Technology for removing carbon dioxide in combined process for manufacturing soda ash and ammonium chloride

A technology of carbon dioxide and combined alkali production, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as deterioration of mother liquor conditions, reduced salt dissolution rate, and increased washing water equivalent, so as to ensure normal mother liquor conditions and salt Increased dissolution rate and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

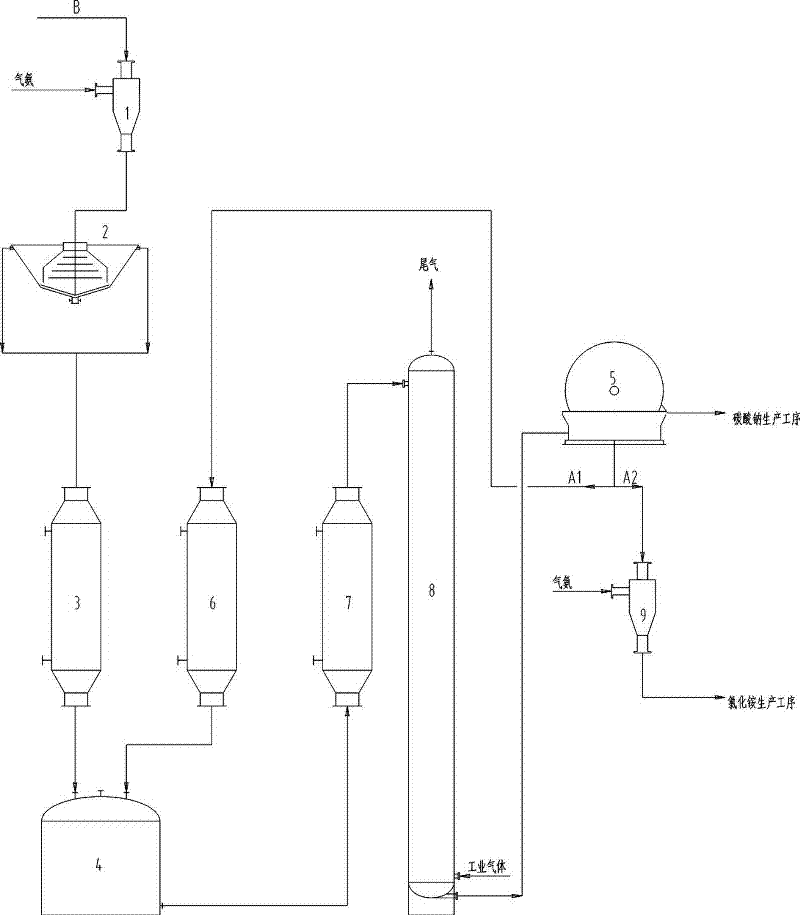

[0025] The carbon dioxide removal method in the combined soda production process, the process is as follows figure 1 As shown, the mother liquor B after ammonium chloride separation in the ammonium chloride production process is heated (temperature is 26-32°C) and enters ammonia absorber 1 to absorb ammonia, and the mother liquor after ammonia absorption (temperature is 36-54°C) enters clarification The barrel 2 separates the calcium and magnesium ion impurities carried in it, and after separating the impurities, it exchanges heat with the cooling device 3 and is cooled. The temperature after cooling is 26-36°C. After cooling, it enters the mixer 4; the alkali filter 5 separates the decarburization tower 8 out The mother liquor after the solid sodium bicarbonate in the tower liquid (temperature is 34-44°C) is divided into two parts, the first part mother liquor A1 is cooled by heat exchange with the cooling device 6, and the temperature after cooling is 26-42°C, after cooling, ...

Embodiment 2

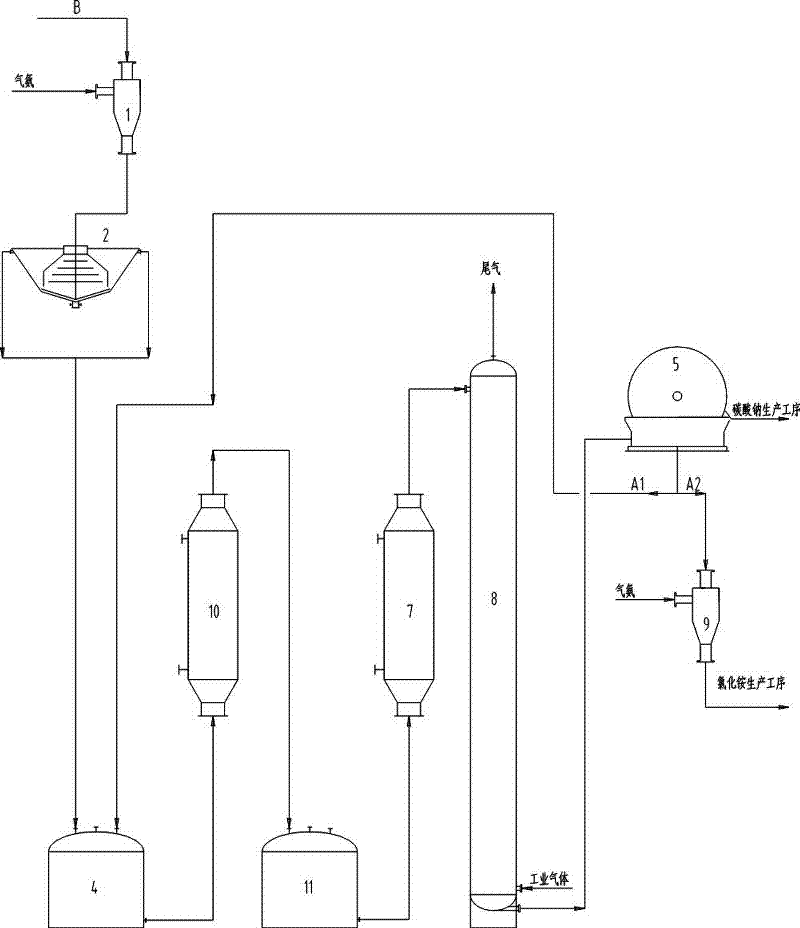

[0031] The removal method of carbon dioxide in the combined soda production process, the process is as follows figure 2 As shown, the mother liquor B after ammonium chloride separation in the ammonium chloride production process is heated (temperature is 26-32°C) and enters ammonia absorber 1 to absorb ammonia, and the mother liquor after ammonia absorption (temperature is 36-54°C) enters clarification Barrel 2 separates the calcium and magnesium ion impurities carried in it, and enters the mixer 4 after separating the impurities; the mother liquor (temperature is 34-44°C) after separating the solid sodium bicarbonate in the tower liquid from the decarbonization tower 8 by the alkali filter 5 is divided into two Part, the first part of mother liquid A1 enters the mixer 4; A1 and B are mixed according to the volume ratio = 0.6 ~ 1.6:1, the temperature of the mixed liquid is 35 ~ 49 ° C, the temperature of the mixed liquid at 35 ~ 49 ° C is exchanged with the cooling device 10 ...

Embodiment 3

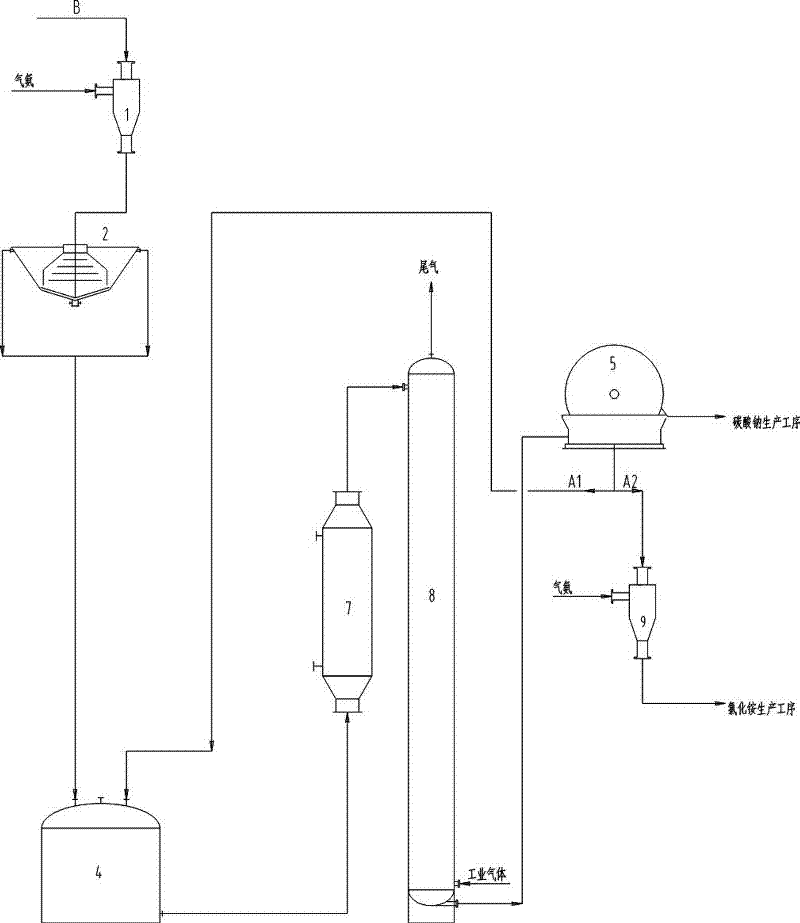

[0037] The removal method of carbon dioxide in the combined soda production process, the process is as follows image 3As shown, the mother liquor B after ammonium chloride separation in the ammonium chloride production process is heated (temperature is 26-32°C) and enters ammonia absorber 1 to absorb ammonia, and the mother liquor after ammonia absorption (temperature is 36-54°C) enters clarification Barrel 2 separates the calcium and magnesium ion impurities carried in it, and enters the mixer 4 after separating the impurities; the alkali filter 5 separates the mother liquor after the solid sodium bicarbonate in the decarburization tower 8 exits the tower liquid (temperature is 34 ~ 44 ℃) is divided into two Part, the first part of mother liquid A1 enters the mixer 4; A1 and B are mixed according to the volume ratio = 0.6 ~ 1.6: 1, the temperature of the mixed liquid is 35 ~ 49 ° C, the mixed liquid is cooled by heat exchange with the cooling device 7, and the temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com