Process for removing carbon dioxide in combined alkali preparation method

A technology of carbon dioxide and combined alkali production, which is applied in the direction of ammonium halide, separation method, carbonate preparation, etc., can solve the problems of short operation period, blockage, and hidden dangers of long-term stable operation, and achieve good absorption effect and smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

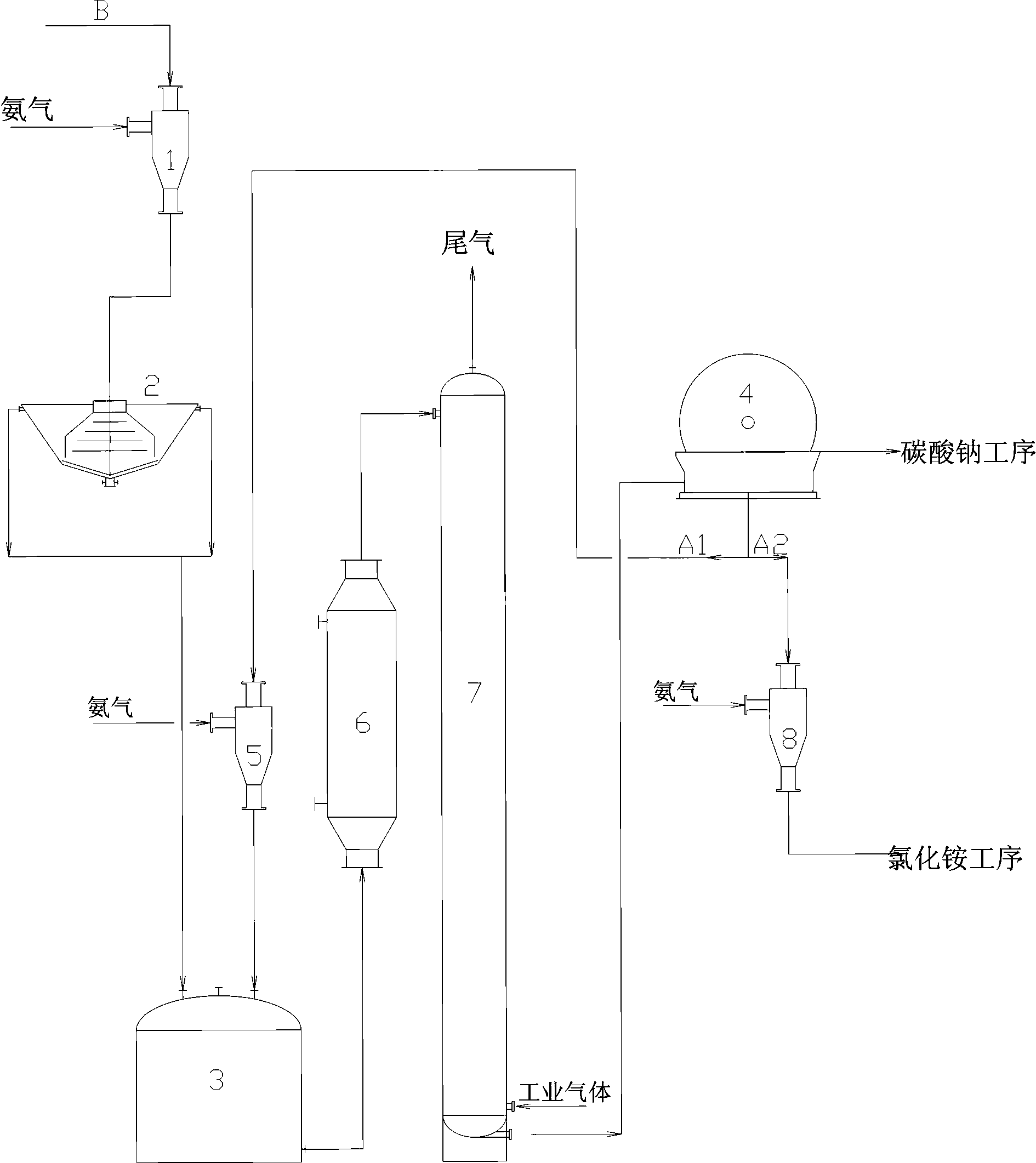

Image

Examples

Embodiment 1

[0019] The diameter of the decarbonization tower is 4.6 meters, and the height of the decarbonization tower is 42 meters. The decarbonization liquid enters the decarbonization tower from the upper part, and the tower liquid exits the decarbonization tower from the bottom, and the industrial gas with a carbon dioxide content of 96% enters the decarbonization tower from the lower part. The gas after removing carbon dioxide exits the decarbonization tower from the top, and the carbon dioxide removal rate is 99.68%.

[0020] A1 after ammonia absorption: B after ammonia absorption (volume ratio) = 1:1 to form a decarburization liquid, the temperature is 20.5°C, and the flow rate is: 226 m 3 / h, the composition is shown in the table below:

[0021] project free ammonia fixed ammonia total ammonia total chlorine carbon dioxide components F NH3 C NH3 T NH3 T cl CO 2 unit Mol / l Mol / l Mol / l Mol / l Mol / l quantity 2.588 3.052 5.64 ...

Embodiment 2

[0024] The diameter of the decarbonization tower is 4.6 meters, and the height of the decarbonization tower is 42 meters. The decarbonization liquid enters the decarbonization tower from the upper part, and the tower liquid exits the decarbonization tower from the bottom, and the industrial gas containing 85% carbon dioxide enters the decarbonization tower from the lower part. The gas after removing carbon dioxide exits the decarbonization tower from the top, and the carbon dioxide removal rate is 99.66%.

[0025] A1 after ammonia absorption: B after ammonia absorption (volume ratio) = 0.6:1 to form a decarburization liquid, the temperature is 18.5°C, and the flow rate is: 180.8 m 3 / h, the composition is shown in the table below:

[0026] project free ammonia fixed ammonia total ammonia total chlorine carbon dioxide components F NH3 C NH3 T NH3 T cl CO 2 unit Mol / l Mol / l Mol / l Mol / l Mol / l quantity 2.782 2.676 5.458 5...

Embodiment 3

[0029] The diameter of the decarbonization tower is 4.6 meters, and the height of the decarbonization tower is 42 meters. The decarbonization liquid enters the decarbonization tower from the upper part, and the tower liquid exits the decarbonization tower from the bottom, and the industrial gas with a carbon dioxide content of 22.2% enters the decarbonization tower from the lower part. The gas after removing carbon dioxide exits the decarbonization tower from the top, and the carbon dioxide removal rate is 99.70%.

[0030] A1 after ammonia absorption: B after ammonia absorption (volume ratio) = 1.6:1 to form a decarburization liquid, the temperature is 22.5°C, and the flow rate is: 293.8 m 3 / h, the composition is shown in the table below:

[0031] project free ammonia fixed ammonia total ammonia total chlorine carbon dioxide components F NH3 C NH3 T NH3 T cl CO 2 unit Mol / l Mol / l Mol / l Mol / l Mol / l quantity 2.388 3.132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com