Heat pipe type solar vacuum tube water boiler and water boiling system

A technology of boiling water system and vacuum tube, which is applied in the field of heat pipe type solar vacuum tube water boiler and boiling water system, can solve the problem of difficulty in meeting the requirements of medium temperature, and achieve the effects of reducing sensible heat, easy installation and maintenance, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

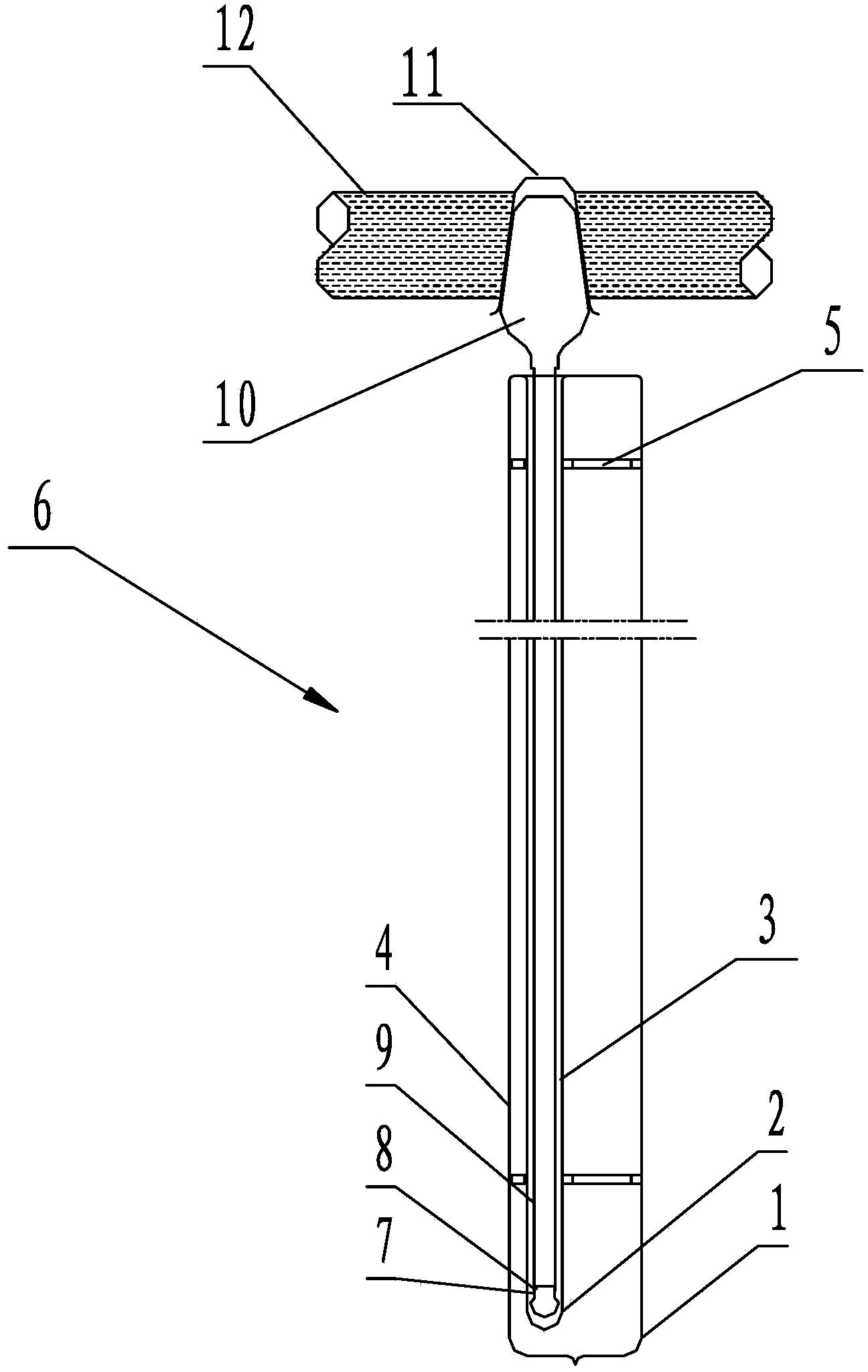

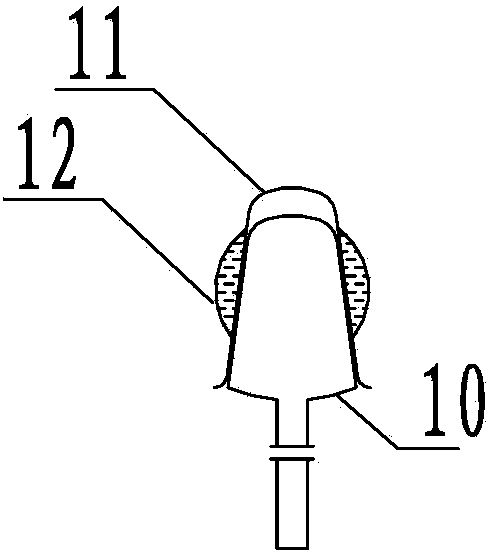

[0028] A heat pipe type solar vacuum tube water boiler, comprising 21 heat collecting single pipes 6 and a heat conduction pipe 12 connecting each heat collecting single pipe;

[0029] The heat-collecting single tube 6 includes an outer cover glass tube 1, a heated glass tube 2 arranged in the inner cavity of the outer cover glass tube 1, and a metal vacuum tube 9 inserted in the heated glass tube 2. The heated glass tube 2 and the outer cover glass tube 1 parallel, and the heated glass tube 2 is set off-axis in the outer cover glass tube 1 through the metal bracket 5, the outer wall of the heated glass tube 2 is kept separated from the inner wall of the outer cover glass tube 1, and is close to the outer cover glass tube 1 of the heated glass tube 2 Half of the inner wall is coated with metal reflective coating 4;

[0030] One end of the metal vacuum tube 9 located in the heated glass tube 2 is closed by a heat pipe pin 8 to fix the heat pipe plug 7, and the other exposed end...

Embodiment 2

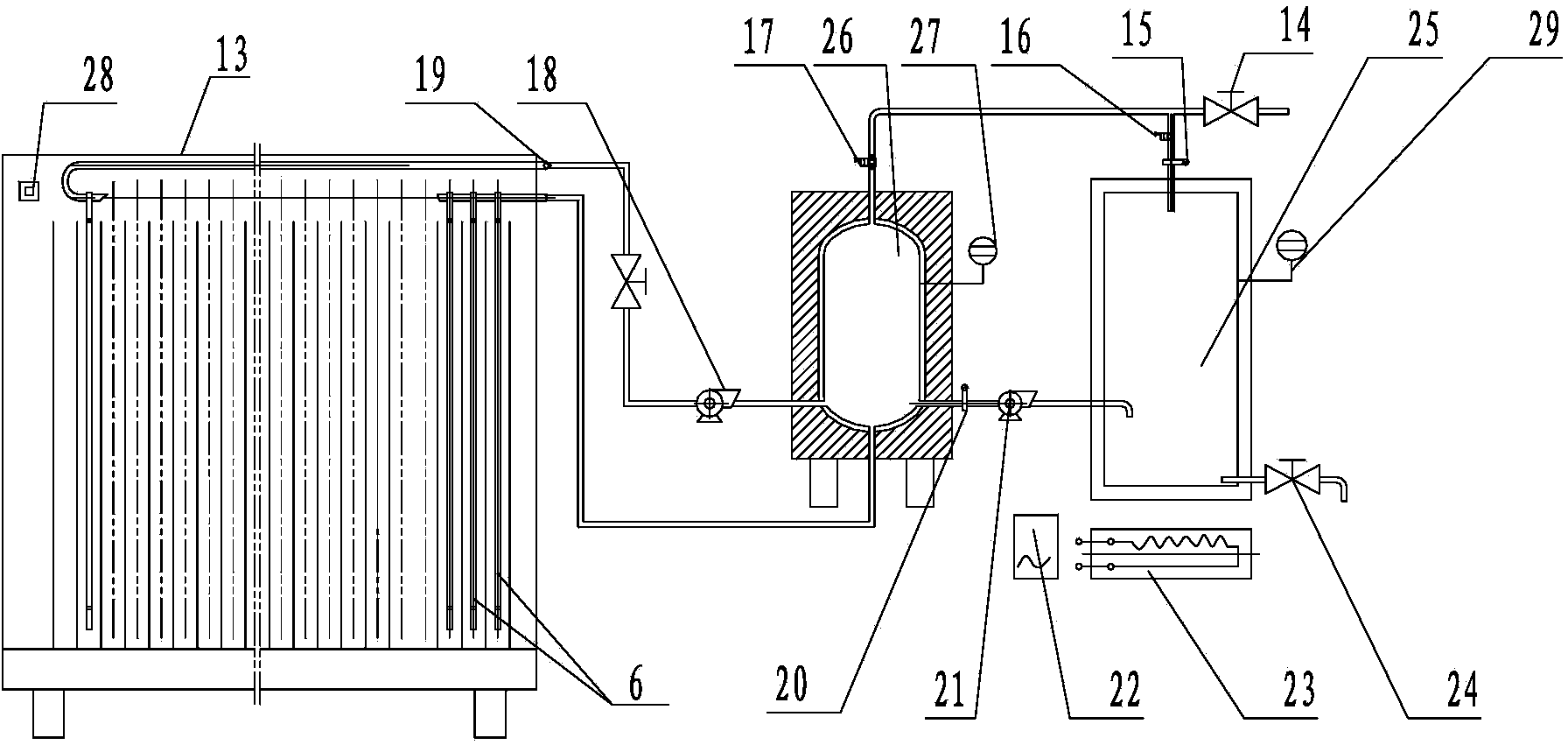

[0035] A heat pipe type solar vacuum tube water boiling system, comprising the heat pipe type solar vacuum tube water boiler described in embodiment 1, an electric heating type water boiler 25, a hot water storage tank 26, the two ends of the heat pipe 12 of the heat pipe type solar vacuum tube water boiler and the storage tank respectively The hot water inlet of the hot water tank 26 is connected to the water return port, and the hot water storage tank 26 is also provided with a cold water inlet and a water outlet connected to the hot water inlet of the electric water boiler 25 .

[0036] The heat pipe type solar vacuum tube water boiler is provided with a heat collector 13 outside, on which a photosensitive sensor 28 with a photovoltaic panel is installed.

[0037] One end of the heat conducting pipe 12 connected to the water return port of the heat storage tank 26 is provided with a water inlet check valve 19 . The water return port of the hot water storage tank 26 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com