Liquid-solid phase change absorbent used for carbon dioxide capture and application of absorbent

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation of dispersed particles, air quality improvement, etc., can solve the problem of high regeneration energy consumption, and achieve the effects of low volatility, strong tolerance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

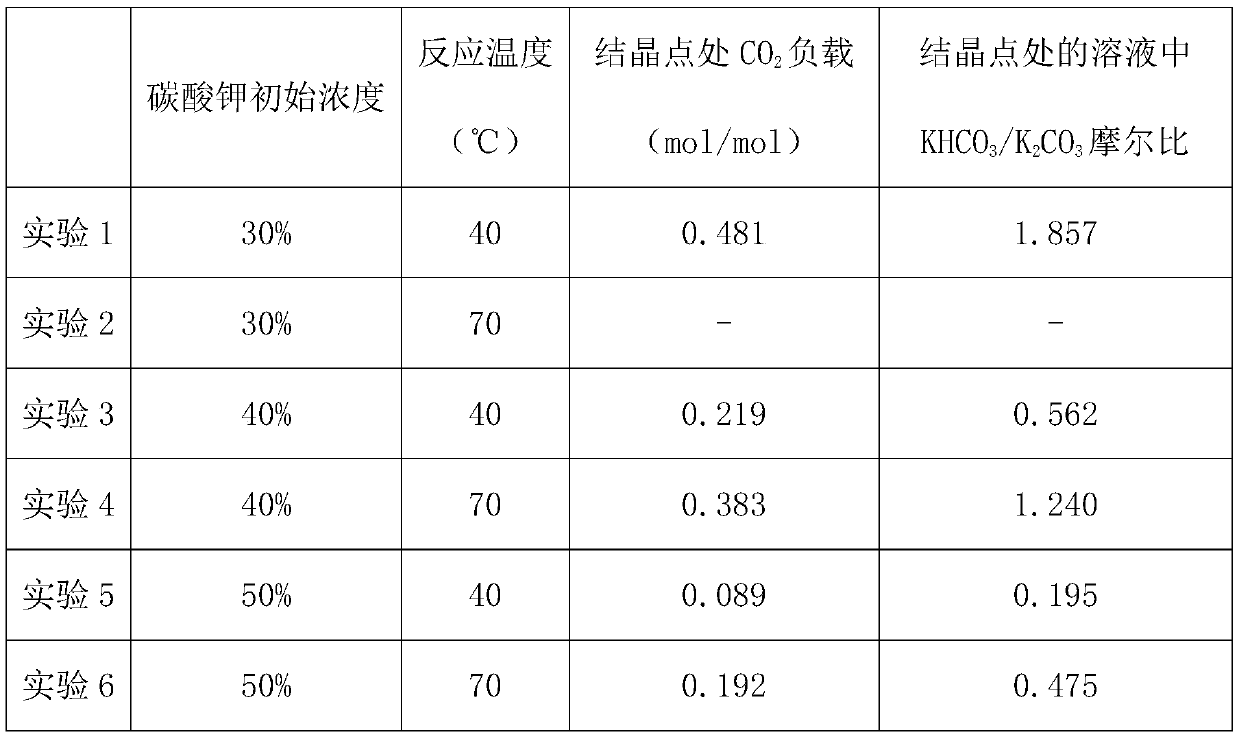

Examples

Embodiment 1

[0029] 1. In terms of mass percentage, weigh the following three components, 10% carbonate, 2% bicarbonate, 1% absorption activator, 0.01% absorption aid, and the balance is water , and mix each component evenly to obtain three parts of liquid-solid phase-change absorbent;

[0030] 2. Set the temperature to 40°C, gas phase CO 2 Partial pressure of 10.8kPa, 29.5kPa, 79.0kPa containing CO 2 and N 2 The mixed gas is input into three parts of the liquid-solid phase-change absorbent respectively, and after the gas-liquid two-phase reaches equilibrium, the CO in the absorption solvent is 2 See Table 1 for load capacity. of which CO 2 The load is defined as the absorbed CO 2 Amount and initial K in solution 2 CO 3 The molar ratio of the amount, mol / mol.

[0031] Table 1 Experimental results of 30% potassium carbonate aqueous solution at 40°C

[0032]

Embodiment 2

[0034] 1. In terms of mass percentage, weigh the following three components, 30% carbonate, 20% bicarbonate, 15% absorption activator, 5% absorption aid, and the balance is water , and mix each component evenly to obtain three parts of liquid-solid phase-change absorbent;

[0035] 2. Set the temperature to 70°C, gas phase CO 2 Partial pressure of 10.3kPa, 40.9kPa, 83.4kPa containing CO 2 and N 2 The mixed gas of the mixed gas is input into three parts of the solvent respectively, and after the gas-liquid two-phase reaches equilibrium, the CO in the solvent is absorbed 2 Refer to Table 2 for load capacity.

[0036] Table 2 Experimental results of 30% potassium carbonate aqueous solution at 70°C

[0037]

Embodiment 3

[0039] 1. In terms of mass percentage, weigh the following three components, 60% of carbonate, 40% of bicarbonate, 20% of absorption activator, 10% of absorption aid, and the balance is water , and mix each component evenly to obtain three parts of liquid-solid phase-change absorbent;

[0040] 2. Set the temperature to 120°C, gas phase CO 2 Partial pressure of 16kPa, 56kPa, 105kPa containing CO 2 and N 2 The mixed gas of the mixed gas is input into three parts of the solvent respectively, and after the gas-liquid two-phase reaches equilibrium, the CO in the solvent is absorbed 2 Refer to Table 3 for load capacity.

[0041] Table 3 Experimental results of 30% potassium carbonate aqueous solution at 120°C

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com