Production of biological diesel oil by fixed enzyme method

A technology for immobilizing enzymes and biodiesel, which is applied in the preparation of biological raw materials, biofuels, and liquid hydrocarbon mixtures. It can solve the problems of high cost of enzyme and enzyme immobilization, difficult recovery of esterification products, and low enzymatic conversion rate. , to achieve the effect of simple immobilization method, strong tolerance and strong reaction specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 0.5g lipase to 30ml solution containing 0.3g sodium alginate (0.046mol / L) and 0.6g kaolin (20g / L), add 0.5ml gelatin (10g / L), 0.5ml lactose (10g / L ) and 0.3ml of 5% glutaraldehyde solution, stirred for 10 minutes, mixed evenly, shaken for 1h at 42°C, and then injected 25g / L of 100ml CaCl 2 The solution was solidified at 4°C for 4h. Stacked in the first, second and third reactors in a natural state;

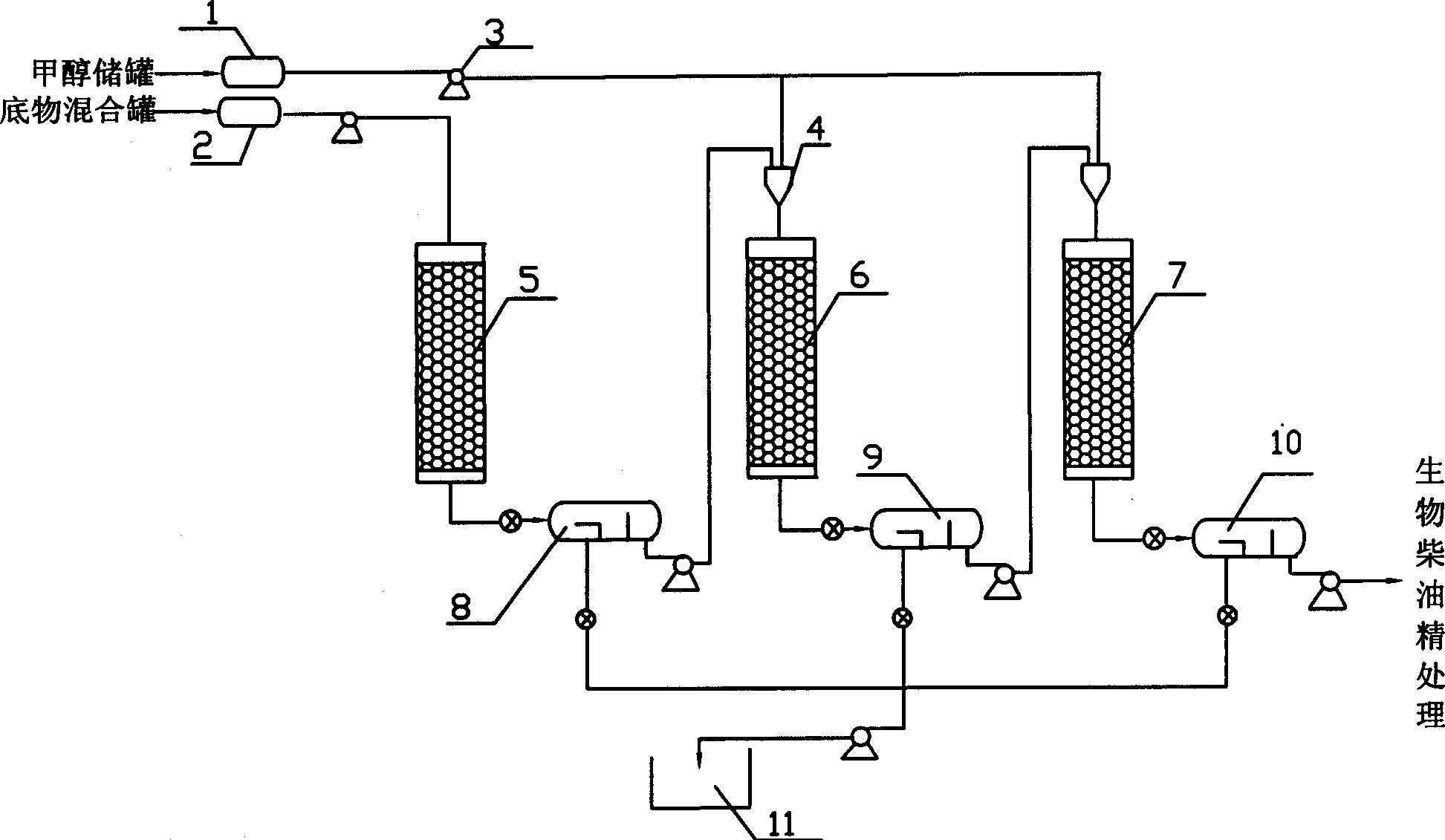

[0035]Animal and vegetable oils and methanol are mixed in a molar ratio of 1:1, and biodiesel with a weight ratio of 5:1 is added as a solvent and 20% water of oil weight to form a substrate mixture, and the substrate mixture is placed Magnetic stirring and heating are carried out in the substrate mixing tank, so that methanol and animal and vegetable oils are evenly mixed; after the substrate is evenly mixed, it is pumped into the first-stage reactor by an oil pump and reacted under the catalysis of immobilized enzymes. The reaction solution coming out of the first-s...

Embodiment 2

[0038] Add 0.5g enzyme to 30ml solution containing 0.6g sodium alginate (0.046mol / L) and 0.6g kaolin (20g / L), add 0.5ml gelatin (10g / L), 0.5ml lactose (10g / L) and 0.3ml of 5% glutaraldehyde solution, stirred for 10 minutes, mixed well, shaken for 1h at 40°C, and then injected 20g / L of 100ml of CaCl 2 The solution was solidified at 4°C for 4 hours, filtered, and accumulated in the first, second and third reactors in a natural state.

[0039] Animal and vegetable oils and methanol are mixed in a molar ratio of 1:1, and biodiesel with a weight ratio of 5:1 is added as a solvent and 20% water of oil weight to form a substrate mixture, and the substrate mixture is placed Put it in the substrate mixing tank and carry out magnetic stirring and heating to make methanol and animal and vegetable oils mix evenly; after the substrate mixture is evenly mixed, it is pumped into the first-stage reactor by an oil pump and reacted under the catalysis of immobilized enzyme, and the rest of the ...

Embodiment 3

[0042] Add 0.5g enzyme to 30ml solution containing 0.9g sodium alginate (0.046mol / L) and 0.6g kaolin (20g / L), add 0.5ml gelatin (10g / L), 0.5ml lactose (5g / L) and 0.3ml of 5% glutaraldehyde solution, stirred for 10 minutes, mixed evenly, shaken for 1h at 42°C, and then injected 20g / L of 100ml of CaCl 2 The solution was solidified at 4°C for 4 hours, and accumulated in the first, second and third reactors in a natural state.

[0043] Animal and vegetable oils and methanol are mixed in a molar ratio of 1:1, and biodiesel with a weight ratio of 4:1 is added as a solvent and 20% water of oil weight to form a substrate mixture, and the substrate mixture is placed Put it in the substrate mixing tank and carry out magnetic stirring and heating to make methanol and animal and vegetable oils mix evenly; after the substrate mixture is evenly mixed, it is pumped into the first-stage reactor by an oil pump and reacted under the catalysis of immobilized enzyme, and the rest of the steps are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com