Patents

Literature

30results about How to "Solve the clumping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

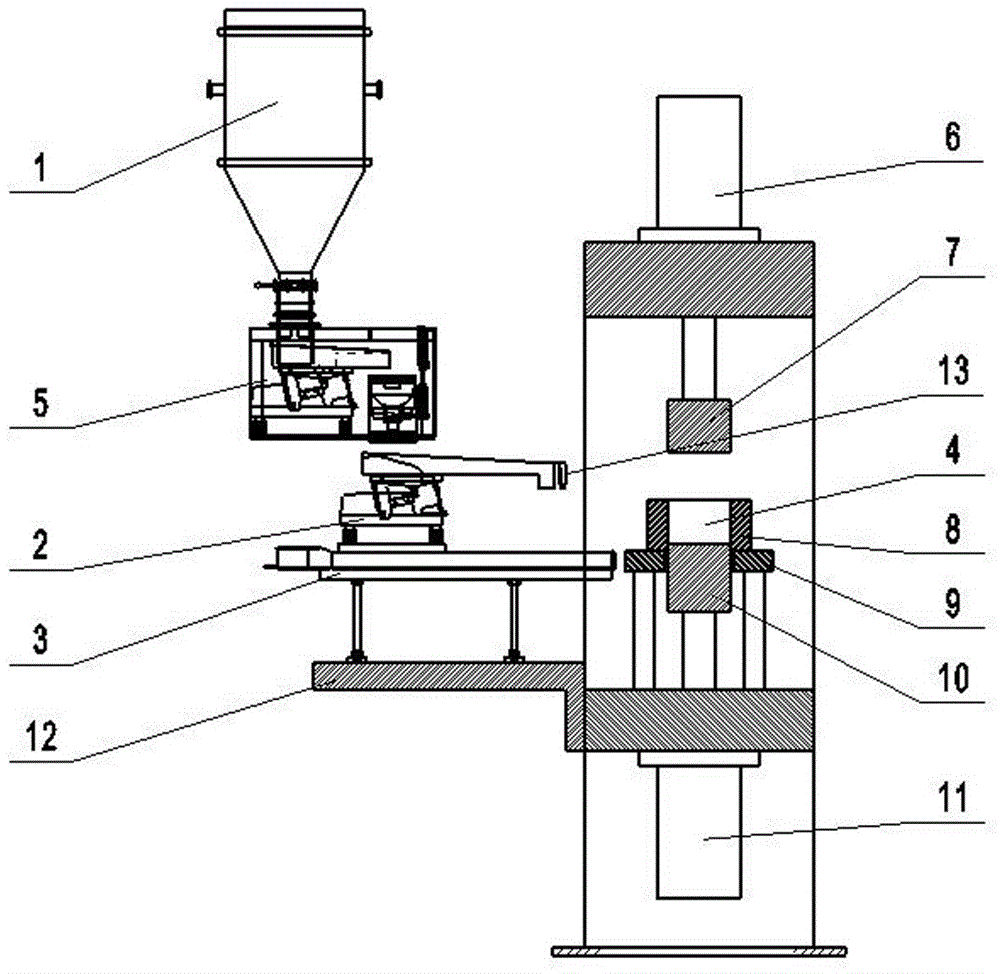

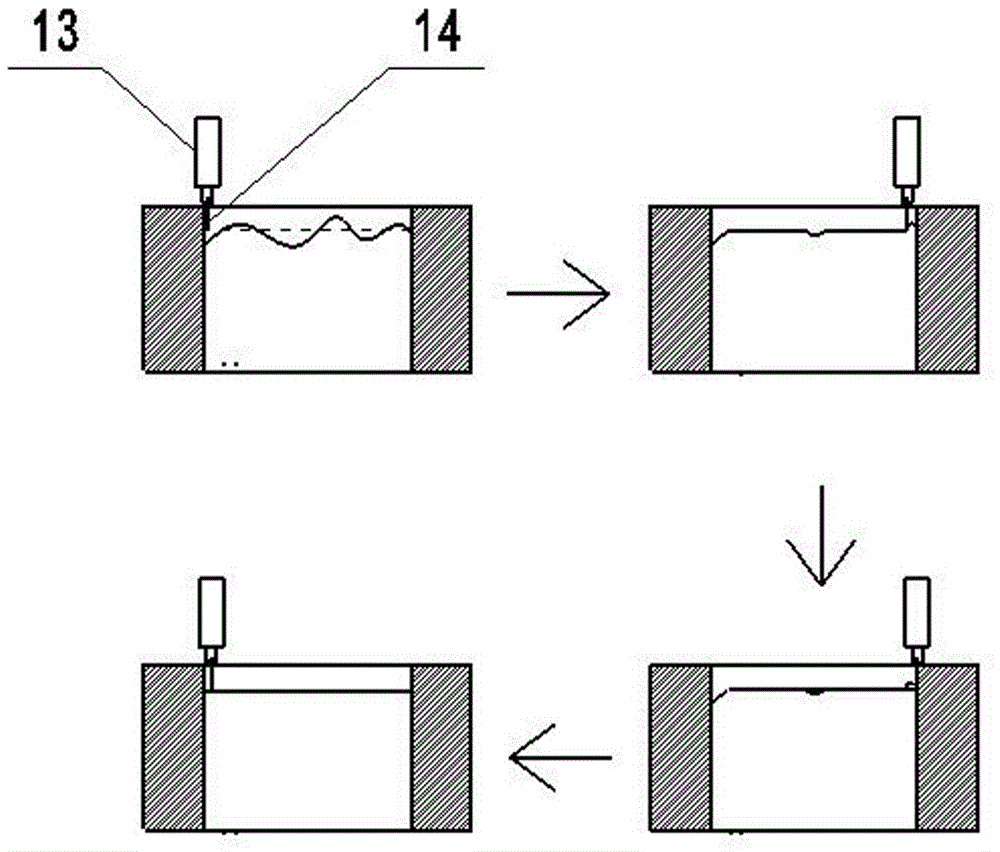

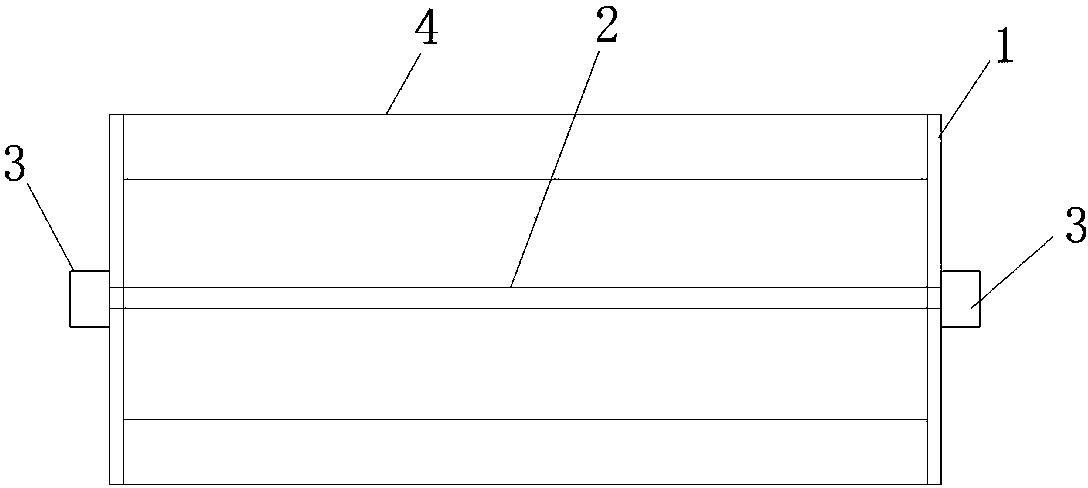

Quantitative powder adding method and device

InactiveCN106079550AEvenly distributedPrevent leakageLoading/unloadingShaping pressReciprocating motionMaterials science

The invention provides a quantitative powder adding method and device. The quantitative powder adding method and device are mainly applied to powder adding. The quantitative powder adding method comprises the steps that powder is weighed through a weighing machine and then poured into a feeder, the feeder is driven to move to the position above a mold by a driving device at the lower end of the feeder, the feeder is started, the powder in the feeder successively falls into a mold cavity of the mold, and the driving device drives the feeder to reciprocate between the two ends of the mold cavity in the process that the powder successively falls into the mold cavity till all the powder is added; and a driving cylinder and a scraping piece are arranged at the front end of the feeder, and the driving cylinder drives the scraping piece to level the powder in the mold cavity after all the powder is added. According to the quantitative powder adding method and device, quantitative powder is stably added into the mold cavity through the feeder and leveled through the scraping piece, so that the powder in the mold cavity is evenly distributed, the defects of powder leakage, caking, bulk specific weight changes and the like in the prior art are overcome, powder waste is reduced, and the benefits of enterprises are increased.

Owner:孔庆虹

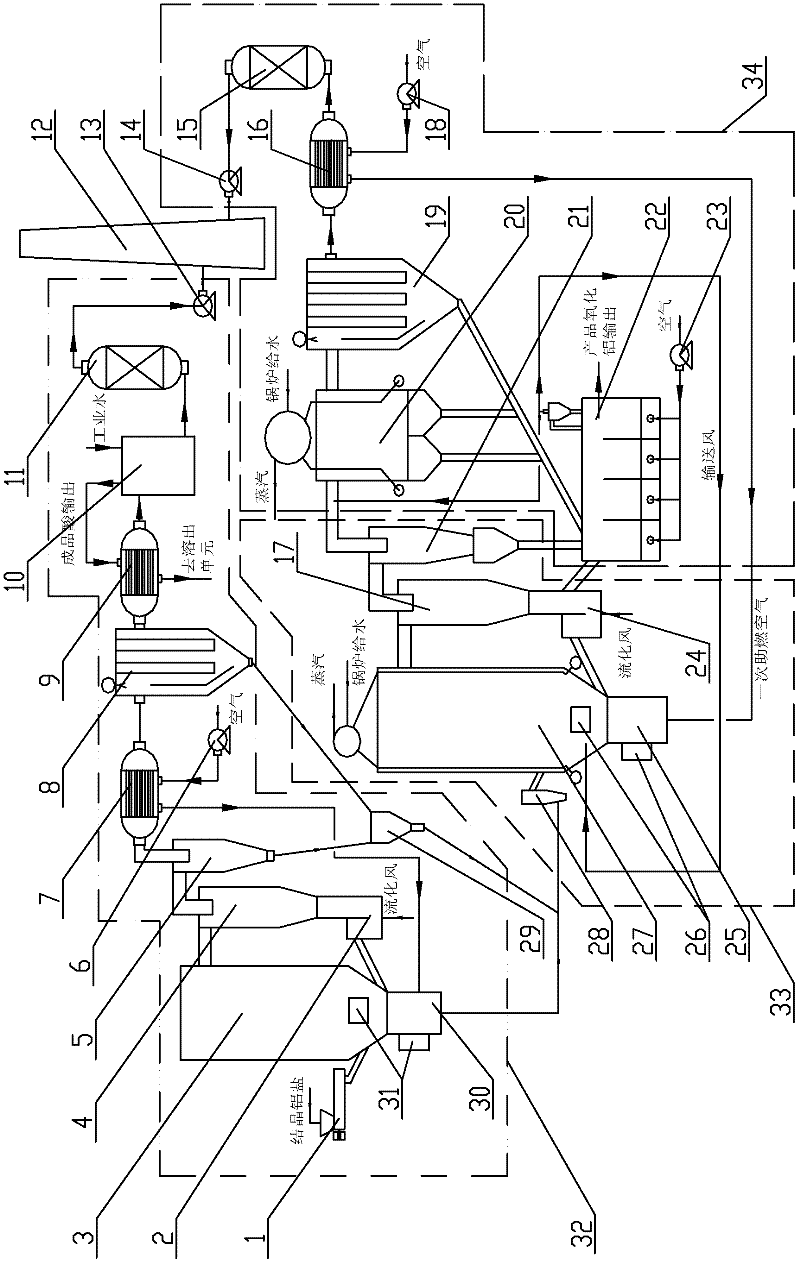

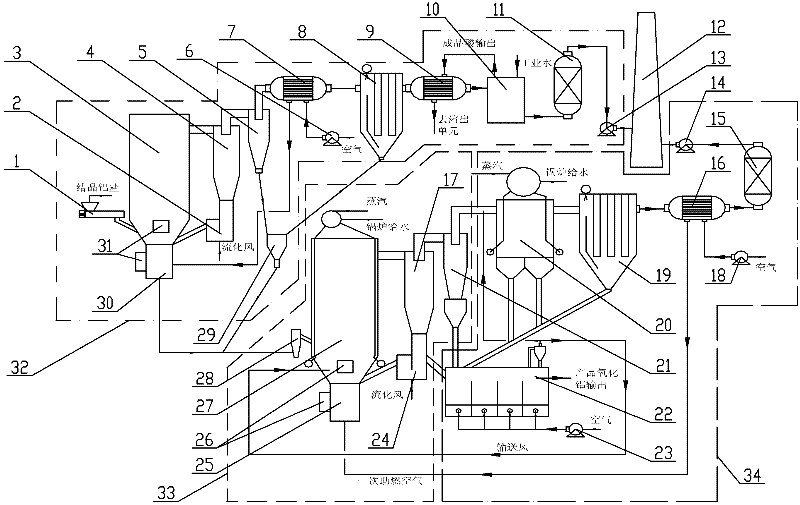

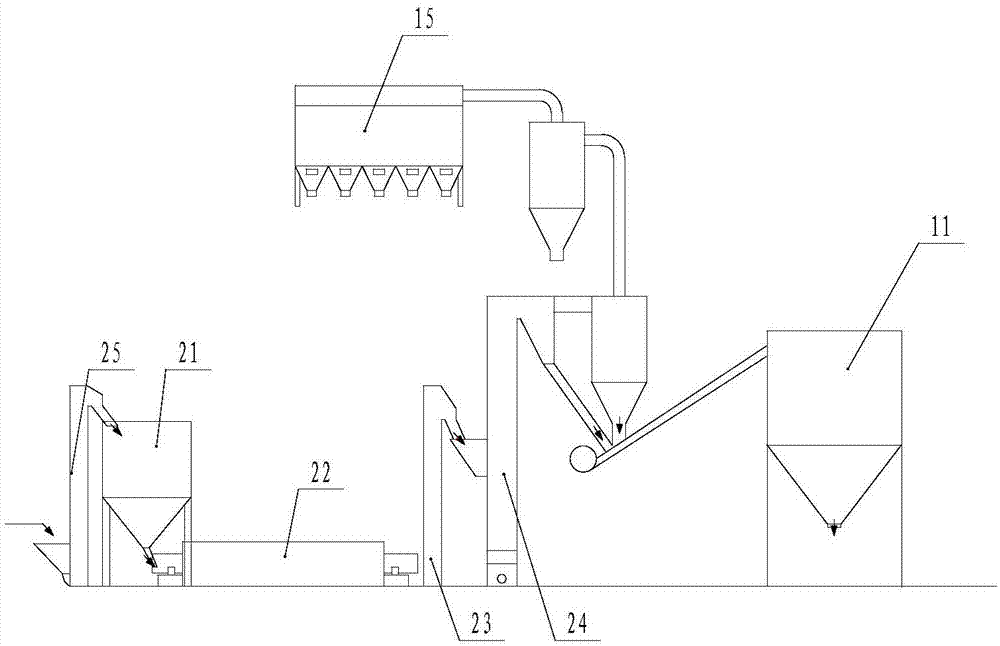

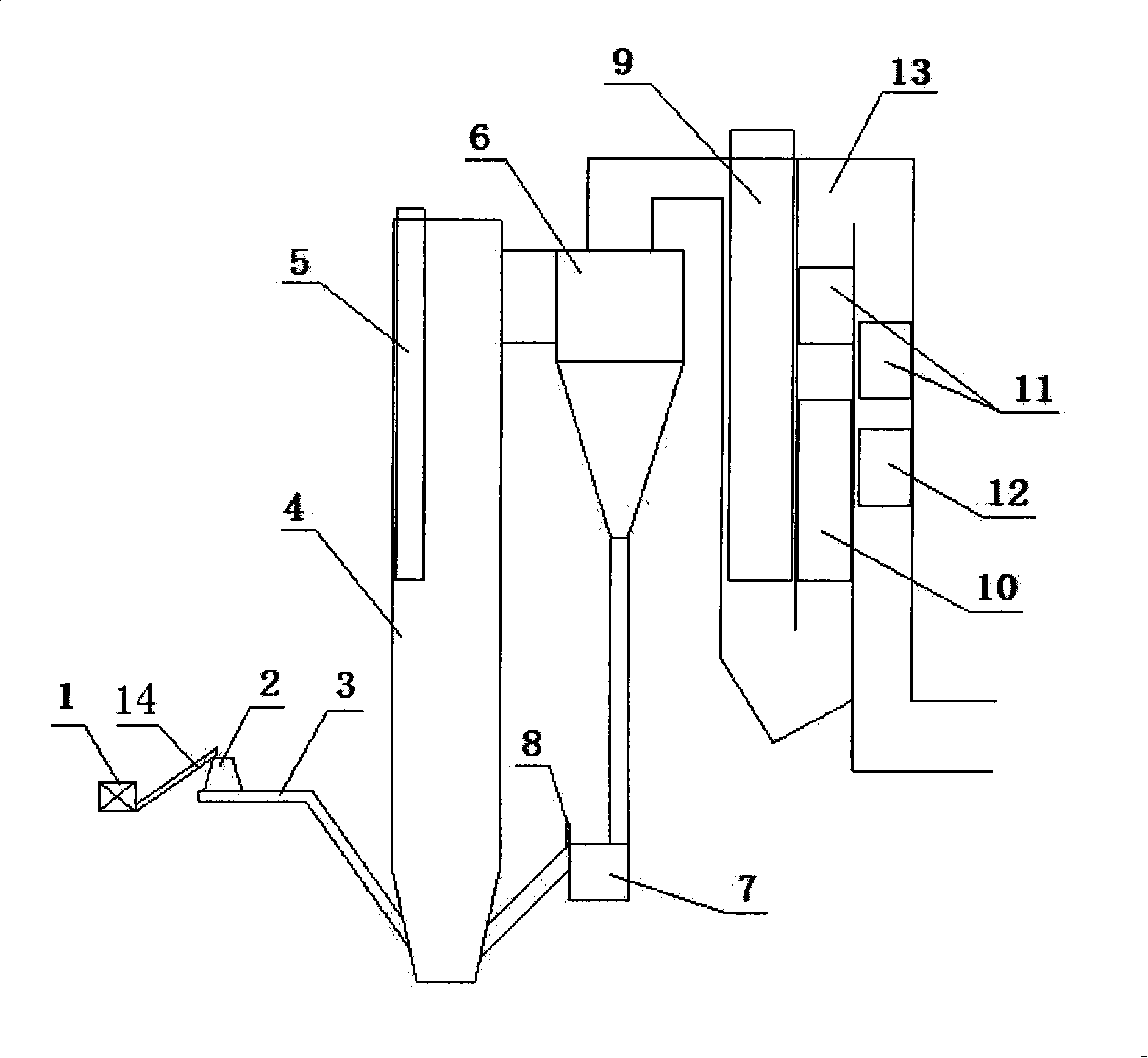

Slagging-free type and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and method thereof

ActiveCN102502744ASolve the problem of large initial investmentReduce energy consumptionEnergy inputAluminium oxide/hydroxide preparationFlue gasProcess engineering

The invention provides a slagging-free type, low-energy consumption and multilevel differential temperature fluidized roasting system for crystallized aluminum salt and a method thereof. The system comprises a crystallized aluminum salt low-temperature roasting system, an aluminum oxide high-temperature finished product roasting system, a high-temperature aluminum oxide multilevel fluidized cooling and heat recovery system and a chimney. The method comprises the following steps of: reducing the outlet temperature of low-temperature roasting flue gas with large gas production rate by adopting a differential temperature multiple roasting method, so that sensible heat carried by the flue gas is greatly reduced; and carrying out reasonable cascade utilization on energy and converting fuel chemical energy inputted by a process system into effective heat of the system to a greatest extent. The slagging-free type and multilevel differential temperature fluidized roasting system has the remarkable advantages of strong adaptability to the content of attached water of the crystallized aluminum salt, good adjustment and stability, high product purity, low energy consumption, low investment, small floor area and the like.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

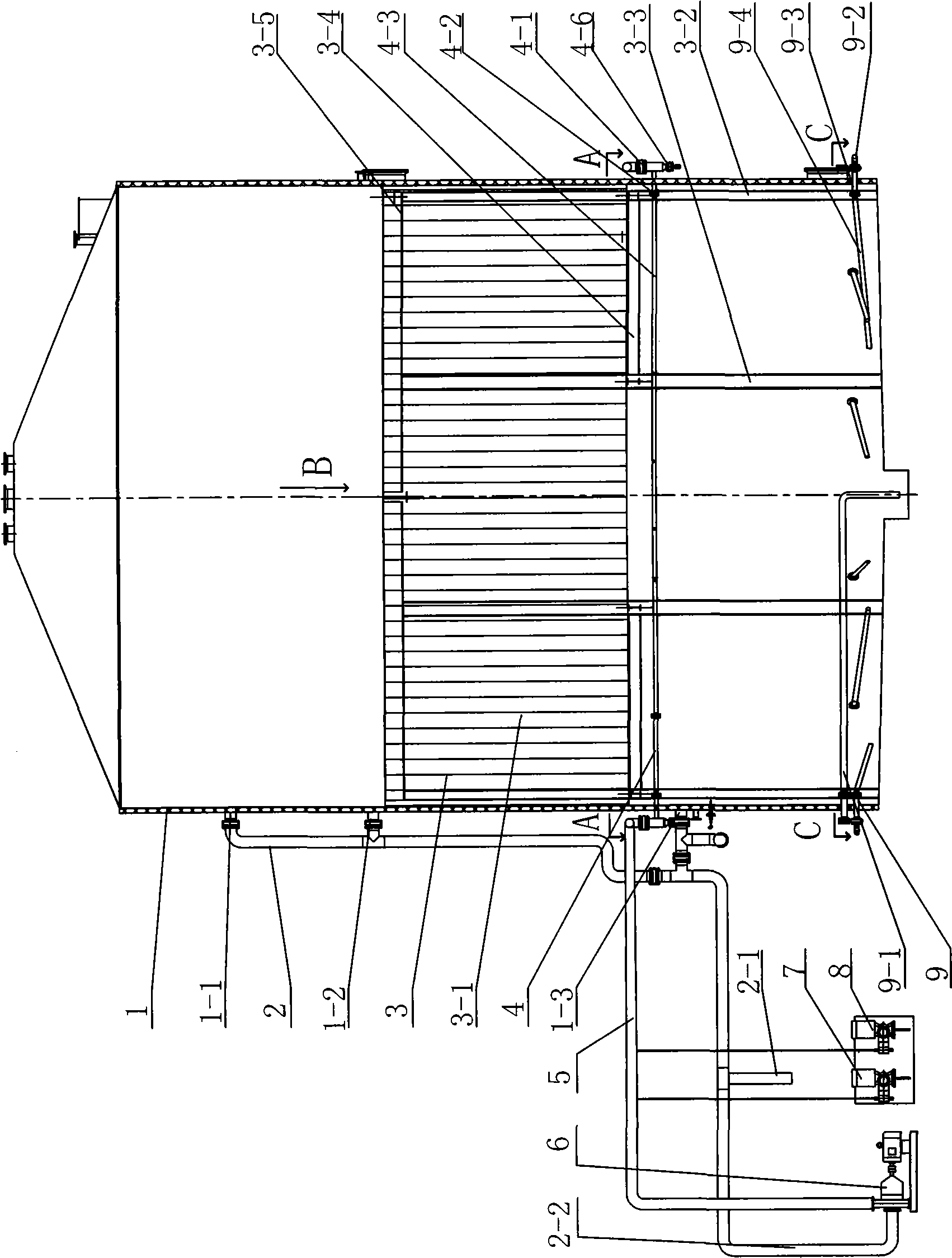

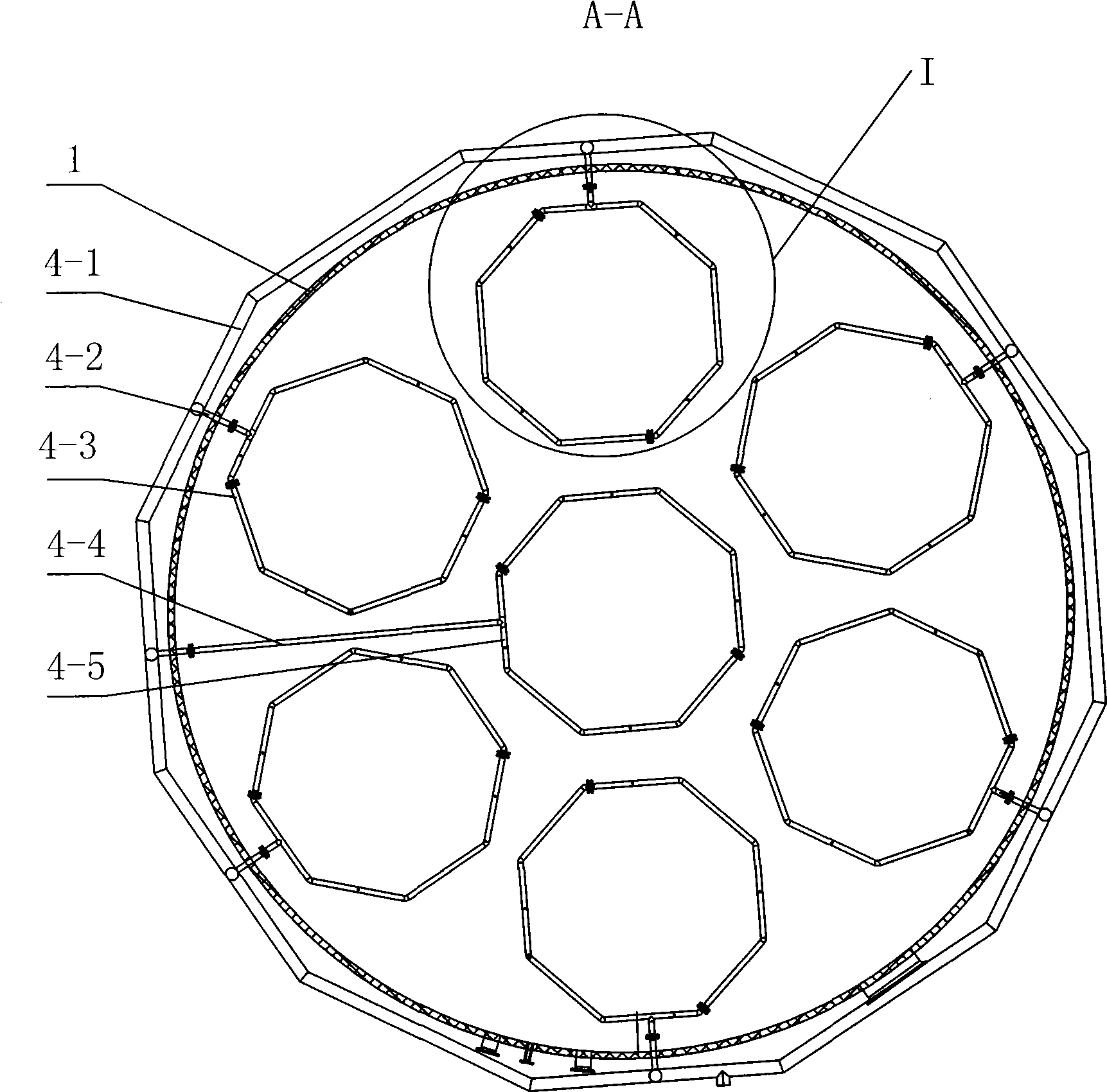

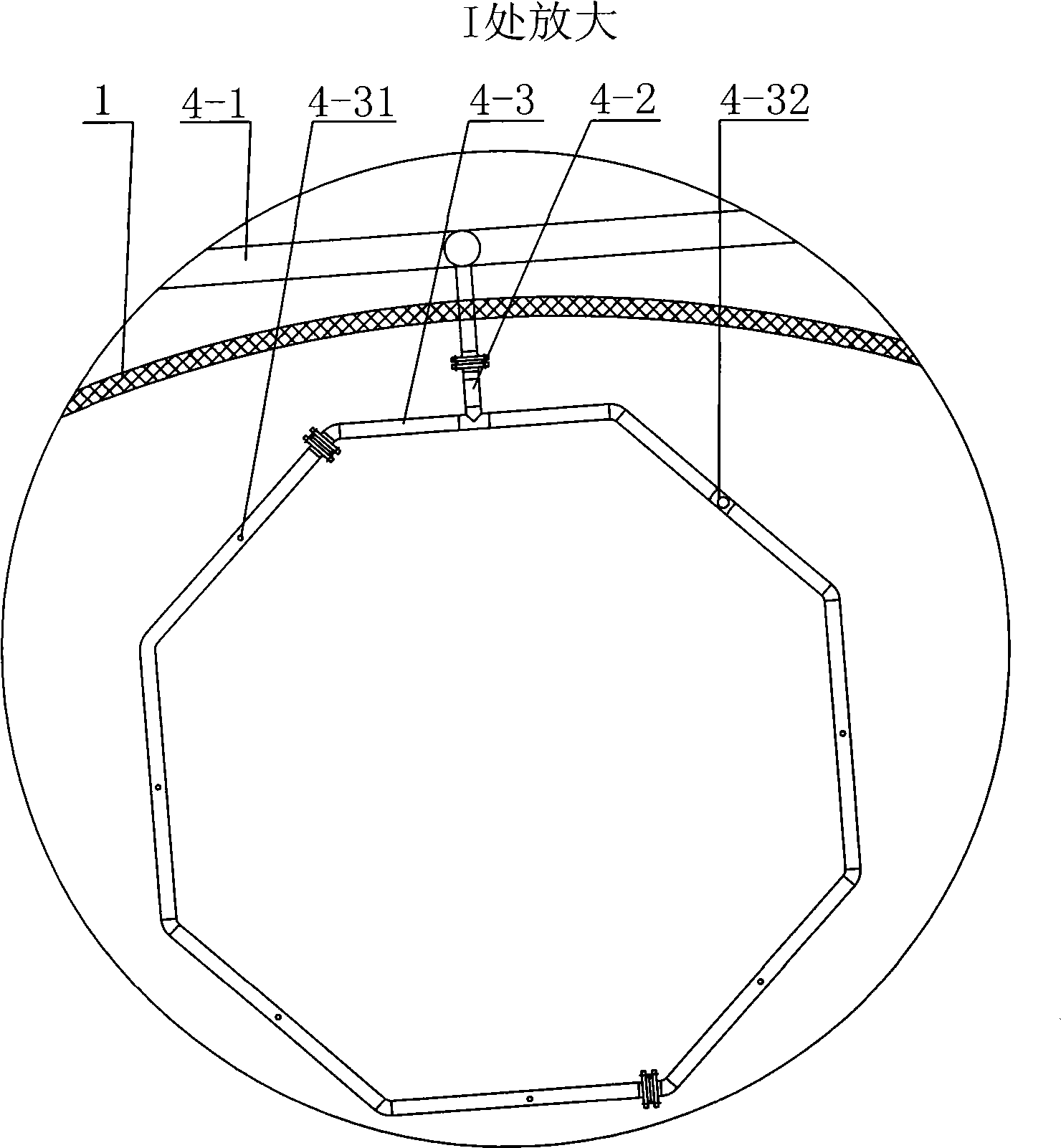

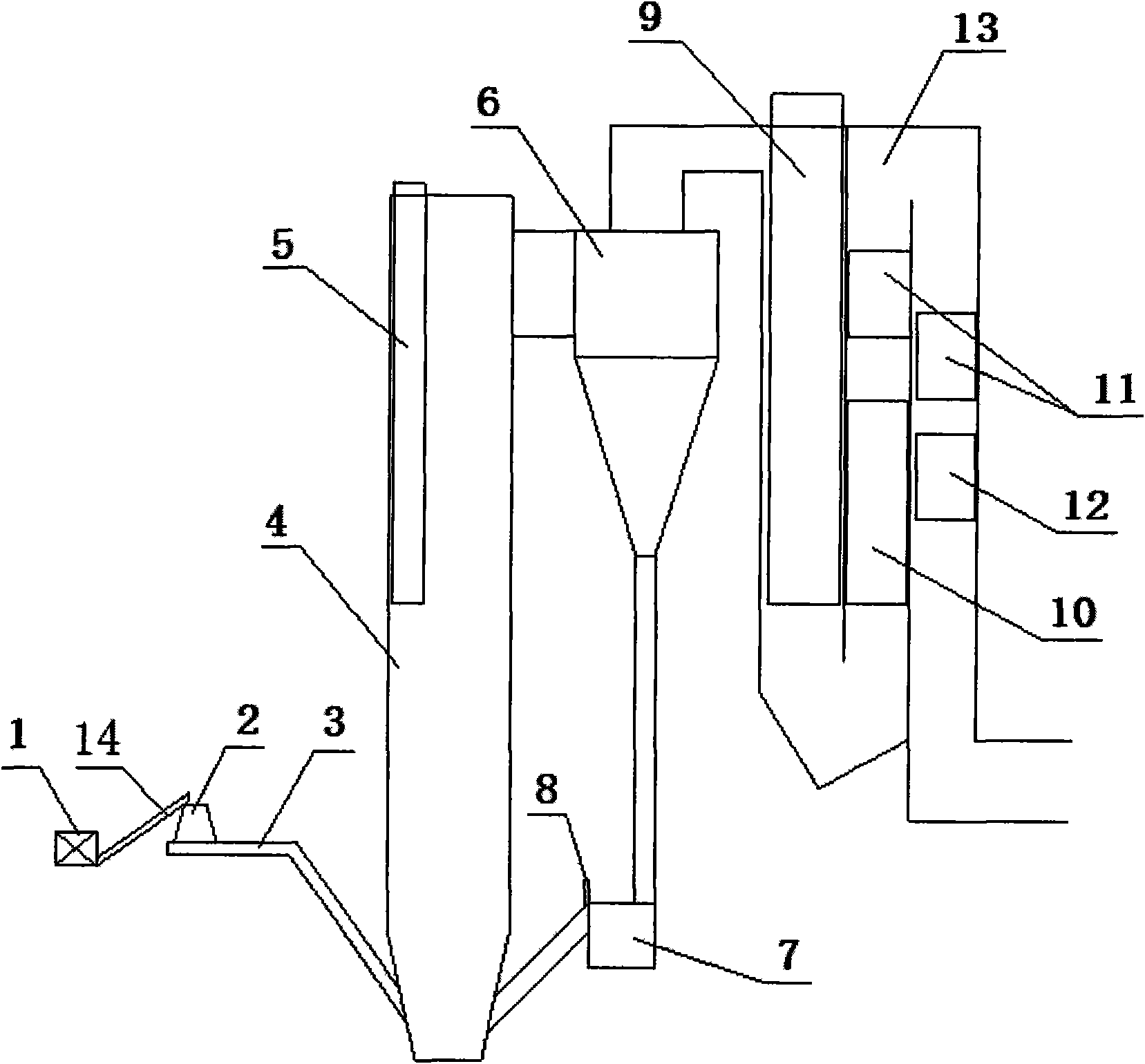

Anaerobic reactor

ActiveCN101497476ASolve easy blockageReduce foulingTreatment with anaerobic digestion processesAnaerobic reactorCirculating pump

The invention relates to an anaerobic reactor. The anaerobic reactor comprises a cylinder body, a water inlet pipe, a water outlet pipe, a filling device on the middle part of the water outlet pipe, a water distribution device at the bottom of the filling device and a sludge discharge device at the bottom of the water distribution device; the water distribution device comprises a water distribution main pipe and more than four closed annular water distribution branch pipes; water outlet holes of the water distribution branch pipes are alternately arranged along more than three concentric circumferences; the cylinder body is positioned on the upper part of the filling device; the lower part of each water distribution branch pipe is provided with more than two water outlets; the water outlets are connected with the water outlet pipe; a reflowing pipe of the water outlet pipe is mixed with the water inlet pipe by a circulating pump and is communicated with the water distribution main pipe; a first medicating device and a second medicating device are communicated with the water inlet pipe respectively through connecting pipes; the filling device comprises a filling rack, a membrane hanging rack and a zonal biomembrane strip; the biomembrane strip is hung on the membrane hanging rack; and the sludge discharge device comprises a sludge discharge main pipe and six sludge discharge branch pipes arranged in length alternation along radial direction. The anaerobic reactor has the characteristics of reasonable water distribution, compact structure and stable operation of the reactor.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Powder wrapping machine

The invention relates to the technical field of food processing, and especially relates to a powder wrapping machine. The powder wrapping machine includes a powder wrapping cylinder body, a material mixing motor, a liquid spraying mechanism, a powder dusting mechanism, a material mixing mechanism and a powder feeding cylinder body; and the upper part of the powder wrapping cylinder body is provided with a food inlet. To-be-wrapped food, powder and liquid flavouring agents are respectively fed in the powder wrapping cylinder body; through centrifugal effects, the powder and the liquid flavouring agents can be uniformly mixed and wrapped on the outside of the food, so that the problems of caked powder and non-uniform powder wrapping can be effectively solved; a powder feeding mechanism disperses the powder to convey to a powder rolling cylinder body, so that the powder can be uniformly sprayed on the outside of the food; through a liquid feeding pump, a ring pipe and a liquid dividing device, the liquid spraying mechanism can uniformly spray the liquid flavouring agents and mix the food and the powder; and through a centrifugal plate, a discharging cylinder and a supporting-telescoping rod, the food wrapped with the powder can be rapidly and effectively discharged and unloaded.

Owner:杭州森宝食品有限公司

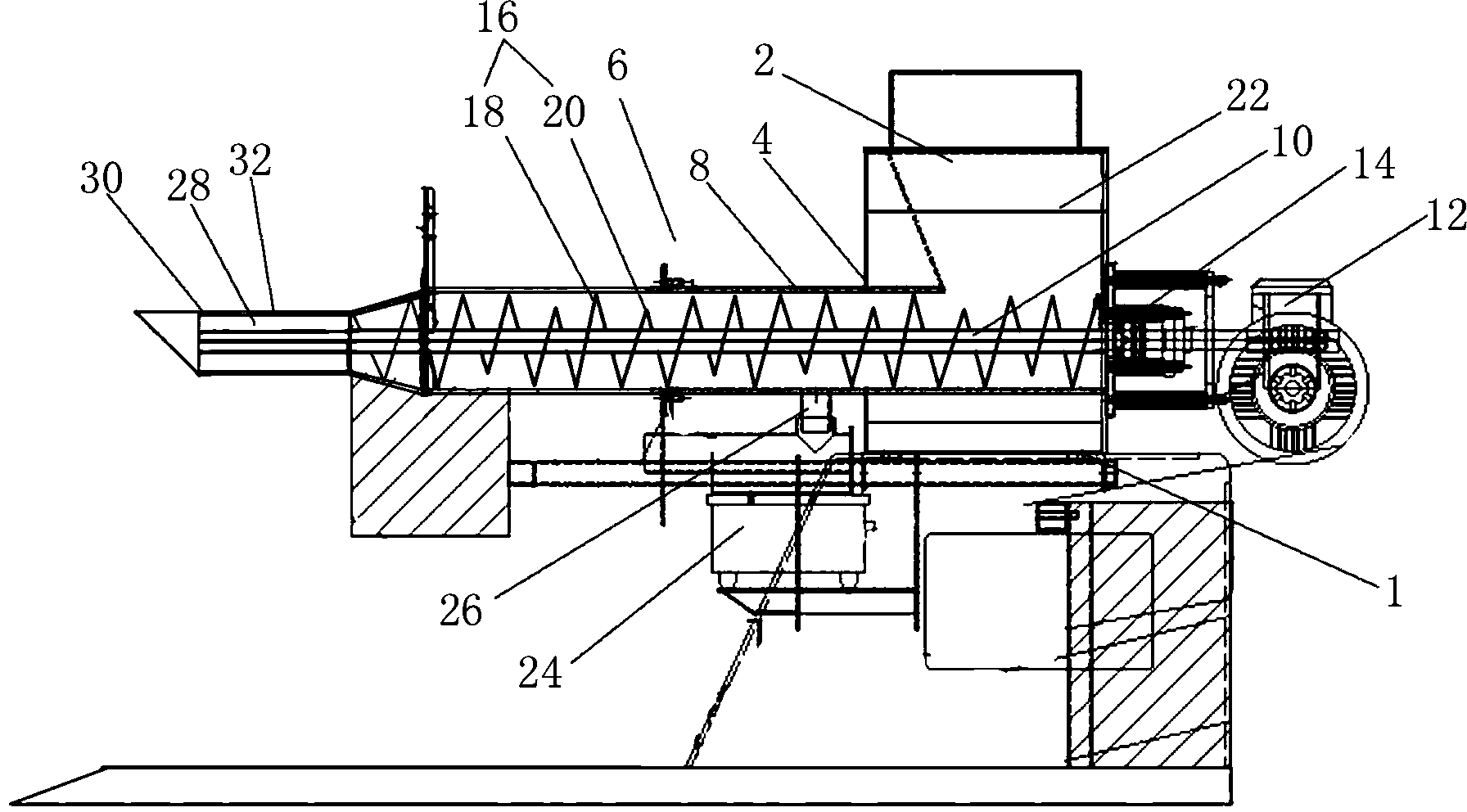

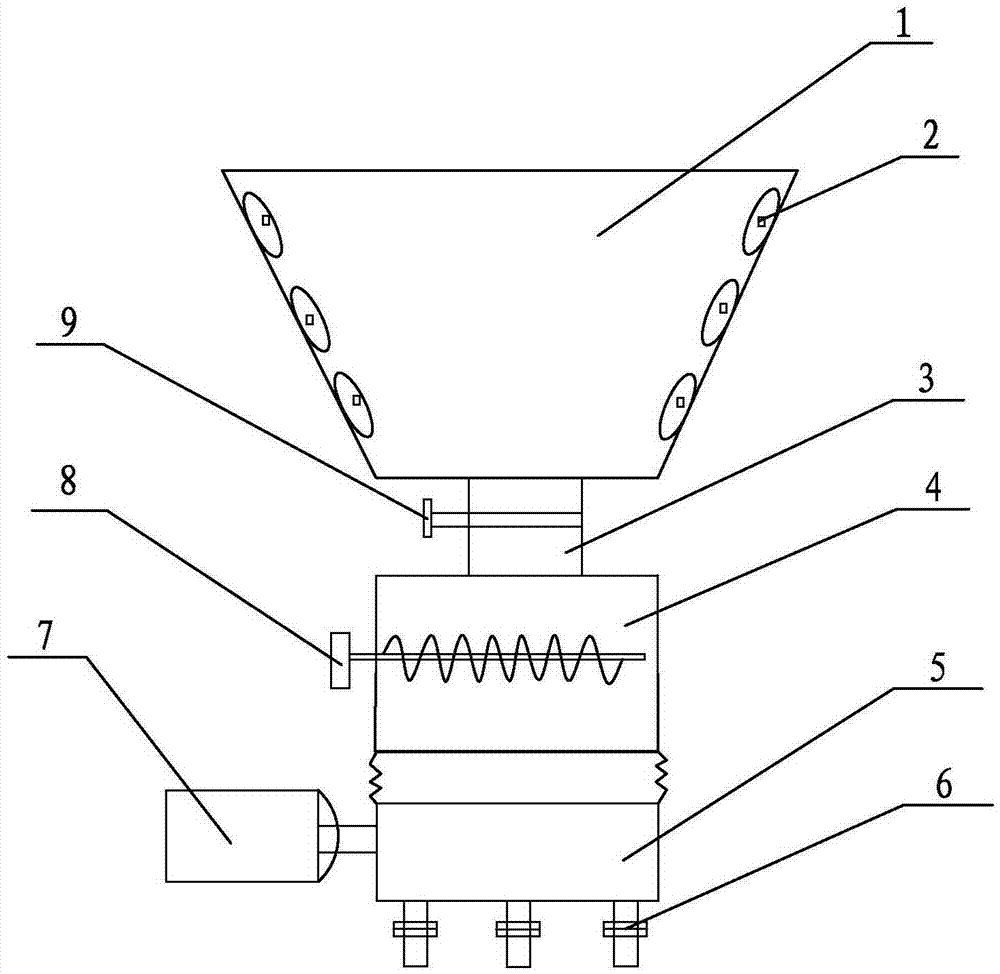

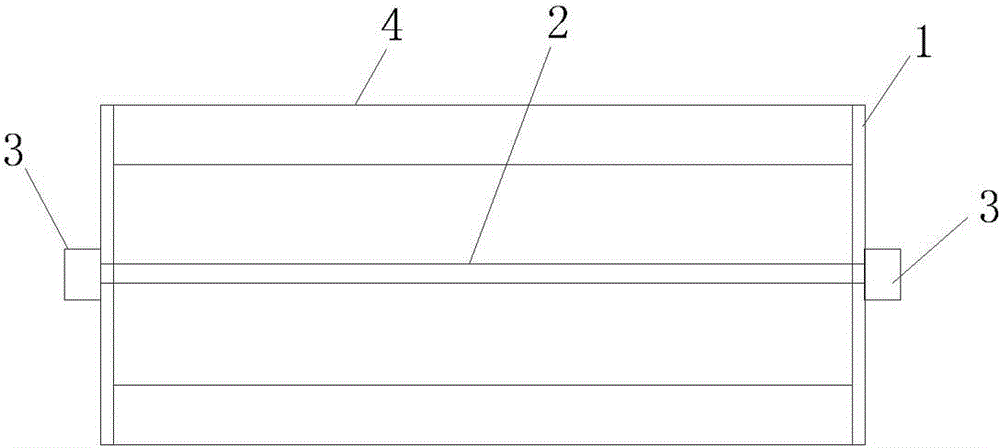

Spiral pusher

ActiveCN103482316ASolve bridgingSolve the clumpingLarge containersLoading/unloadingElectric machineryStructural engineering

The invention discloses a spiral pusher, comprising a storage silo and a pusher, wherein a fixed frame of the storage silo is arranged on a horizontal workbench; an opening is formed in the lower end of one side of the storage silo; the pusher which is used for pushing materials is communicated with the interior of the storage silo by the opening; the pusher comprises a hollow feeding pipe body, a push rod and a motor; the push rod penetrates through the feeding pipe body and is coaxially arranged with the feeding pipe body; the motor is used for driving the push rod to rotate around the self-axis of the push rod; one end, rotatably connected with the motor, of the push rod penetrates through the interior of the storage silo, outwards extends out of the storage silo and is rotatably connected with the motor by a bearing frame. The spiral pusher is characterized in that blades which are used for pushing materials are spirally coiled at the outer wall of the push rod. Compared with the traditional pusher, for the materials which are high in water content and poor in mobility and are easily caked and clotted, the spiral pusher solves the problems of bridging or clotting, and has the advantages that the structure is simple and the feeding efficiency is high.

Owner:CHINA WEIGHING EQUIP SUZHOU FACTORY

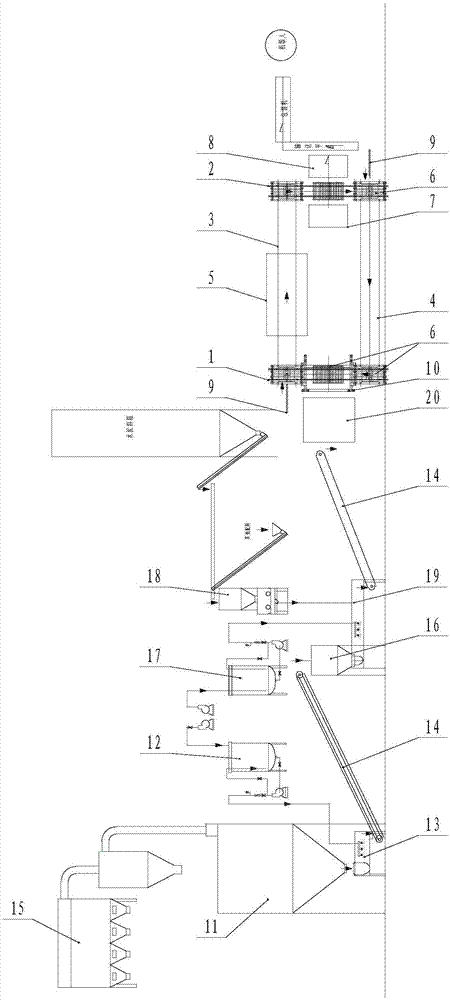

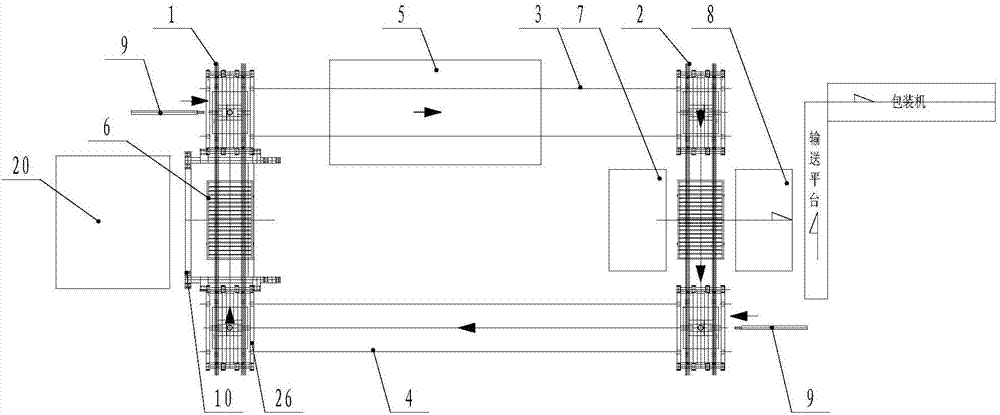

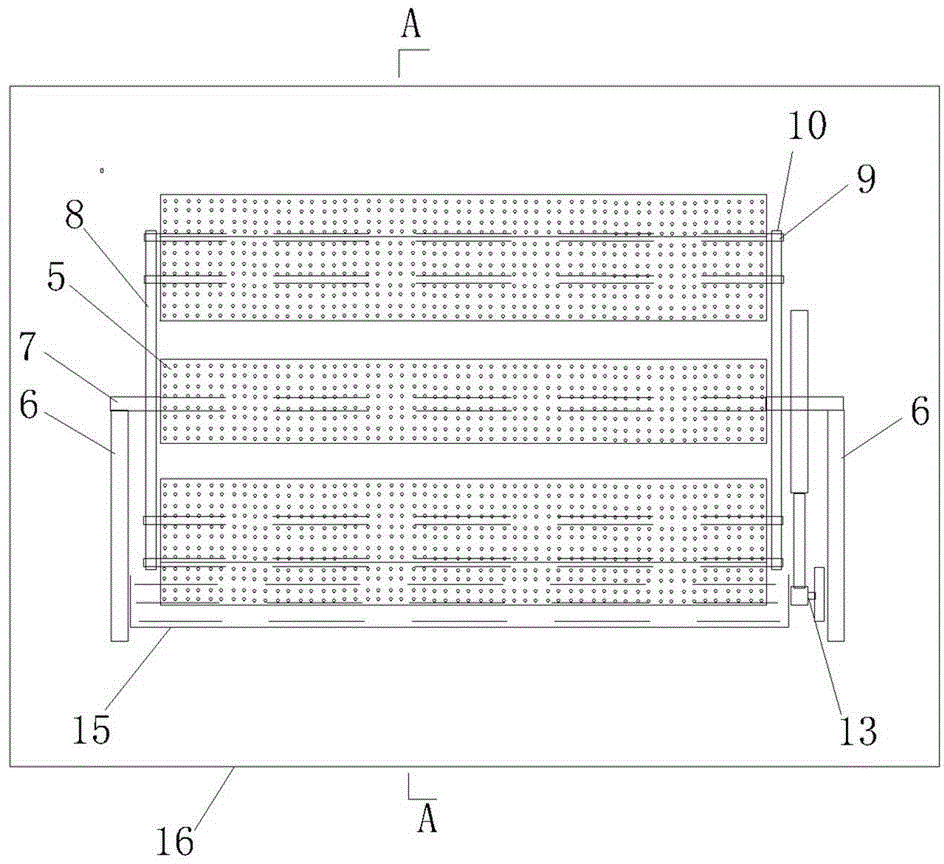

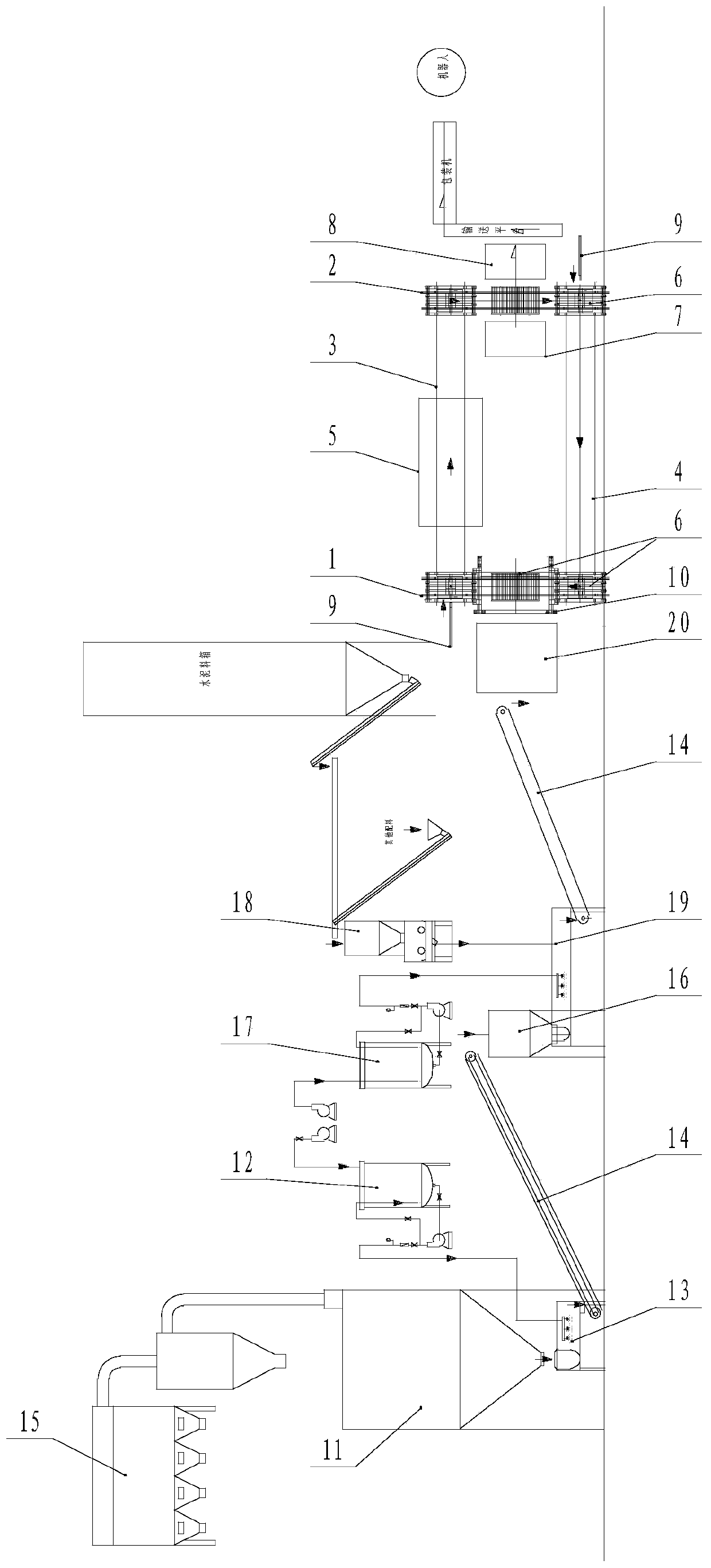

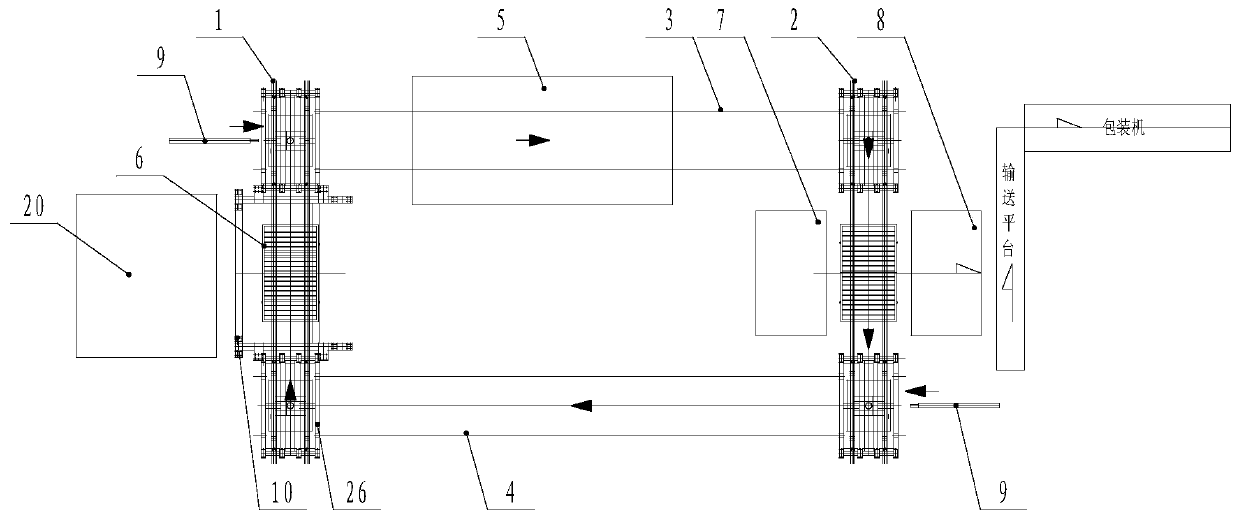

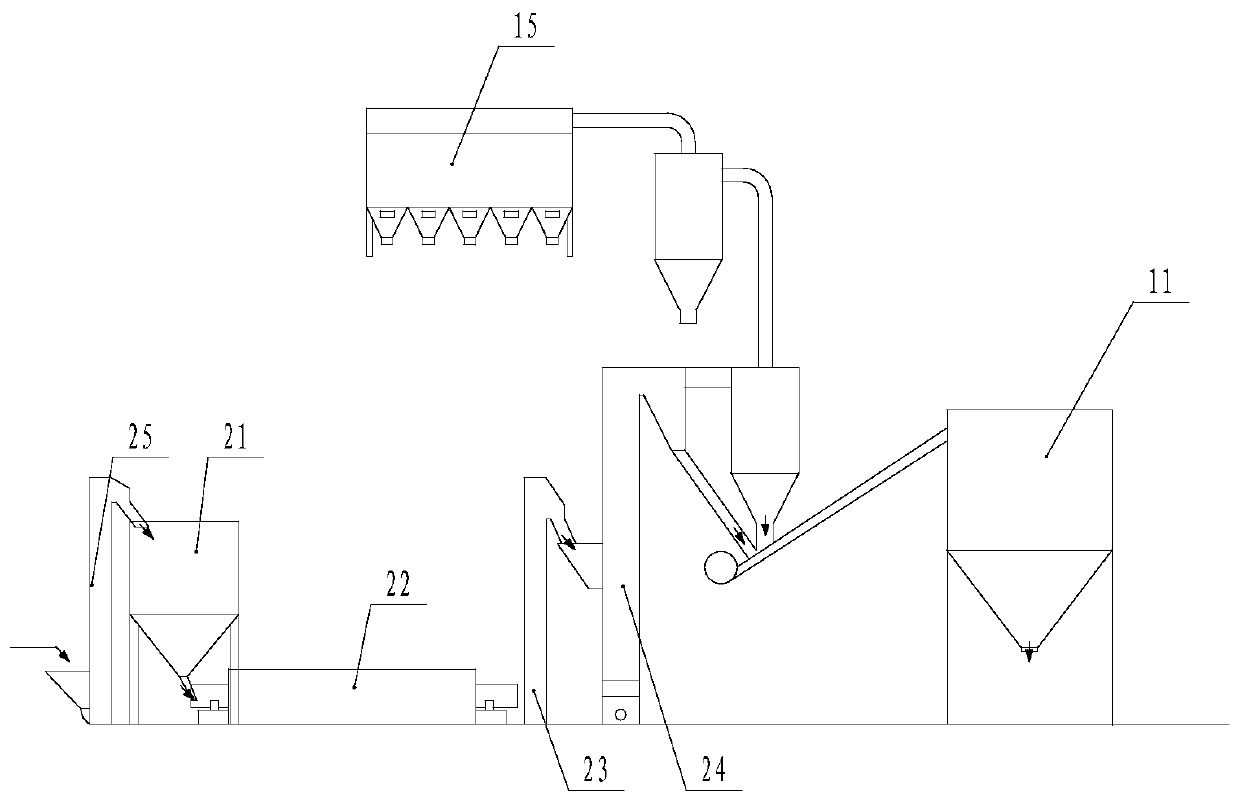

Full-automatic production device for expanded perlite heat preserving board

ActiveCN107571388ASave manpower and investmentStable transmissionCeramic shaping plantsAuxillary shaping apparatusPerliteProcess engineering

The invention discloses a full-automatic production device for an expanded perlite heat preserving board and relates to the field of heat preserving board production devices. The full-automatic production device for the expanded perlite heat preserving board is used for overcoming the defects that in the process of producing the expanded perlite heat preserving board, cost is high, efficiency is low, consumed time is long and assembly line production cannot be achieved. The full-automatic production device for the expanded perlite heat preserving board comprises a material mixing device, a board pressing device, a drying device and a packaging platform; the material mixing device is used for conveying materials to the board pressing device after the materials are mixed uniformly; the boardpressing device is used for pressing the mixed materials into the heat preserving board; the drying device is used for drying the heat preserving board; and then the dried heat preserving board enters the packaging platform to be packaged. The full-automatic production device for the expanded perlite heat preserving board is used for assembly line production of the expanded perlite heat preserving board.

Owner:华亿建材科技有限公司

Circulating fluidized bed boiler burning straw-like biomass and feeding method

ActiveCN101614392AReduce volumeSimple compositionFluidized bed combustionIndirect carbon-dioxide mitigationBiomassCirculating fluidized bed boiler

The invention discloses a circulating fluidized bed boiler burning straw-like biomass and a feeding method. The feeding method comprises the following steps that: before being delivered into a furnace, the straw-like biomass serving as a fuel is crushed and compressed by compression molding equipment so as to be solidified; and the solidified straw-like biomass is conveyed to a furnace by a conveying belt so as to be burnt. By compressing the light and large-volume straw-like biomass before conveying the light and large-volume straw-like biomass to the furnace, the method reduces the volume of the straw-like biomass, has the advantages of simple structure and low cost, keeps the straw-like biomass away from bridging and block which frequently occur in a conveying process, ensures smooth feeding and the safe operation of the boiler, and effectively guarantees the continuous, reliable and safe operation of biomass power plants.

Owner:CHINA HUADIAN ENG +1

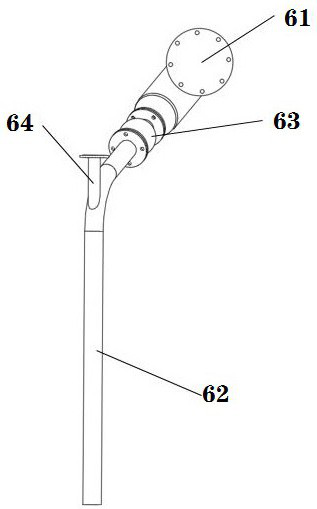

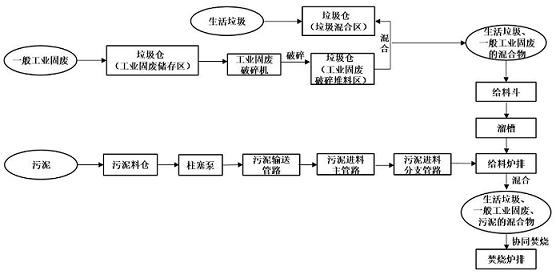

Feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge

PendingCN113339809AWell mixedAvoid uneven calorific valueIncinerator apparatusSludgeRefuse Disposals

The invention discloses a feeding system for collaborative incineration of household garbage, general industrial solid waste and sludge, and belongs to the technical field of garbage treatment. The feeding system comprises a garbage bin, a garbage grab bucket, a feeding hopper, a chute, a feeding fire grate, a sludge feeding pipeline and an incinerator fire grate, wherein the garbage grab bucket is arranged at the top of the garbage bin; the top of the feeding hopper is communicated with the garbage bin; the bottom of the feeding hopper is communicated with the chute; the feeding fire grate is arranged at the bottom of the chute; the sludge feeding pipeline is arranged above the feeding fire grate; an inlet of the incinerator fire grate is communicated with an outlet of the feeding fire grate; an industrial solid waste storage area, an industrial solid waste crushing area, an industrial solid waste crushing and stacking area and a garbage mixing area are sequentially arranged in the garbage bin; an industrial solid waste crusher is arranged in the industrial solid waste crushing area; and a sliding way is arranged at the bottom of the industrial solid waste crusher and used for conveying crushed general industrial solid waste to the industrial solid waste crushing and stacking area. According to the feeding system, the three wastes can be uniformly mixed, and stable combustion is promoted.

Owner:EVERBRIGHT ENVIRONMENTAL TECH CHINA CO LTD +2

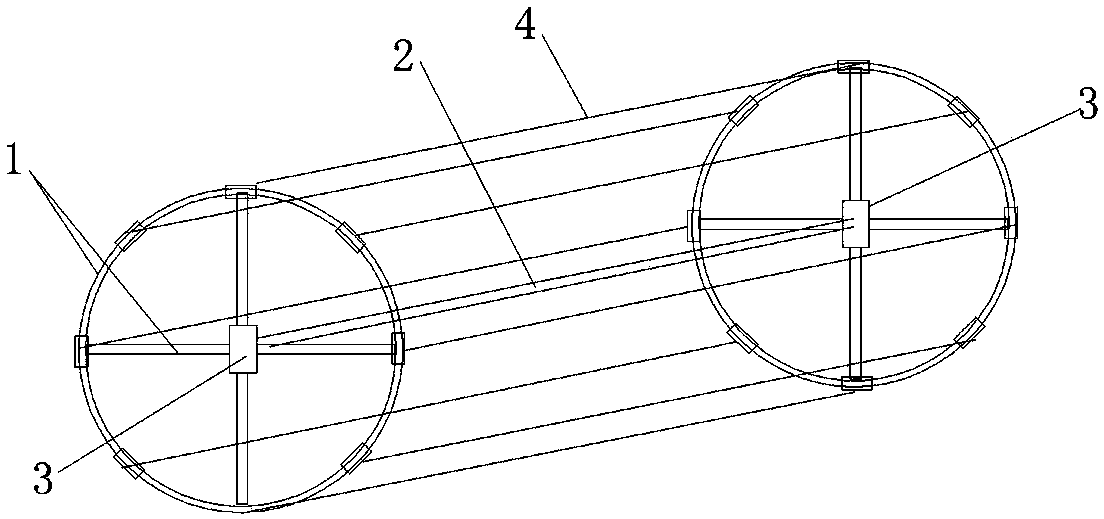

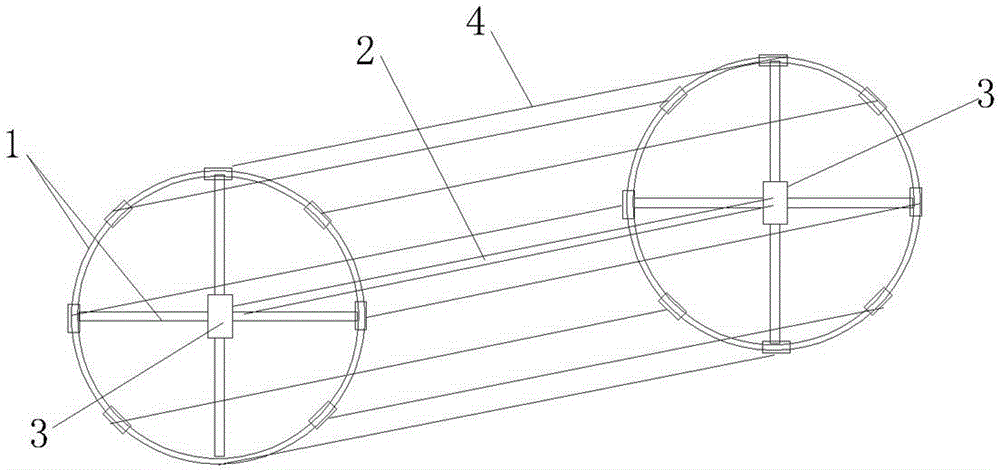

Flaxseed germination device

ActiveCN103797933AGermination does not affectInhibition of germinationGerminating apparatusSurface layerMotor drive

The invention discloses a flaxseed germination device, comprising a screen roller device, a support device, a drive device, a liquid tank and an environmentally controlled device, wherein the screen roller device comprises a roller bracket, a connecting shaft, a support end, a support rib and a screen ring; the support device comprises a support frame, a rotation shaft, a rotation wheel, a support arm, an open slot and a movable locking device; the drive device comprises a motor, a speed reducer and a belt; the motor drives the germination device to slowly rotate via the rotation wheel; an ethanol water solution is contained in the liquid tank; the overall germination device is arranged inside the environmentally controlled device; a 10-100-mesh net is adopted as the screen; the ethanol concentration of the water solution is 6.5-17.5%; slow rotation indicates that the rotation speed of the germination device is 0.2-5 r / min. The device disclosed by the invention is simple in structure and convenient to operate, a continuous operation can be carried out, and the problem that the germination product cannot be produced on a large scale due to sticky ingredients such as a lot of flax gum contained in the surface layer of the flaxseed is solved.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

Storing and discharging device used for chemical powder materials

InactiveCN106865263ASolve the sticky wall problemEvenly distributedConveyorsLoading/unloadingCompound (substance)Caking

The invention relates to a powder material bin, in particular to a storing and discharging device used for chemical powder materials. The storing and discharging device used for the chemical powder materials comprises a main stock bin; gas disks are arranged around the main stock bin; the bottom of the main stock bin is connected with a stirring bin through a pipeline provided with a valve; a stirring spiral is installed in the stirring bin; the position of an outlet of the stirring bin is movably connected with a discharging bin; a vibration motor is connected to one side of the discharging bin; and a discharging port is formed in the bottom of the discharging bin. According to the storing and discharging device used for the chemical powder materials, after entering the main stock bin, the chemical powder materials gradually move to the bottom of the main stock bin, the chemical powder materials move downwards through the main stock bin by means of the gas disks arranged around the main stock bin, the problem that the chemical powder materials adhere to the wall is solved, the chemical powder materials can be distributed uniformly through the spiral stirring bin, the problems that caking is caused and the weighing error is large are solved, discharging is smoother through a vibration bin at the lower end of the main stock bin, the structure is simple, using is convenient, and practicability is high.

Owner:钟年伟

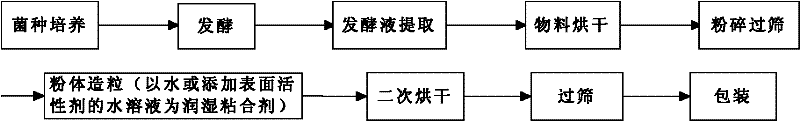

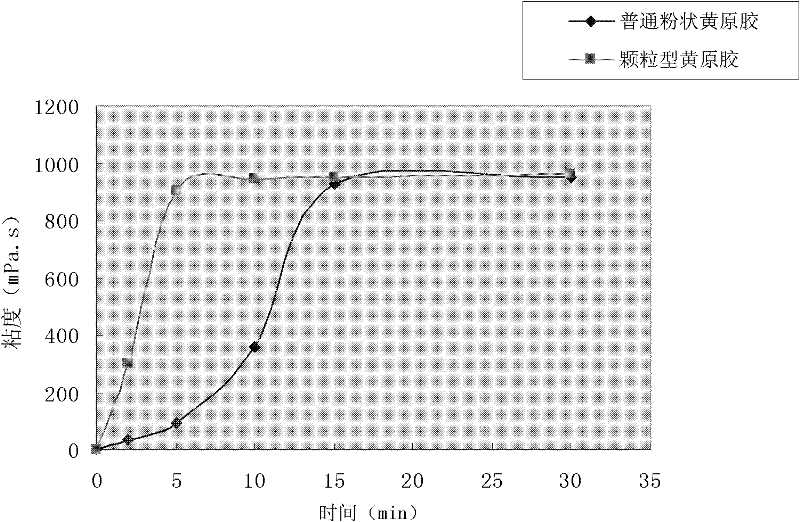

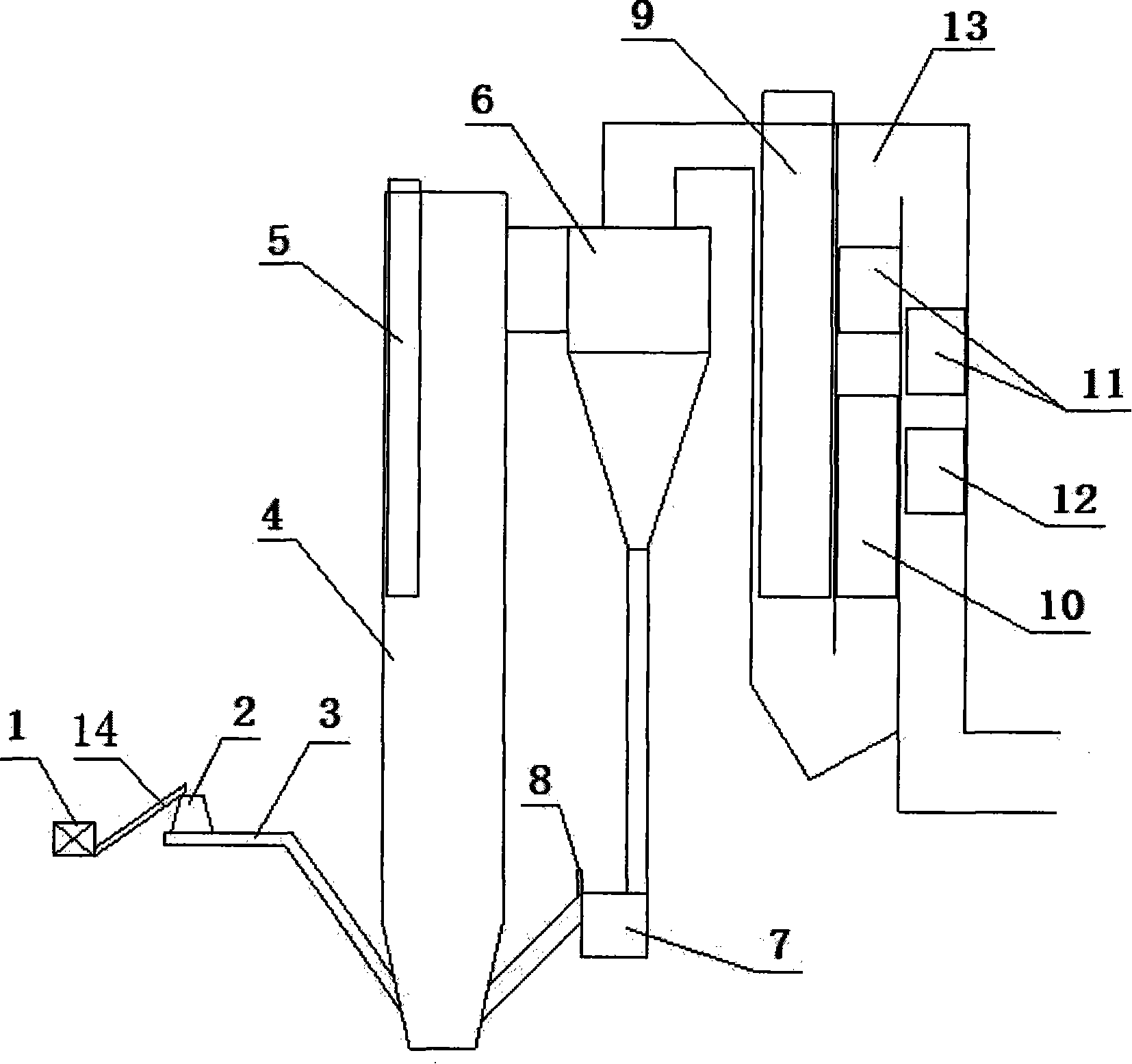

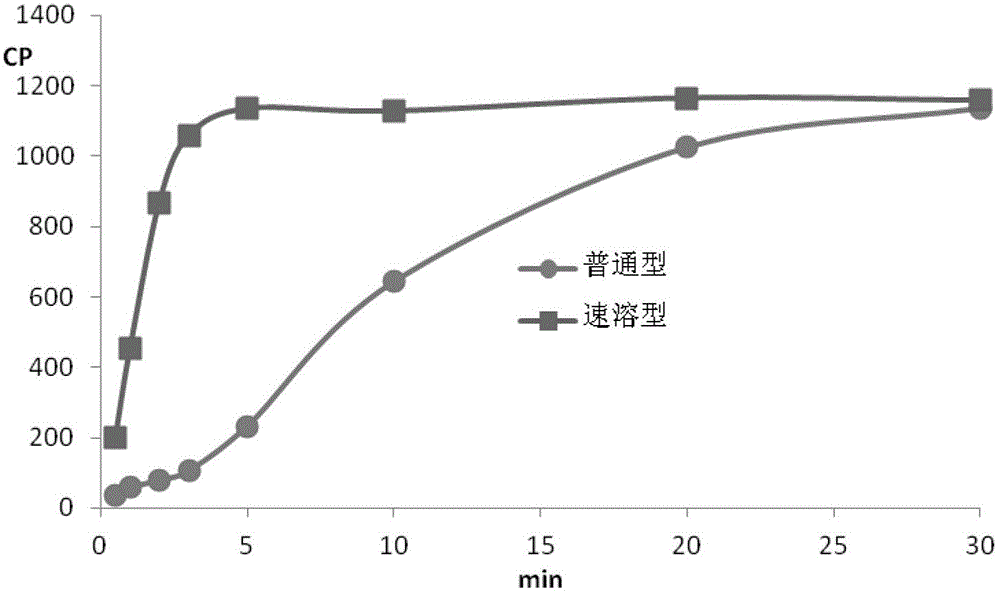

Preparation method for granular type xanthan gum

ActiveCN102219912BLarge specific surface areaGood dispersionPharmaceutical non-active ingredientsFood preparationProcess engineeringXanthan gum

The invention relates to a preparation method for granular type xanthan gum, belonging to the field of preparing glucose residue-containing compound. The preparation method is characterized by taking xanthan gum powder as starting raw materials, adopting a boiling granulation drying device to prepare the granular type xanthan gum, and comprises the following steps of 1.discharging of xanthan gum powder; 2. introduction of hot air; 3. spraying of atomized water; 4. boiling granulation; 5. secondary drying; 6. screening; and 7. quality inspection, and finally packaging for storage after qualification. The invention provides a preparation method for granular type xanthan gum with large specific area and high porosity. The prepared granular type xanthan gum substitutes powder products sellingon the market, and solves the problems that the powder xanthan gum in the prior art is slowly dissolved, and blocked during dissolving process and has dust pollution. The preparation method is applicable for granulation and processing of unpackaged powder after crushing and screening during production process of xanthan gum powder production devices, as well as granulation and processing xanthan gum powder used in market sauce seasoning, soup bases, drinks, food, drug industry and petroleum industry.

Owner:ORDOS ZHONGXUAN BIOCHEM

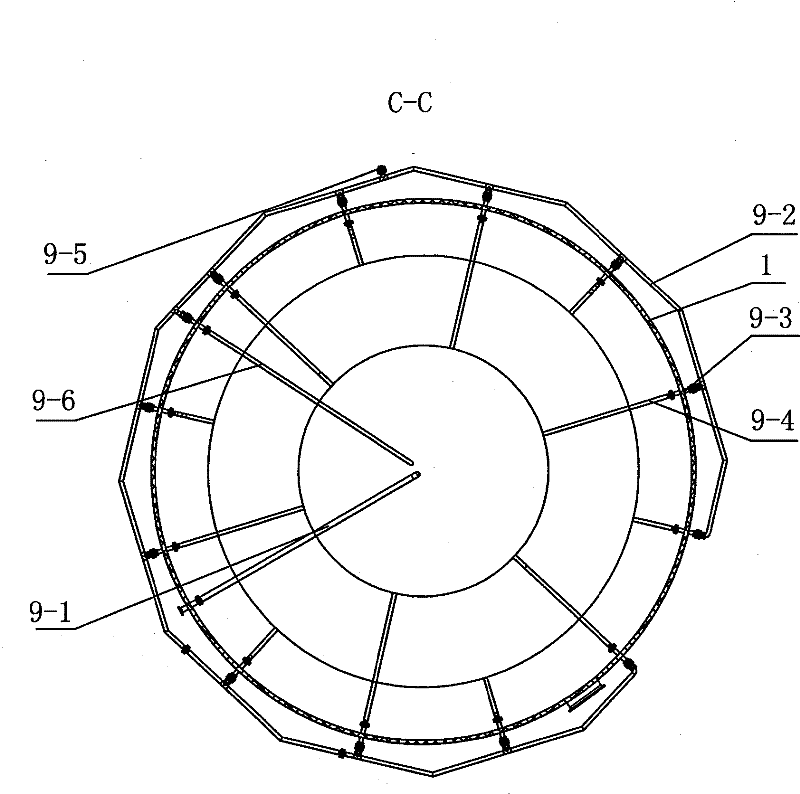

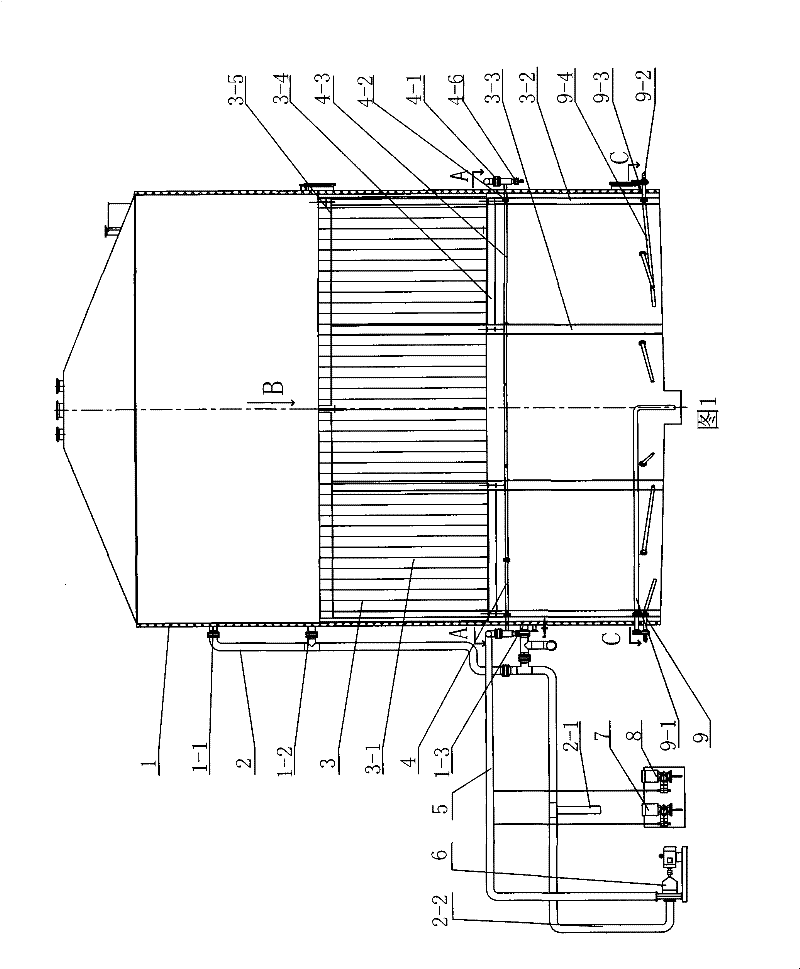

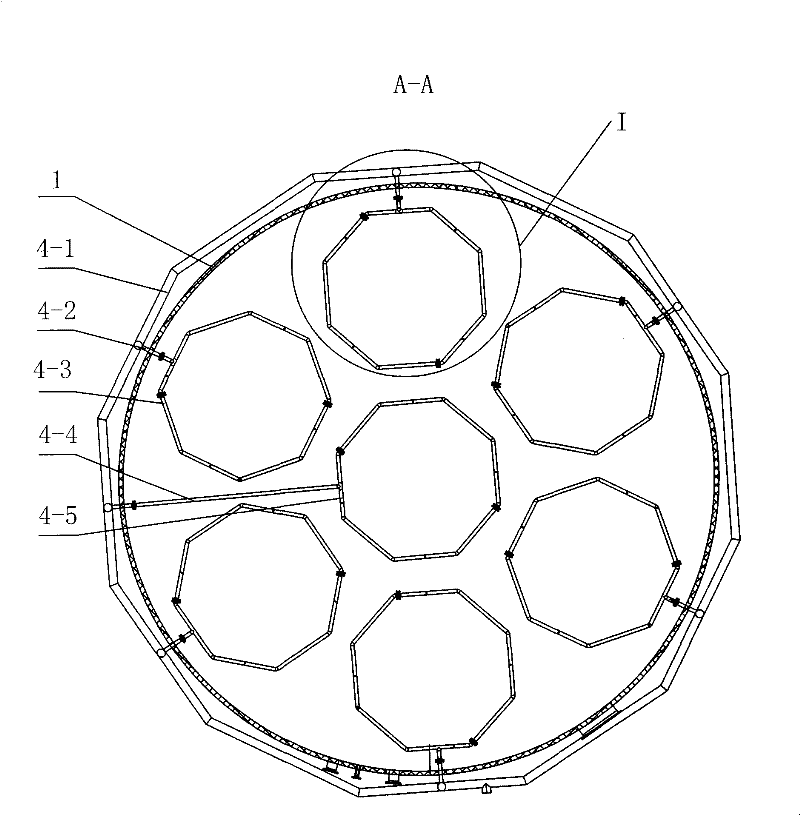

Anaerobic reactor

ActiveCN101497476BSolve easy blockageReduce foulingTreatment with anaerobic digestion processesAnaerobic reactorCirculating pump

The invention relates to an anaerobic reactor. The anaerobic reactor comprises a cylinder body, a water inlet pipe, a water outlet pipe, a filling device on the middle part of the water outlet pipe, a water distribution device at the bottom of the filling device and a sludge discharge device at the bottom of the water distribution device; the water distribution device comprises a water distribution main pipe and more than four closed annular water distribution branch pipes; water outlet holes of the water distribution branch pipes are alternately arranged along more than three concentric circumferences; the cylinder body is positioned on the upper part of the filling device; the lower part of each water distribution branch pipe is provided with more than two water outlets; the water outlets are connected with the water outlet pipe; a reflowing pipe of the water outlet pipe is mixed with the water inlet pipe by a circulating pump and is communicated with the water distribution main pipe; a first medicating device and a second medicating device are communicated with the water inlet pipe respectively through connecting pipes; the filling device comprises a filling rack, a membrane hanging rack and a zonal biomembrane strip; the biomembrane strip is hung on the membrane hanging rack; and the sludge discharge device comprises a sludge discharge main pipe and six sludge discharge branch pipes arranged in length alternation along radial direction. The anaerobic reactor has the characteristics of reasonable water distribution, compact structure and stable operation of the reactor.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

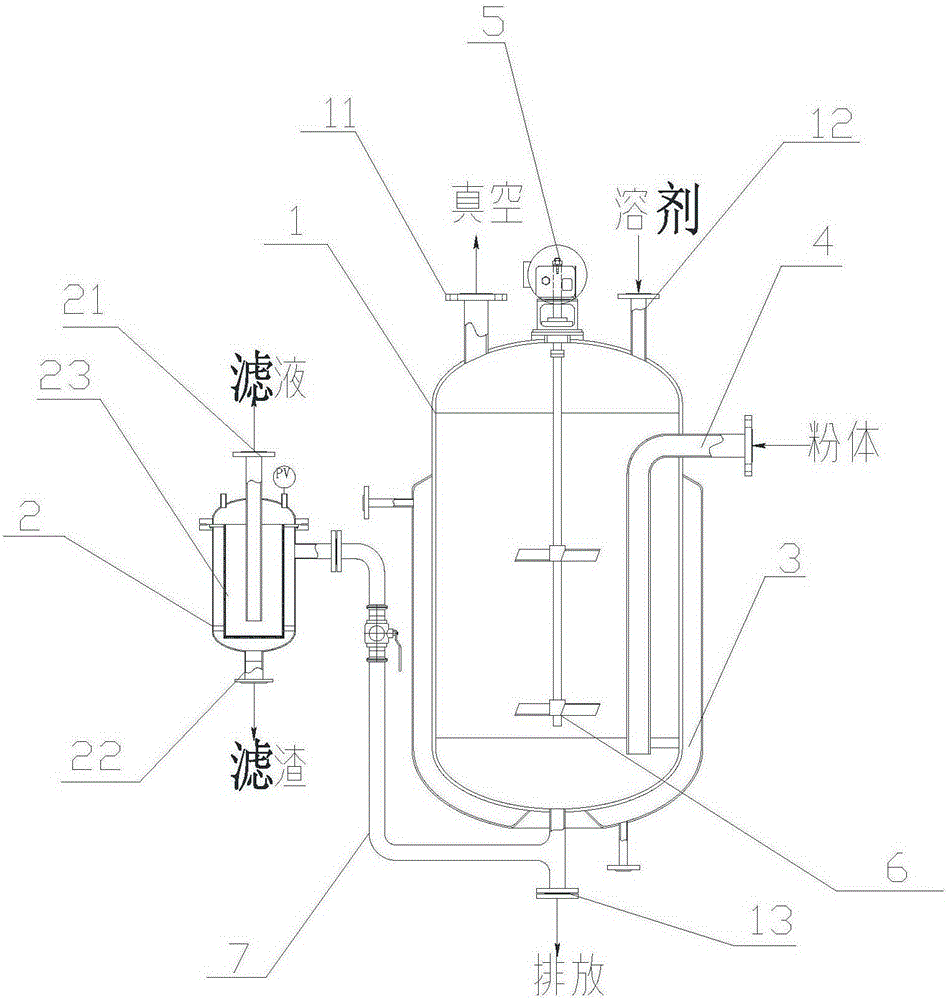

Cosmetic powder pretreatment device and pretreatment method

InactiveCN105311986AImprove accuracyProtect healthRotary stirring mixersMixer accessoriesSolventPre treatment

The invention provides a cosmetic powder pretreatment device and pretreatment method. The device comprises a stirring tank and a filtering tank which are communicated with each other through a communicating pipe, the outer side wall of the stirring tank is sleeved with a clamping sleeve, a powder feed pipe is arranged on the clamping sleeve in a penetrating mode, and the powder feed pipe extends to the bottom of the stirring tank. The method comprises the following steps that solvent is added through a solvent feed hole, and the liquid level of the solvent is not lower than the lowest point of the powder feed pipe extending into the stirring tank; the vacuum degree is regulated, and the powder is pumped into the stirring tank through the powder feed pipe; a stirring motor is started, stirring and mixing are conducted through stirring paddles, and initial feed liquid is obtained; the initial feed liquid is conveyed into the filtering tank through the communicating pipe, by means of filtration of a filtration medium, supernate flows out through a mixed liquor outlet and is collected, and waste residues are discharged through a residue discharge port. The cosmetic powder pretreatment device and pretreatment method have the advantages that the accuracy of feeding is improved, environmental protection is achieved, the health of operating personnel is protected, and the caking problem is solved.

Owner:SHANGHAI FOREST CABIN BIOLOGICAL TECH

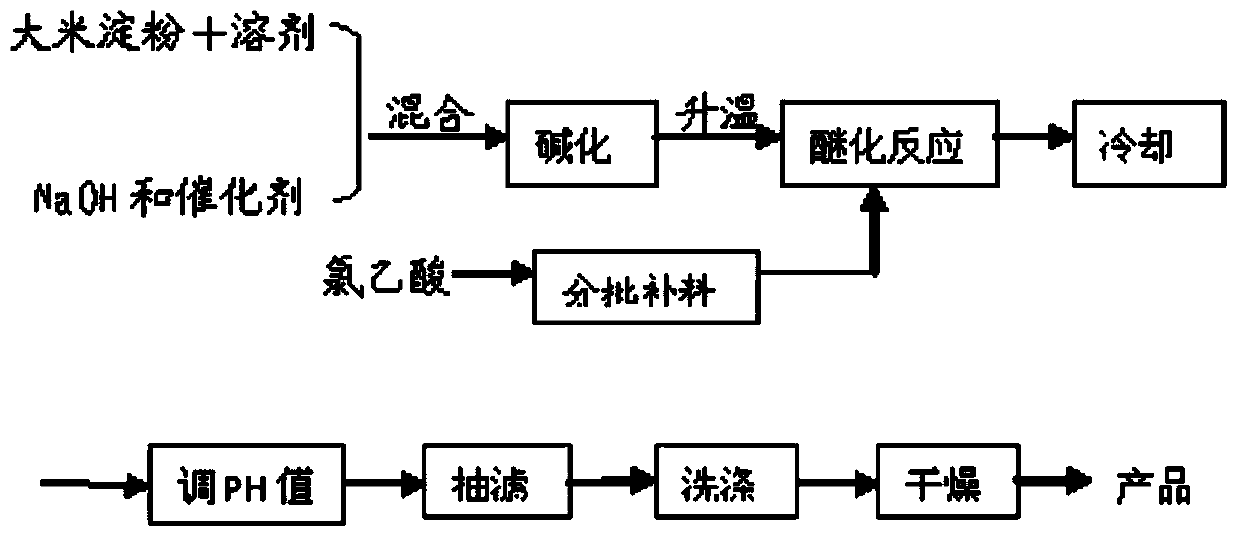

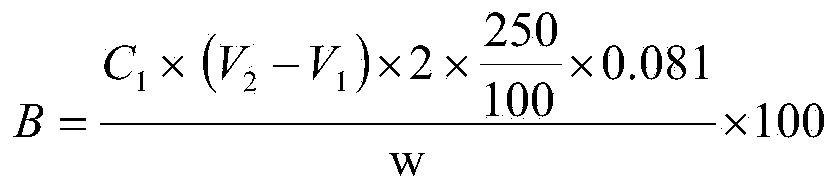

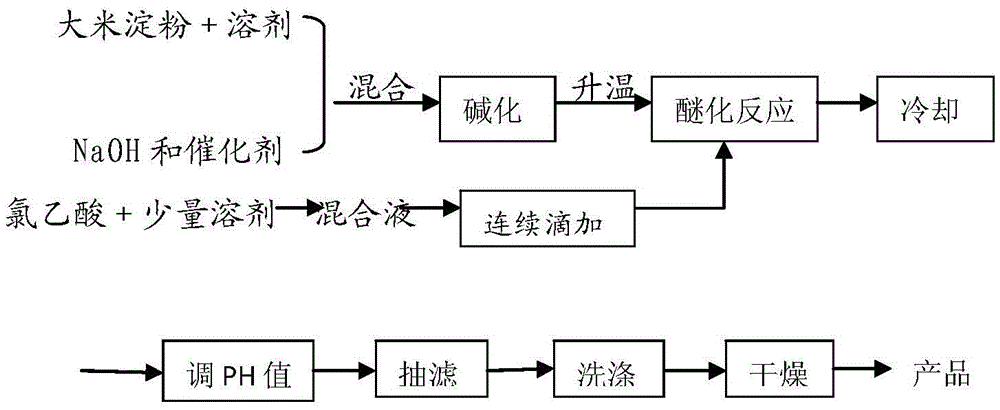

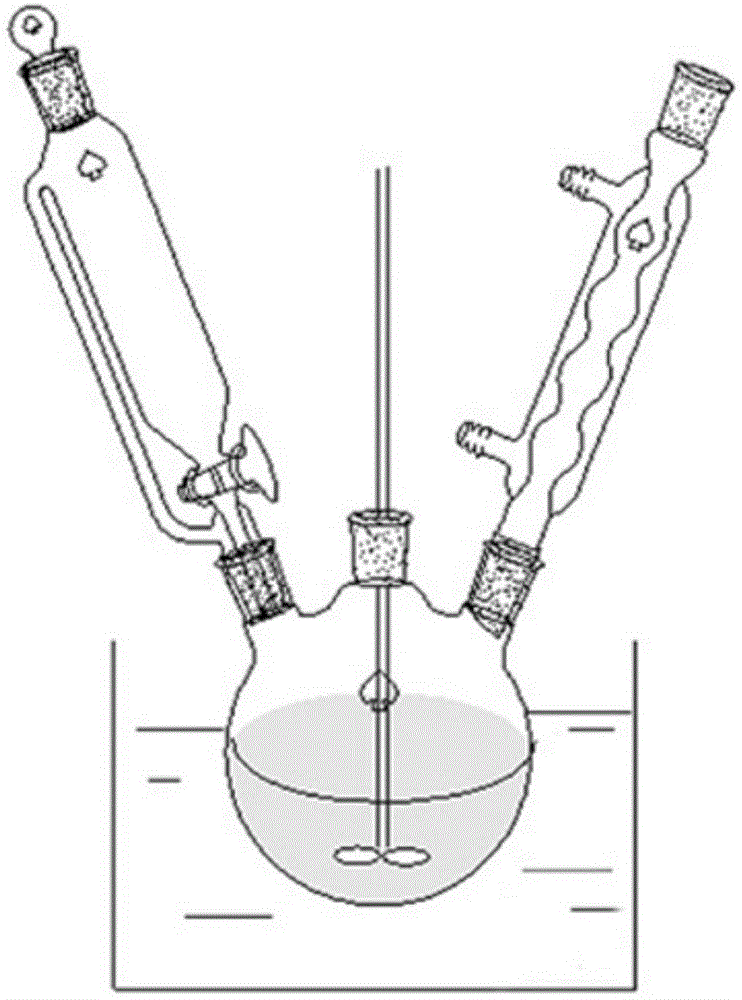

Method for preparing carboxymethyl rice starch via intermittent feeding method

The invention relates to a method for preparing carboxymethyl rice starch via an intermittent feeding method. The method comprises the following steps: adding NaOH and a catalyst into rice starch, dissolving the starch with an isopropyl alcohol solution and fully stirring to alkalify the starch; adding chloroacetic acid multiple times to etherify the starch, maintaining system alkalinity, stirring, cooling after the reaction, regulating a pH value, carrying out suction filtration, cleanly rinsing filter residues with ethanol, drying and screening. In the etherifying process of the rice starch prepared via a dissolvant method, the chloroacetic acid is intermittently added in batches, and the stirring speed is regulated during a reaction process to maintain the alkaline environment of the reaction system, so that the operation that the reactant chloroacetic acid is added by one step is avoided, and thus the stability of the reaction system is improved and the normal running of the reaction is ensured. Therefore, the problem of caking caused by overquick increasing of viscosity in the reaction process is effectively solved, and the degree of substitution (DS) of the prepared carboxymethyl starch can reach above 0.7. The method is simple, easy, feasible and stable in reaction, and guarantees high DS of the carboxymethyl starch.

Owner:无锡市善源生物科技有限公司

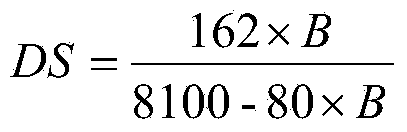

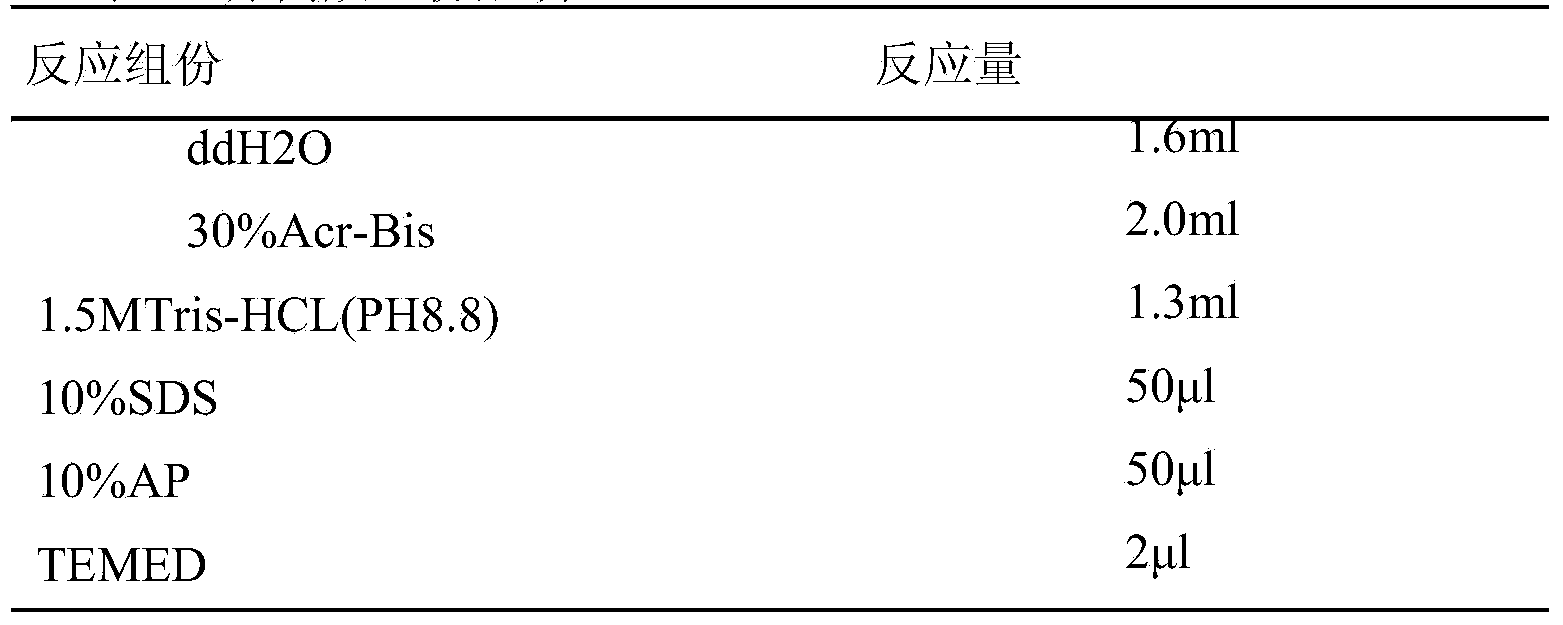

Preparation method of periodic Wuchereria malayi compound polyvalent protein vaccine

InactiveCN103834687ASolve the clumpingBeat evenlyAntiparasitic agentsAntibody medical ingredientsEukaryotic plasmidsMolecular level

The invention discloses a preparation method of a periodic Wuchereria malayi compound polyvalent protein vaccine. The preparation method comprises the steps of extraction of recombinant plasmids of the periodic Wuchereria malayi pcDNA3.1(+)-BmCPI / BmGAPDH, gene transfection, screening of positive clones, extraction and enlarge cultivation of the positive clones, cryopreservation of the positive clones, detection of the positive clones, extraction of cell total RNA (Ribose Nucleic Acid), molecular level detection of expression of the recombinant plasmids in cells, protein level detection of expression of the recombinant plasmids in cells, SDS-PAGE (Sodium Dodecyl Sulfate-Polyacrylamide Gel Electrophoresis) analysis of expression products, extraction and purification of periodic Wuchereria malayi recombinant protein, and the like. The preparation method is simple and convenient, and good in effect.

Owner:NANTONG UNIVERSITY

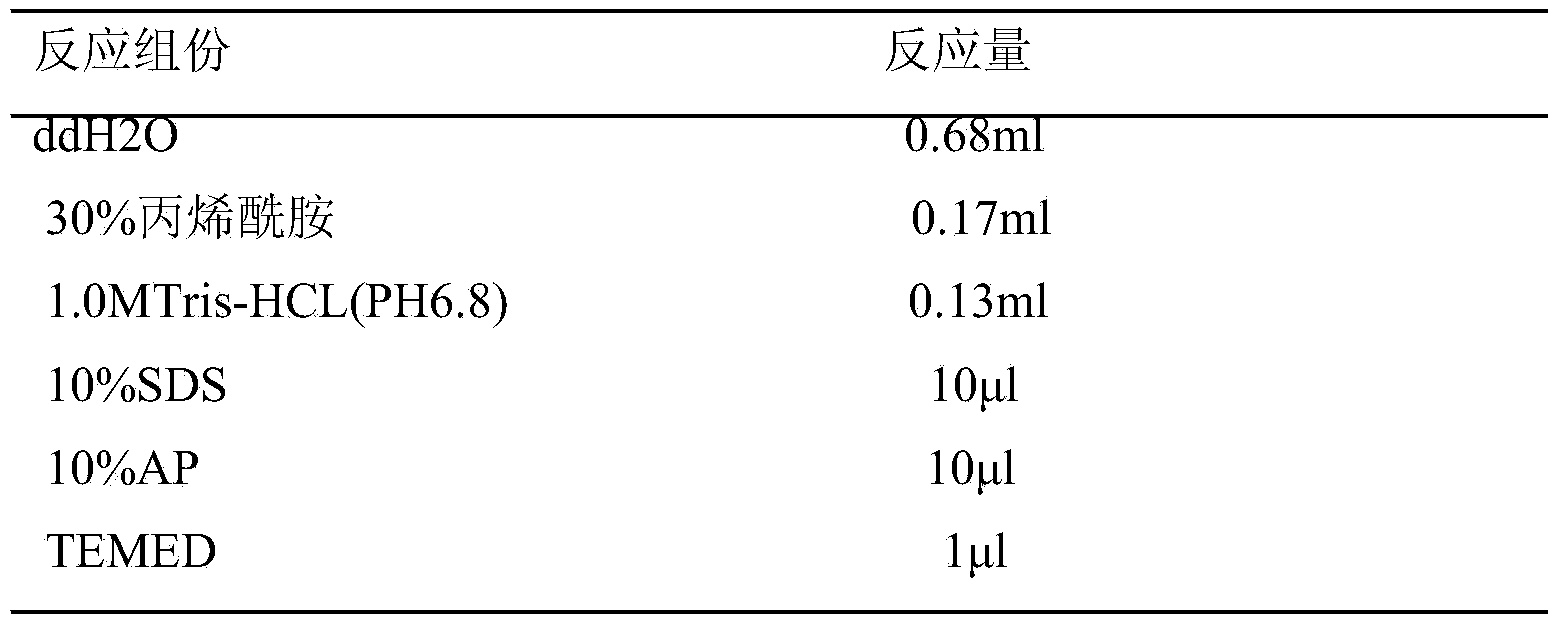

A comprehensive recovery process for selectively and efficiently extracting copper from lead matte

ActiveCN104789783BNo pollution to the environmentNo pollution in the processPhotography auxillary processesProcess efficiency improvementElectrolytic agentLead(II) sulfate

The invention discloses a process for selective efficient copper extraction and comprehensive recovery from lead copper matte and belongs to the field of wet processes of non-ferrous metal metallurgy. According to the process disclosed by the invention, the lead copper matte is taken as a raw material, and the process comprises the following steps: crushing, grinding and screening the lead copper matte, performing pulp conditioning on the lead copper matte after screening and sulfuric acid (or a waste electrolyte), then pouring into a high-pressure kettle, performing leaching, adding an adjusting agent A and introducing pure oxygen; controlling technical conditions, oxidizing sulfur in the lead copper matte to elemental sulfur in the oxidization and leaching processes, and transferring into slag; oxidizing copper to enable the copper to enter a solution in the form of copper ions and enabling lead to leave in the slag in the form of lead sulfate with gold and silver; and enabling most of iron to enter into the slag in the forms of hematite and yellow calcium iron vitriol under high-temperature, high-pressure and high-acid conditions. After the completion of the leaching process, liquid-solid separation is performed to realize primary separation of the copper and other valuable elements; after acid adjustment of a leachate, cyclone electrolysis is directly performed to extract the copper in the leachate, and then a cathode copper product which is in line with a national standard can be obtained; and leaching residues are sent into a lead pyrometallurgy system for comprehensively recovering Pb, Ag, Au and other valuable elements.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

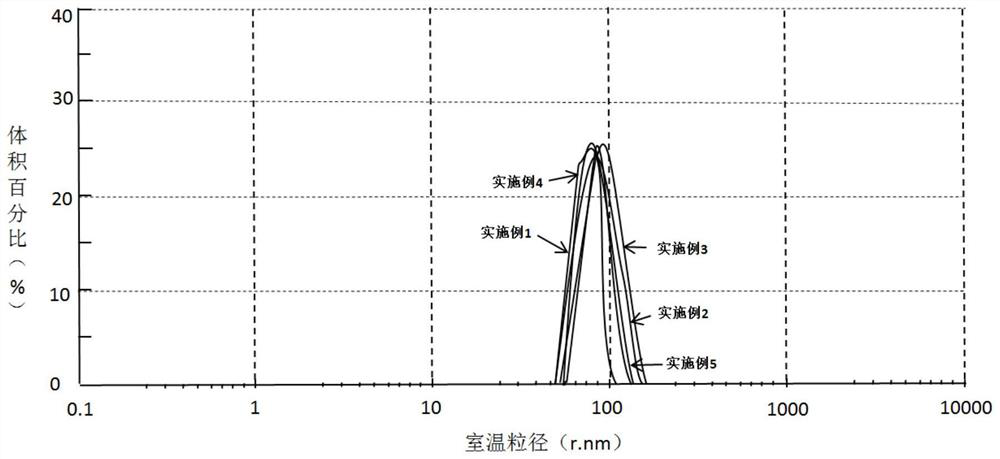

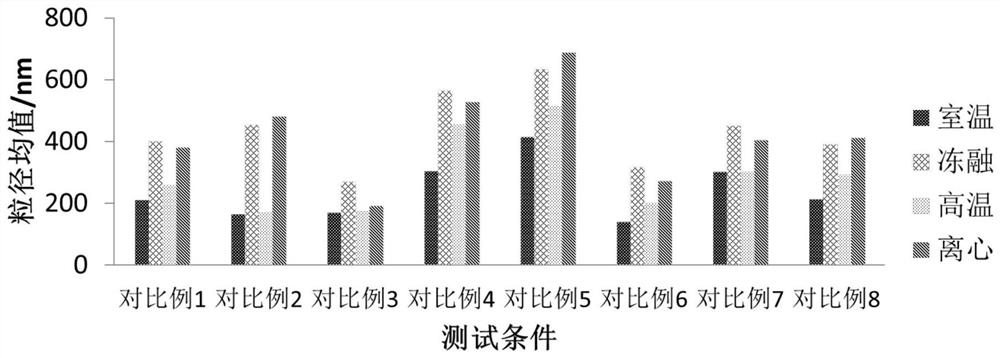

Glazing care emulsion and preparation method thereof

ActiveCN110408325ASolve the Stability ConundrumGood emulsificationAqueous dispersionsAdditive ingredientStearate

The invention discloses a glazing care emulsion and a preparation method thereof, and relates to the technical field of glazing care agents. The glazing care emulsion is prepared from, by mass, 10-25%of a liquid glazing agent, 0.5-5% of an emulsifying agent and 0.01-0.15% of a chelating agent; the emulsifying agent is formed by compounding polyglyceryl-2 isostearate, liquid C10-13 isomeric alcohol ethoxylates, oleic acid and triethanolamine, and the mass ratio of the polyglyceryl-2 isostearate to the liquid C10-13 isomeric alcohol ethoxylates to the oleic acid to the triethanolamine is (1-22.5):(1.5-25):(1-5):(0.5-2.5). The ingredients of the glazing care emulsion is in a liquid state at the room temperature, thereby solving the problem that caking or trace leaving occurs on the applyingsurface due to the fact that solid raw materials are applied unevenly; in addition, in the normal-temperature preparation process of the glazing care emulsion, heating and cooling are not needed, theprocess is simple, and the energy consumption is low.

Owner:广州超威生物科技有限公司

Flaxseed germination device

ActiveCN103797933BGermination does not affectInhibition of germinationGerminating apparatusSurface layerMotor drive

The invention discloses a flaxseed germination device, comprising a screen roller device, a support device, a drive device, a liquid tank and an environmentally controlled device, wherein the screen roller device comprises a roller bracket, a connecting shaft, a support end, a support rib and a screen ring; the support device comprises a support frame, a rotation shaft, a rotation wheel, a support arm, an open slot and a movable locking device; the drive device comprises a motor, a speed reducer and a belt; the motor drives the germination device to slowly rotate via the rotation wheel; an ethanol water solution is contained in the liquid tank; the overall germination device is arranged inside the environmentally controlled device; a 10-100-mesh net is adopted as the screen; the ethanol concentration of the water solution is 6.5-17.5%; slow rotation indicates that the rotation speed of the germination device is 0.2-5 r / min. The device disclosed by the invention is simple in structure and convenient to operate, a continuous operation can be carried out, and the problem that the germination product cannot be produced on a large scale due to sticky ingredients such as a lot of flax gum contained in the surface layer of the flaxseed is solved.

Owner:RES INST OF AGRO PROD PROCESSING SHANXI ACADEMY OF AGRI SCI

A method for preparing carboxymethyl rice starch by continuous feed method

The invention discloses a method for preparing carboxymethyl rice starch by virtue of a continuous supplementing method. The method comprises the following steps: adding NaOH and a catalyst to alkalify starch by taking rice starch as a raw material and an isopropanol solution as a reaction medium, continuously dropwise adding a mixed isopropanol solution doped with a certain amount of chloroacetic acid with certain time, keeping the alkaline environment of a system in an etherification process, regulating the stirring speed depending on the circumstances, and controlling reaction temperature and time; after reaction is finished, cooling, regulating the pH value, carrying out suction filtration, washing, drying to constant weight, and screening. The method disclosed by the invention substitutes the measures of dropping the chloroacetic acid dissolved in isopropanol in a continuous supplementing way in the etherification process of the rich starch and regulating the stirring speed and keeping the alkaline environment of the reaction system in a reaction process for the measure of adding the reactant chloroacetic acid for one time, thereby improving the stability of the reaction system, ensuring that the normal progress of the reaction and effectively solving the problem of conglomeration caused due to excessively fast viscosity increase in the reaction process; the prepared carboxymethyl starch can achieve the maximal DS (Degree of Substitution) of 0.76.

Owner:广西利佰兴食品集团有限公司

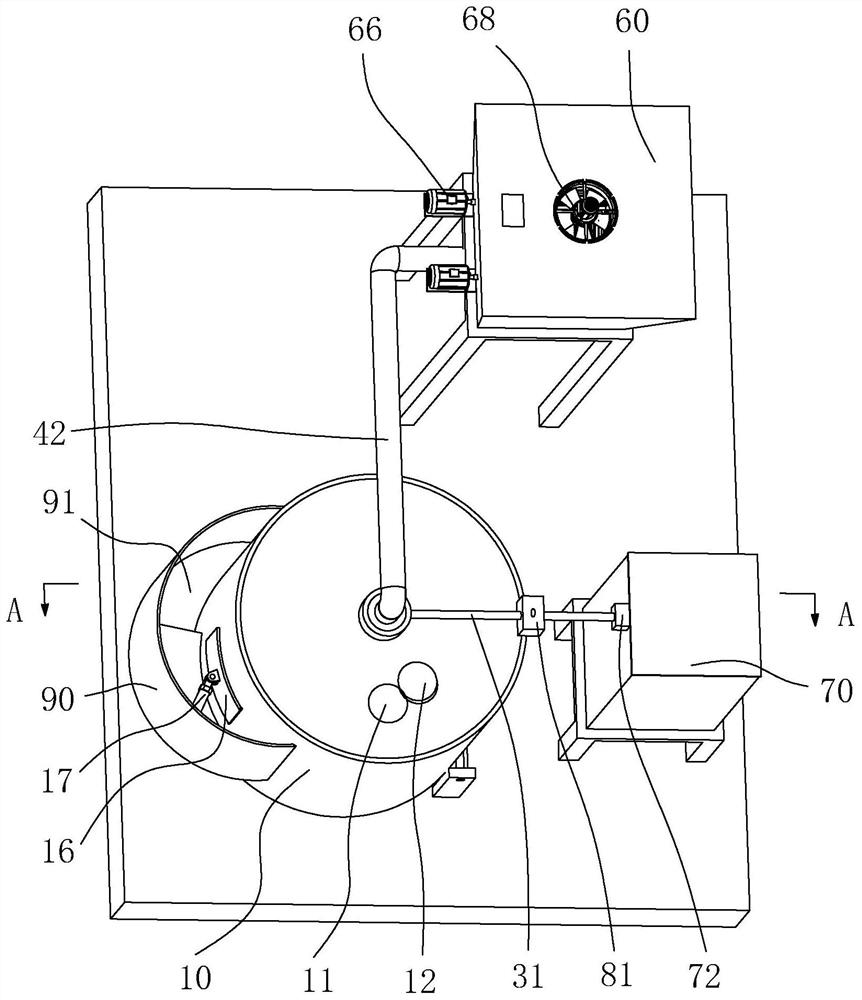

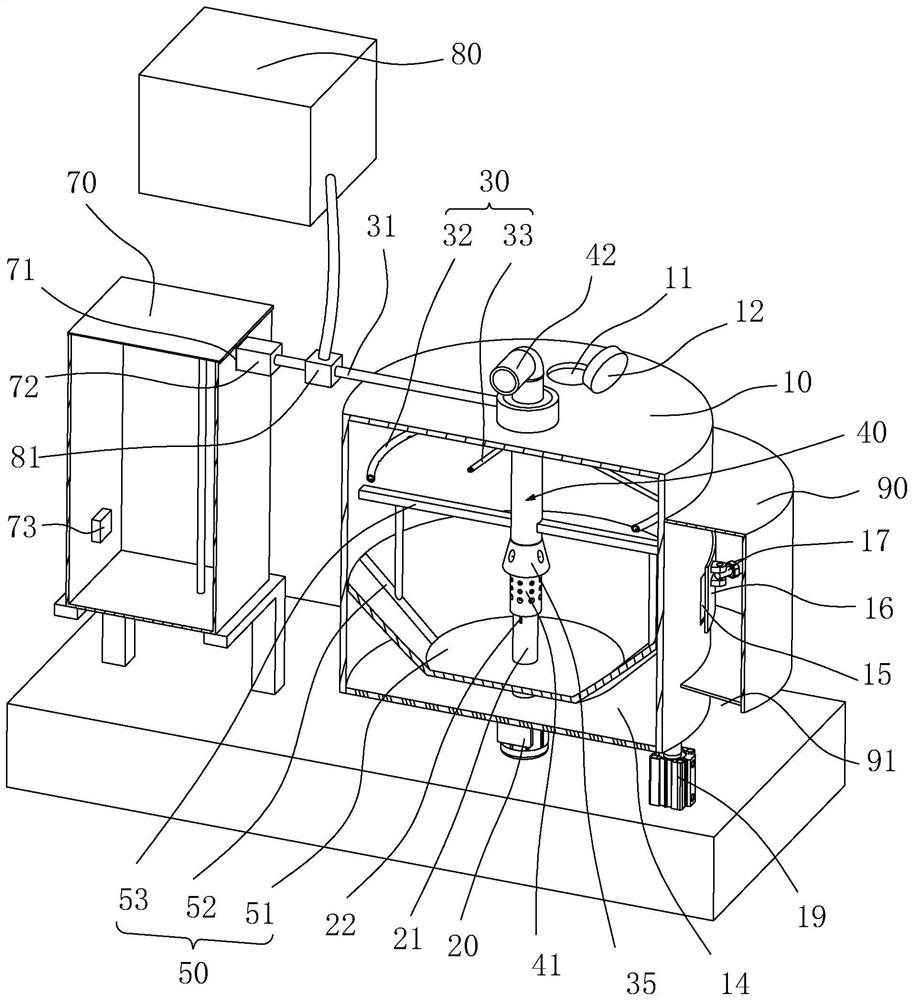

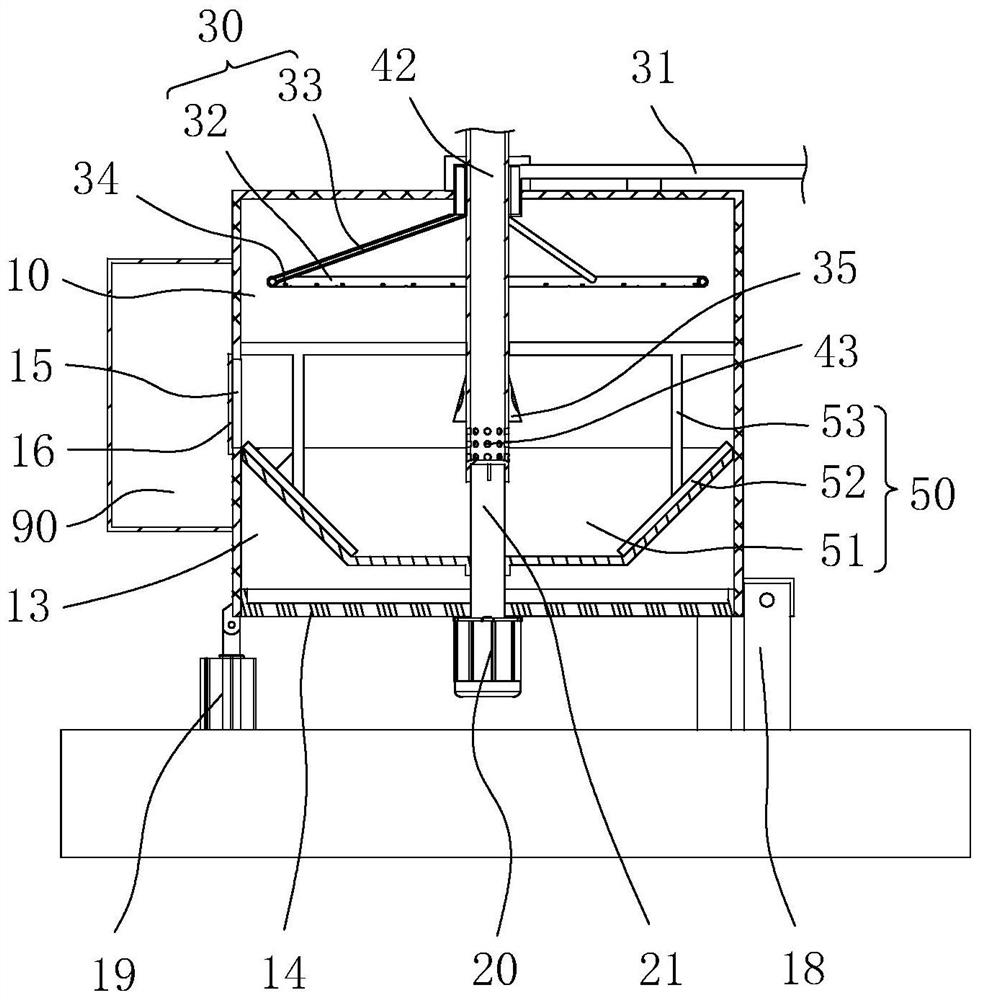

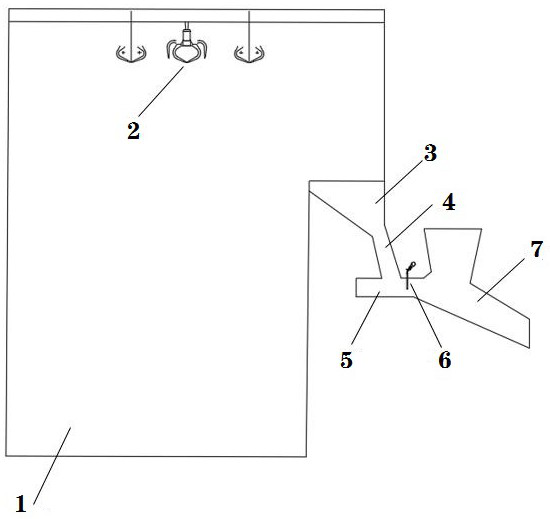

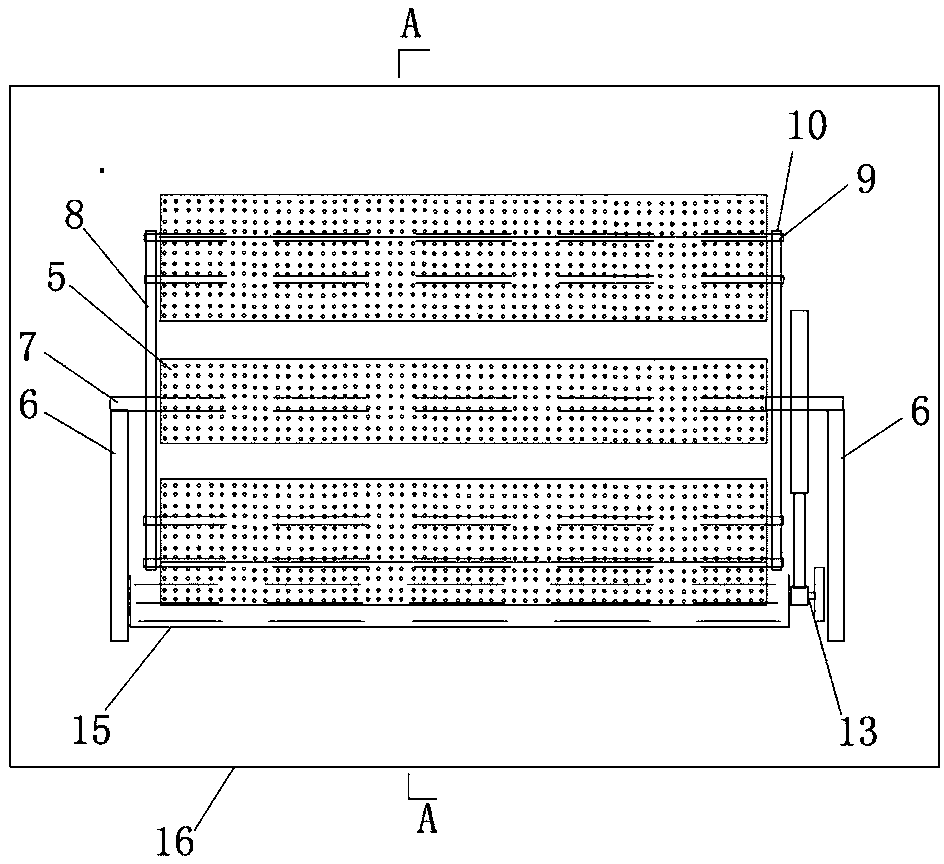

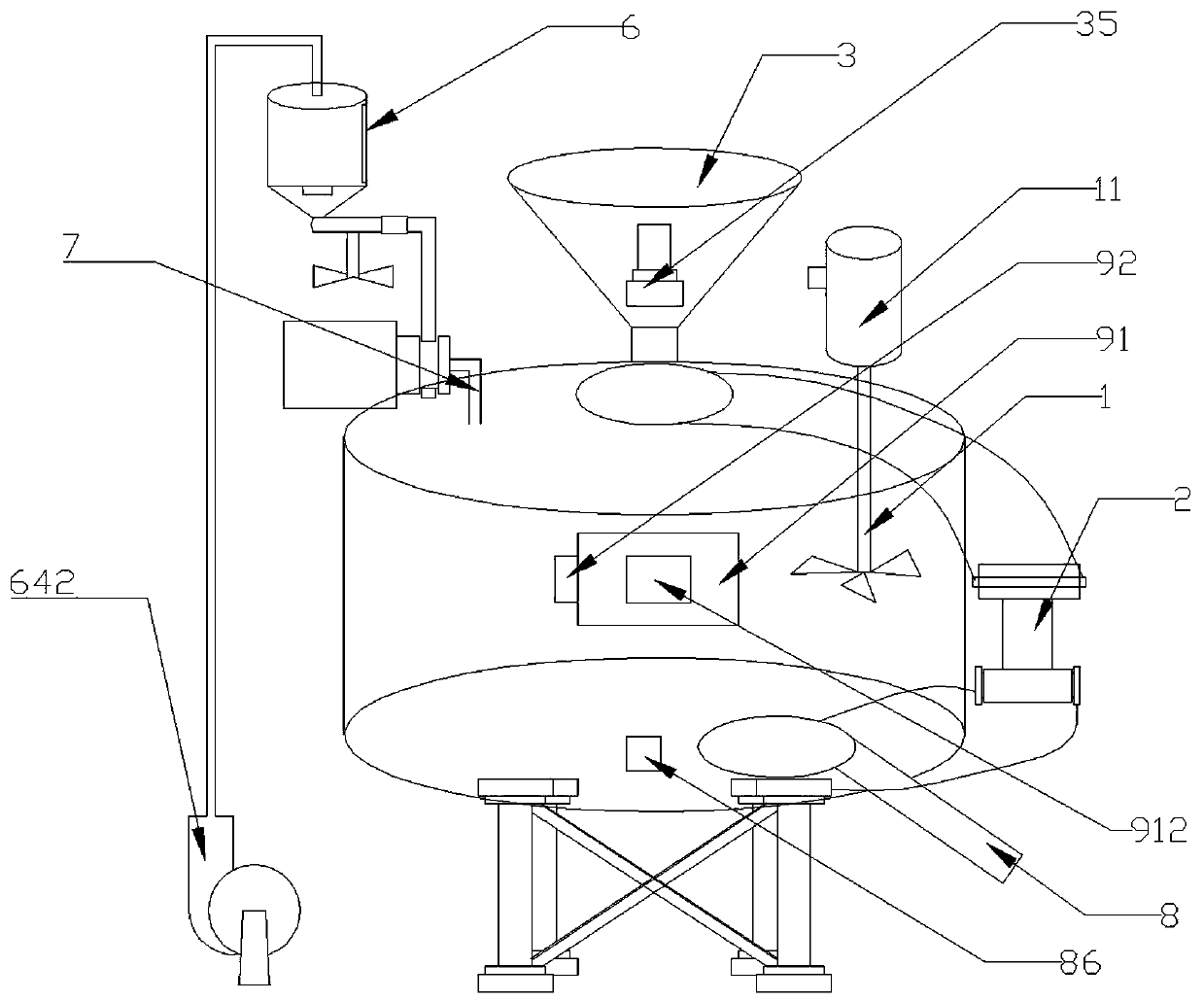

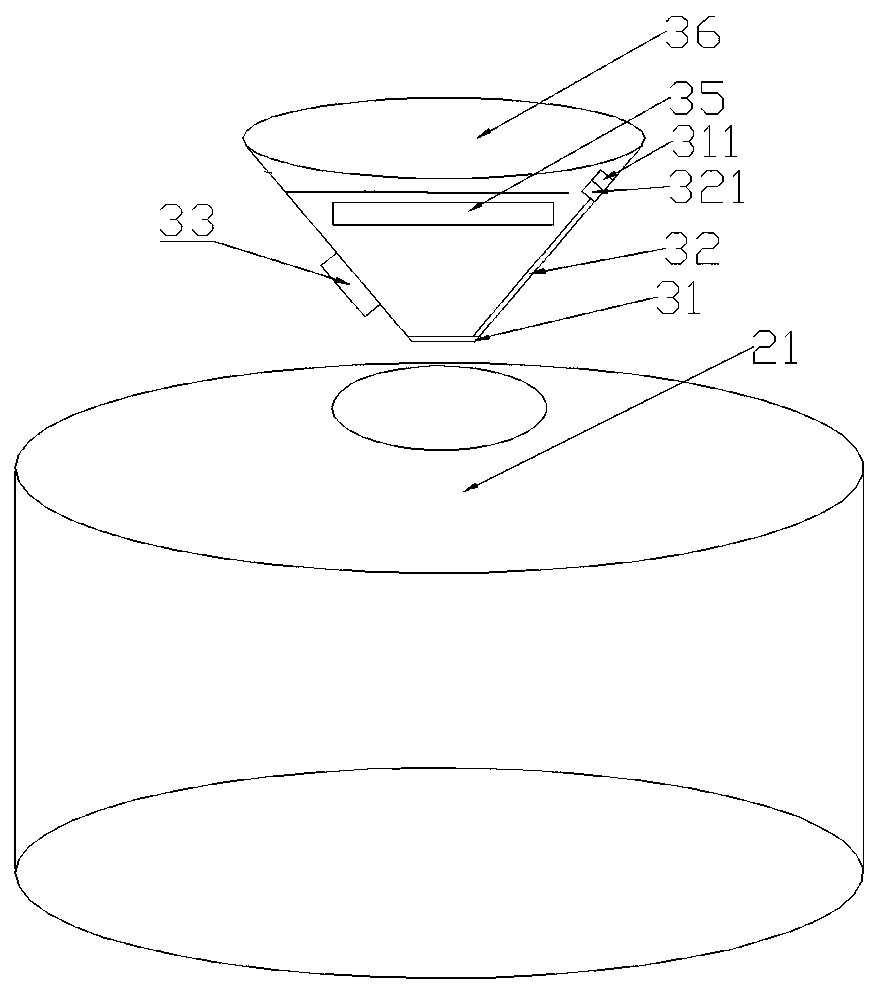

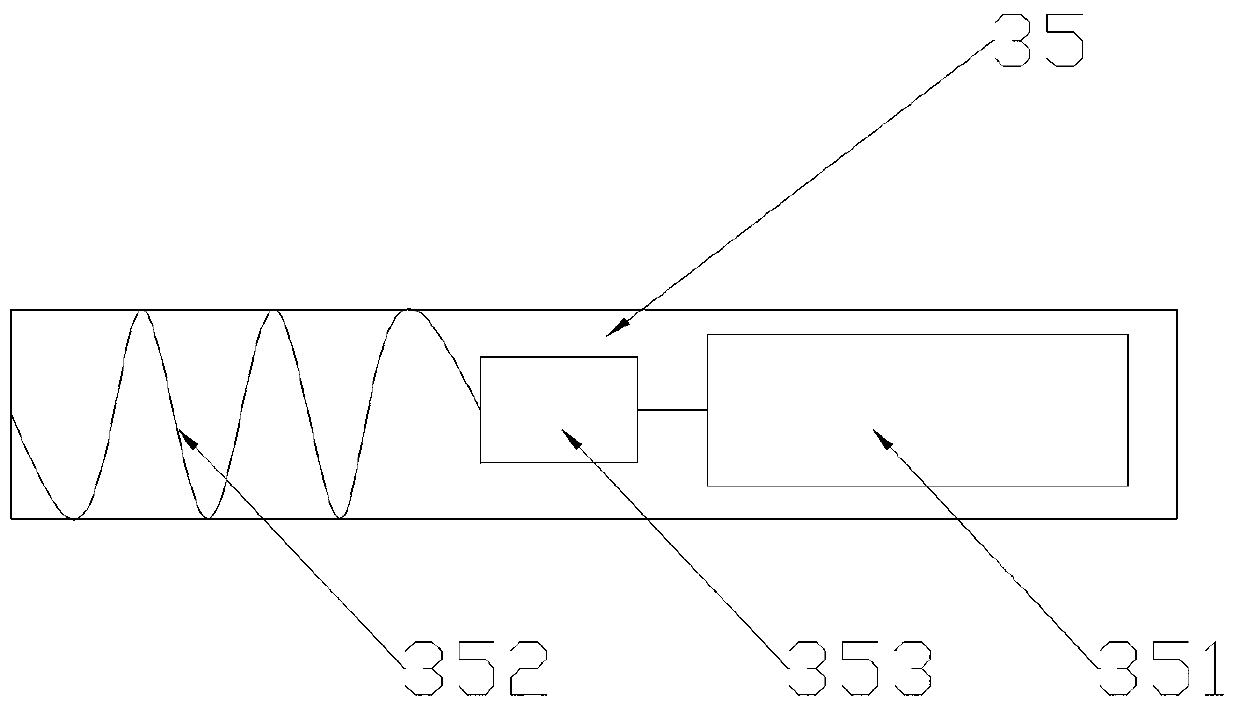

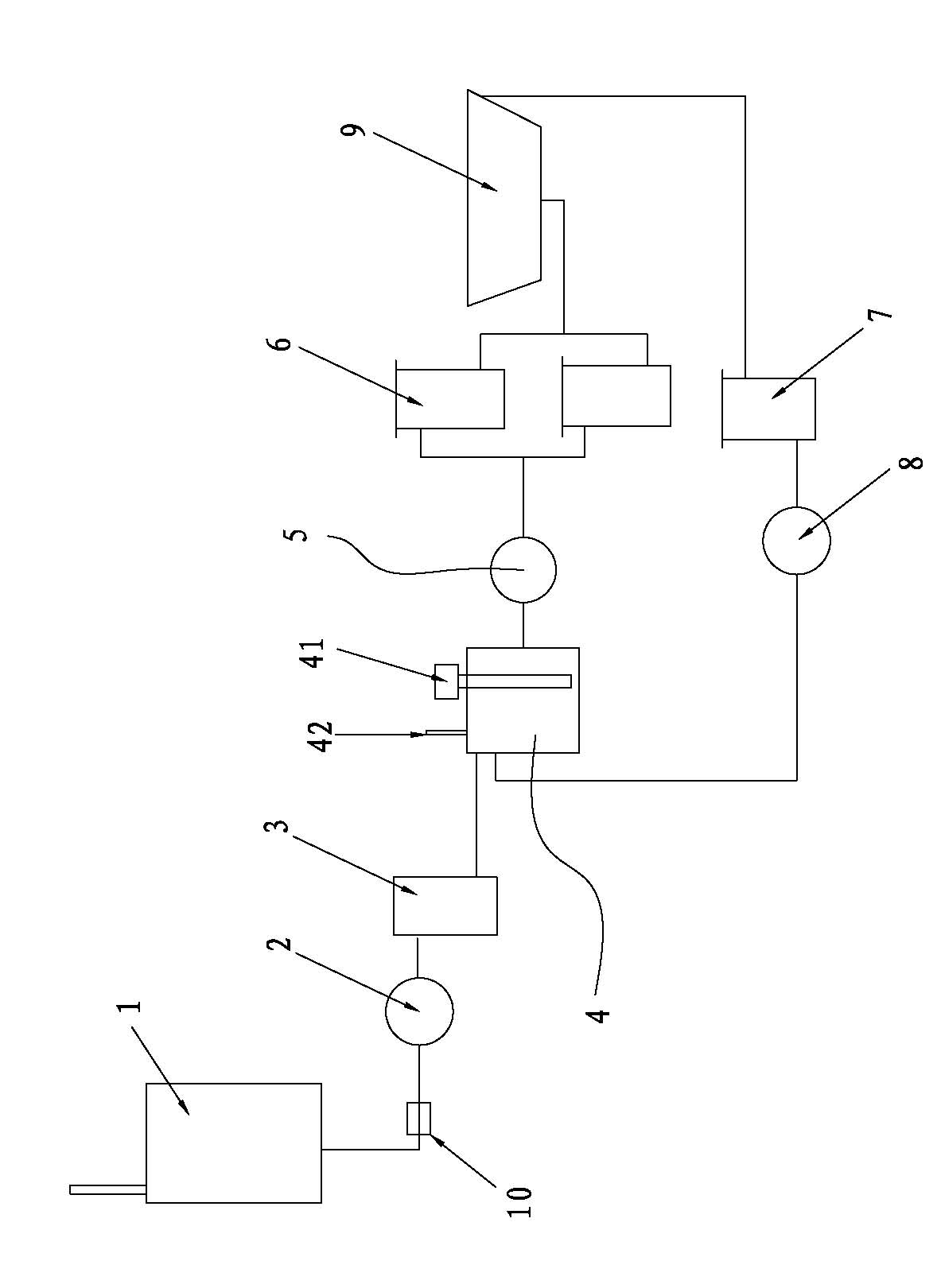

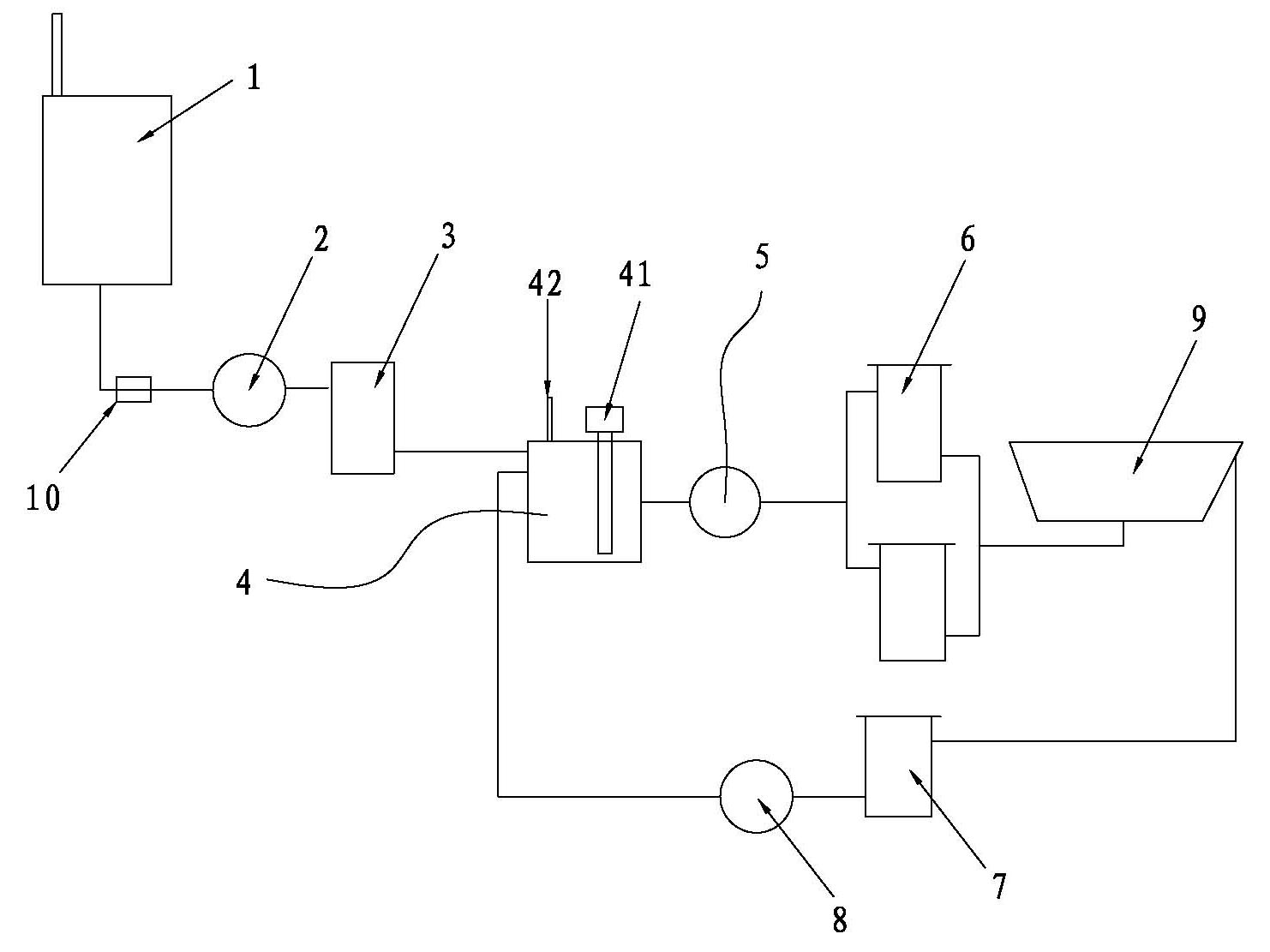

Reactive powder concrete intelligent stirring system

PendingCN110666978AQuality assuranceSolve the clumpingDispersed particle filtrationMixing operation control apparatusStructural engineeringProcess engineering

A reactive powder concrete intelligent stirring system mainly solves the technical problems that an existing stirring machine is low in reactive powder concrete stirring efficiency, instable in stirring quality and large in water addition amount error and causes steel fiber caking. According to the technical scheme, the reactive powder concrete intelligent stirring system is characterized in thatthe reactive powder concrete intelligent stirring system comprises a stirring mechanism (1), a stirring round barrel (2), a feeding mechanism (3), a spraying water addition device (7), a water addition metering system (6), a discharging system (8), a stirring intelligent control system (9) and a dustproof system (5); the stirring mechanism (1) is installed in the stirring round barrel (2); the feeding mechanism (3) is arranged on one side of the stirring round barrel (2); the spraying water addition device (7) and the water addition metering system (6) are arranged on the other side of the stirring round barrel (2); and the discharging system (8) is arranged below the stirring round barrel (2). The reactive powder concrete intelligent stirring system is mainly applied to reactive powder concrete stirring and production.

Owner:HUNAN ZHONGLU HUACHENG BRIDGE TECH CO LTD

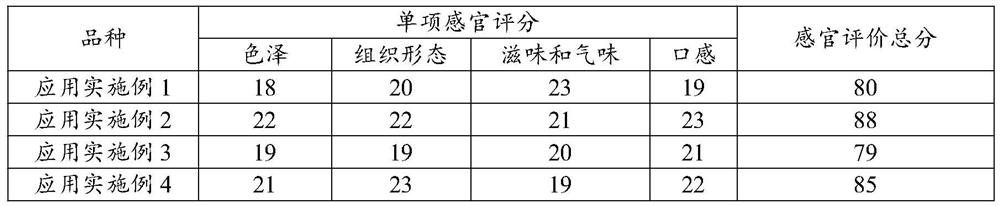

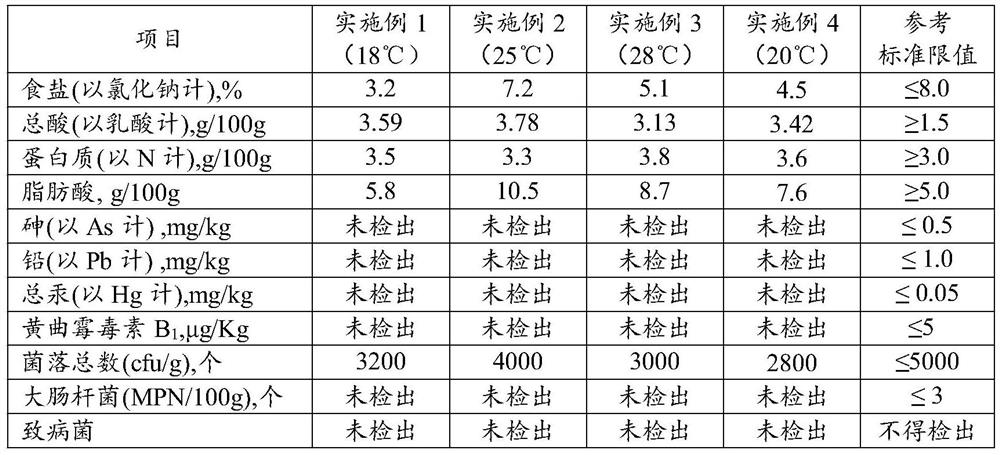

Compound lactic acid bacteria, fermented-alcoholized chili and preparation method of fermented-alcoholized chili

PendingCN112106953AAdvantages of preparation methodShorten production timeBacteriaMicroorganism based processesBiotechnologyLactic acid bacterium

The invention belongs to the technical field of agricultural product processing, and particularly relates to compound lactic acid bacteria, fermented-alcoholized chili and a preparation method of thefermented-alcoholized chili. The preparation method of the fermented-alcoholized chili comprises the following steps of performing pretreatment, performing color-protection sterilization, performing fermentation, performing alcoholization and performing stir-frying. The fermented-alcoholized chili prepared according to the preparation method is sour, fragrant, tasty and refreshing and lasting in flavor, can be directly eaten together with rice or bread or used as an ingredient of stir-fried dishes, meets the consumption requirements of people on flavor characteristic foods, and overcomes the defects that traditional fermented-alcoholized chili is long in making consumed time, prone to aging and caking and mildewing and single in nutrition and flavor.

Owner:CHONGQING ACAD OF AGRI SCI

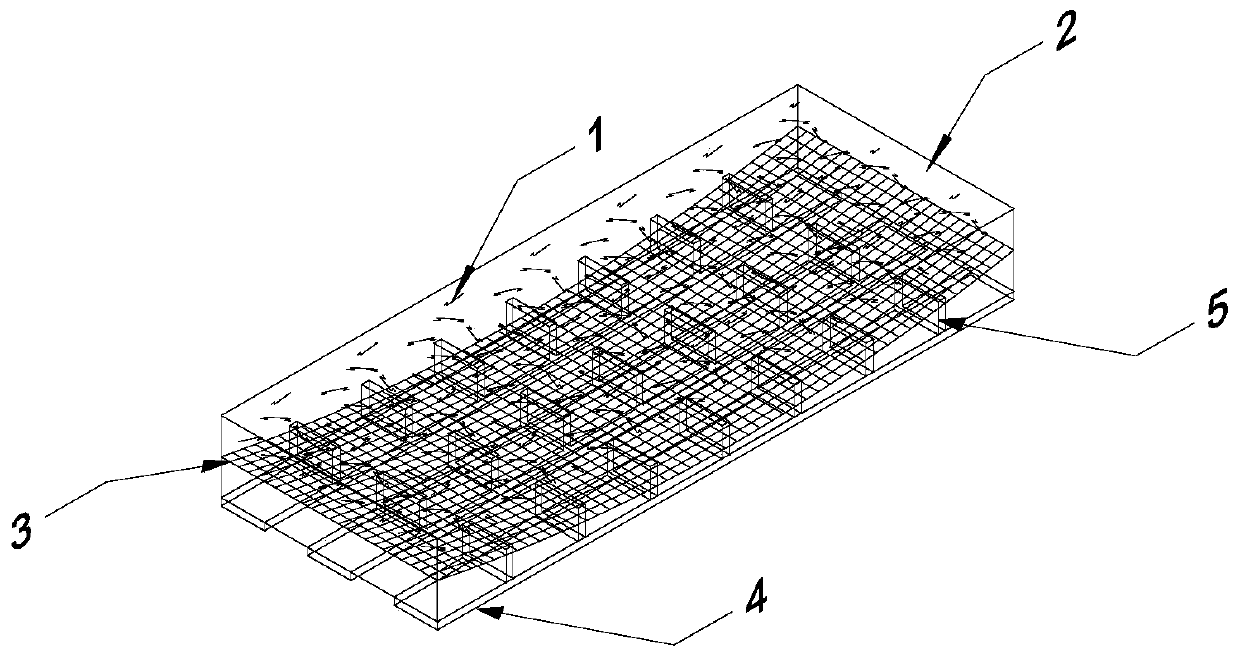

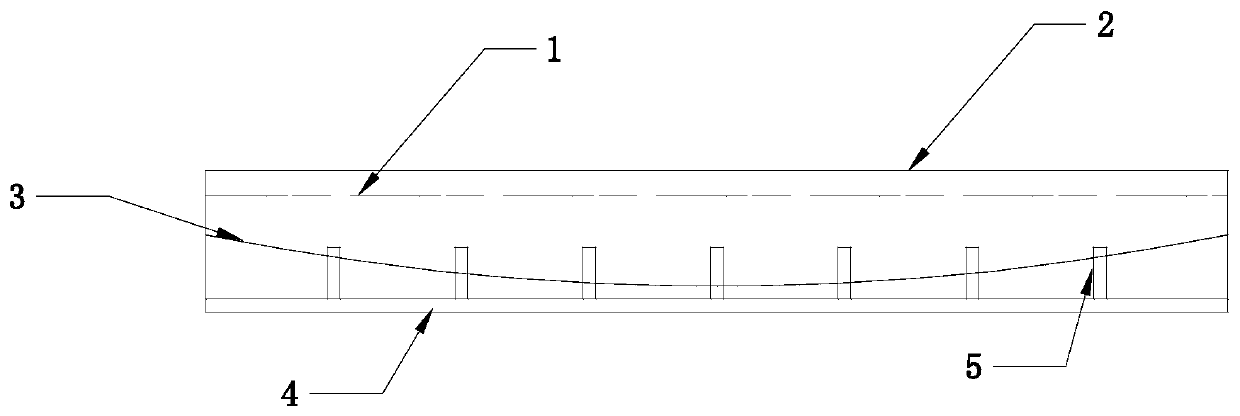

Bending-resistant prefabricated concrete pavement structure with steel fibers laid on upper layer and lower layer

The invention discloses a bending-resistant prefabricated concrete pavement structure with steel fibers laid on an upper layer and a lower layer. The bending-resistant prefabricated concrete pavementstructure comprises a common steel fiber laying layer, a prefabricated concrete base body, a latticed steel fiber laying layer and a bottom surface ribbed steel plate, the common steel fiber laying layer and the latticed steel fiber laying layer are laid in the prefabricated concrete base body, and the bottom surface ribbed steel plate is fixed at the bottom of the prefabricated concrete base body. According to the bending-resistant prefabricated concrete pavement structure with the steel fibers laid on the upper layer and the lower layer, the steel fiber concrete base body and the bottom surface ribbed steel plate are organically combined, so that the high-toughness and high-bending-resistance prefabricated steel fiber concrete pavement structure is formed.

Owner:HOHAI UNIV

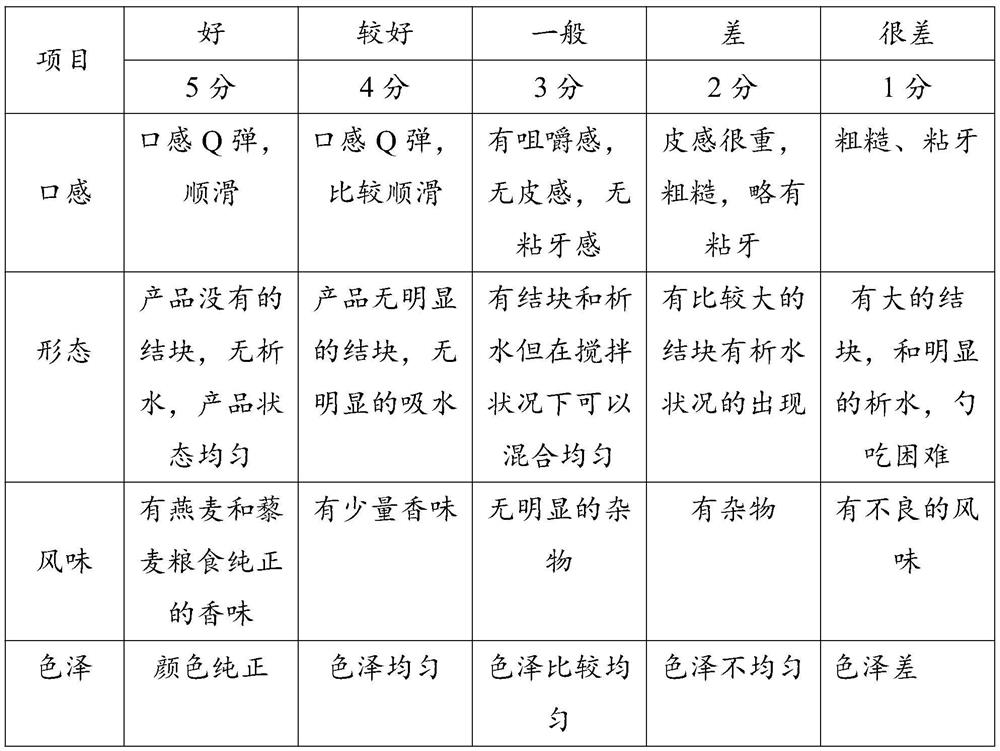

Sucrose-free instant quinoa oat porridge with long shelf life and preparation method thereof

PendingCN113575850ASmooth tastePromote bowel movementsFood ingredient functionsHorticultureDry matter

The invention discloses a preparation method of a sucrose-free instant quinoa oat porridge with the long shelf life. The preparation method comprises the following steps: S1, weighing 50-80 parts by weight of dry oats and 20-50 parts by weight of quinoa, and respectively pretreating the oats and the quinoa; S2, adding tremella fuciformis and plantain seed husks into water, obtaining soup after stirring,wherein the content of the tremella fuciformis accounts for 0.05%-0.12% of the soup, and the content of the plantain seed husks accounts for 0.05%-0.15% of the soup; S3, uniformly stirring the pretreated oats and quinoa, adding the oats and the quinoa into a container tank, then pouring 800-1200 parts of the soup, and sealing the container tank with a cover; and S4, putting the sealed container in an environment of 110-140 DEG C, carrying out rolling sterilization treatment for 25-60 minutes, and performing cooling to obtain the sucrose-free instant quinoa oat porridge with a long shelf life. According to the method, the problems of taste and caking of the coarse grain porridge are effectively solved by adding the tremella fuciformis and the plantain seed husks, the taste of the coarse grain porridge is smoother under the condition that cane sugar is not added, and the healthy and low-energy instant porridge is obtained.

Owner:XIAMEN YINLU FOOD GROUP

Circulating fluidized bed boiler burning straw-like biomass and feeding method

ActiveCN101614392BReduce volumePrevent bridgingFluidized bed combustionIndirect carbon-dioxide mitigationCompression moldingPower station

The invention discloses a circulating fluidized bed boiler burning straw-like biomass and a feeding method. The feeding method comprises the following steps that: before being delivered into a furnace, the straw-like biomass serving as a fuel is crushed and compressed by compression molding equipment so as to be solidified; and the solidified straw-like biomass is conveyed to a furnace by a conveying belt so as to be burnt. By compressing the light and large-volume straw-like biomass before conveying the light and large-volume straw-like biomass to the furnace, the method reduces the volume of the straw-like biomass, has the advantages of simple structure and low cost, keeps the straw-like biomass away from bridging and block which frequently occur in a conveying process, ensures smooth feeding and the safe operation of the boiler, and effectively guarantees the continuous, reliable and safe operation of biomass power plants.

Owner:CHINA HUADIAN ENG +1

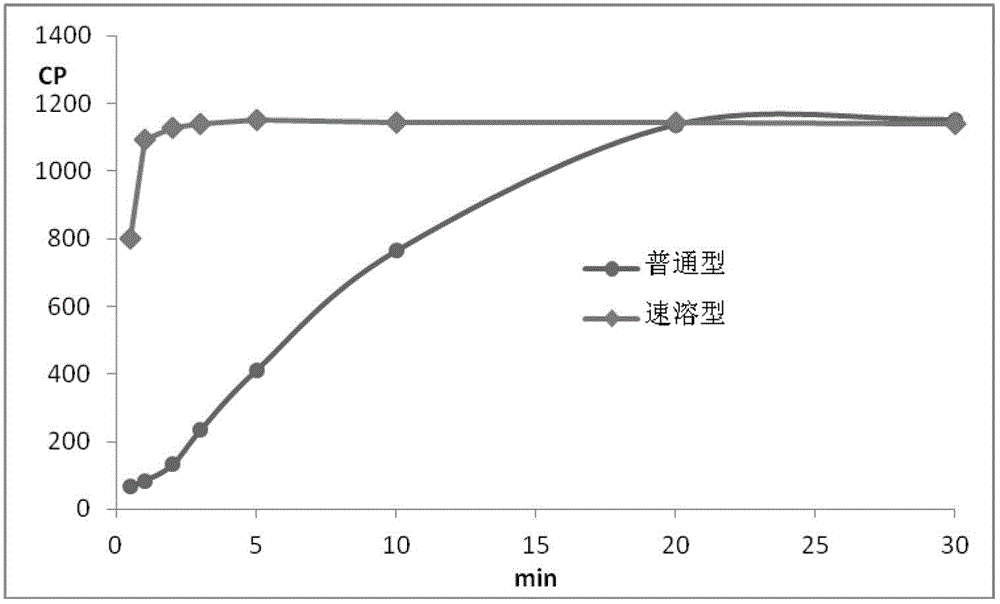

Instant gellan gum and its preparation method

The invention discloses an instant gellan gum and its preparation method. The instant gellan gum is prepared through treating gellan gum powder as an initial raw material and adopting a boiling, granulating and drying device. The method comprises the following steps: 1, gellan gum powder feeding: introducing the raw material gellan gum powder to the fluidized bed bottom of the boiling, granulating and drying device through purified cold air in order to make the raw material in a boiling state; 3, aqueous KCl solution wetting: injecting an aqueous KCl solution to humidify and granulate the gellan gum powder; 3, gellan gum solution injecting: atomizing a gellan gum solution having a small concentration, and uniformly injecting the raw material gellan gum powder for dressing boiling from the upper portion of the fluidized bed; 4, dressing; and 5, drying the obtained particulate product to obtain an instant colloidal matrix. The instant gellan gum prepared through adopting the method disclosed in the invention is used for solving the problems comprising difficult dissolving, easy formation of fish eye-like blocks in the dissolving process, slow dissolving time and fly dusts of powdery gellan gums produced at present.

Owner:安徽龙津生物科技有限公司

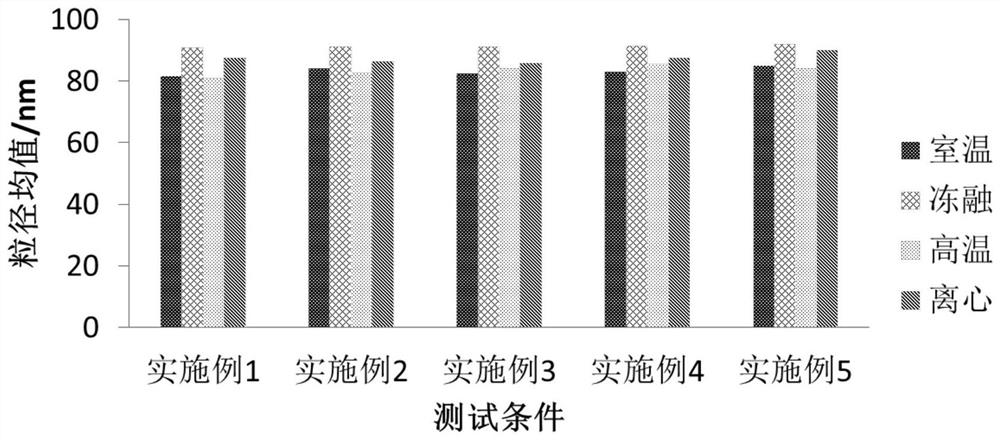

A kind of spirulina composition and preparation method and preparation thereof

ActiveCN104382950BSolve the fragileImprove molding rateMetabolism disorderDigestive systemCelluloseDrugs preparations

The invention relates to the field of pharmaceutical preparations and particularly relates to a spirulina composition and a preparation method and a preparation thereof. The spirulina composition comprises spirulina and high-substituted hydroxypropyl cellulose. The spirulina composition and the preparation thereof provided by the invention are less prone to splitting, the problem of agglomeration of high-substituted hydroxypropyl cellulose can be thoroughly solved, a prepared spirulina health product tablet is high in forming rate, the appearance has no white spots, and the product quality is in line with requirements; and raw materials and auxiliary materials in the spirulina composition and the preparation thereof provided by the invention have high compatibility, and the content of active ingredients is less affected by a tabletting process.

Owner:BY HEALTH CO LTD

A kind of glazing care emulsion and preparation method thereof

ActiveCN110408325BSolve the Stability ConundrumGood emulsificationAqueous dispersionsGlycerolStearic acid

The invention discloses a glazing care emulsion and a preparation method thereof, and relates to the technical field of glazing care agents. The glazing care emulsion is prepared from, by mass, 10-25%of a liquid glazing agent, 0.5-5% of an emulsifying agent and 0.01-0.15% of a chelating agent; the emulsifying agent is formed by compounding polyglyceryl-2 isostearate, liquid C10-13 isomeric alcohol ethoxylates, oleic acid and triethanolamine, and the mass ratio of the polyglyceryl-2 isostearate to the liquid C10-13 isomeric alcohol ethoxylates to the oleic acid to the triethanolamine is (1-22.5):(1.5-25):(1-5):(0.5-2.5). The ingredients of the glazing care emulsion is in a liquid state at the room temperature, thereby solving the problem that caking or trace leaving occurs on the applyingsurface due to the fact that solid raw materials are applied unevenly; in addition, in the normal-temperature preparation process of the glazing care emulsion, heating and cooling are not needed, theprocess is simple, and the energy consumption is low.

Owner:广州超威生物科技有限公司

Expanded perlite insulation board automatic production device

ActiveCN107571388BRealize automatic cycleRealize assembly line productionCeramic shaping plantsAuxillary shaping apparatusAssembly lineProcess engineering

Owner:华亿建材科技有限公司

Glue solution filtering device

InactiveCN102198376ASolve the problem of filler agglomerationSolve the clumpingMixer accessoriesFiltration circuitsDiaphragm pumpBiochemical engineering

The invention relates to a glue solution filtering device, which comprises a stirring tank, a first diaphragm pump, a first filter, a viscosity tank, a second diaphragm pump, a second filter, a backflow filter and a backflow diaphragm pump, wherein the stirring tank, the first diaphragm pump, the first filter and the viscosity tank are communicated sequentially, the second diaphragm pump is communicated with the viscosity tank and the second filter, the second filter is communicated with a glue tank; the backflow filter is communicated with the glue tank; the backflow diaphragm pump is communicated with the viscosity tank and the backflow filter; and a viscosity sensor is arranged in the viscosity tank. Due to the adoption of the structure, glue solution is filtered by the filter, so that fillers are dispersed further under the condition that the speed of the fillers is not influenced to solve the problem of filler agglomeration, pipelines are not blocked any more, and prepreg does not have non-dispersed powder points in appearance.

Owner:KAIPING PACIFIC INSULATION MATERIAL

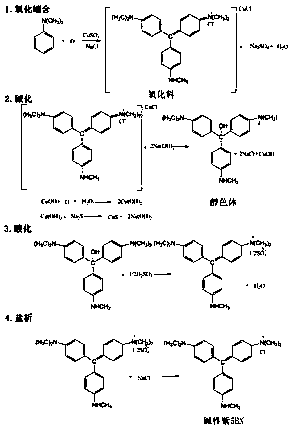

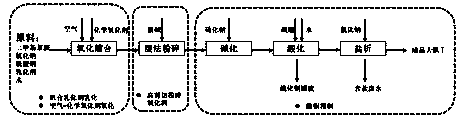

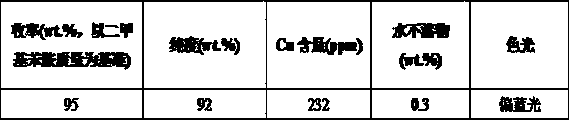

Novel phenol-free technology for producing basic violet 5BN

InactiveCN110551405AIncrease active oxygen concentrationSolve hard problemsDiaryl/thriaryl methane dyesCopperPhenol

The invention relates to novel phenol-free technology for producing basic violet 5BN, which comprises the following steps: replacing phenol with a combined emulsifier consisting of a nonionic emulsifier and a cationic emulsifier for heterogeneous reaction of oxidative condensation; the oxidative condensation reaction time is shortened through joint oxidation of air and a chemical oxidant; adoptinghigh-shear wet crushing technology for treating an obtained oxidized material to increase the contact area of the oxidized material and alkali; removing copper ions through converting of copper ionsinto copper sulphide which is removed.

Owner:丰城三友制笔科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com