Clothing stain remover and preparation process thereof

A stain remover and clothing technology, which is applied in the direction of detergent compounding agent, detergent composition, detergent composition fragrance, etc., can solve the problems of affecting the washing power of enzymes, high phosphorus content, environmental pollution, etc., and achieve enhanced stain removal ability , strong stain removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

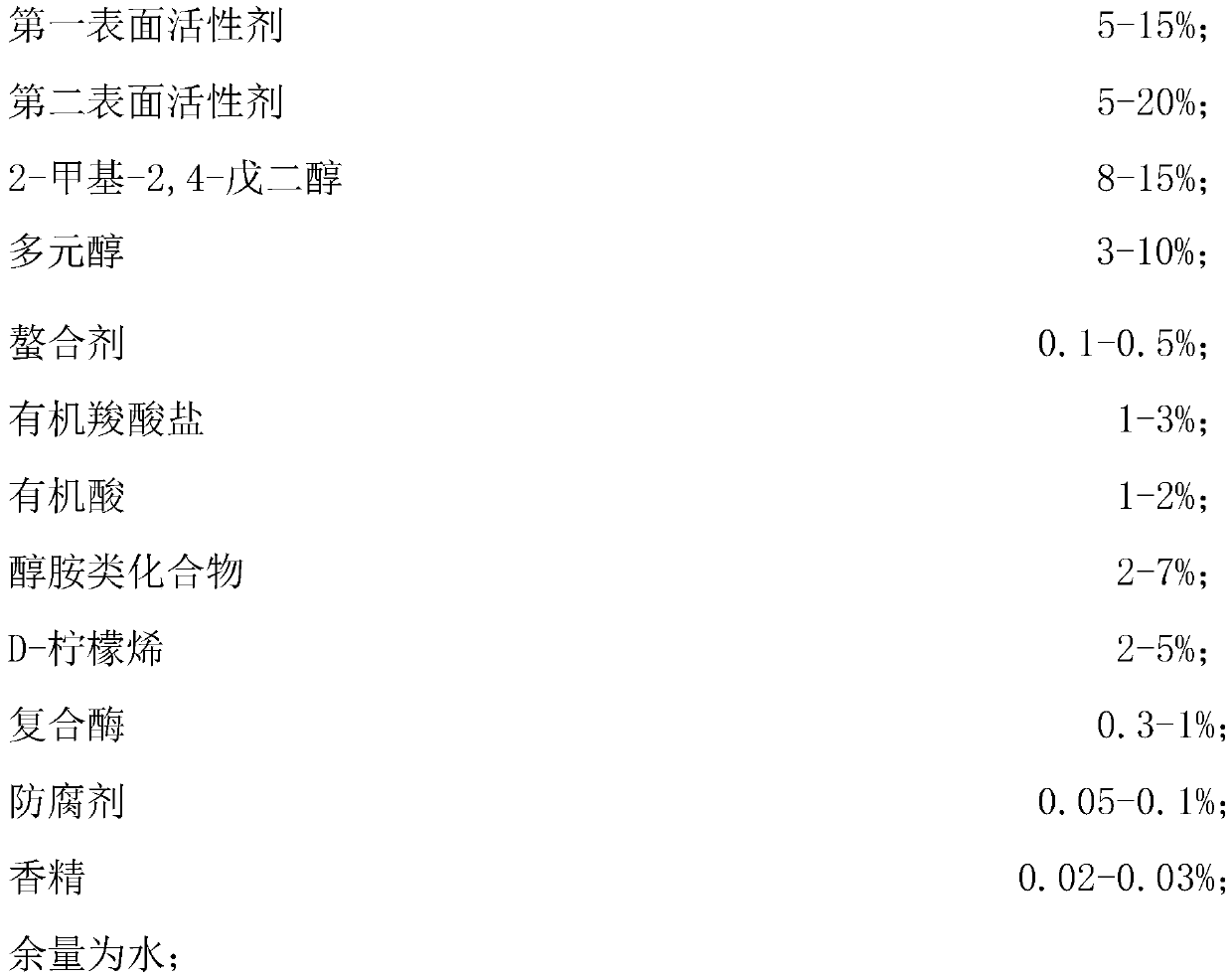

[0056] Embodiment 1 a kind of clothing stain remover

[0057] Weigh the components of the following mass: (total 100kg)

[0058]

[0059] The first surfactant is C 13 h 27 O(CH 2 CH 2 O) 8 H,

[0060] The second surfactant is C 12 h 25 O(CH 2 CH 2 O) 4 (CH 2 CH 2 OCH 2 ) 4 H,

[0061] Described polyhydric alcohol is glycerol,

[0062] The chelating agent is ethylenediaminetetraacetic acid disodium salt;

[0063]The alcohol amine compound is triethanolamine;

[0064] Described organic carboxylate is sodium acetate;

[0065] The organic acid is citric acid;

[0066] The compound enzyme includes protease, amylase and lipase, and the mass ratio of the protease, amylase and lipase is 1:1:1.

[0067] S1: According to the above-mentioned components and proportions, first add water to the reactor and heat it to 40-50°C, then put the first surfactant and the second surfactant into the reactor, and stir evenly;

[0068] S2: Put 2-methyl-2,4-pentanediol, polyol, a...

Embodiment 2

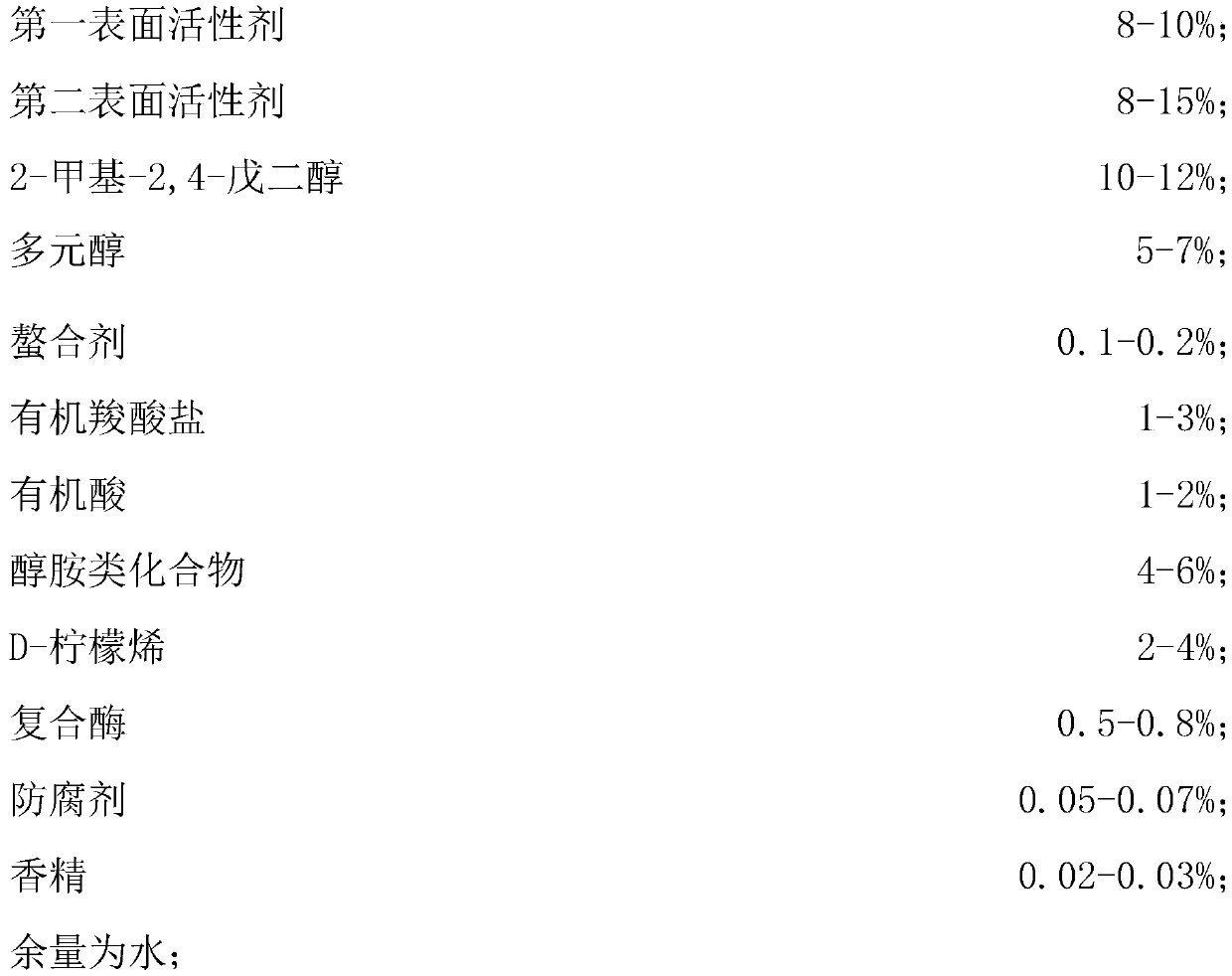

[0074] Embodiment 2 A kind of clothing stain remover

[0075] Weigh the components of the following mass: (total 100kg)

[0076]

[0077]

[0078] The first surfactant is C 12 h 25 O(CH 2 CH 2 O) 7 H and C 13 h 27 O(CH 2 CH 2 O) 8 H, the mass ratio is 1:1,

[0079] The second surfactant is C 12 h 25 O(CH 2 CH 2 O) 6 (CH 2 CH 2 OCH 2 ) 6 H,

[0080] Described polyhydric alcohol is pentaerythritol;

[0081] The chelating agent is tetrasodium ethylenediaminetetraacetic acid;

[0082] The alcohol amine compound is triethanolamine;

[0083] The organic carboxylate is selected from sodium formate and / or sodium acetate;

[0084] The organic acid is citric acid;

[0085] The compound enzymes include protease, amylase and lipase.

[0086] S1: According to the above-mentioned components and proportions, first add water to the reactor and heat it to 40-50°C, then put the first surfactant and the second surfactant into the reactor, and stir evenly;

[0087]...

Embodiment 3

[0093] Embodiment 3 a kind of clothing stain remover

[0094] Weigh the components of the following mass: (total 100kg)

[0095]

[0096] The first surfactant is C 14 h 29 O(CH 2 CH 2 O) 10 H,

[0097] The second surfactant is C 10 h 21 O(CH 2 CH 2 O) 10 (CH 2 CH 2 OCH 2 ) 2 H,

[0098] The polyol is C 6 h 10 (OH) 4 ,

[0099] The chelating agent is tetrasodium ethylenediaminetetraacetic acid;

[0100] The alcohol amine compound is diethanolamine;

[0101] Described organic carboxylate is sodium propionate;

[0102] The organic acid is sulfamic acid;

[0103] The compound enzyme includes protease, amylase and lipase, and the mass ratio of the protease, amylase and lipase is 1:1:1.

[0104] S1: According to the above-mentioned components and proportions, first add water to the reactor and heat it to 40-50°C, then put the first surfactant and the second surfactant into the reactor, and stir evenly;

[0105] S2: Put 2-methyl-2,4-pentanediol, polyol, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com