Circulating fluidized bed boiler burning straw-like biomass and feeding method

A circulating fluidized bed and biomass technology, applied in the field of boilers and feeding materials, can solve problems such as affecting the continuous and reliable operation and production efficiency of biomass power plants, affecting the safe operation of boilers, and complex feeding systems, avoiding bridges and Clogging phenomenon, simple structure, high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

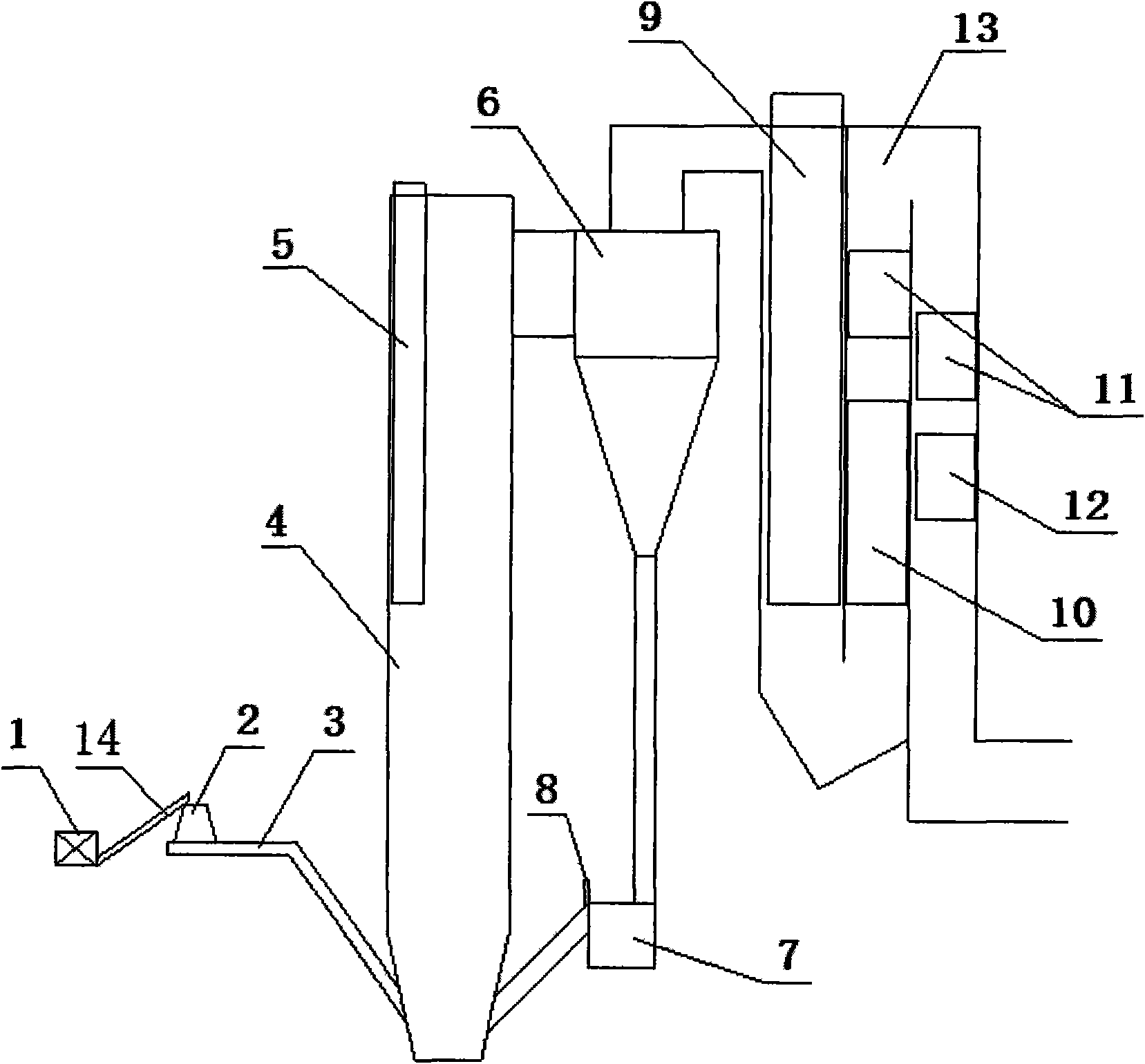

[0016] Embodiments of the present invention: as attached figure 1 As shown, it includes a compression molding equipment 1 for compressing straw-like biomass, a front feeder 2 and a belt feeder 3 . Wherein the compression molding equipment 1 is connected with the feeding port of the feeder bin 2 through the conveyor belt 14, the discharge port of the feeder bin 2 is connected with the belt feeder 3, and the belt feeder 3 is connected with the feeding port of the furnace 4 connected. A water-cooled evaporation panel heating surface 5 is provided in the upper space of the furnace 4, and the water-cooled evaporation panel heating surface 5 can further reduce the flue gas temperature at the outlet of the furnace; The lower end is connected with a circulation loop and a feeder 7 and is connected with the dense-phase area of the furnace 4, and a replenishment port 8 for bed materials and circulating materials is provided above the return pipe at the outlet of the feeder 7 . The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com