Slagging-free type and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and method thereof

A low-temperature roasting and aluminum salt technology is applied to the slagging-free, multi-stage differential temperature fluidized roasting system and field of crystalline aluminum salt, which can solve the problems of high material requirements, low reaction efficiency, poor continuous operation performance of equipment, etc. The effect of good system regulation and stability, high product purity and minimal energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

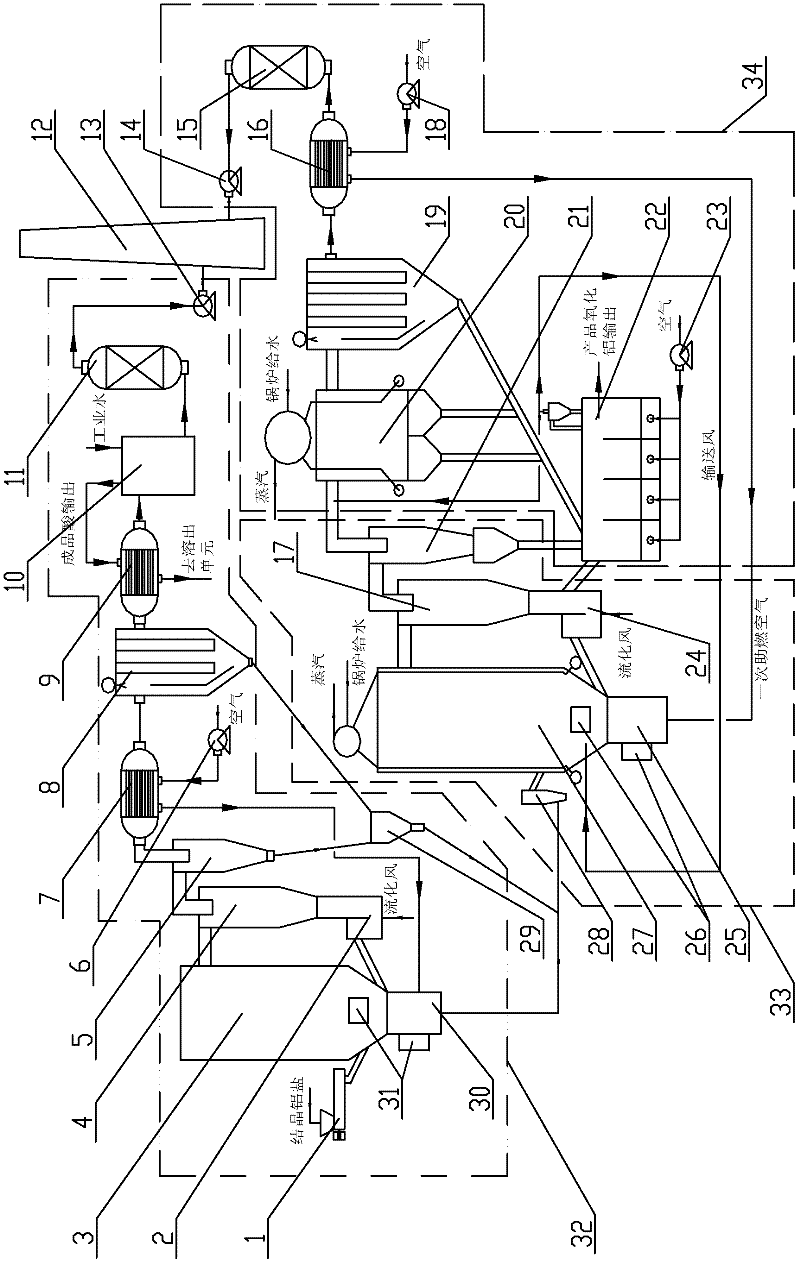

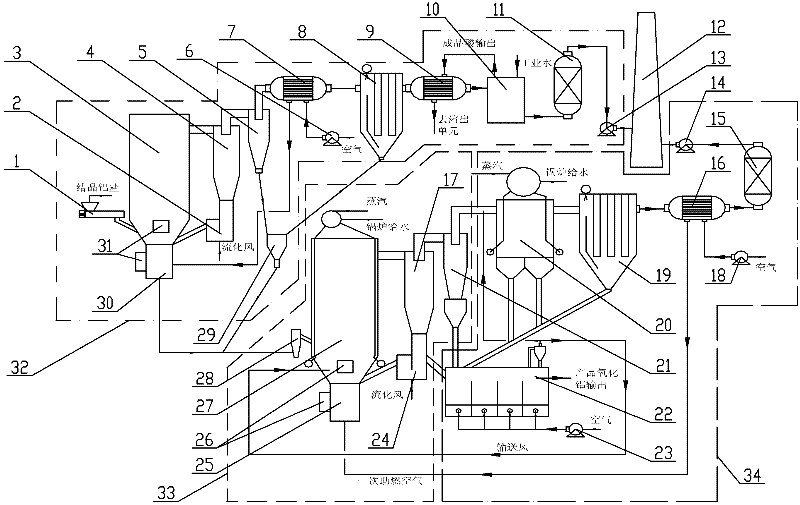

[0032] Such as figure 1 As shown, a slagging-free, multi-stage differential temperature fluidized roasting system for crystalline aluminum salts according to the present invention includes a low-temperature roasting system 32 for crystalline aluminum salts, a high-temperature alumina finished product roasting system 33, and a multi-stage fluidized cooling system for high-temperature alumina. And heat recovery system 34 and chimney 12;

[0033] The crystalline aluminum salt low-temperature roasting system 32 includes a low-temperature roasted fluidized bed body 3, the bottom of the low-temperature roasted fluidized bed body 3 is connected to a low-temperature roasted fluidized bed air chamber 30, and the lower part of the low-temperature roasted fluidized bed body 3 is also connected to the crystallization The aluminum salt silo and the feeding device 1 are fixedly connected, and the top outlet of the low-temperature roasting fluidized bed body 3 is fixedly connected to the upp...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that if the roasted crystalline aluminum salt is crystalline aluminum hydroxide, the finished acid preheater 9, the acid gas absorption system 10, the first alkali washing tower 11 and the second alkali washing tower 11 in the system are cancelled. Alkali washing tower 15. The first bag filter 8 is a conventional temperature-resistant bag filter. The flue gas temperature after leaving the first bag filter 8 and the second bag filter 19 is 130-150°C. Other composition, connection mode are identical with embodiment 1.

[0057] The independent temperature control operation of each fractional bed in the present invention satisfies the requirement of a large amount of heat-absorbing characteristics in the low-temperature roasting stage of the crystalline aluminum salt, and solves the problem that the aluminum salt is easily slagged and agglomerated in the low-temperature roasting stage; at the same time, the roastin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com