Cosmetic powder pretreatment device and pretreatment method

A technology of pretreatment device and cosmetics, applied in the direction of chemical instruments and methods, separation methods, mixers with rotating stirring devices, etc., can solve problems such as inaccurate measurement, pimples, flying dust, etc., to improve accuracy, improve Stability, health protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

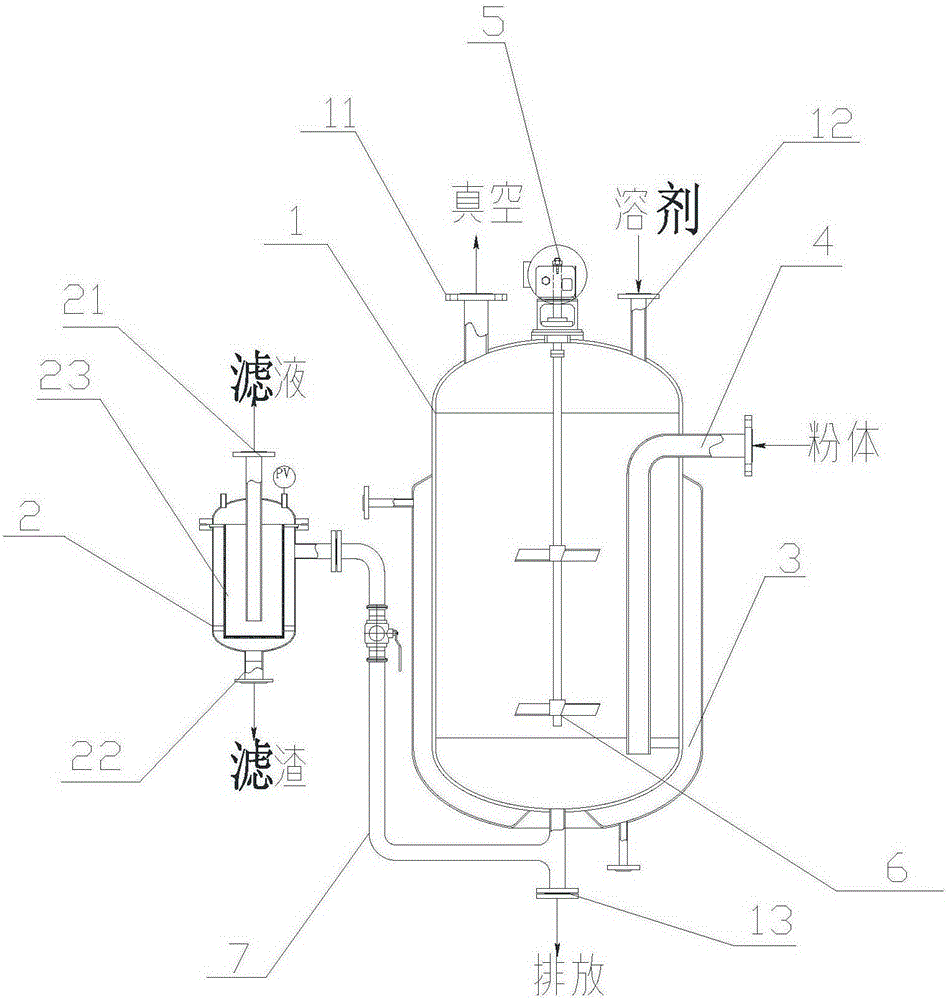

[0038] The present embodiment relates to the pretreatment method of Poria cocos polysaccharide, comprises the steps:

[0039] Add an aqueous solution of 100 times the mass of the polysaccharide powder in the mixing tank, start stirring at 200 rpm, vacuumize the powder of the polysaccharide, stir for 10 minutes after completion, turn on the vacuum device on the emulsification pot, and suck the liquid in the mixing tank into the filter tank In the process, the filter medium is 2μm ceramic membrane and other materials, after filtration, it is pumped into the emulsification pot, and the solution is clarified.

Embodiment 2

[0041] The present embodiment relates to the pretreatment method of lotus leaf total flavonoids, comprising the following steps:

[0042] Add 4% 1,3-butanediol aqueous solution 200 times the mass of lotus leaf total flavonoids extract into the mixing tank, start stirring at 30 rpm, vacuumize lotus leaf total flavonoids extract, and heat to 60°C after completion , stirred for 10 minutes, cooled to <35°C, turned on the vacuum device on the emulsification pot, sucked the liquid in the stirring tank into the filter tank, and filtered it with 0.03μm ceramic membrane and other materials, and pumped it into the emulsification pot after filtration, and the solution was clarified.

Embodiment 3

[0044] The present embodiment relates to the pretreatment method of aloe, comprises the steps:

[0045] Add an aqueous solution of 10 times the mass of aloe freeze-dried powder into the mixing tank, start stirring at 70 rpm, vacuumize the aloe freeze-dried powder, stir for 5 minutes after completion, turn on the vacuum device on the emulsification pot, and suck the liquid in the mixing tank In the filter tank, the filter medium is an 800-mesh filter bag. After filtering, it is pumped into the emulsification pot. The solution is clarified, and the test feed loss rate is 0.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com