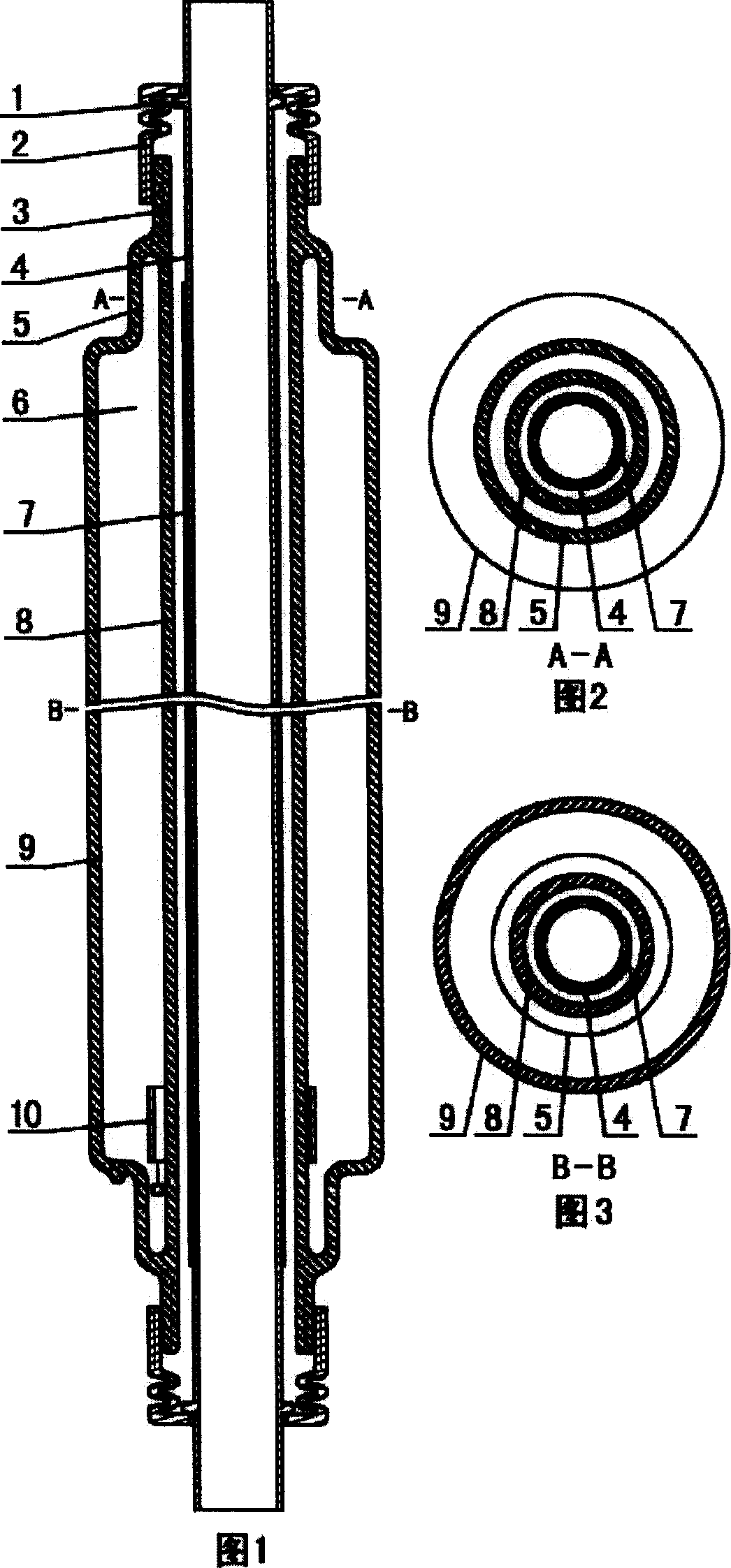

Solar vacuum tranducing tube having photo-heat conversion film compounded on pressure-bearing straight-through tube

A technology of light-to-heat conversion and energy conversion tube, which is applied in the field of solar energy applications, can solve the problems of system paralysis, unable to bear the pressure of structural characteristics, unable to meet the pressure-bearing operation of the system, etc., and achieve the effect of easy processing and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 example

[0055] In the third embodiment: the cross-section of the outer glass tube 9 of the solar vacuum transducer tube is a closed line connecting a curve and an arc line, and the others are equal to the second embodiment.

[0056] In the fourth embodiment: the solar vacuum transducer tube 9 of the solar vacuum transducer tube is inserted with a condenser mirror 13 , and a pressure-balanced pressure-bearing sealing assembly 12 is installed on the top of the pressure-bearing heat-absorbing tube 4 . Others are equal to the second embodiment.

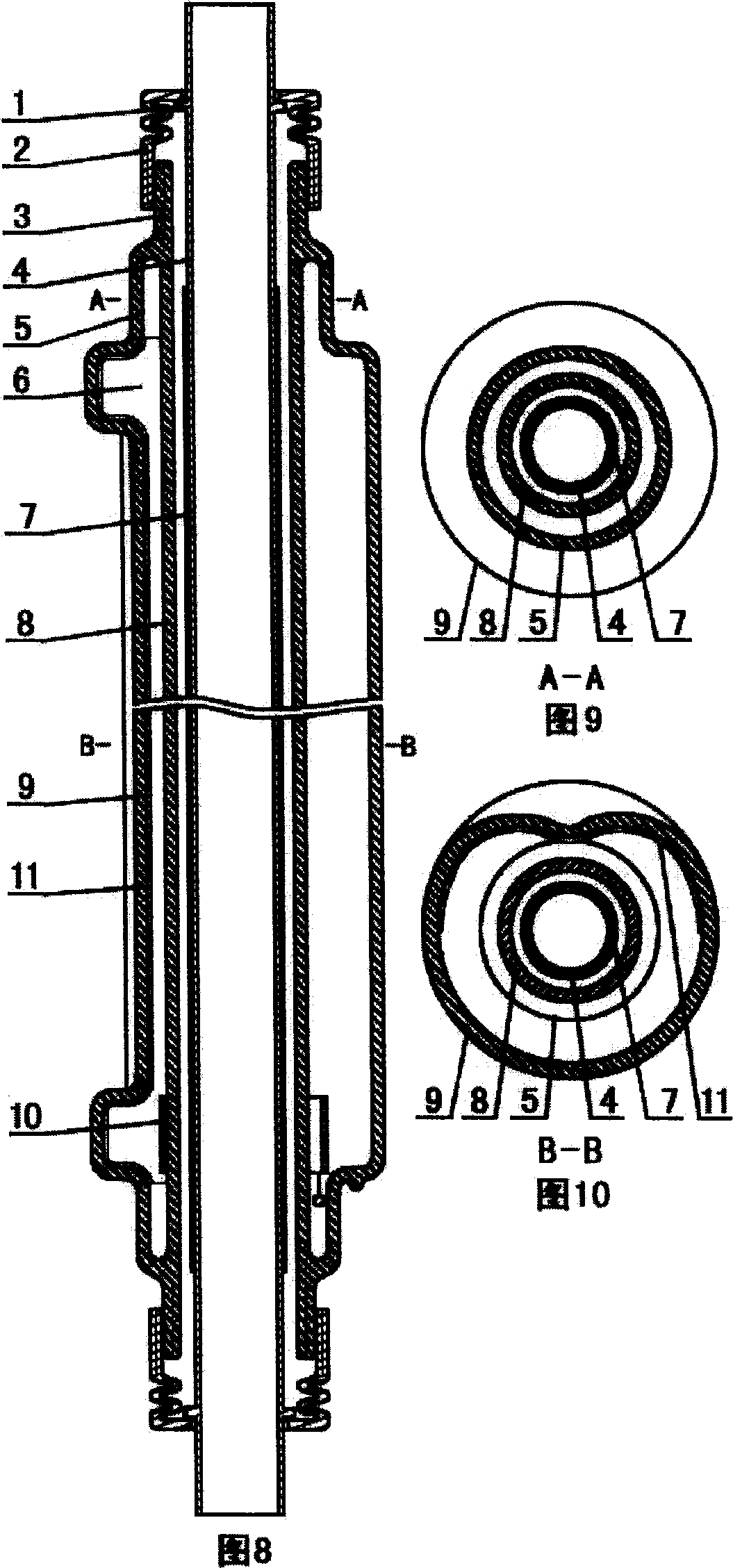

[0057] In the fifth embodiment: heat-absorbing fins 15 are compounded on the pressure-bearing heat-absorbing pipe 4 . Others are the same as the first embodiment.

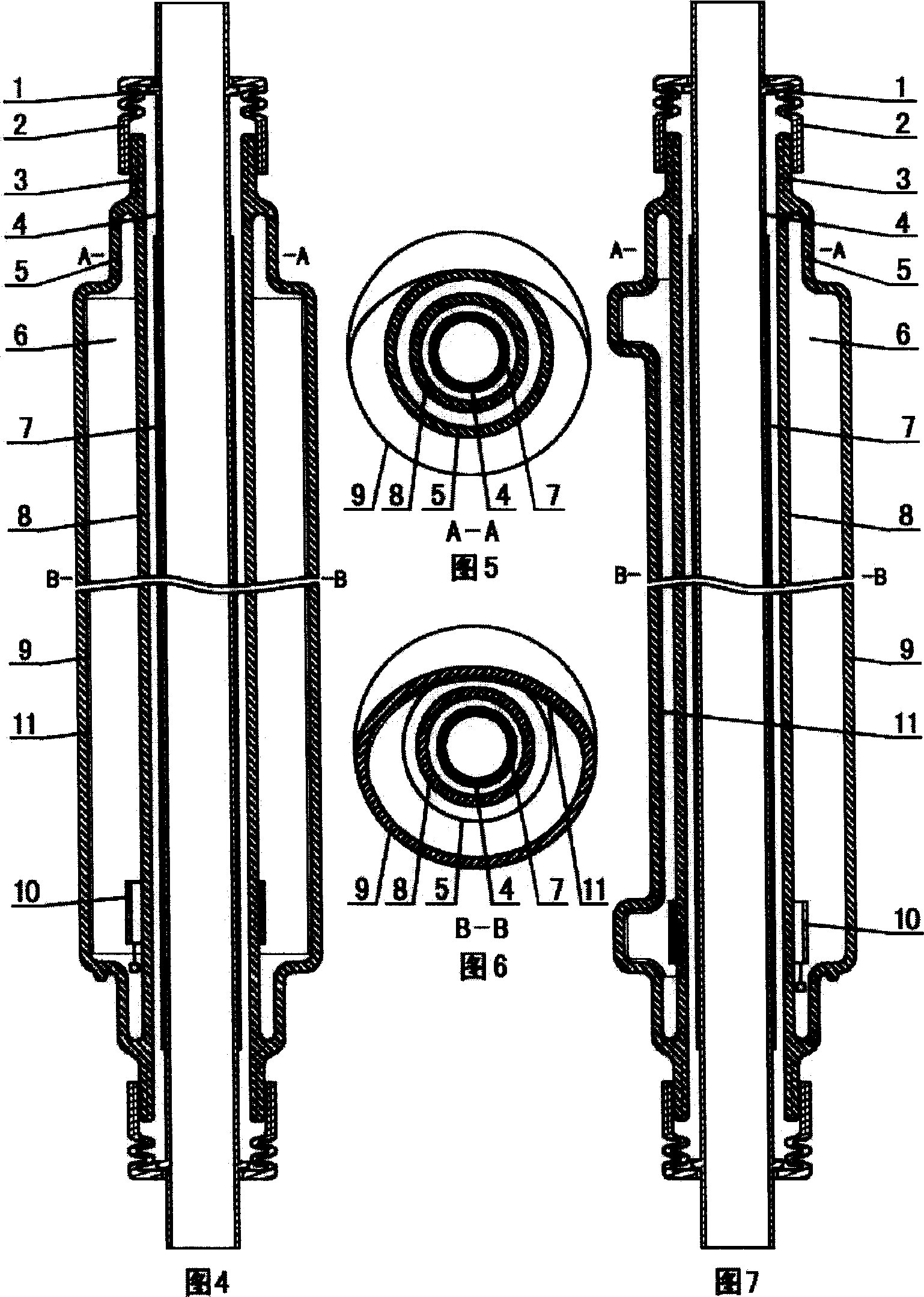

no. 6 example

[0058] In the sixth embodiment: the cross section of the outer glass tube 9 of the solar vacuum transducer tube is an elliptical special-shaped tube, and the wall of the outer glass tube 9 of the solar vacuum transducer tube is coated with a concentrating mirror 11, and the others are equal to the fifth embodiment.

[0059] In the seventh embodiment: the section of the outer glass tube 9 of the solar vacuum transducer tube is a closed line connecting a curve and an arc line, the outer glass tube 9 of the solar vacuum transducer tube is coated with a concentrating mirror 11, and others are equal to the fifth Example.

no. 8 example

[0060] In the eighth embodiment: the solar vacuum transducer tube 9 is inserted with a condenser mirror 13 . Others are equivalent to the fifth embodiment.

[0061] In the ninth embodiment: the solar vacuum transducer tubes compounded with light-to-heat conversion film on the pressure-bearing straight-through tube are connected to each other through gaskets 19, lock nuts 17, and telescopic tube junctions 18, and the solar vacuum transducer tubes are wrapped with thermal insulation materials 16 .

[0062] In the tenth embodiment: the outer glass tube 9 of the solar vacuum transducer tube with a light-to-heat conversion film compounded on the pressure-bearing straight-through tube is provided with a concentrating mirror 11, and the others are identical to the ninth embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com