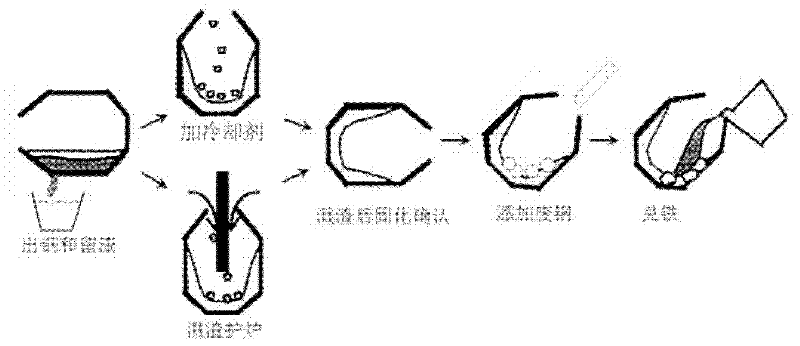

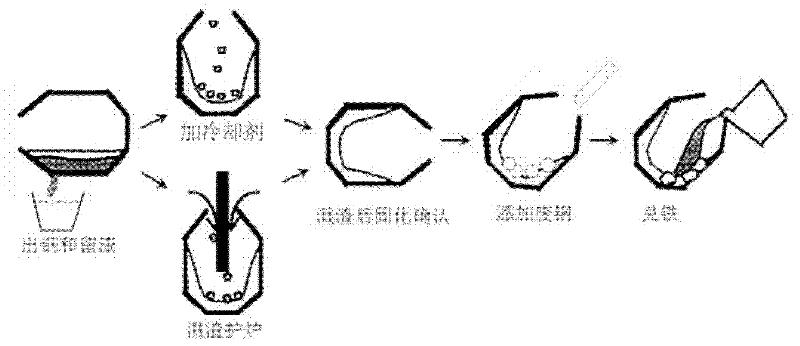

Cooling solidification recycling method for high-temperature liquid-state slag in steelmaking furnace

A slag cooling and steel-making furnace technology, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve the problems of incapable of making full use of high-temperature converter slag, unfavorable storage and transportation, waste of heat, etc., and achieves good slag reaction kinetic conditions, The effect of fast slag removal and sensible heat saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] After the steel tapping in the upper furnace is completed, the slag operation is adopted. According to the carbon content of the end point and the slag remaining after tapping, 1.0t of lime, 1.5t of magnesia carbon balls and 0.2t of dolomite are added to the converter, and the slag is splashed with a gun. 2 Injection, the flow rate is 40000Nm 3 / h, the pressure is 1.2MPa, and the temperature is 25°C. According to the specific situation, lift the gun after 5 minutes of slag splashing, and then shake the furnace to observe the slag splashing effect. According to the situation in the furnace, add 1.5t of lime to the converter again, confirm that the high temperature liquid slag of the upper furnace is cooled and solidified, add 15t of scrap steel, and mix Iron 208t. During the operation, the condition inside the converter was stable, and there was no tendency of splashing or explosion. In the converter smelting process, the slag formation in the furnace is faster, the st...

Embodiment 2

[0023] After tapping the upper furnace, the operation of leaving slag is adopted. According to the carbon content of the end point and the slag remaining after tapping, 0.5t of lime, 3.0t of magnesia carbon balls and 1.5t of dolomite are added to the converter, and the slag is splashed with a gun. 2 Injection, the flow rate is 30000Nm 3 / h, the pressure is 1.35MPa, and the temperature is 32°C. According to the specific situation, lift the gun after 3 minutes of slag splashing, and then shake the furnace to observe the slag splashing effect. According to the situation in the furnace, add 0.5t of lime into the converter again, confirm that the high temperature liquid slag of the upper furnace is cooled and solidified, add 20t of scrap steel, and mix Iron 205t. During the operation, the condition inside the converter was stable, and there was no tendency of splashing or explosion. In the converter smelting process, the slag formation in the furnace is faster, the steel slag rea...

Embodiment 3

[0025] After tapping the upper furnace, the operation of leaving slag is adopted. According to the carbon content of the end point and the slag remaining after tapping, 1.5t of lime, 1.0t of magnesia carbon balls and 3.0t of dolomite are added to the converter, and the slag is splashed with a gun. 2 Injection, the flow rate is 50000Nm 3 / h, the pressure is 1.5MPa, and the temperature is 30°C. According to the specific situation, lift the gun after 7 minutes of slag splashing, and then shake the furnace to observe the slag splashing effect. According to the situation in the furnace, add 2.0t of lime to the converter again, confirm that the high temperature liquid slag of the previous furnace is cooled and solidified, add 15t of scrap steel, and mix Iron 208t. During the operation, the condition inside the converter was stable, and there was no tendency of splashing or explosion. In the converter smelting process, the slag formation in the furnace is faster, the steel slag rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com