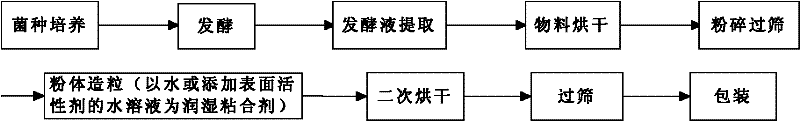

Preparation method for granular type xanthan gum

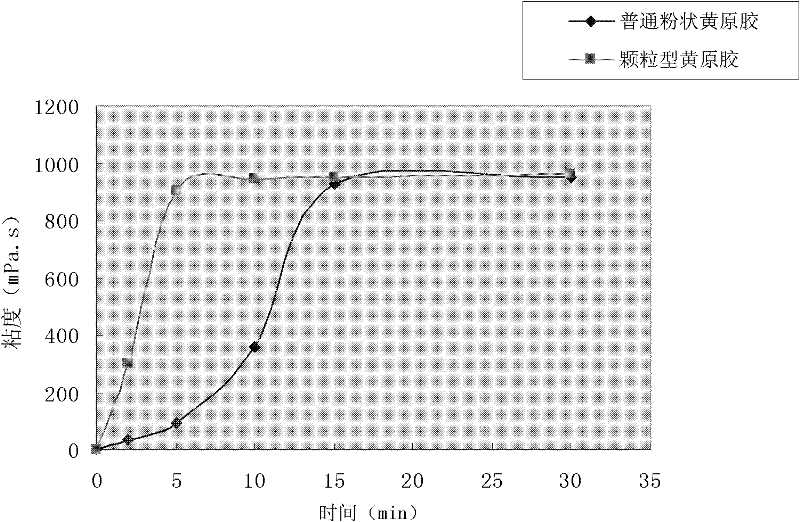

A xanthan gum, granule-type technology, applied in food preparation, medical preparations with inactive ingredients, pharmaceutical formulations, etc., can solve the problems of slow dissolution rate, flying dust, pollute the environment, etc., achieve fast hydration rate, improve dispersion The effect of hydration speed and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Using xanthan gum powder as the starting material, it is made into granular xanthan gum products suitable for sauces, condiments, soups, beverages, and food industries by using FL-300 boiling granulation dryer, including the following Steps:

[0044] ①. Xanthan gum powder feeding

[0045] According to the production capacity of the selected fluidized granulation drying device, the raw material xanthan gum powder is put into the fluidized bed, and the feeding amount is 200 kg.

[0046] ②.Introduction of hot air

[0047] After the purified cold air is preheated by steam, it is introduced from the bottom of the fluidized bed of the fluidized granulation drying device, so that the raw material xanthan gum powder is in a boiling state, the temperature of the hot air is 60-90°C, and the steam pressure is 0.4Mpa-0.8Mpa;

[0048] ③. Spray into atomized water

[0049] The BT600-2J peristaltic pump is used, and the water inlet speed is controlled by the speed of the peristaltic ...

Embodiment 2

[0058] According to the method and steps of Example 1, xanthan gum particles suitable for non-food, medicine and beverages were prepared. The preparation differs in that 0.6 kg of sorbitan monostearate is dissolved in atomized water. The prepared granular xanthan gum product is suitable for use in petroleum industry and water treatment industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com