Thermosyphon type reboiler for industrial refrigeration device

An industrial refrigeration and thermosiphon technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of reducing the effective heat exchange length of heat exchange tube boiling, increasing the refrigerant charge of the evaporator, and the volume of pure liquid refrigerant. Large and other problems, to achieve the effect of reducing the charging amount, improving the boiling heat transfer efficiency, and reducing the sensible heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

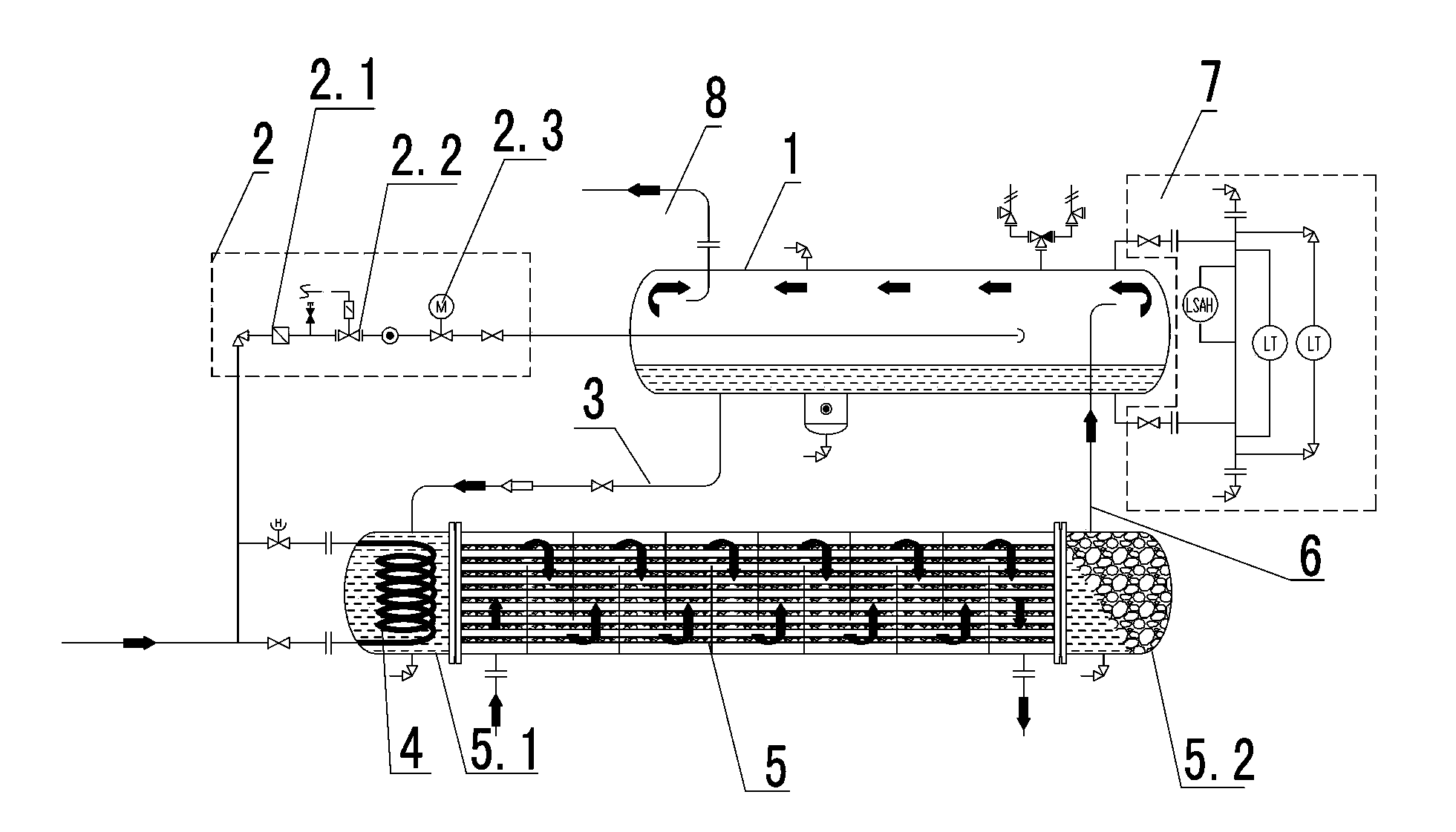

[0014] like figure 1 The shown thermosyphon reboiler for industrial refrigeration equipment includes a gas-liquid separator 1, a dry evaporator 5 located below the gas-liquid separator 1, and a liquid level control throttling unit 7, which controls throttling The two ends of the unit 7 are respectively connected with the upper part and the lower part of the gas-liquid separator 1 . The upper part of the gas-liquid separator 1 is connected with a suction pipe 8 connected to the suction port of the compressor, the inlet of the dry evaporator 5 is provided with an inlet pipe box 5.1, and the outlet of the dry evaporator 5 is provided with an outlet pipe Box 5.2, inlet pipe box 5.1 is equipped with a heat exchange coil 4, one end of the heat exchange coil 4 is the refrigerant liquid inlet, and the other end is connected with an expansion liquid sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com