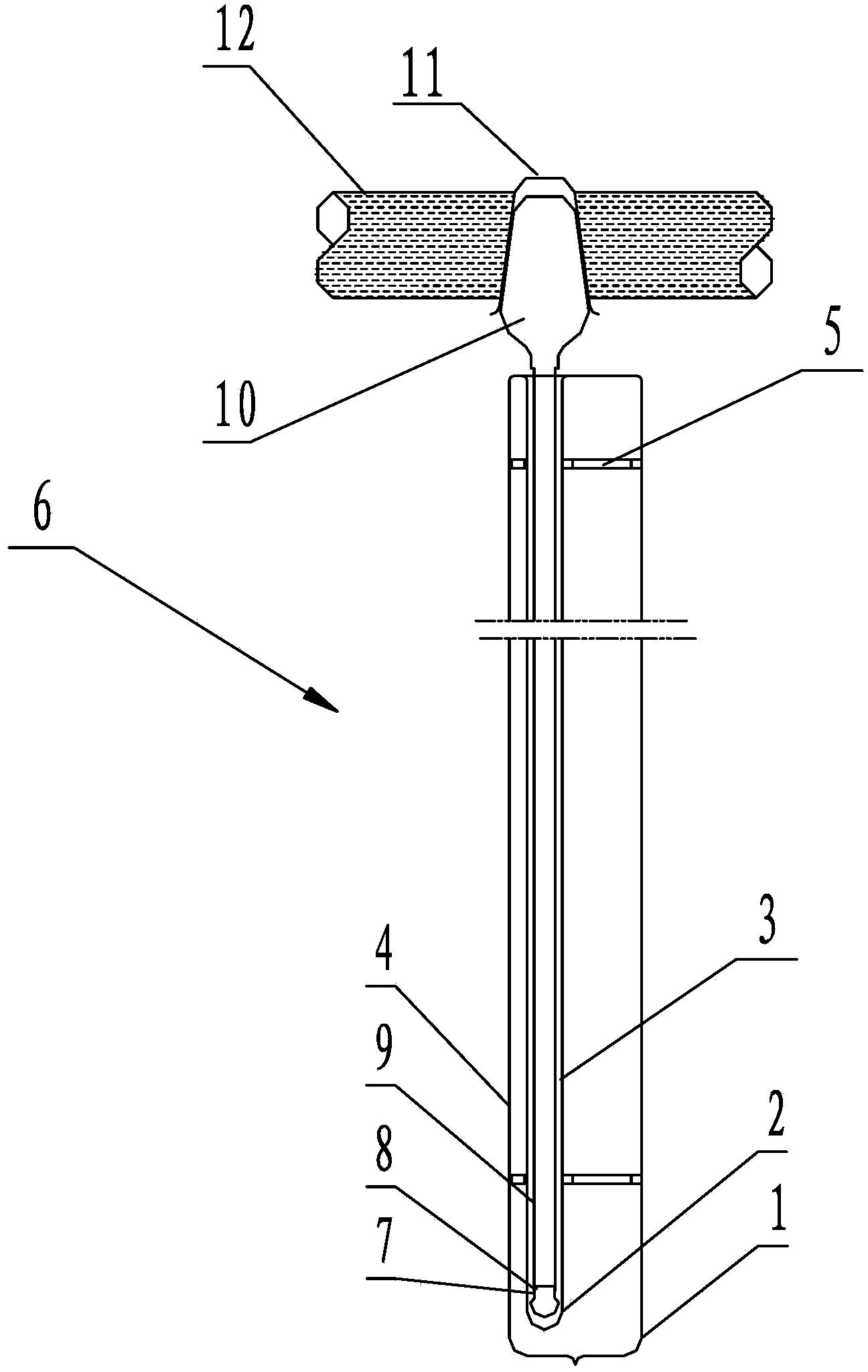

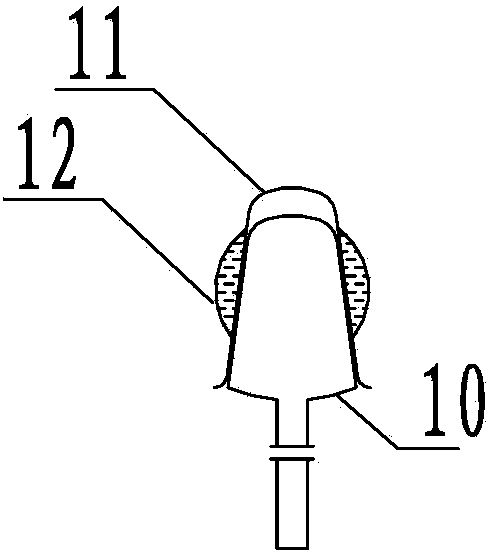

Thermosyphon type reboiler for industrial refrigeration device

InactiveCN103836842AReduce sensible heatIncrease subcoolingEvaporators/condensersVapor–liquid separatorReboiler

The invention relates to a thermosyphon type reboiler for an industrial refrigeration device. The thermosyphon type reboiler for the industrial refrigeration device comprises a gas-liquid separator and a dry-type evaporator located under the gas-liquid separator, wherein the upper portion of the gas-liquid separator is connected with an air sucking pipe connected with an air sucking port of a compressor. The thermosyphon type reboiler for the industrial refrigeration device is characterized in that an inlet pipe box is arranged at the inlet of the dry-type evaporator, an outlet pipe box is arranged at the outlet of the dry-type evaporator, a heat exchange coil pipe is arranged in the inlet pipe box, one end of the heat exchange coil pipe is a refrigerant liquid inlet, the other end of the heat exchanger coil pipe is connected with an expansion liquid supply throttling unit, the expansion liquid supply throttling unit is connected with the inlet end of the gas-liquid separator, a liquid outlet of the gas-liquid separator is communicated with the inlet pipe box through a liquid outlet pipe, the outlet pipe box is connected with an air return pipe, and the air return pipe is communicated with a cavity at the upper portion of the gas-liquid separator. The thermosyphon type reboiler for the industrial refrigeration device improves the energy efficiency of the system, improves the stability of a throttling device, reduces the size of the throttling device, and lowers controlling cost.

Owner:MCQUAY AIR CONDITIONING & REFRIGERATION WUHAN

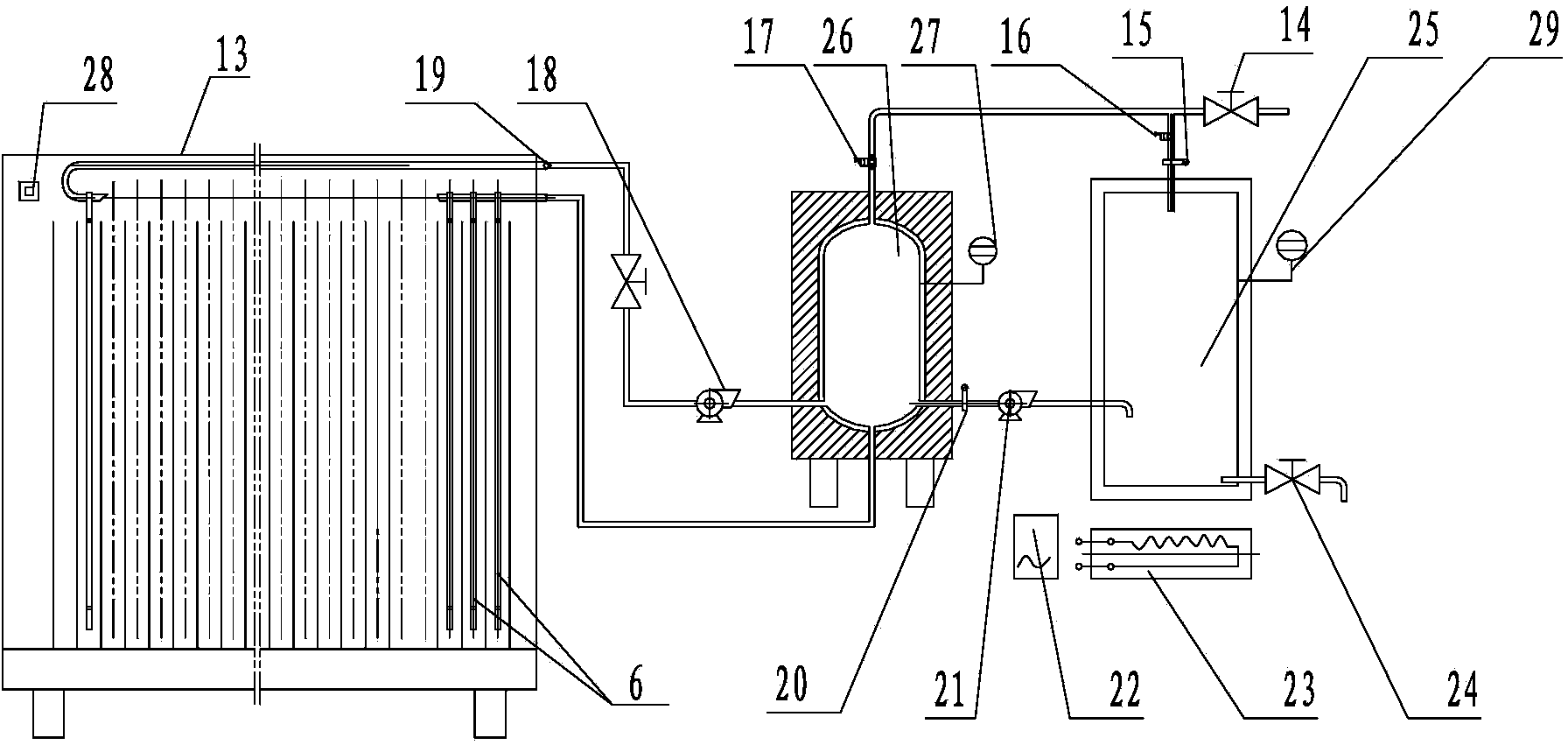

Heat pipe type solar vacuum tube water boiler and water boiling system

ActiveCN104048424AEfficient heat collectionReduce sensible heatSolar heating energySolar heat devicesHigh volume manufacturingEngineering

The invention discloses a heat pipe type solar vacuum tube water boiler and a water boiling system. The water boiler comprises a plurality of single connector tubes and a heat conduction water pipe connected with the single connector tubes; each single connector tube comprises an outer glass tube, a heated glass tube and a metal vacuum tube; each heated glass tube is arranged in the corresponding outer glass tube through a metal bracket in the manner of deviating from the axis; a metal reflective coating is plated on the inner wall of a half side of each outer glass tube close to the corresponding heated glass tube; one end, positioned in each heated glass tube, of the corresponding metal vacuum tube is closed through fixing a heat pipe seal head with a heat pipe pin, and the other end, which is exposed, of each metal vacuum tube extends outwards and is expanded to form a heat pipe seal head with a closed tail end and taking the shape of a cone frustum; a plurality of groove-shaped seal head taper sleeves are arranged on the heat conduction water pipe in an equally-spaced manner; each seal head taper sleeve takes the shape of an inverted cone frustum; the heat pipe seal heads are inserted in the seal head taper sleeves. Through the use of an all-glass internal light-focusing eccentric vacuum tube structure and other structures, heat is collected efficiently, high-temperature boiled water is produced continuously, the structure is simple, and the mass production is facilitated.

Owner:浙江毕星新能源科技有限公司 +1

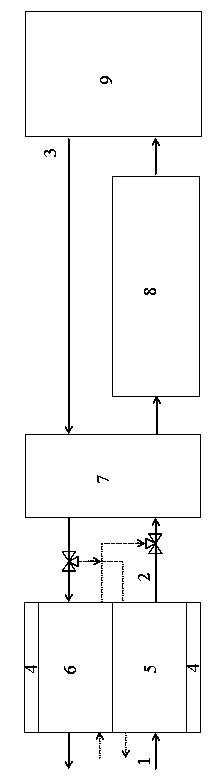

Optimized carbon dioxide capture process

InactiveCN108568192AFull recoverySolve the problem of energy consumptionGas treatmentDispersed particle separationVapor–liquid separatorReboiler

The invention discloses an optimized carbon dioxide capture process, which solves the problems of high regeneration energy consumption and high investment in the carbon dioxide capture process of theprior art and has the effects of reducing heat loss, sufficiently recovering solution in tail gas and reducing cost. The technical scheme is characterized in that the optimized carbon dioxide captureprocess comprises the following steps: under the function of a fan, exhaust gas is dehydrated and cooled and then gets into an absorption tower to flow from bottom to top, alkanolamine solution is fedas absorption solution from the top of the absorption tower, and the absorption solution is in countercurrent contact with the exhaust gas to remove carbon dioxide; the purified decarbonized exhaustgas gets into a water scrubbing tower; enriched liquid absorbed from the bottom of the absorption tower is sent into a heat exchanger by an enriched liquid pump, the enriched liquid gets in from the top of a regeneration tower after heat exchange, and after stripping desorption, the enriched liquid is sent into a reboiler and reboiled; gas mixture which is discharged from the top of the regeneration tower is guided into a heat exchanger to undergo water cooling, and then gets into a gas-liquid separator to undergo gas-liquid separation, and separated liquid is guided into the water scrubbing tower.

Owner:青岛海山减碳环保科技有限公司

A liquid-liquid phase transition absorbent for acid gas separation

ActiveCN105536434BReduce sensible heatReduce desorption energy consumptionGas treatmentDispersed particle separationDesorptionEthanolamines

The invention relates to a liquid-liquid phase change absorbent for separating acid gas. The absorbent comprises the following components in percentages by mass: 10-60% of ethanolamine, 20-60% of other water-soluble organic compounds and 10-70% of water. Before the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent is a homogeneous-phase body, and after the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent forms into liquid-liquid phase spontaneously; the upper liquid phase is a barren liquor phase which loads acid gas, the lower liquid phase is a rich liquor phase which loads acid gas, and only the rich liquor phase enters a desorption unit, so that desorption energy consumption is reduced. After the liquid-liquid phase change absorbent absorbs acid gas, the liquid-liquid phase change absorbent forms into liquid-liquid phase for facilitating separation; according to characteristics of the absorbed acid gas, ratio of the absorbent can be adjusted for adapting to optimal volume ratio of the upper liquid phase and the lower liquid phase and load capacity of the absorbent in the process, so that amount of the rich liquor phase which enters the desorption unit in industrial environment is reduced, and energy consumption in the desorption process is reduced as possible.

Owner:BEIJING UNIV OF CHEM TECH

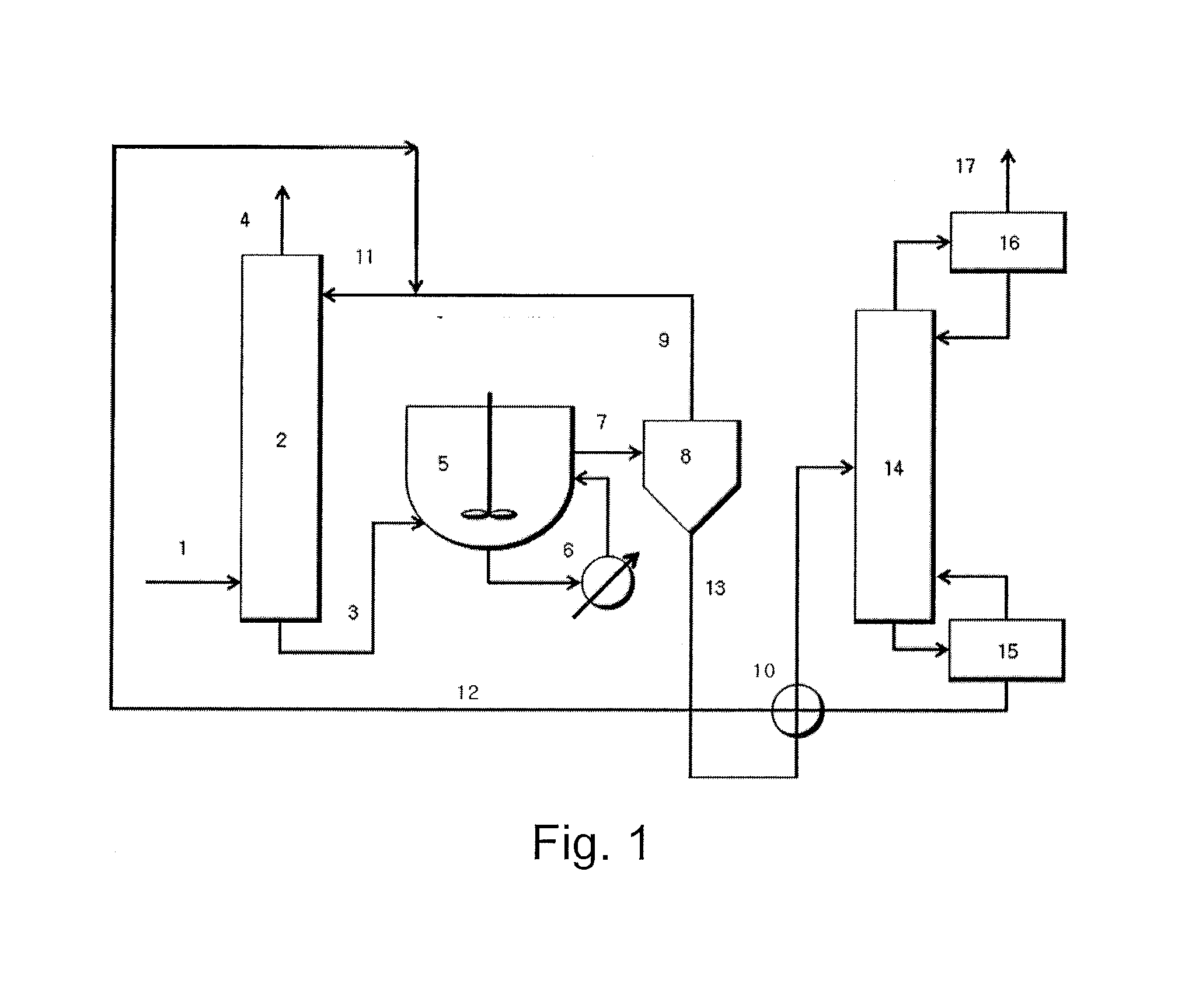

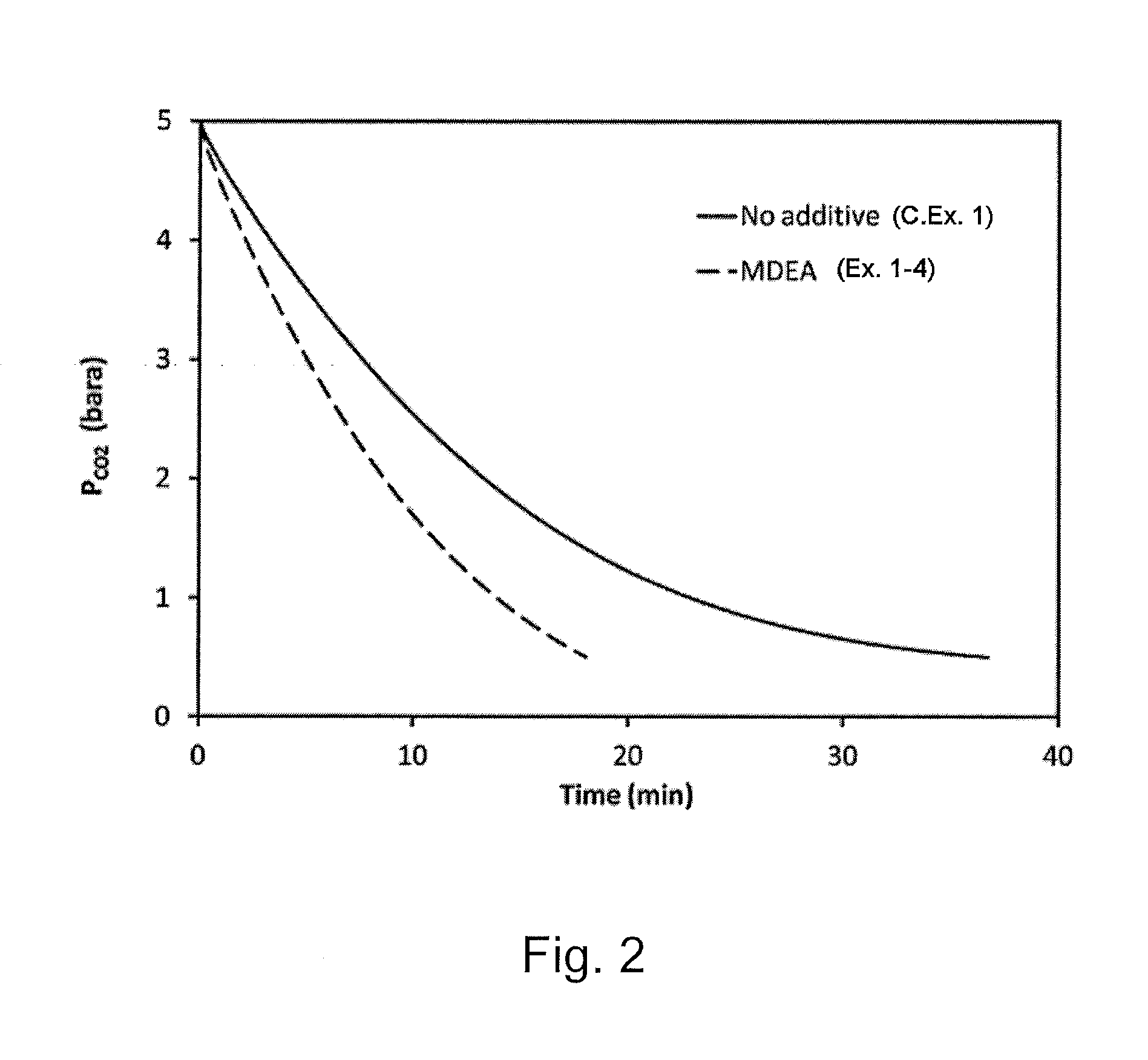

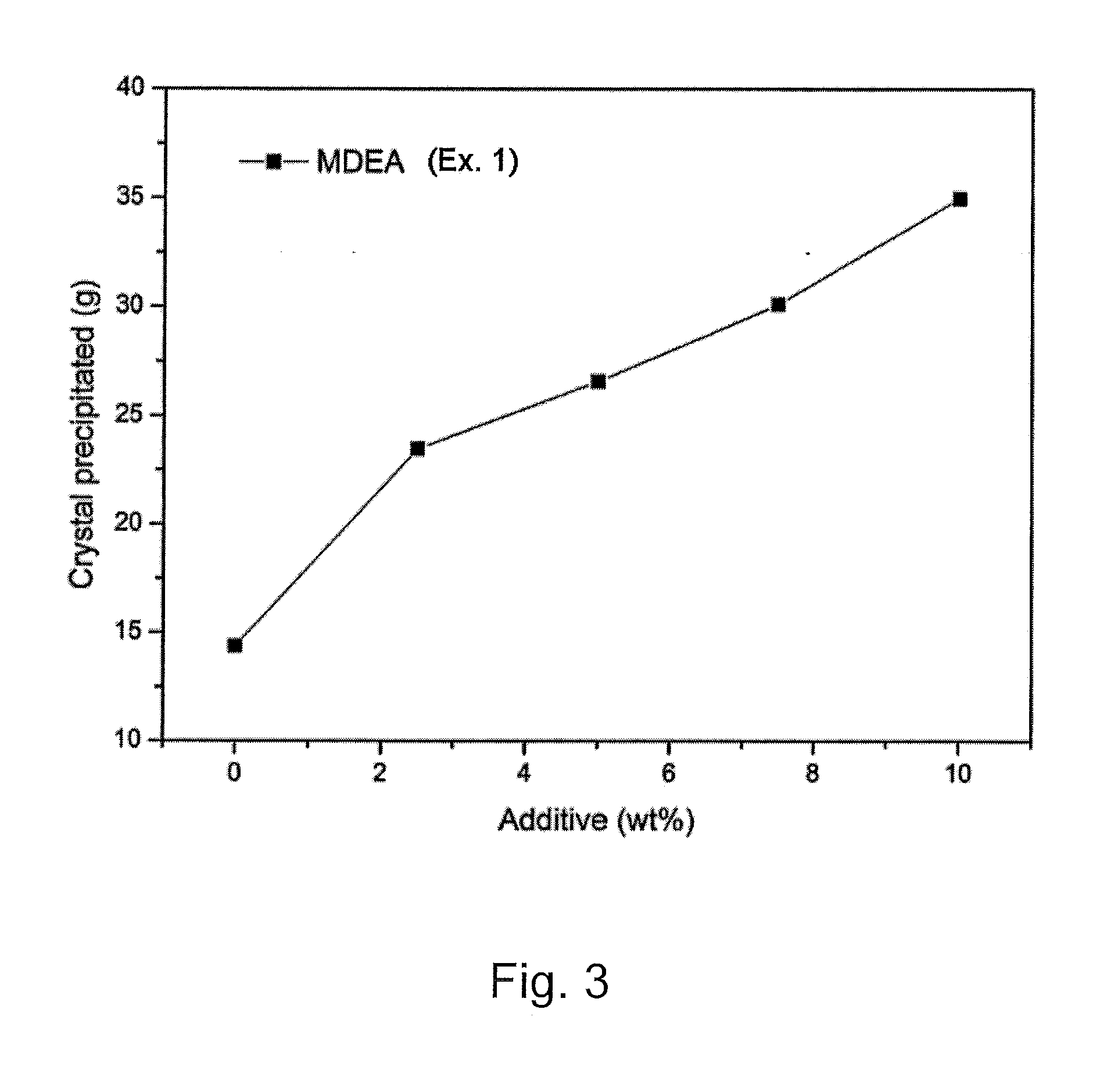

Carbon dioxide absorbing composition including tertiary alkanolamine, and method and apparatus for absorbing carbon dioxide using the same

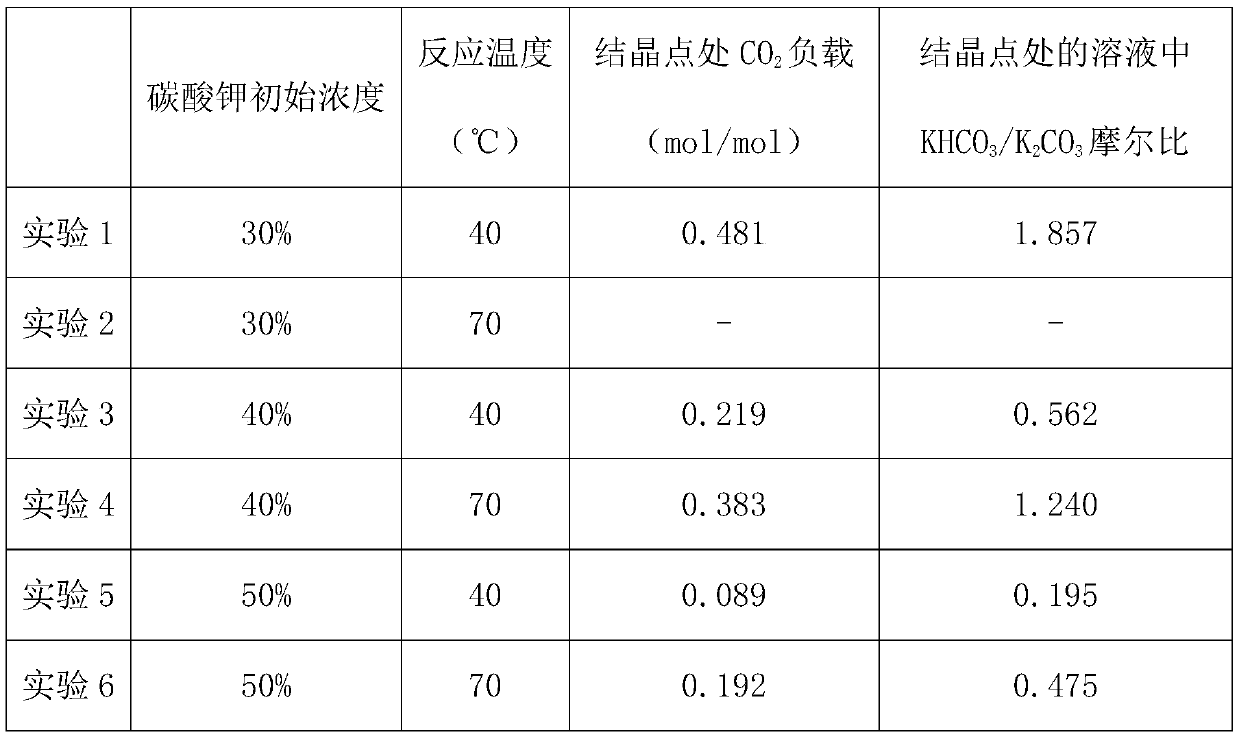

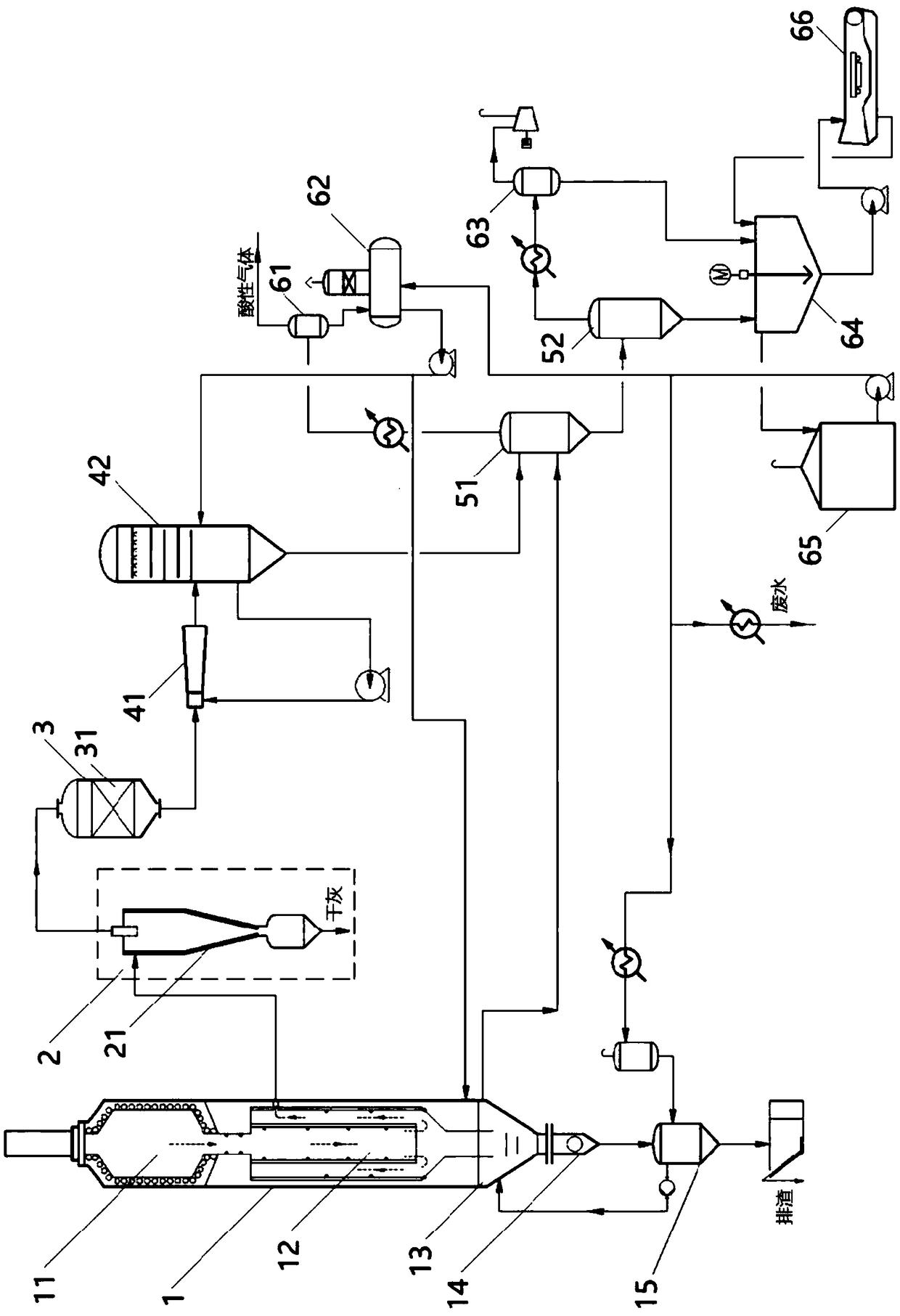

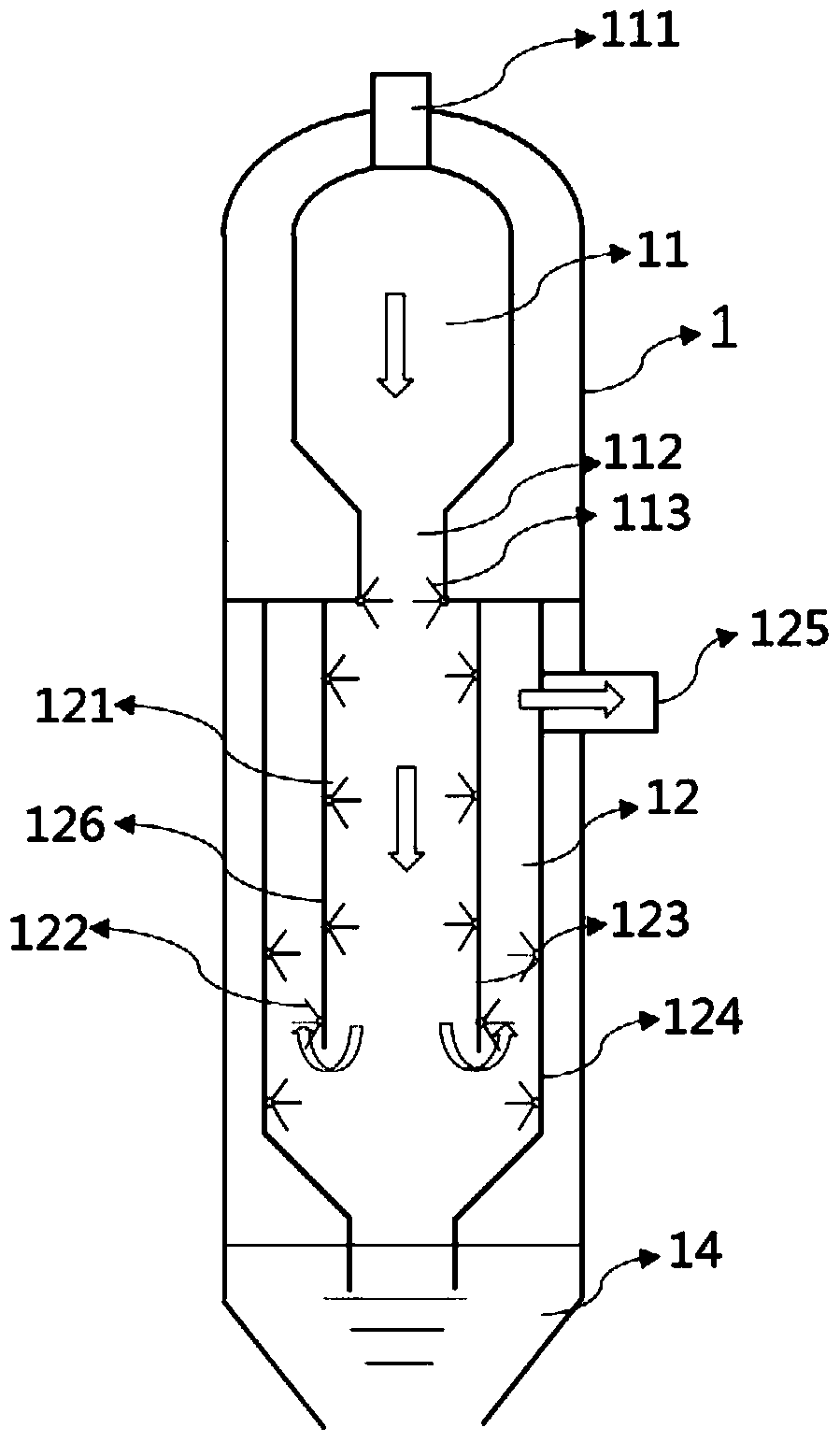

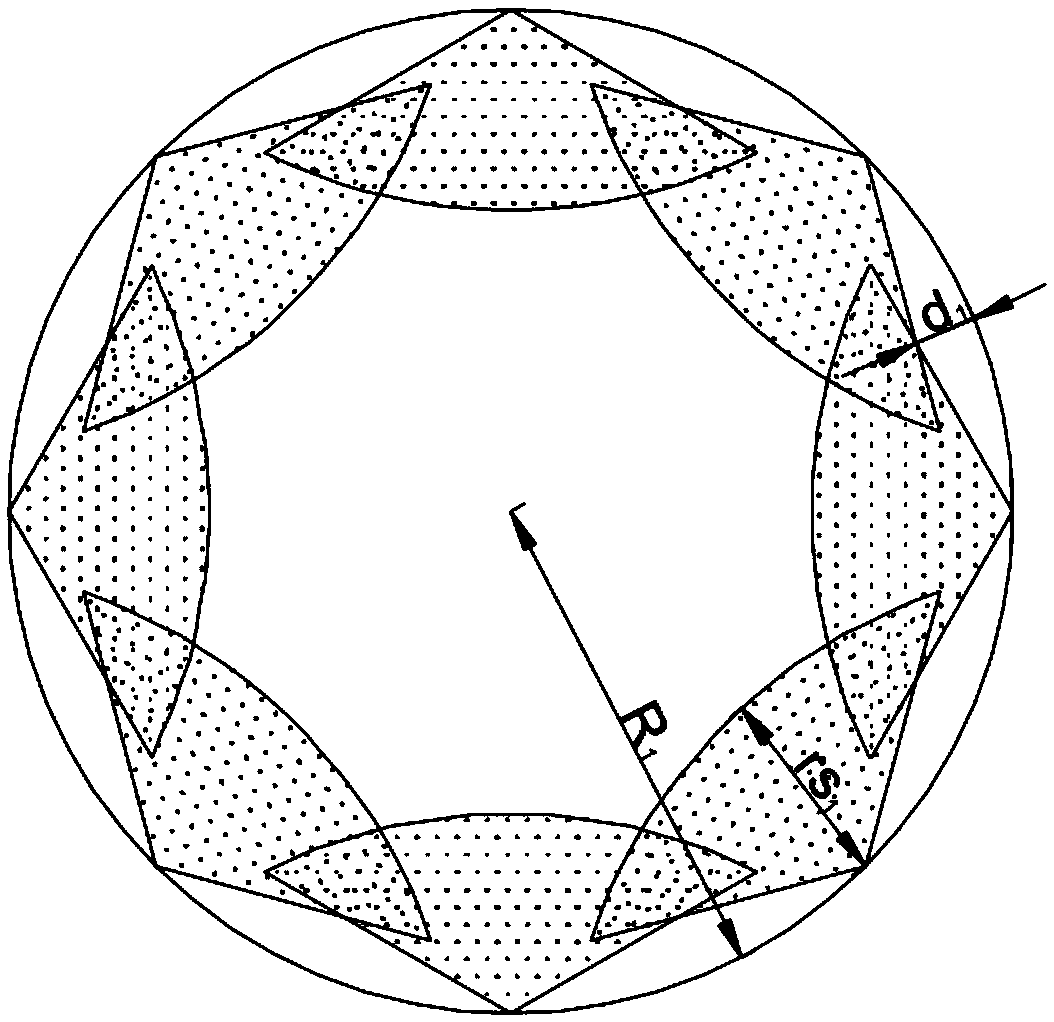

InactiveUS20150098889A1High solid-phase bicarbonate crystal yieldIncreasing carbon dioxide recovery efficiencyProductsGas treatmentHigh concentrationCo2 absorption

This invention relates to a carbon dioxide absorbing composition including a tertiary alkanolamine, and to a method and apparatus for absorbing carbon dioxide using the same, wherein in a process and apparatus for absorbing and recovering carbon dioxide from a gas mixture including carbon dioxide, a solid-phase bicarbonate crystal including high-concentration carbon dioxide is crystallized from a carbon dioxide absorbing composition having absorbed carbon dioxide and is then selectively separated, thereby efficiently recovering and regenerating carbon dioxide.

Owner:KOREA INST OF ENERGY RES

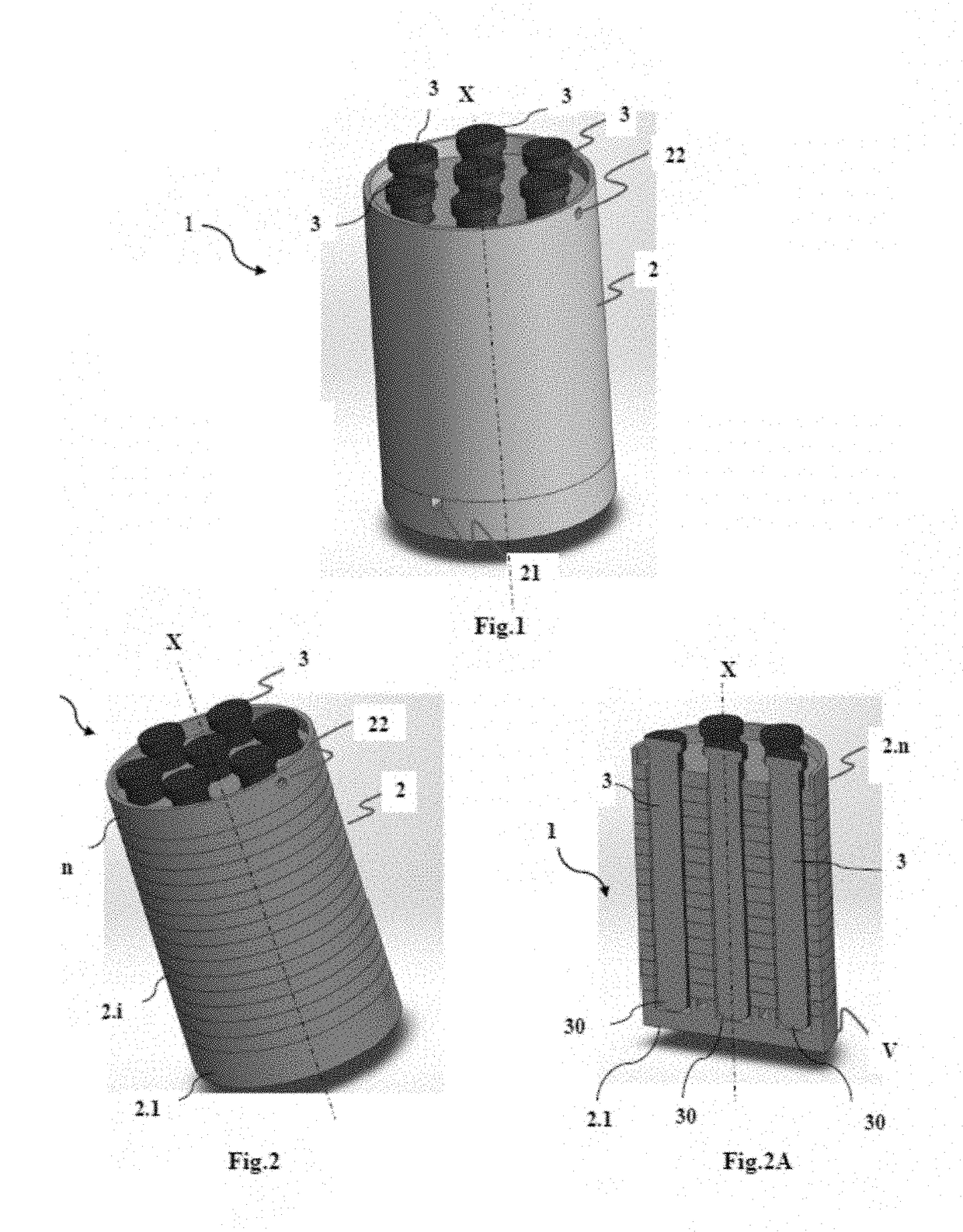

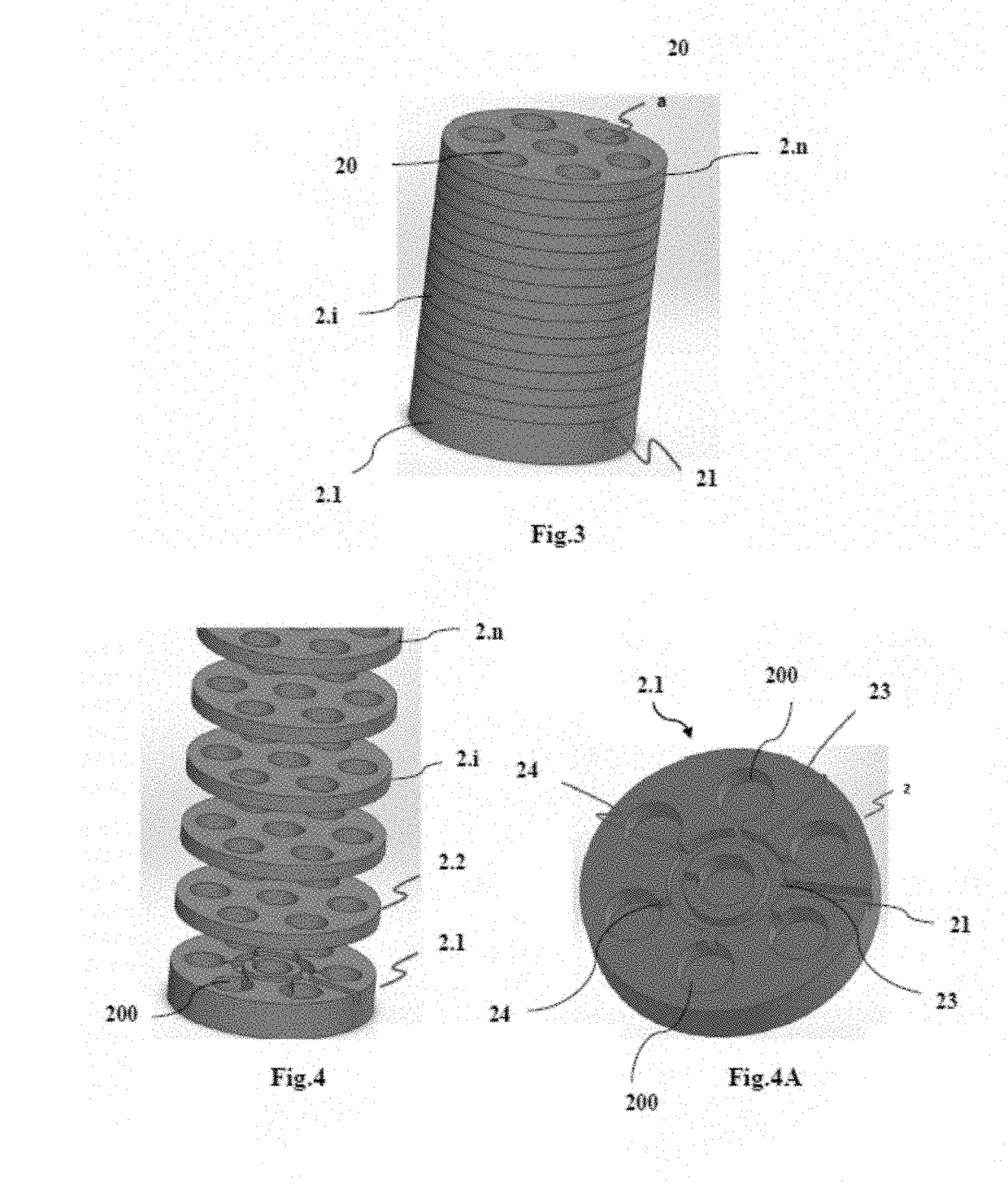

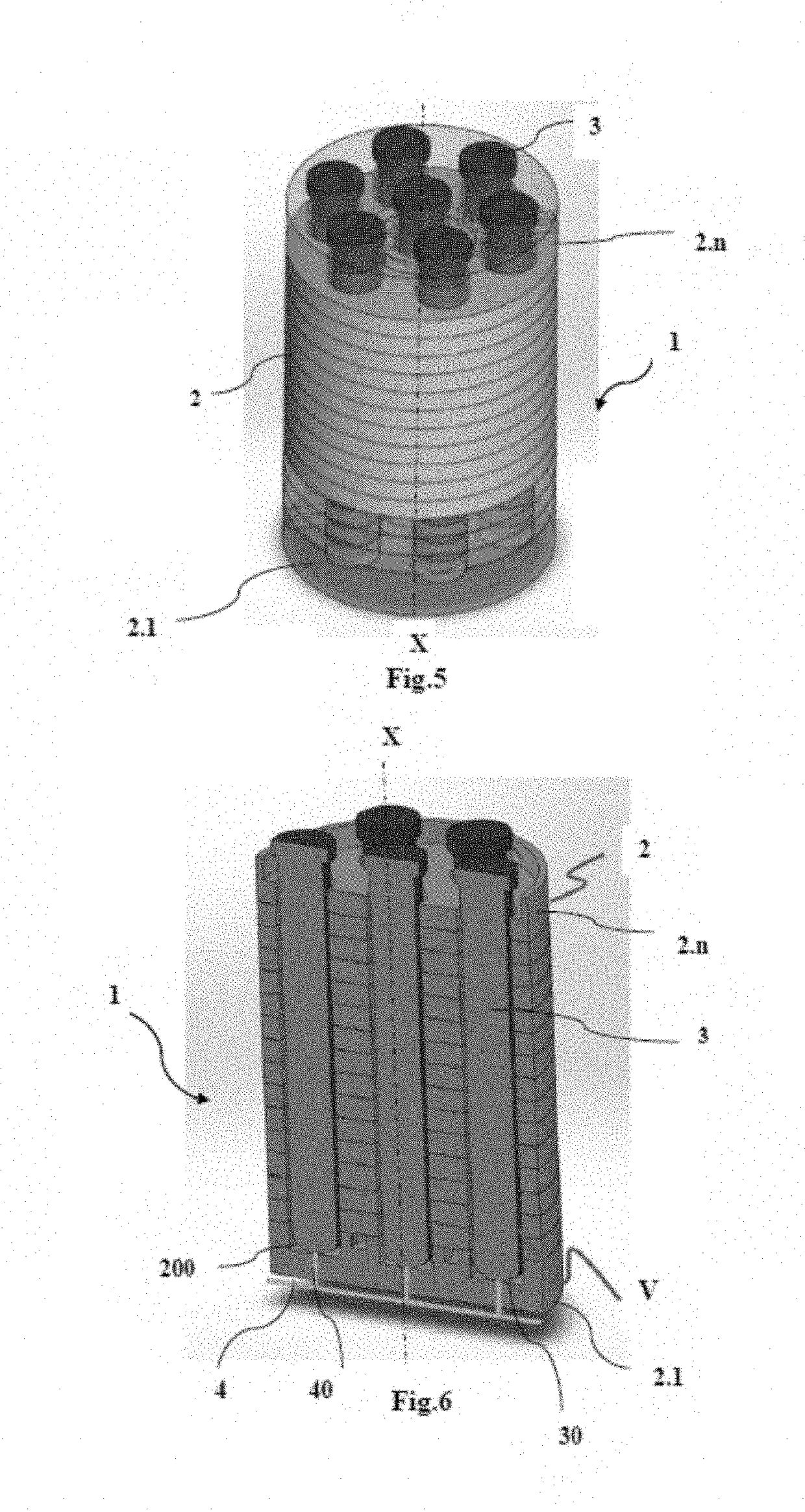

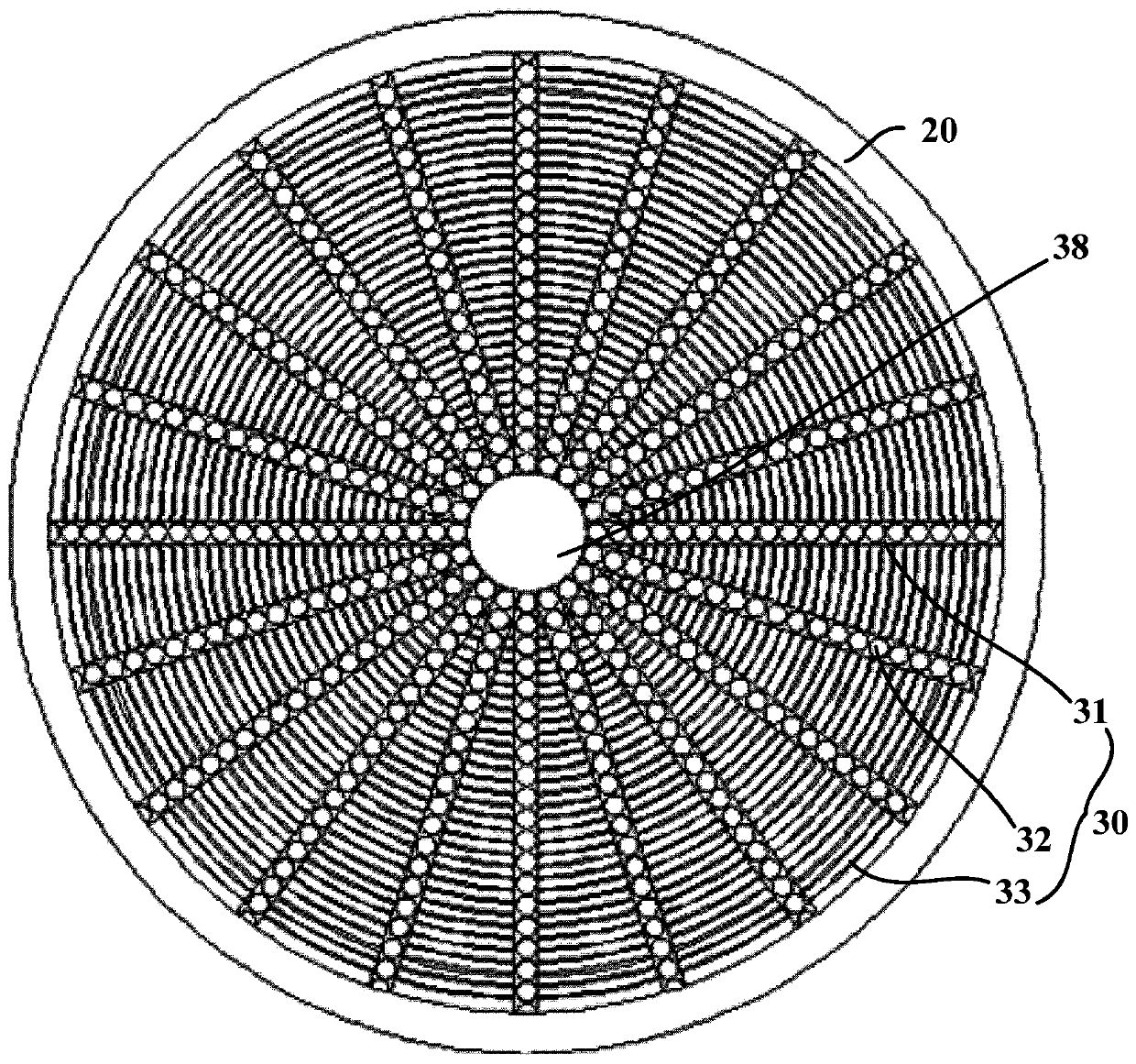

Hydrogen storage tank produced from a thermally insulating material forming cylindrical casings containing hydrides

InactiveUS20180356040A1Quantity minimizationReduce capacityReversible hydrogen uptakeVessel geometry/arrangement/sizeEngineeringHeat transfer fluid

A tank configured to reversibly store hydrogen, including: a plurality of cylindrically shaped casings each containing hydrides and each configured to be filled or emptied by the hydrogen being respectively absorbed or desorbed by the hydrides; a solid part made from thermally insulating material and having a low heat capacity being penetrated, within, by a plurality of cylindrically-shaped slots, the diameter of each of which is greater than that of a casing; a tank in which the casing is housed individually in a slot leaving an annular volume free between same such that to be traversed by a heat transfer fluid, following a defined circuit in each annular volume from an inlet common to all the annular volumes to an outlet which is also common.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

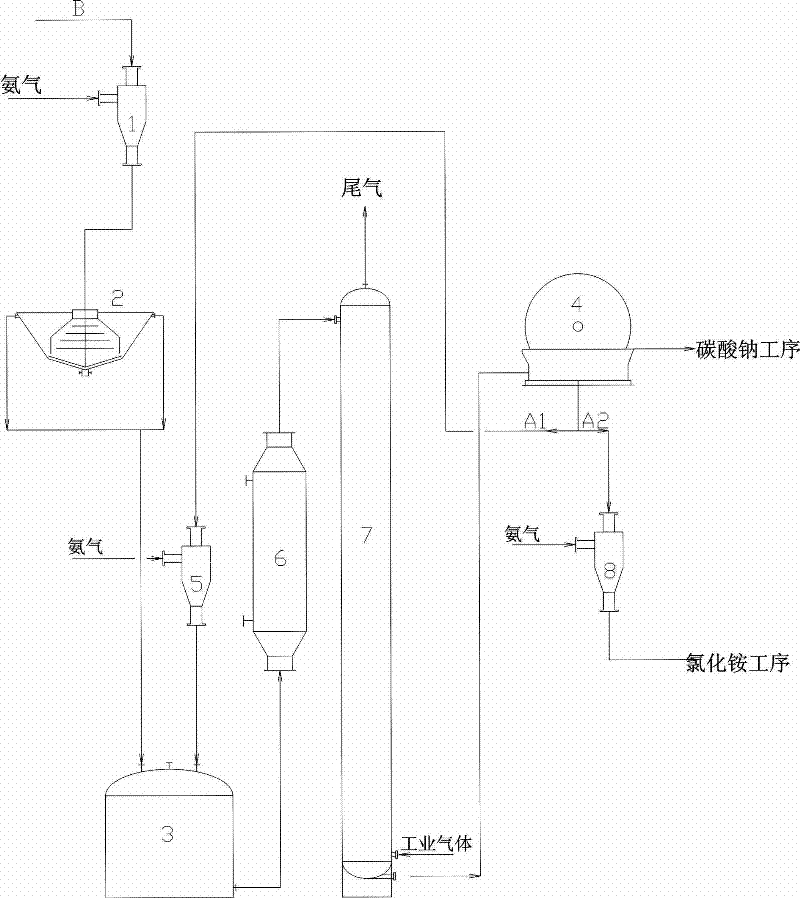

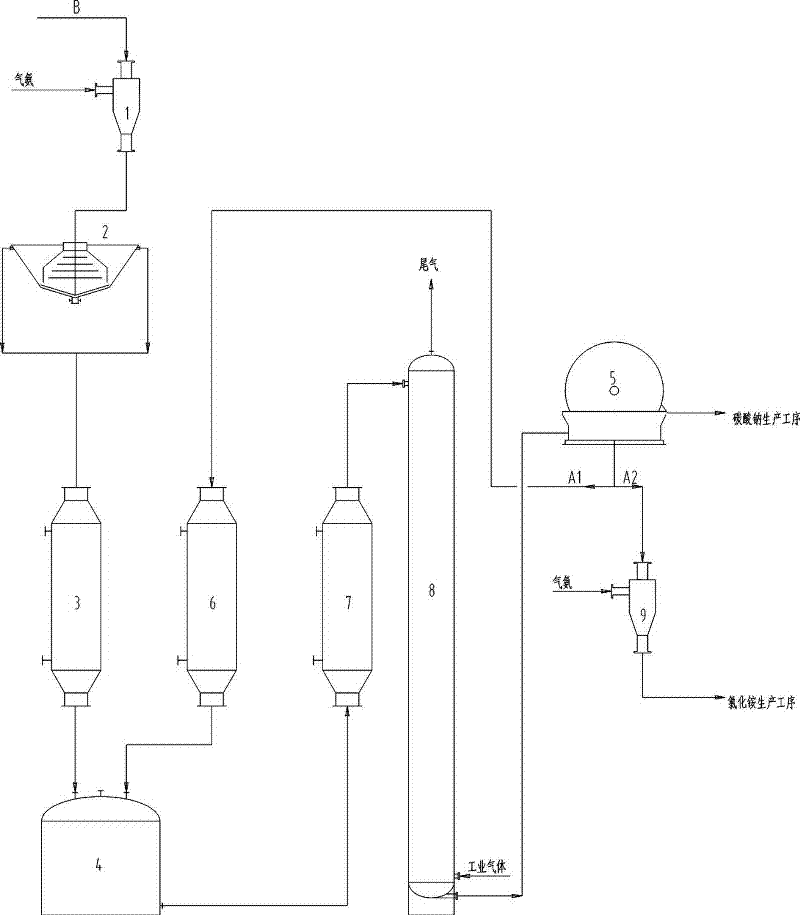

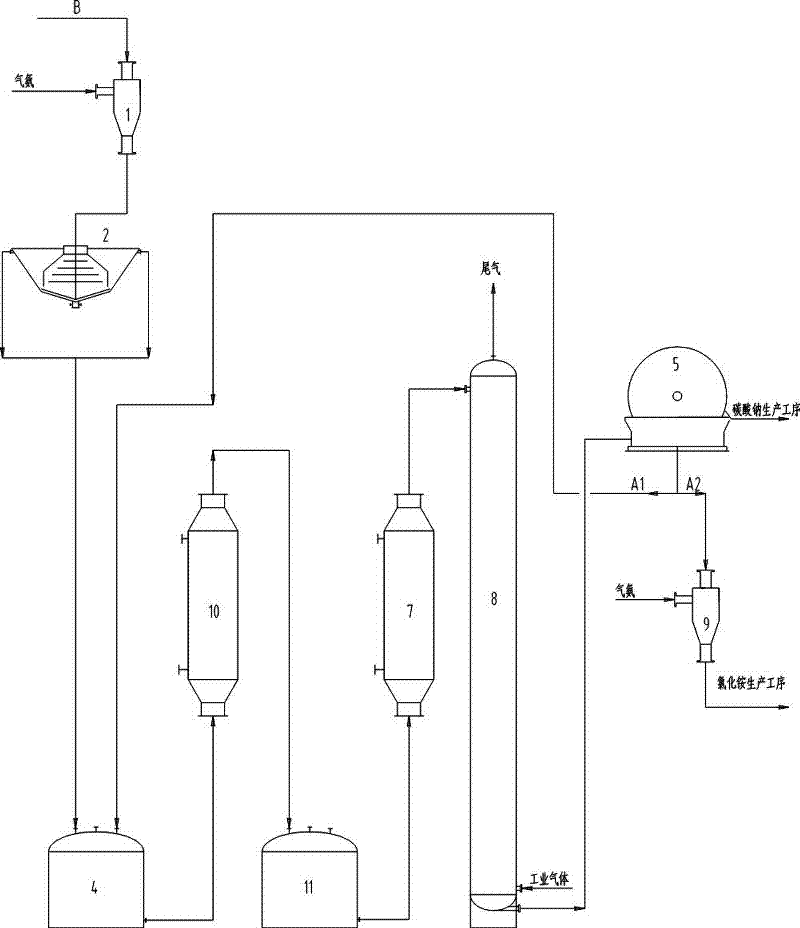

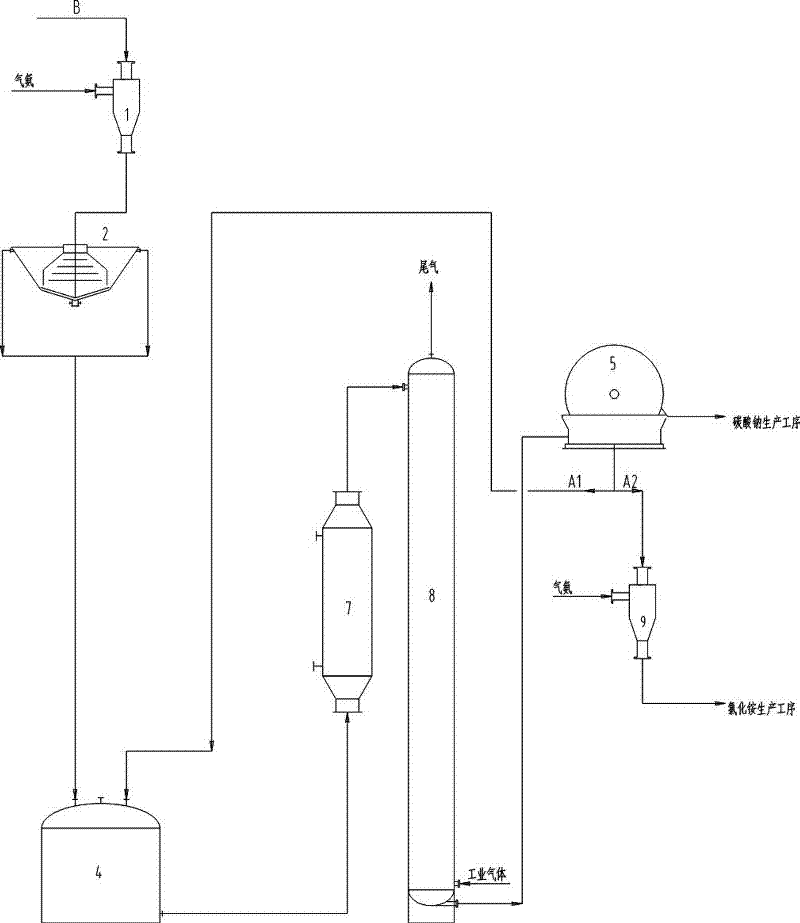

Process for removing carbon dioxide in combined alkali preparation method

The invention especially relates to a process for removing carbon dioxide produced in a combined alkali preparation method, which belongs to the technical field of combined alkali preparation methods. The process is as follows: mother liquor obtained after separation of solid sodium bicarbonate from liquid coming out from a decarburization tower is divided into two parts, i.e., A1 and A2, and A1 enters into a mixer after absorbing ammonia; after ammonium chloride is separated from mother liquor used in a procedure for producing ammonium chloride, the mother liquor adsorbs heat and ammonia, impurities of calcium-magnesium ions in the mother liquor are removed, and then the mother liquor is mixed with A1; obtained mixed liquor enters into the decarburization tower after cooling so as to remove carbon dioxide. The process provided in the invention enables a reaction for removing carbon dioxide to be carried out normally under the condition that a built-in or external cooler is not provided, i.e., that no cooling means is needed for heat exchange of decarburization liquid in the decarburization tower from the moment the decarburization liquid enters into the decarburization tower to the moment the decarburization liquid goes out from the decarburization tower; the decarburization tower can stably operate for a long period, with an operational period being more than 60 days; a goodabsorption effect of carbon dioxide is achieved, and a utilization rate reaches more than 99.6%.

Owner:张志广 +1

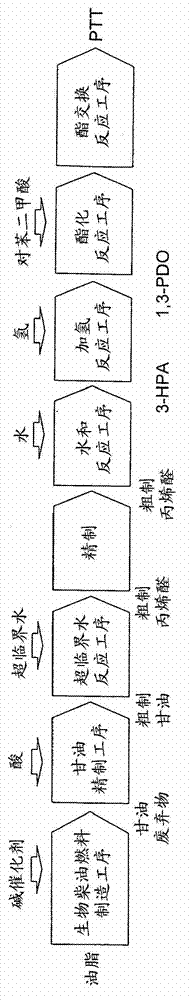

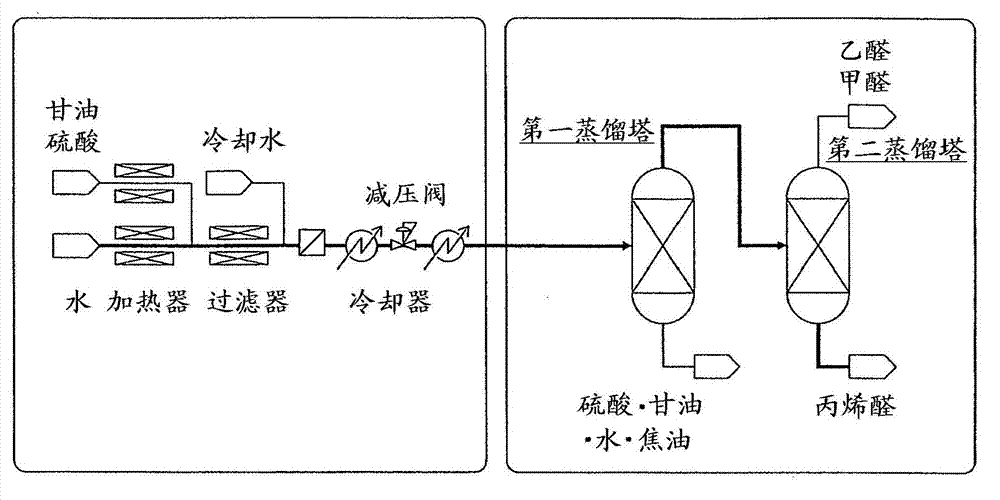

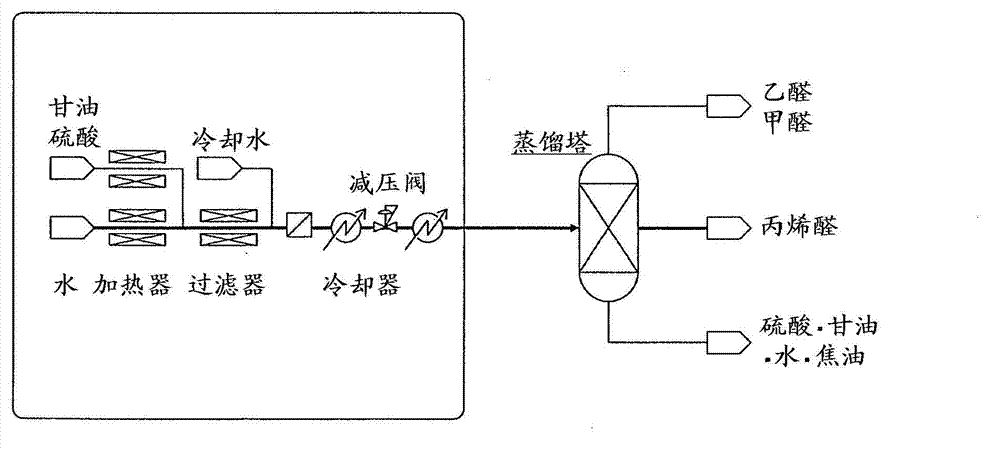

Manufacturing method of acrolein

InactiveCN103242148AReduce the number of machinesLow costOrganic compound preparationCarbonyl compound separation/purificationBoiling pointAcrolein

The present invention discloses a manufacturing method of acrolein. The present invention provides the manufacturing method of acrolein, which can simplify equipment for refining process of acrolein and reduce necessary energy required for refining in a process for causing reaction of supercritical Water and synthesizing acrolein from glycerin. The manufacturing method of the acrolein is characterized by comprising the following steps: causing the supercritical water and sulfuric acid to react on glycerin; performing cooling and decompression on the obtained reaction liquid; feeding the reaction liquid to a first distillation tower; recycling sulfuric acid, glycerin and water as high-boiling-point components at the bottom of the first distillation tower; recycling acrolein, acetaldehyde and formaldehyde as low-boiling-point components at top of the distillation tower; condensing the low-boiling-point components and feeding condensate to a second distillation tower; recycling the acetaldehyde and the formaldehyde as the low-boiling-point components at the top of the second distillation tower; and recycling the acrolein as the high-boilding-point component at the tower bottom.

Owner:HITACHI LTD

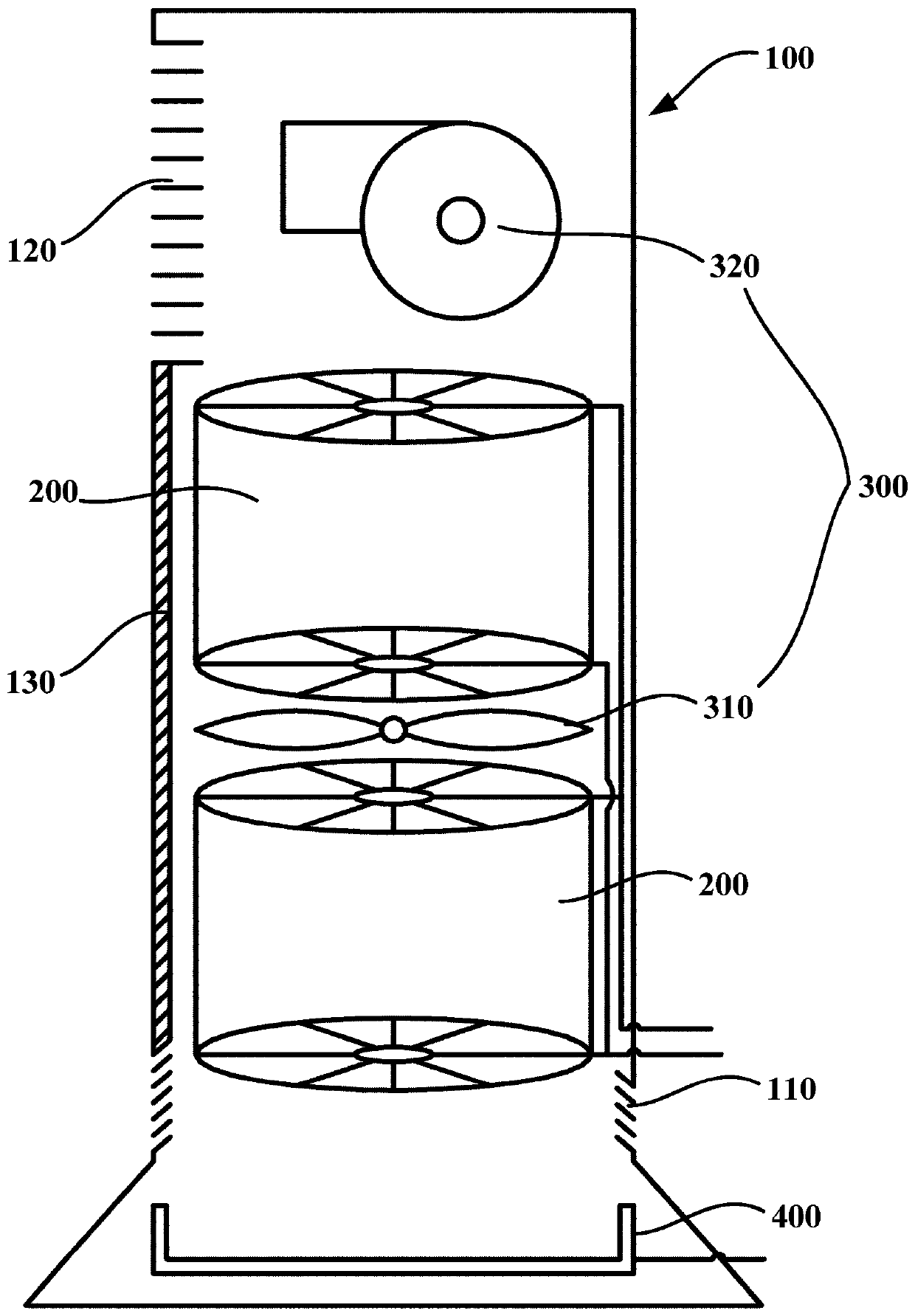

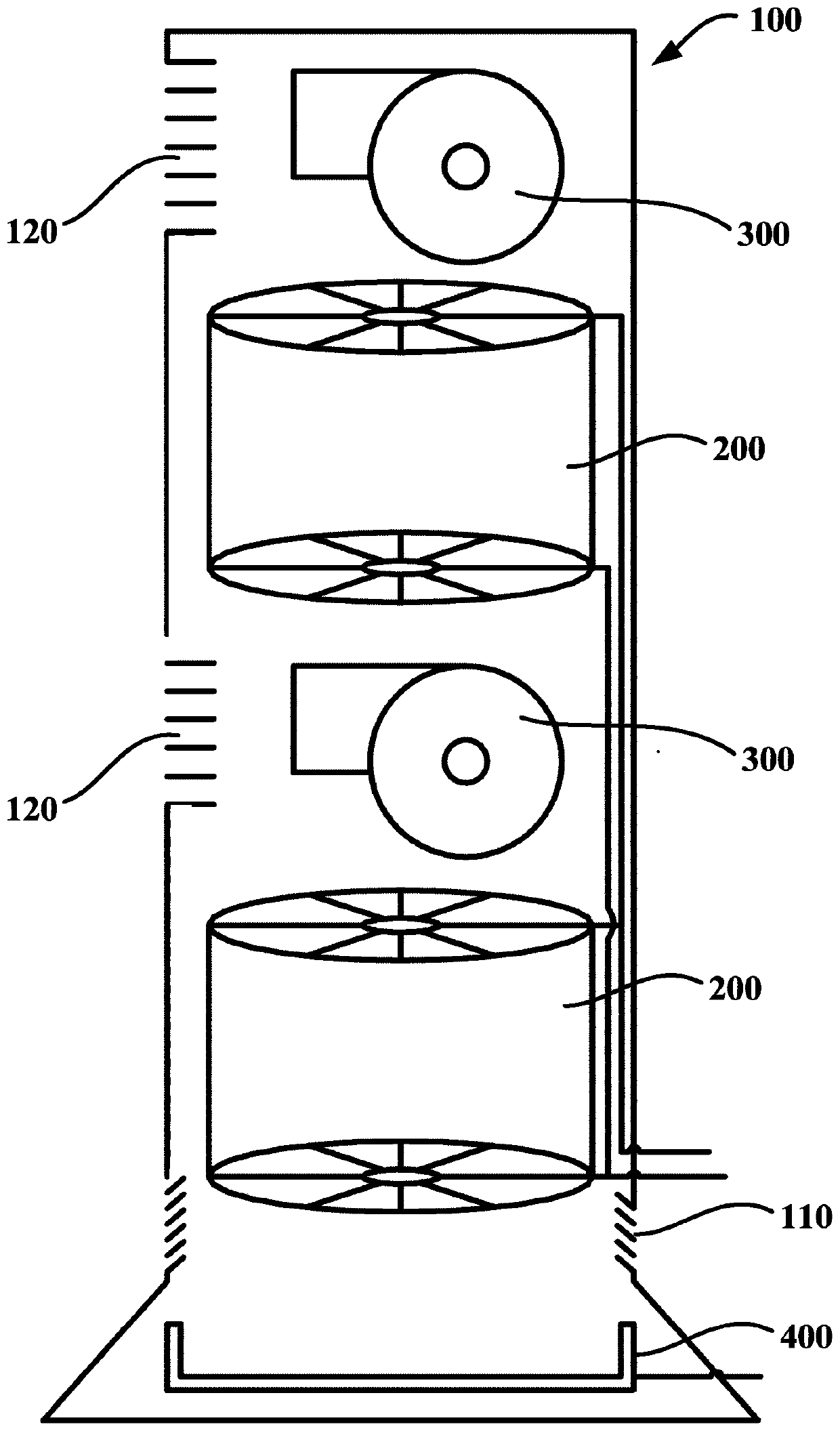

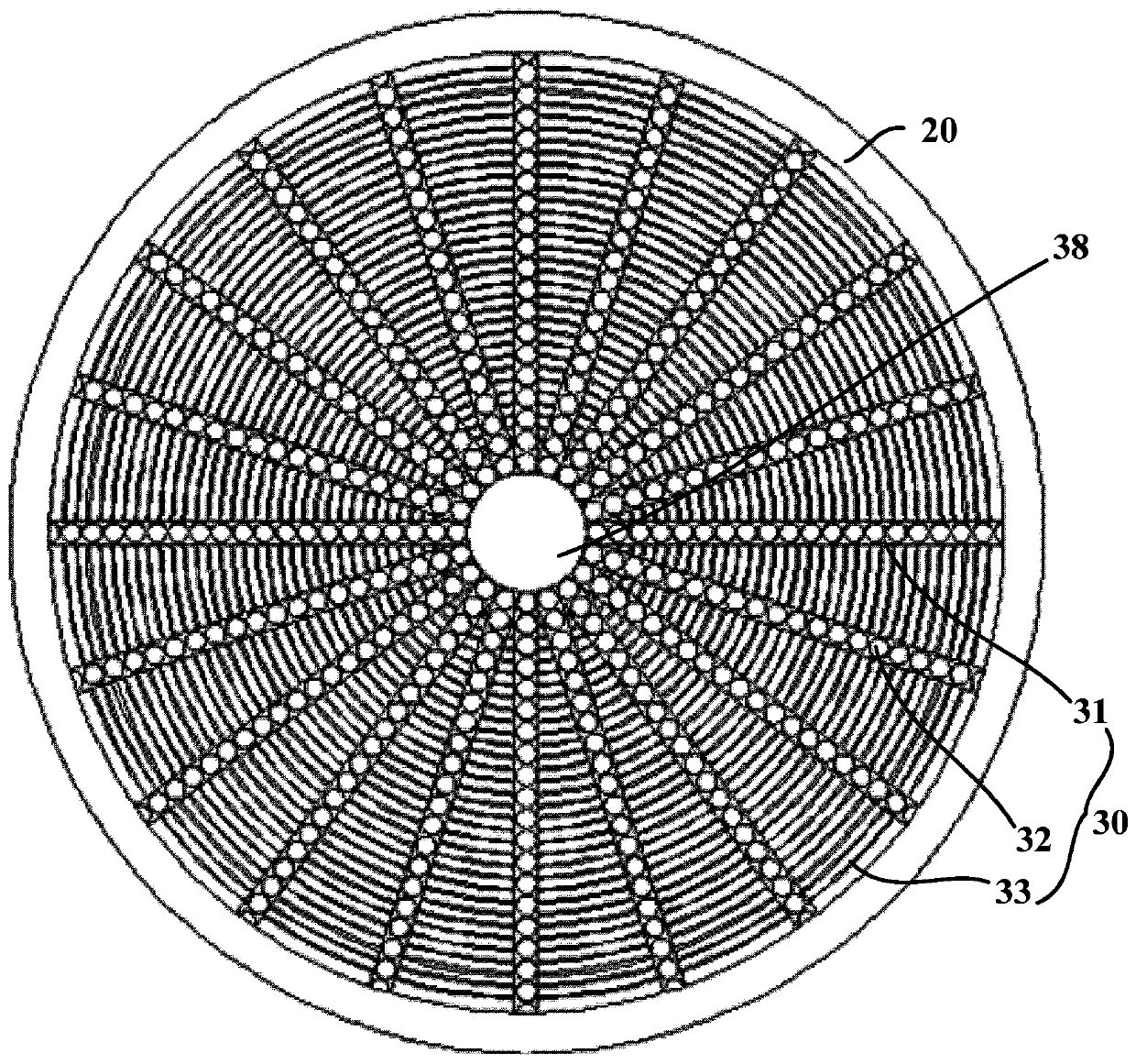

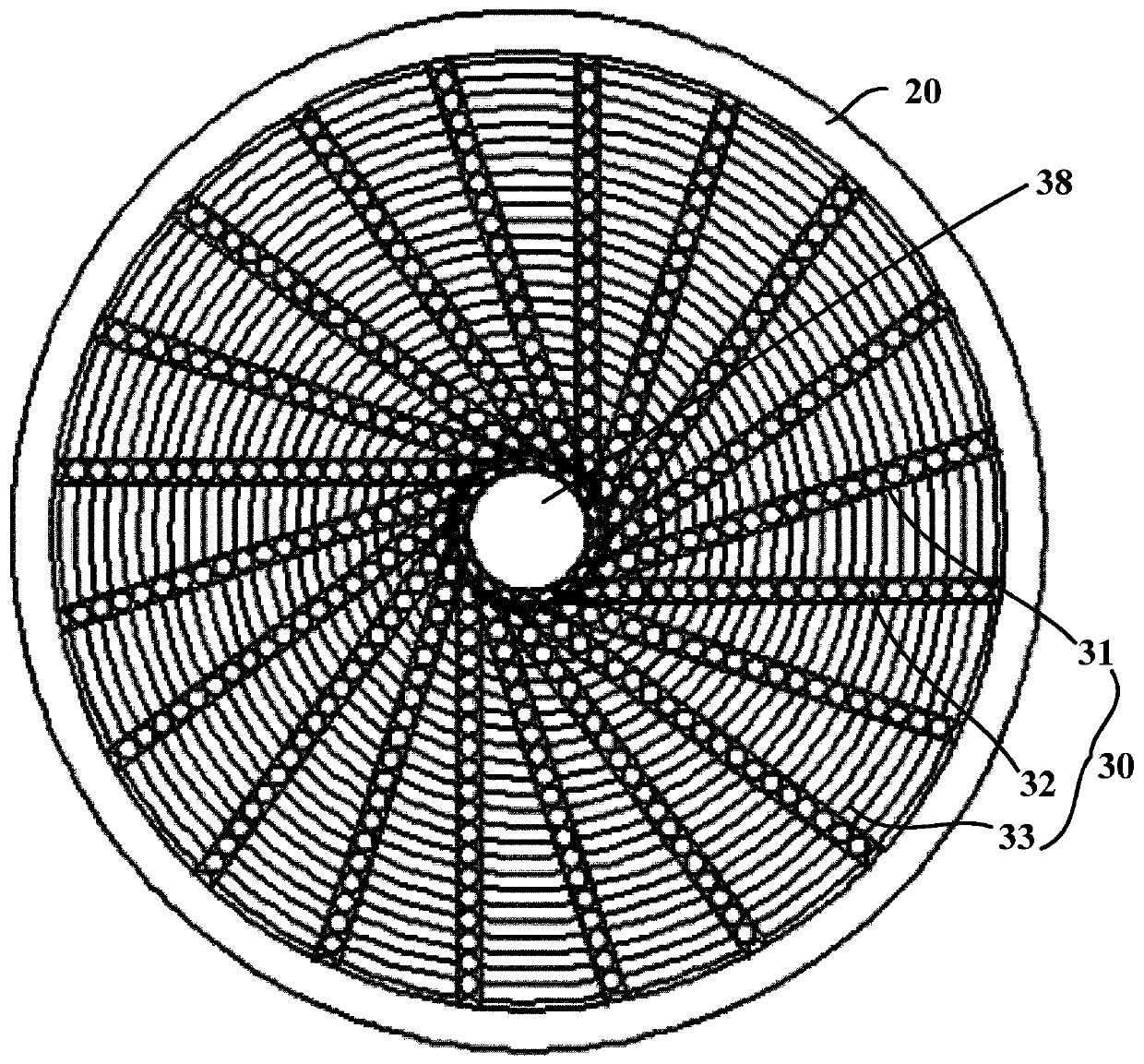

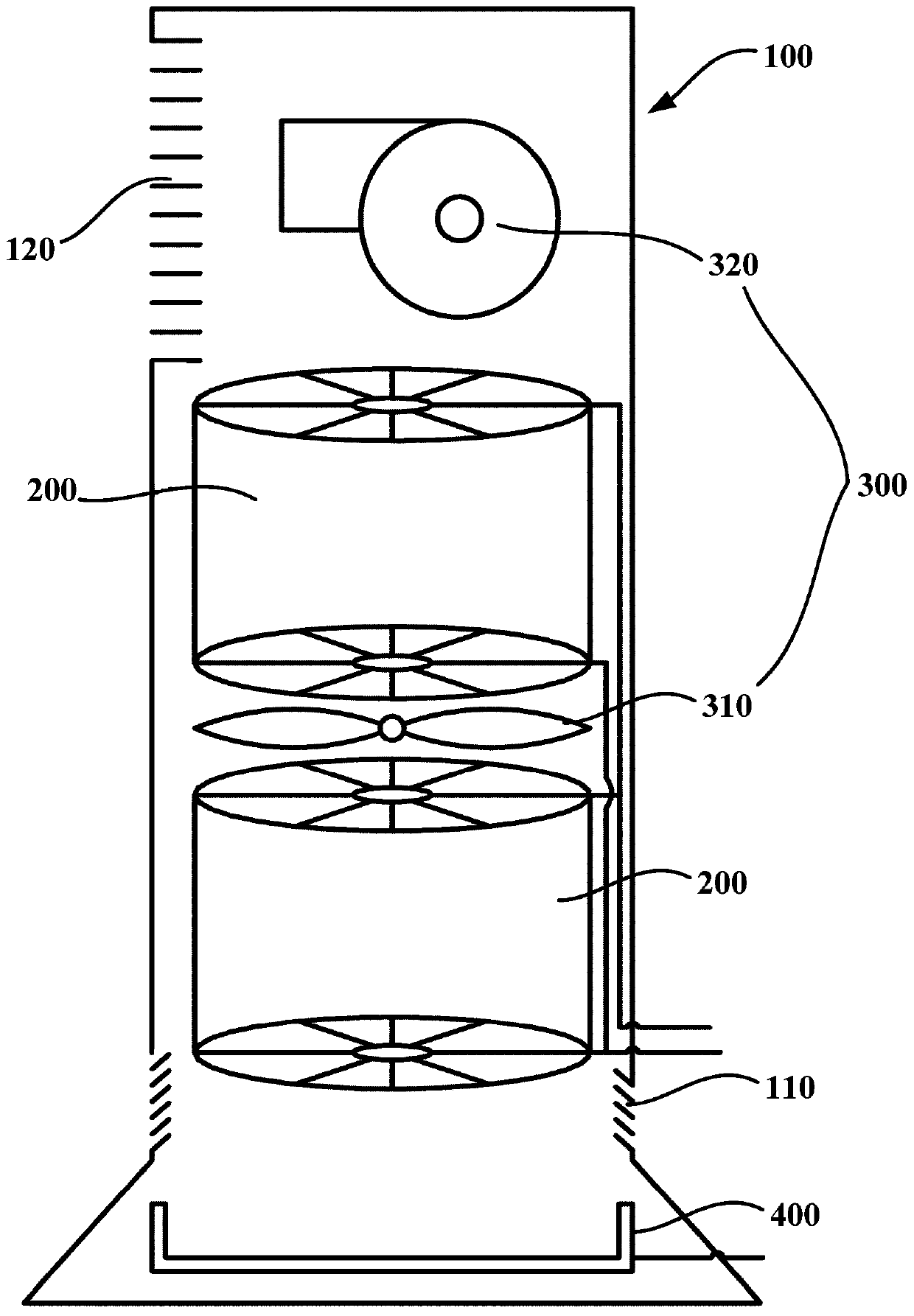

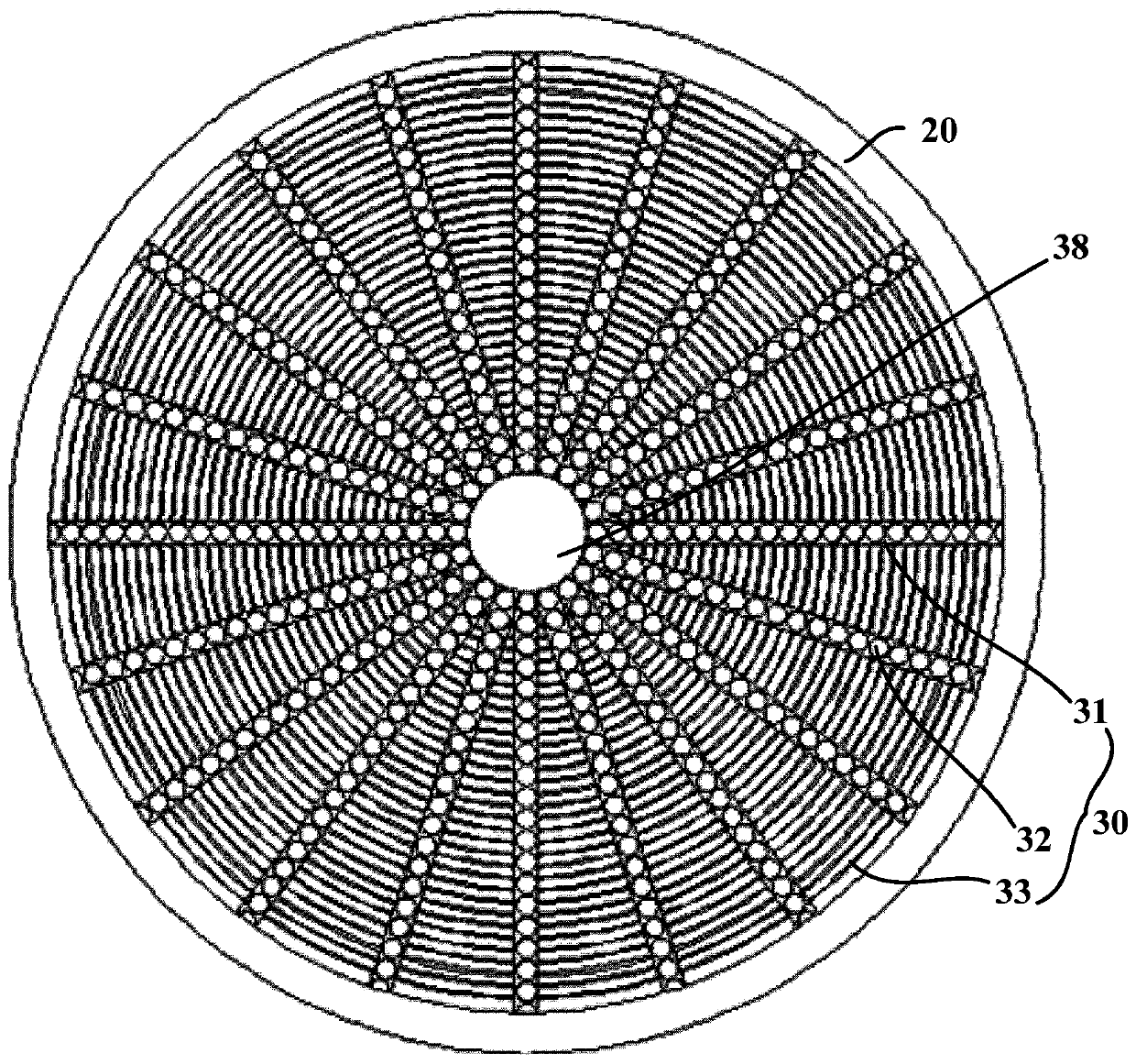

Vertical cabinet type air conditioner indoor unit

PendingCN111435010AImprove energy efficiencyOptimized airflow organizationLighting and heating apparatusSpace heating and ventilation detailsEngineeringConvection heat

The invention provides a vertical cabinet type air conditioner indoor unit. The vertical cabinet type air conditioner indoor unit comprises a shell, multiple radiation and convection type heat exchangers and an air supply device. An air inlet is formed in the lower portion of the shell, an air supply opening is formed in the upper portion of the shell, and the front portion of the shell comprisesa radiant panel. The radiation convection type heat exchangers are provided with radiation heat exchange parts and convection heat exchange parts, and are mounted in the shell, the radiation heat exchange parts are in cylinder shapes with openings in two ends and extending in the vertical direction, the radiation heat exchange parts are configured to absorb heat or cold from the inner wall faces thereof, and transmit the heat or cold to the radiant panel from the outer wall faces thereof, the convection heat exchange parts are arranged on the inner sides of the radiation heat exchange parts, are configured to generate heat or cold, transmit the heat or cold to air flowing through the inner sides of the radiation heat exchange parts and transmit the heat or cold to the inner wall faces of the radiation heat exchange parts, the radiation heat exchange parts are sequentially and coaxially mounted in the vertical direction, the air supply device is mounted in the shell, and is configured to at least prompt the air flow to enter the inner sides of the radiation heat exchange parts from the air inlet, and after heat exchange with the convection heat exchange parts, the air flow flows outof the air supply opening.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Slagging-free type and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and method thereof

ActiveCN102502744BSolve the problem of large initial investmentReduce energy consumptionEnergy inputAluminium oxide/hydroxide preparationFlue gasEngineering

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

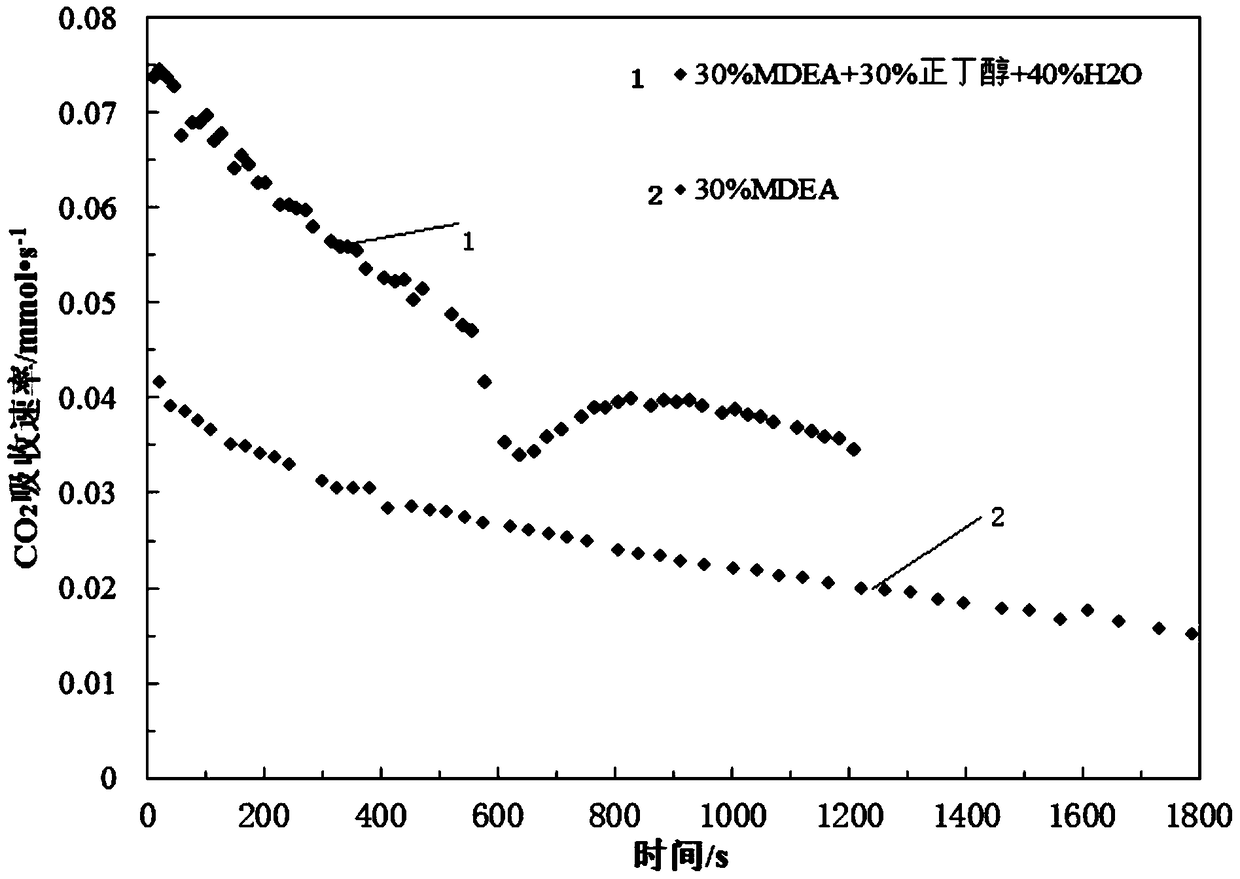

A kind of mdea composite absorbent for acid gas separation and separation method

ActiveCN105536437BReduce sensible heatReduce desorption energy consumptionDispersed particle separationAlcoholFluid phase

The invention discloses an MDEA compound absorbent for acid gas separation and a separation method, and belongs to the technical field of gas separation. The MDEA compound absorbent comprises MDEA, alcohols immiscible with water and water, wherein the weight percentage of MDEA is 10-60%, the weight percentage of alcohols immiscible with water is 10-60%, and the weight percentage of water is 10%-80%; due to the solubilization assisting effect of MDEA, the compound absorbent has a homogeneous phase before absorbing acid gas, and is formed into liquid-liquid phases after absorbing acid gas, the upper liquid phase is the barren liquid phase loaded with acid gas, the lower liquid phase is the rich liquid phase loaded with acid gas, and only the rich liquid phase enters a desorption unit, so that the desorption energy consumption is reduced. The compound absorbent is formed into liquid-liquid phases after absorbing acid gas, the liquid-liquid phases are easy to separate, and the composition proportion of the absorbent is adjusted to adapt to the optimal volume ratio of the upper liquid phase and the lower liquid phase and loading capacity of the absorbent in the process, so that amount of the rich liquid phase entering the desorption unit is reduced, and the desorption energy consumption is reduced.

Owner:BEIJING UNIV OF CHEM TECH

Solar solid dehumidifying and regenerating air-conditioning system

ActiveCN102620369BReduce heat lossImprove the utilization rate of solar heatEnergy recovery in ventilation and heatingLighting and heating apparatusGlass coverHigh energy

The invention discloses a solar solid dehumidifying and regenerating air-conditioning system. The solar solid dehumidifying and regenerating air-conditioning system comprises a moisture absorption bed (5), a generation bed (6), a sensible heat exchanger (7), an air cooling device (8), a cabin body (10), an air flow baffle (11), a thin solid adsorption layer (12) and a glass cover plate (13), wherein the moisture absorption bed (5) has the same structure as the regeneration bed (6), and comprises the cabin body (10), the air flow baffle (11), the thin solid adsorption layer (12) and the glass cover plate (13). The invention discloses a solid moisture absorption and regeneration bed integrating a flat solar heat collector with a thin solid adsorption layer. The invention discloses a solid adsorbing dehumidifying and regenerating air-conditioning system with novelty, high energy efficiency, low manufacturing cost, low air flow resistance, high moisture absorption capability, small size and high solar heat utilization rate. The solar solid dehumidifying and regenerating air-conditioning system has a potential to develop into a low (zero) carbon air-conditioning system using solar energy and natural energy, and can be widely applied to buildings.

Owner:GUANGDONG UNIV OF TECH

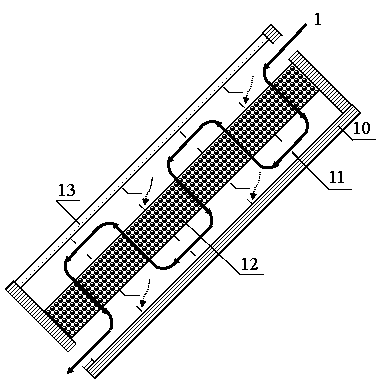

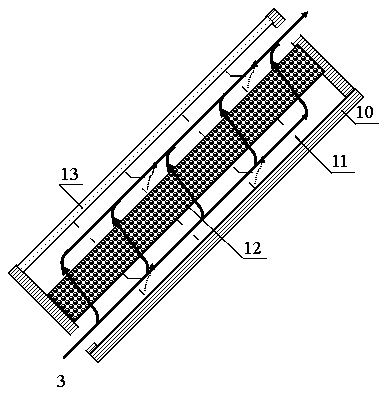

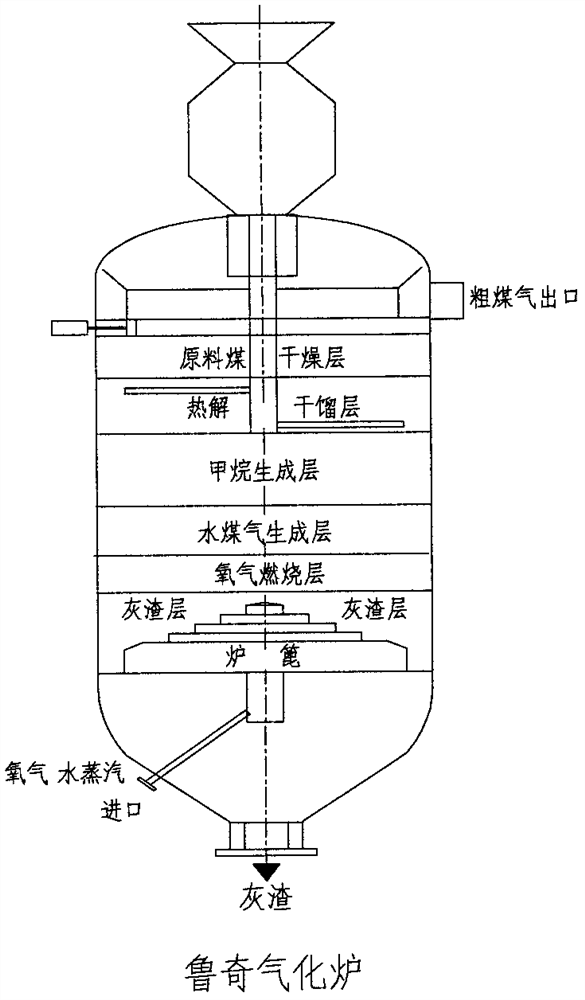

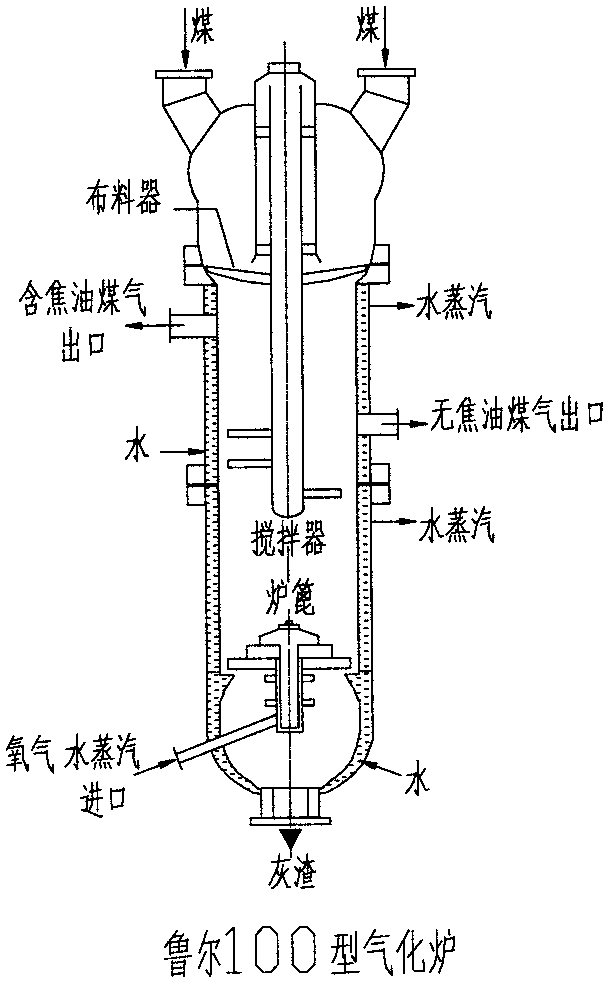

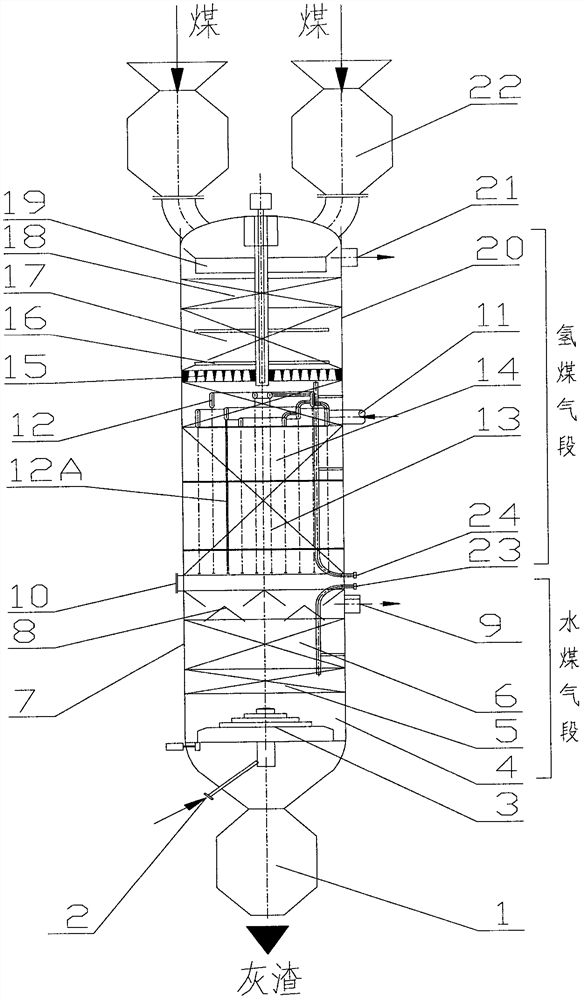

Pressurized moving bed hydrocarbon-rich hydrogen gas and water gas graded production furnace

ActiveCN110358584BReduce sensible heatHigh thermal efficiencyChemical industryGasification processes detailsFuel oilMoving bed

Pressurized moving bed hydrocarbon-rich hydrogen gas and water gas graded production furnace, the raw coal is first gasified with hydrogen to produce hydrogen gas rich in methane and multi-carbon hydrocarbons, and then the residual coke left after the hydrogen gas is produced Water gas gasification, the hydrocarbon-rich hydrogen gas and water gas are released separately, the gasification agent and the gasified solid particles flow countercurrently, the heat is fully utilized, the energy conversion efficiency is high, the steam and oxygen consumption are small, and the carbon dioxide emission is small; the water gas condensate Relatively reduced, and does not contain phenolic compounds, low processing cost, environmentally friendly; high content of methane and multi-carbon hydrocarbons in hydrogen gas, low purification and separation costs; pressurized moving bed hydrocarbon-rich hydrogen gas and water gas graded production furnace, available Coal-to-natural gas, coal-to-fuel oil, coal-to-olefins, coal-to-methanol, IGCC integrated coal gasification combined cycle power generation and other industries.

Owner:成都聚实节能科技有限公司

Technology for removing carbon dioxide in combined process for manufacturing soda ash and ammonium chloride

ActiveCN102350199AGet rid of normalReduce the temperatureDispersed particle separationAir quality improvementSodium bicarbonateAbsorption effect

The invention belongs to the technical field of a combined process for manufacturing soda ash and ammonium chloride, and especially relates to a technology for removing carbon dioxide in the combined process for manufacturing soda ash and ammonium chloride. According to the invention, solid sodium bicarbonate is separated from a liquid discharged from a decarburization tower, such that a mother liquid is obtained; the mother liquid is divided into two parts which are A1 and A2; ammonium chloride is separated from a liquid discharged from an ammonium chloride producing process, such that a mother liquid B is obtained; the mother liquid B is processed through ammonia adsorption, and calcium and magnesium ionic impurities are removed from the mother liquid B; the mother liquid B is mixed with A1; the temperature of the mixed liquid is regulated to 18 to 24 DEG C, and carbon dioxide is removed from the mixed liquid in the decarburization tower. With the technology provided by the invention, a carbon dioxide removal reaction can be normally carried out with no internal or external cooling device arranged in the decarburization tower. That is to say, during the process since the decarburization solution is delivered into the decarburization tower to the decarburization solution is discharged from the tower, no heat exchanging by cooling is required. The decarburization tower can smoothly operate in a long period, wherein a task cycle is more than 60 days. With the technology, the carbon dioxide absorption effect is good, and a utilization rate is higher than 99.6%.

Owner:张志广 +1

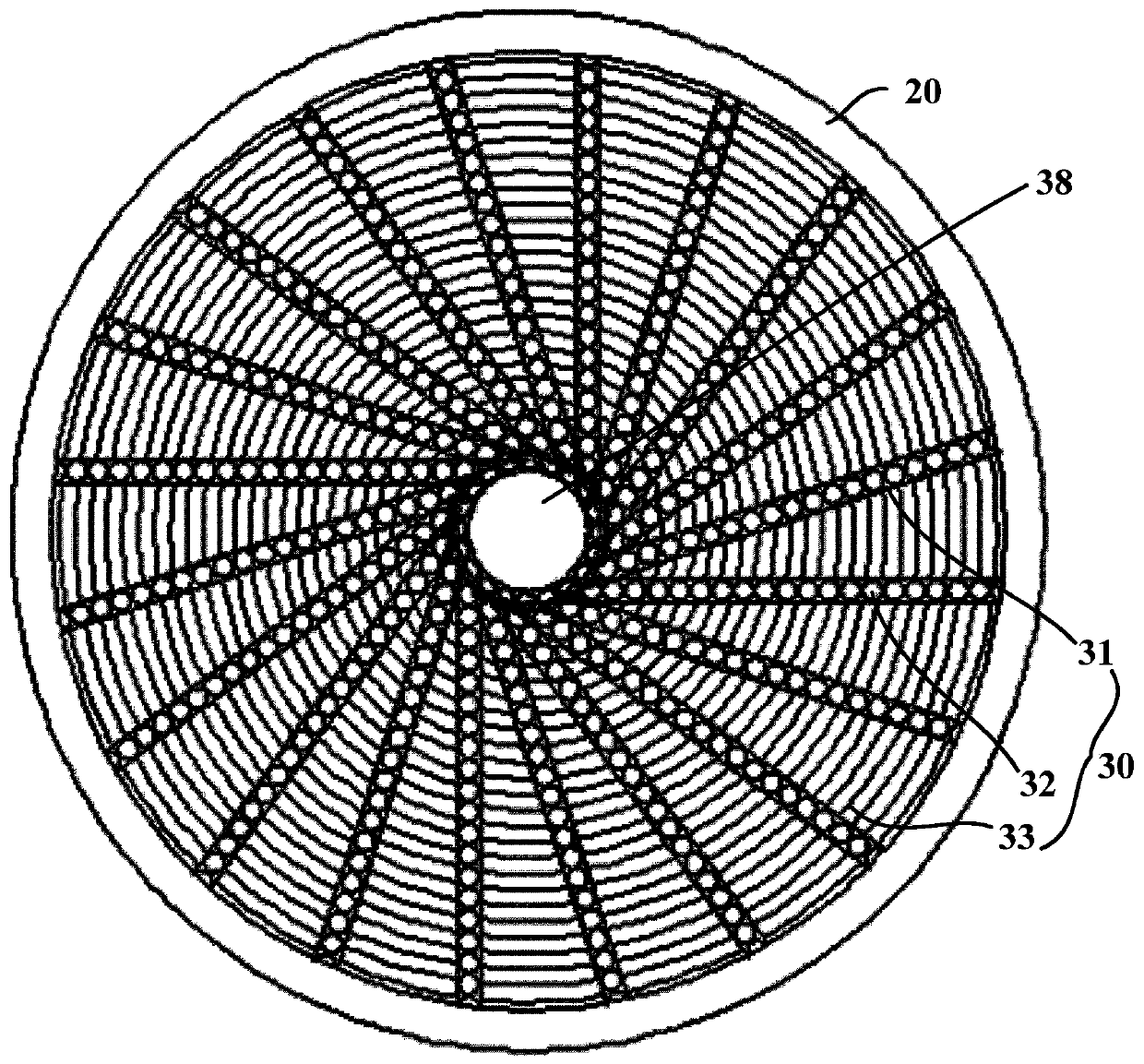

Vertical cabinet type air-conditioner indoor unit

PendingCN111435008AImprove energy efficiencyReduce local resistanceLighting and heating apparatusSpace heating and ventilation detailsEngineeringConvection heat

The invention provides a vertical cabinet type air-conditioner indoor unit which comprises a shell, multiple convection type heat exchangers and an air supply device. The shell is provided with an airinlet and multiple air supply openings. The air inlet is formed in the lower portion of the shell. The multiple air supply openings are sequentially arranged in the vertical direction. The multiple convection type heat exchangers are arranged in the shell. At least one convection type heat exchanger is arranged on the lower side of a position where each air supply opening is located with a same height. Each convection type heat exchanger is provided with an airflow gathering portion and a convection heat exchange portion. Each airflow gathering portion is in a cylinder shape with openings formed in two ends, wherein the cylinder shape extends in the vertical direction. Each convection heat exchange portion is arranged on the inner side of the corresponding airflow gathering portion. The multiple airflow gathering portions are sequentially arranged in the vertical direction. The multiple airflow gathering portions are arranged coaxially. The air supply device is arranged in the shell,and is arranged to urge airflow to enter the shell from the air inlet, and flow out of the shell from one or more air supply openings. The airflow flowing out of each air supply opening exchanges heatwith the corresponding convection heat exchange portion at the lower side of the height position where the air supply openings are located.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Vertical cabinet type air conditioner indoor unit

PendingCN111435011AOptimized airflow organizationIncrease the flow speedLighting and heating apparatusSpace heating and ventilation detailsEngineeringAir velocity

The invention provides a vertical cabinet type air conditioner indoor unit. A shell is included, an air inlet is formed in the lower part of the shell, and an air supply outlet is formed in the upperpart of the shell; a plurality of convection type heat exchangers are also included, are provided with airflow gathering parts and convection heat exchange parts, and are arranged in the shell; each airflow gathering part is in a barrel shape with openings in the two ends and extending in the vertical direction; each convection heat exchange part is arranged on the inner side of the correspondingairflow gathering part and is configured to generate heat or cold and transmit the heat or cold to air flowing through the inner side of the corresponding airflow gathering part; the plurality of airflow gathering parts are sequentially and coaxially arranged in the vertical direction; and an air supply device is further included, is arranged in the shell and is configured to at least promote theairflow to enter the inner sides of the air flow gathering parts from the air inlet, exchange heat with the convection type heat exchange parts and then flow out from the air supply outlet. The airflow organization of the convection type heat exchangers is optimized, the overflowing wind speed is increased, and the improvement of the air conditioner energy efficiency is promoted.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com