Gas-fired boiler system and operation method thereof

A gas-fired boiler and gas technology, which is applied in the field of boilers, can solve the problems of difficult NOx emission to meet emission standards, difficult to capture, and large amount of combustion flue gas, and achieves low flue gas amount, zero emission, and significant environmental benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

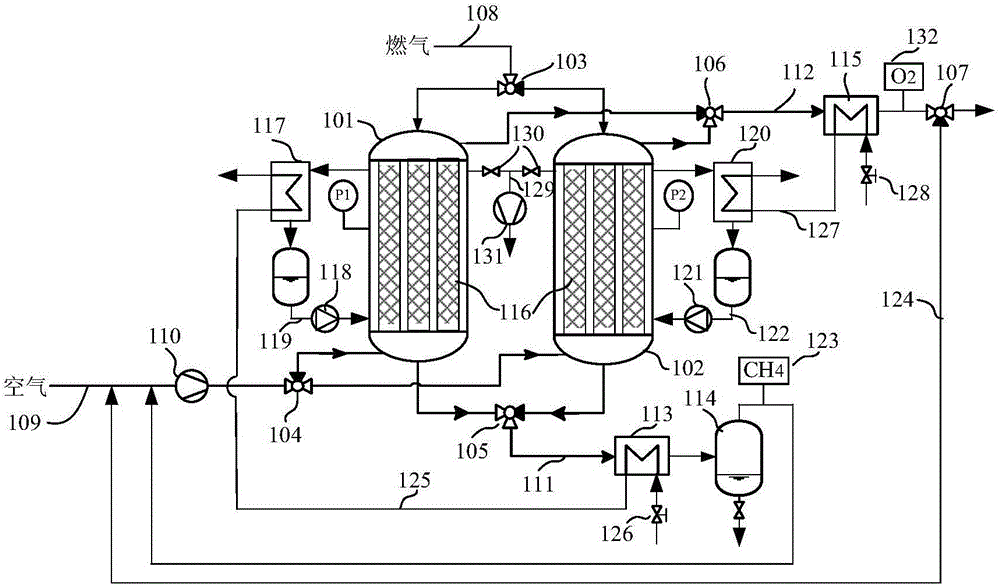

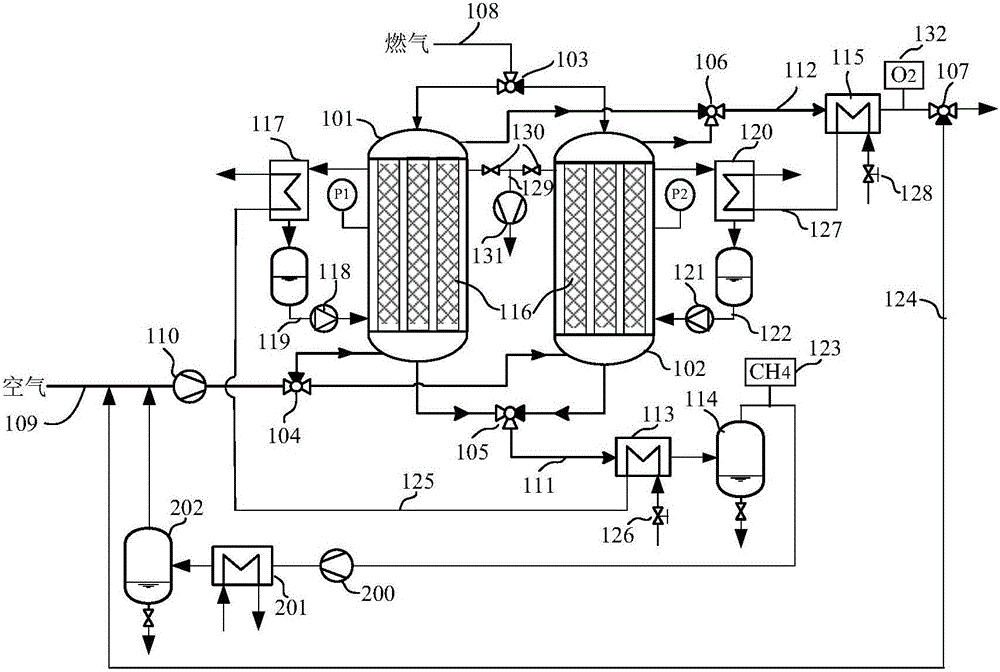

[0043] figure 1 and figure 2 It is a schematic diagram of different embodiments of the gas boiler system of the present invention. see figure 1 and figure 2 , gas boiler system, including:

[0044] The chemical looping combustion reactor 101, 102 has a combustion chamber and a heat medium chamber in the chemical looping combustion reactor. The combustion chamber is filled with an oxygen carrier 116. The heat medium chamber is used to accommodate the heat medium for heat exchange with the combustion chamber. The chamber is connected with heat medium circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com