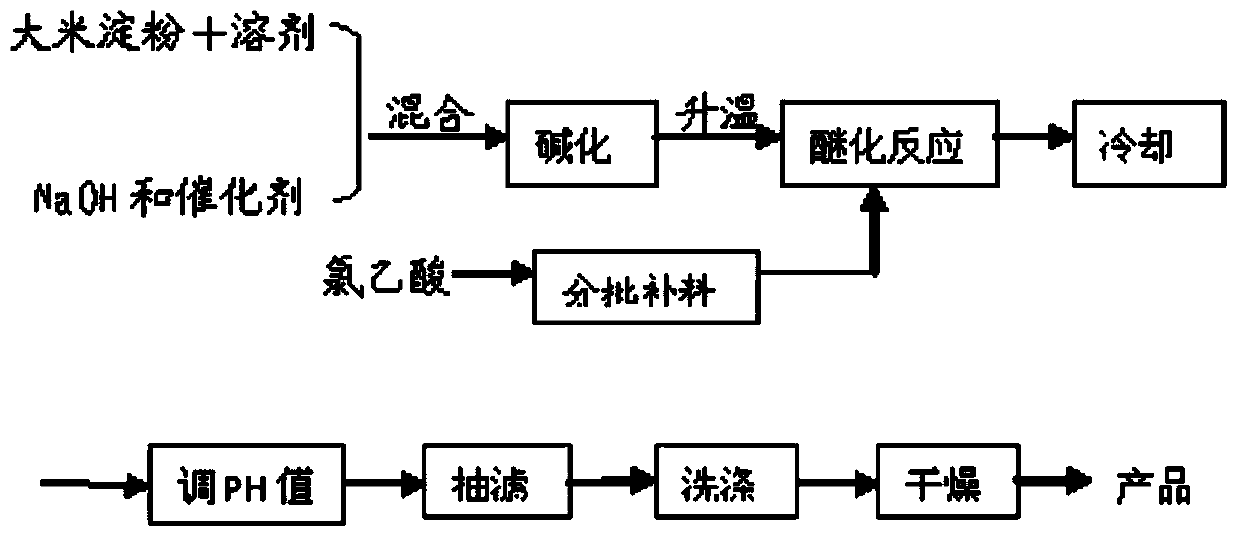

Method for preparing carboxymethyl rice starch via intermittent feeding method

A technology of carboxymethyl starch and rice starch, which is applied in the field of preparing carboxymethyl rice starch by the intermittent feeding method, can solve the problems of abnormal reaction, unstable reaction system, excessive viscosity increase, etc., and achieve stable reaction and easy Control and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

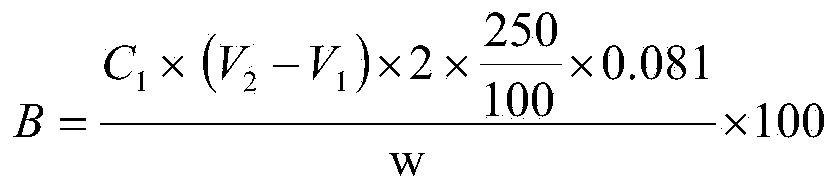

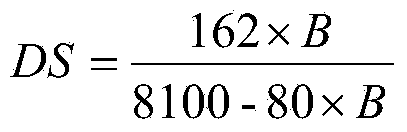

Embodiment 1

[0036] Add 55 parts of NaOH and 6 parts of cetyltrimethylammonium bromide to 100 parts of rice starch, dissolve with 1200 parts of isopropanol and 50 parts of distilled water, stir at a speed of 200 r / min, and fully stir in a water bath at 50 °C Heat for 30 minutes to alkalize the starch. After the temperature rises to 60°C, add a total of 80 parts of chloroacetic acid in six batches. Add 20 parts of chloroacetic acid to the first batch for reaction, and add the second batch of 20 parts of chloroacetic acid after 30 minutes. The third batch of 10 parts of chloroacetic acid was reacted, after 30 minutes, the fourth batch of 10 parts of chloroacetic acid was added for reaction, after 30 minutes, the fifth batch of 10 parts of chloroacetic acid was added for reaction, and after 30 minutes, the sixth batch of 10 parts of chloroacetic acid was added for reaction. Immediately after each addition of chloroacetic acid, adjust the stirring speed to 400r / min, and reduce the speed to 300r...

Embodiment 2

[0038] Add 60 parts of NaOH and 7 parts of cetyltrimethylammonium bromide to 100 parts of rice starch, dissolve with 1210 parts of isopropanol and 52 parts of distilled water, stir at a speed of 250 r / min, and fully stir in a water bath at 50 °C Heat for 32 minutes to alkalize the starch. After the temperature rises to 60°C, add 82 parts of chloroacetic acid in five batches. Add 20 parts of chloroacetic acid in the first batch for reaction, add the second batch of 20 parts of chloroacetic acid for reaction after 30 minutes, and add the third batch after 60 minutes. 20 parts of chloroacetic acid were reacted, and after 30 minutes, the fourth batch of 12 parts of chloroacetic acid was added for reaction, and after 30 minutes, the fifth batch of 10 parts of chloroacetic acid was added for reaction. Immediately after each addition of chloroacetic acid, adjust the stirring speed to 450r / min, and reduce the speed to 300r / min after 15 minutes. In order to maintain the alkaline environme...

Embodiment 3

[0040] Add 52 parts of NaOH and 6.5 parts of cetyltrimethylammonium bromide to 100 parts of rice starch, dissolve with 1250 parts of isopropanol and 55 parts of distilled water, stir at a speed of 200 r / min, and fully stir in a water bath at 50 °C Heat for 35 minutes to alkalize the starch. After the temperature rises to 60°C, add 80 parts of chloroacetic acid in four batches. Add 20 parts of chloroacetic acid to the first batch for reaction, add the second batch of 20 parts of chloroacetic acid to react after 30 minutes, and add the third batch after 60 minutes. 20 parts of chloroacetic acid were reacted, and the fourth batch of 20 parts of chloroacetic acid was added after 60 minutes. Immediately after each addition of chloroacetic acid, adjust the stirring speed to 400r / min, and reduce the speed to 300r / min after 15 minutes. In order to maintain the alkaline environment of the system during the reaction, add 5 parts after 15 minutes after adding chloroacetic acid in each bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com