Pressurized moving bed hydrocarbon-rich hydrogen gas and water gas graded production furnace

A technology of water gas and moving bed, which is applied in the field of coal chemical industry, can solve the problems of high sewage treatment cost, low energy conversion efficiency, low hydrogen mole fraction, etc., and achieve the goal of saving synthesis process, increasing steam decomposition rate, and reducing water steam consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

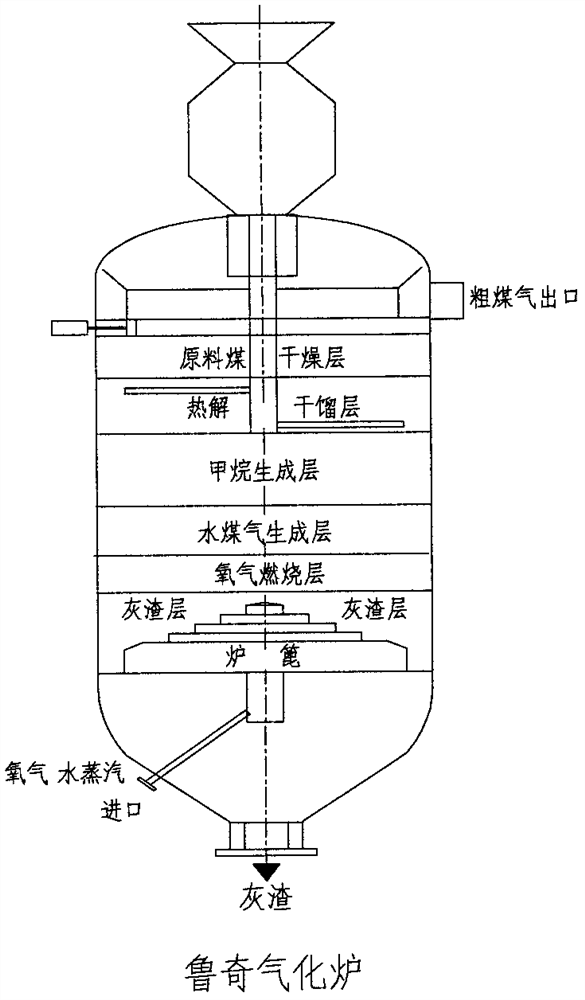

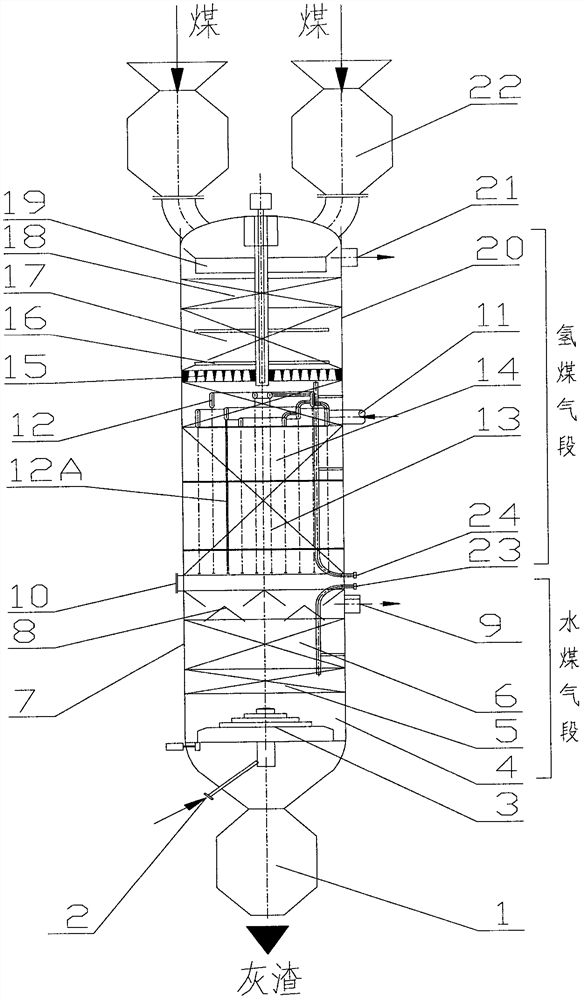

[0066] Based on the complete set of components of the current pressurized moving bed dry slagging gasifier with an inner diameter of 3.8 meters, a height of 13 meters and a working pressure of 3 to 4 MPa, the following changes are made: ①The water jacket pressure-bearing cylinder is increased by 10 meters from the original height , so that the total height of the furnace body reaches 23 meters; ②A water gas collector is installed 3 meters above the top of the grate; The water gas collected by the gas collector flows out through the water gas outlet; ④ Install a hydrogen distributor 12 meters above the top of the grate, and install a heat exchange tube bundle connected to it below the hydrogen distributor; ⑤ Install a hydrogen gas distributor at the same height as the wall Air inlet, and connect the hydrogen distributor with the hydrogen inlet, so that the hydrogen gasification agent enters the heat exchange tube bundle through the hydrogen inlet through the hydrogen distributor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com