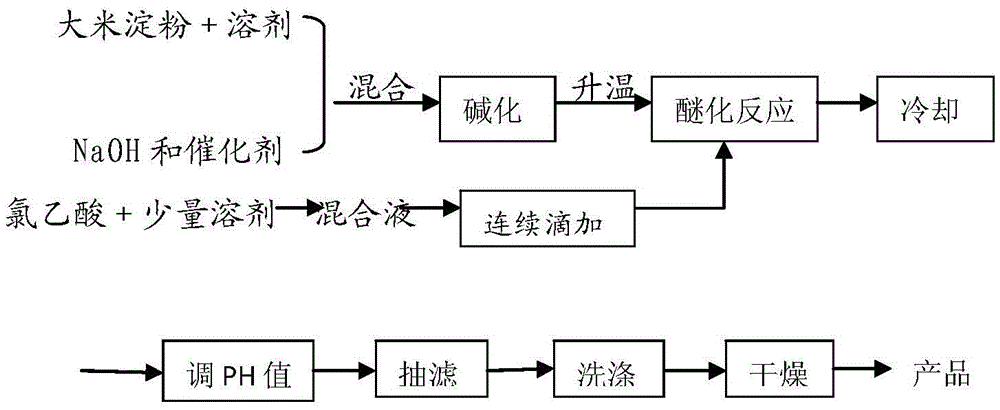

A method for preparing carboxymethyl rice starch by continuous feed method

A technology of rice starch and carboxymethyl, which is applied in the field of preparation of carboxymethyl rice starch, can solve the problems of low product yield, low degree of substitution, unstable reaction system, etc., achieve high degree of product substitution and improve stability , easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

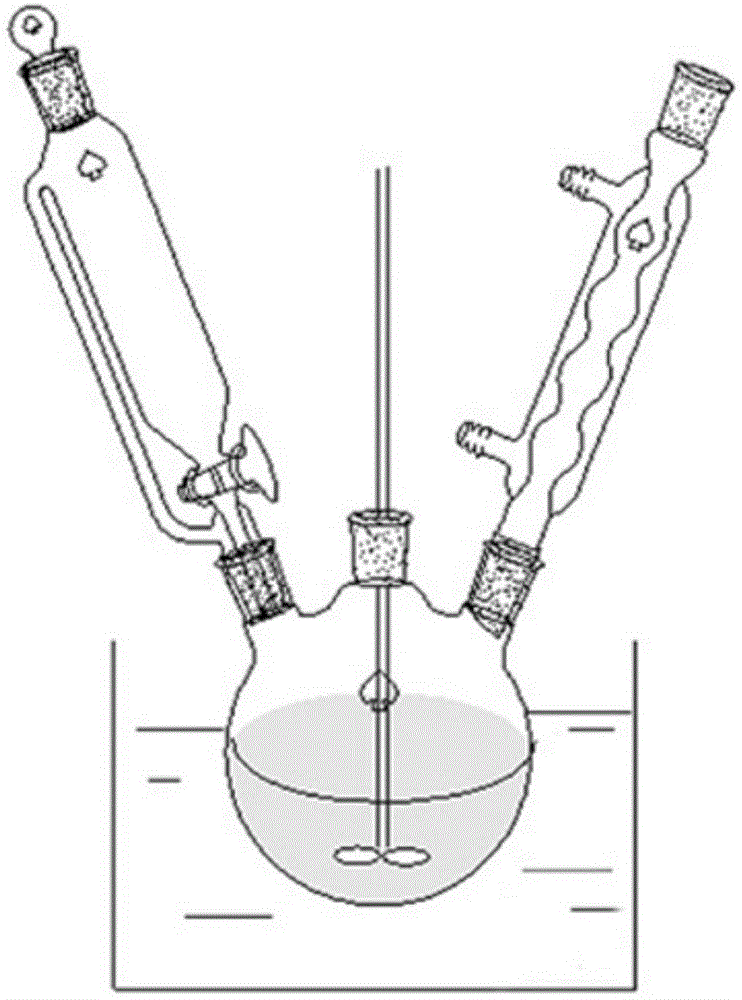

Embodiment 1

[0020] In terms of parts by mass, add 55 parts of NaOH and 6 parts of catalyst cetyltrimethylammonium bromide to 100 parts of rice starch, pour 1200 parts of isopropanol solution and 55 parts of distilled water, and the stirring speed is 200r / min Fully stir and heat in a water bath at 50°C for 35 minutes to fully alkalinize the starch, then heat up to 60°C, and then add a total of 150 parts of isopropanol mixed with 80 parts of chloroacetic acid as follows, firstly Add 35 parts of the mixed solution at one time, immediately adjust the stirrer to 500r / min and stir for 5min, adjust the stirrer speed to 300r / min, continue the reaction for 15min, add 10 parts of NaOH particles to maintain an alkaline reaction environment, and then continue the reaction for 15min Finally, add the remaining mixed solution continuously within 100 minutes, and the rate of dropping in the first half of the time is 1.2 times that of the second half of the time. 10 parts of NaOH pellets were added at tim...

Embodiment 2

[0022] In terms of parts by mass, add 55 parts of NaOH and 5 parts of catalyst cetyltrimethylammonium bromide to 100 parts of rice starch, pour 1250 parts of isopropanol solution and 45 parts of distilled water, and the stirring speed is 250r / min Fully stir and heat in a water bath at 50°C for 30 minutes to fully alkalinize the starch, then heat up to 60°C, and then add a total of 120 parts of isopropanol mixed with 70 parts of chloroacetic acid as follows, firstly Add 30 parts of the mixed solution at one time, immediately adjust the stirrer to 400r / min and stir for 10min, adjust the stirrer speed to 300r / min, continue the reaction for 15min, add 10 parts of NaOH particles to maintain an alkaline reaction environment, and then continue the reaction for 10min Finally, add the remaining mixed solution continuously within 90 minutes, and the rate of dropping in the first half of the time is 1.1 times that of the second half of the time. 10 and 5 parts of NaOH pellets were added ...

Embodiment 3

[0024] In terms of parts by mass, add 60 parts of NaOH and 7 parts of catalyst cetyltrimethylammonium bromide to 100 parts of rice starch, pour 1200 parts of isopropanol solution and 55 parts of distilled water, and the stirring speed is 250r / min Fully stir and heat in a water bath at 50°C for 35 minutes to fully alkalinize the starch, then heat up to 60°C, then add a total of 160 parts of isopropanol mixed with 85 parts of chloroacetic acid as follows, first Add 40 parts of the mixture at one time, immediately adjust the stirrer to 450r / min and stir for 10min, adjust the stirrer speed to 350r / min, continue the reaction for 10min, add 10 parts of NaOH particles to maintain an alkaline reaction environment, and then continue the reaction for 10min Finally, the remaining mixed solution was continuously added dropwise within 110 minutes, and the rate of dropping in the first half of the time was 1.1 times that of the second half of the time. 10 parts of NaOH pellets were added at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com