Device and method for preparing reducing gas through lignite gasification poly-generation

A technology of coal gasification and polygeneration, applied in the metallurgical field, can solve the problems of high gasifier pressure, high gas production cost, and harsh raw material requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

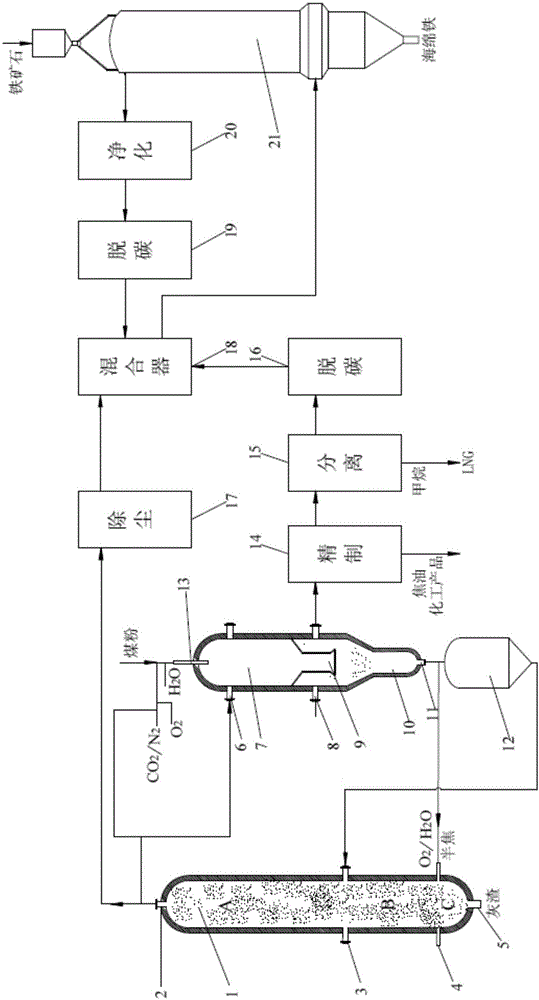

[0076] This embodiment provides a device for producing reducing gas by lignite gasification polygeneration, and its schematic diagram is as follows figure 1As shown, the device includes a gasifier 1, a pyrolysis / partial gasifier 7, a semi-coke storage tank 12, a dust removal unit 17 and a mixer 18; wherein:

[0077] The gasifier 1 is divided into a first reaction zone A, a second reaction zone B and a third reaction zone C from top to bottom;

[0078] A catalyst inlet 3 is provided between the first reaction zone and the second reaction zone;

[0079] A semi-coke / gasifying agent inlet 4 is provided between the second reaction zone and the third reaction zone;

[0080] The top and the bottom of the gasifier are respectively provided with a synthesis gas outlet 2 and an ash outlet 5;

[0081] The furnace of the pyrolysis / partial gasification furnace 7 is provided with a guide tube 9, and the guide tube 9 divides the pyrolysis / partial gasification furnace 7 into a pyrolysis / par...

Embodiment 2

[0090] This example uses figure 1 The device shown implements the method for producing reducing gas by lignite gasification polygeneration. After the lignite is crushed, it is ground and sieved to obtain coal powder below 0.1mm, and the gasification agent (H 2 O, O 2 ), and inert gas (N 2 and CO 2 ) or synthesis gas (wherein the mass ratio of oxygen to lignite is 0.2:1, the mass ratio of water vapor to lignite is 0.6:1, and the mass ratio of inert gas to lignite is 0.2:1), and enters the pyrolysis / partial gas through nozzle 13 The chemical furnace 7 is mixed with the high-temperature syngas entering the heat carrier inlet 6 to undergo pyrolysis / partial gasification reaction at a reaction temperature of 850°C to generate CO and H 2 、CH 4 etc. Gas, tar and solid semi-coke; volatiles and semi-coke enter the lower part of the furnace body along the guide tube for separation, volatiles are discharged from the volatiles outlet 8 and enter the refining unit 14; semi-coke falls in...

Embodiment 3

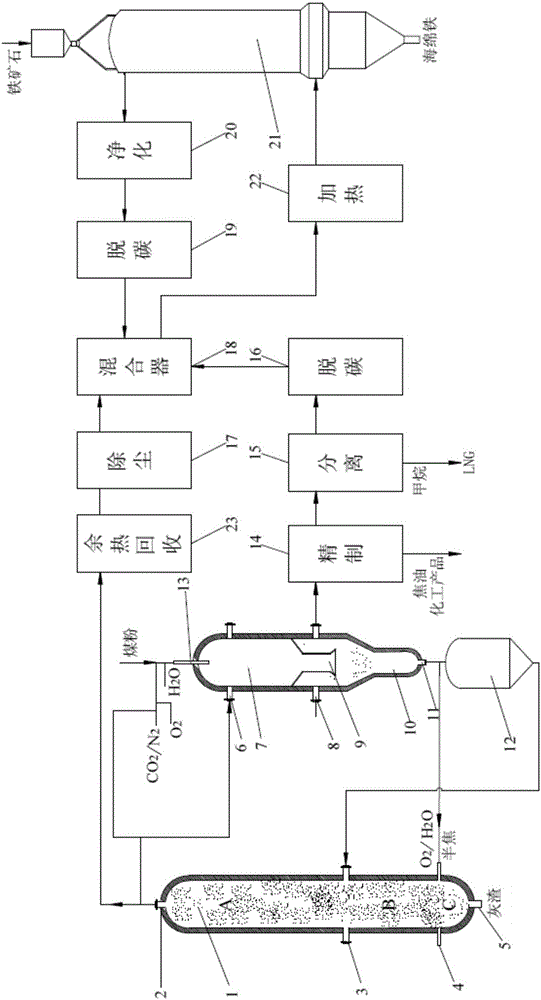

[0092] This example provides figure 2 shown in the device, the device is in figure 1 On the basis of that, a waste heat recovery device 23 is added before the dust removal unit 17, and a heating device 22 is added on the pipeline for transporting reducing gas.

[0093] This example uses figure 2 The device shown implements the method for producing reducing gas by lignite gasification polygeneration, and its method is the same as that of Example 1, except that before the syngas is carried out in the dust removal unit 17, it first enters the waste heat recovery device to recover the sensible heat of the coal gas, and then Enter the mixer 18 through the dust removal unit 17; after the pyrolysis gas, furnace top gas, and synthesis gas entering the mixer 18 are mixed, when the temperature of the output reducing gas is low, add a gas heater in front of the shaft furnace to increase the temperature of the reducing gas. temperature to 900°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com