A kind of mdea composite absorbent for acid gas separation and separation method

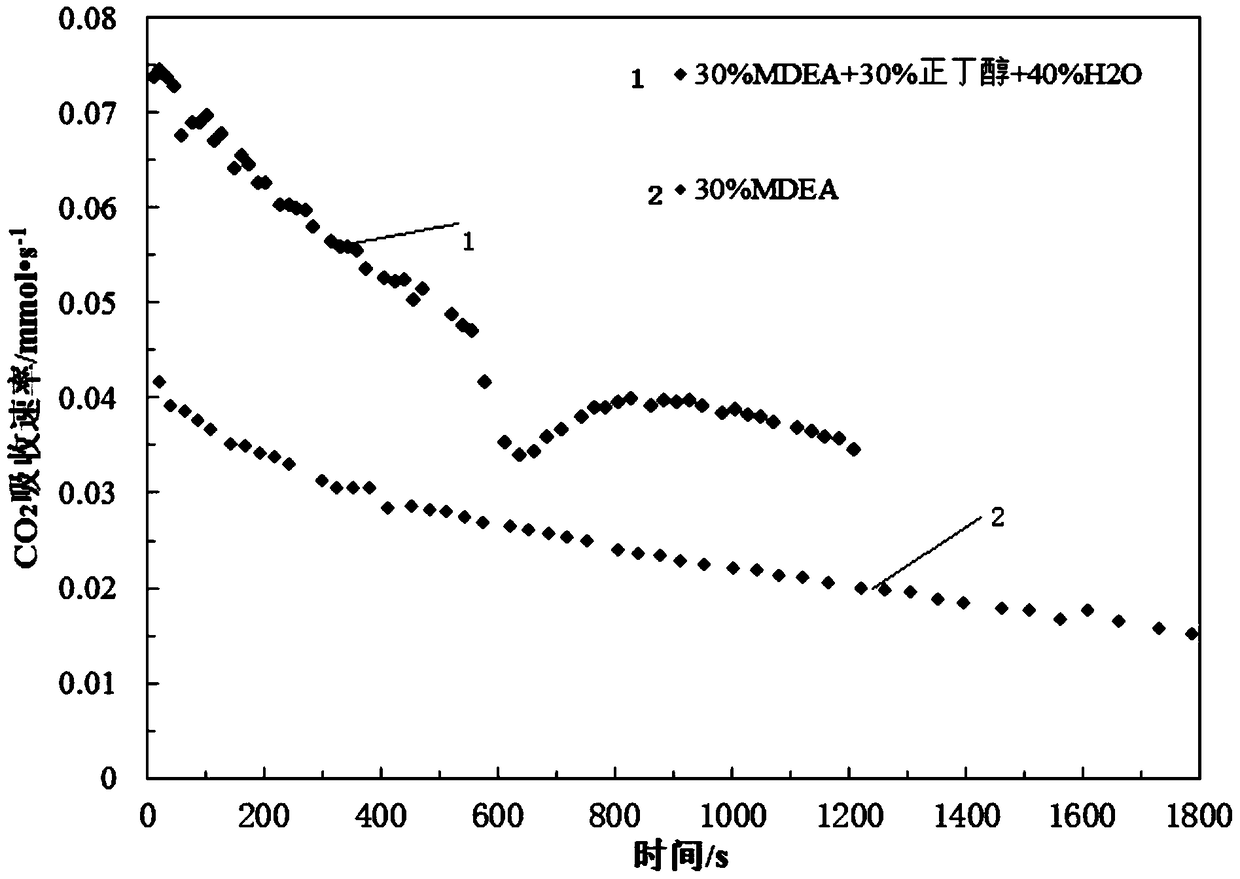

A technology of acidic gas and absorbent, applied in the field of gas separation, can solve the problems of reducing desorption liquid volume, reducing desorption energy consumption, high price, etc., to achieve the effect of increasing cycle processing capacity, increasing absorption rate, and reducing desorption energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]MDEA, n-butanol and water are combined to configure 40 g of absorbent, wherein the mass fraction of MDEA is 30%, the mass fraction of n-butanol is 50%, and the mass fraction of water is 20%. Then, the absorbent is used to absorb CO at a temperature of 20 °C under normal pressure 2 to saturation; CO absorption 2 The final absorbent forms a liquid-liquid two-phase, and the upper liquid phase is 35.0mL CO 2 Lean phase at low load, CO 2 The loading capacity is 0.408mol / L; the lower liquid phase is 9.0mL CO 2 Highly loaded liquid-rich phase, CO 2 The loading capacity is 3.586mol / L.

[0027] Obviously, the upper and lower liquid phase volume ratio is 3.89:1, and the upper and lower liquid phase CO 2 The loading concentration ratio was 0.11:1.

Embodiment 2

[0029] MDEA, n-butanol and water are combined to configure 40 g of absorbent, wherein the mass fraction of MDEA is 30%, the mass fraction of n-butanol is 40%, and the mass fraction of water is 30%. Then, the absorbent is used to absorb CO at a temperature of 20 °C under normal pressure 2 to saturation; CO absorption 2 The final absorbent forms a liquid-liquid two-phase, and the upper liquid phase is 23.0mL CO 2 Lean phase at low load, CO 2 The loading capacity is 0.279mol / L; the lower liquid phase is 20.0mL CO 2 Highly loaded liquid-rich phase, CO 2 The loading capacity is 3.078mol / L.

[0030] Obviously, the upper and lower liquid phase volume ratio is 1.15:1, and the upper and lower liquid phase CO 2 The loading concentration ratio was 0.09:1.

Embodiment 3

[0032] MDEA, isoamyl alcohol and water are combined to configure 40 g of absorbent, wherein the mass fraction of MDEA is 30%, the mass fraction of isoamyl alcohol is 40%, and the mass fraction of water is 30%. Then, the absorbent is used to absorb CO at a temperature of 20 °C under normal pressure 2 to saturation; CO absorption 2 The final absorbent forms a liquid-liquid two-phase, and the upper liquid phase is 22.0mL CO 2 Lean phase at low load, CO 2 The loading capacity is 0.205mol / L; the lower liquid phase is 20.0mL CO 2 Highly loaded liquid-rich phase, CO 2 The loading capacity is 2.492mol / L.

[0033] Obviously, the upper and lower liquid phase volume ratio is 1.1:1, and the upper and lower liquid phase CO 2 The loading concentration ratio was 0.08:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com