Bending-resistant prefabricated concrete pavement structure with steel fibers laid on upper layer and lower layer

A prefabricated concrete and pavement structure technology, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of restricting the application and promotion of steel fiber concrete pavement, the inability to evenly distribute concrete, and the high density of steel fibers, etc., to achieve Save material, improve toughness, high flexural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

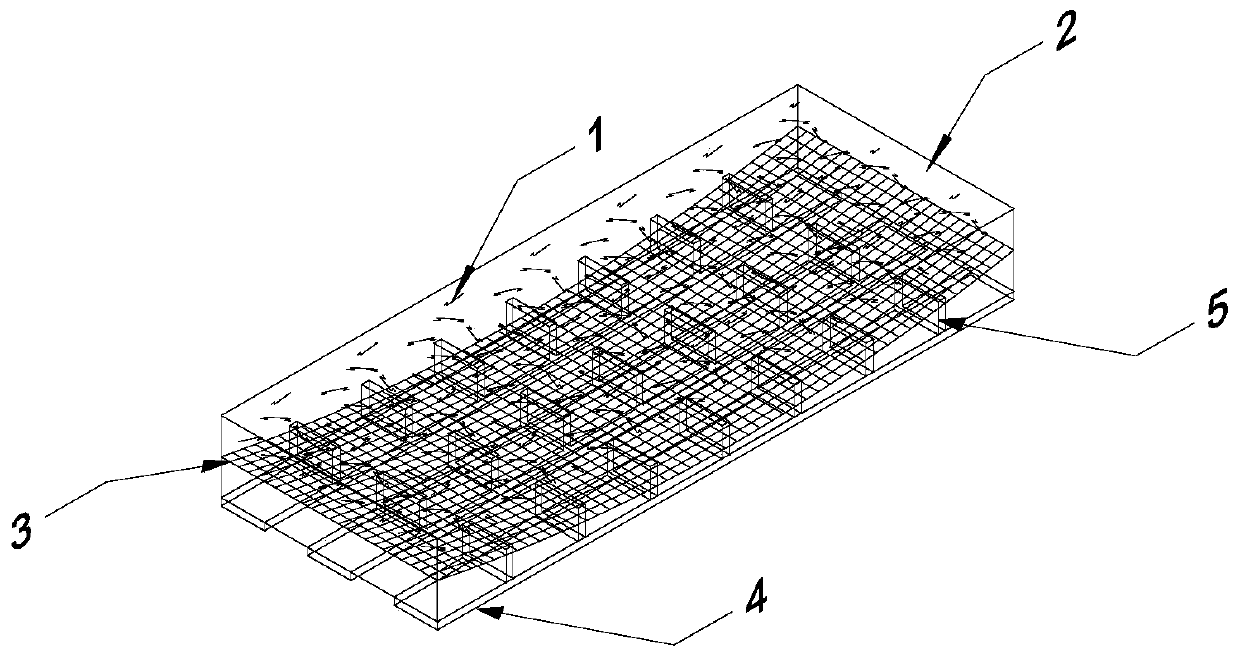

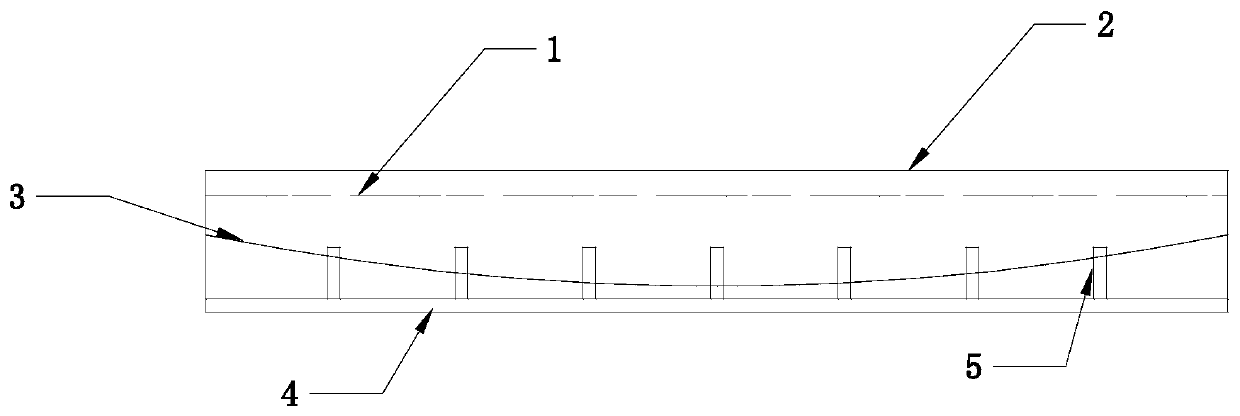

[0020] A flexure-resistant precast concrete pavement structure with steel fibers laid on the upper and lower layers, comprising an ordinary steel fiber laying layer 1, a precast concrete matrix 2, a grid-like steel fiber laying layer 3 and a ribbed steel plate 4 on the bottom; the ordinary steel fiber laying layer 1 and The grid-shaped steel fiber laying layer 3 is laid in the precast concrete matrix 2; the ribbed steel plate 4 on the bottom surface is fixed on the bottom of the precast concrete matrix 2.

[0021] Ordinary steel fiber laying layer 1 is 20-30mm away from the upper plane of precast concrete base 2, and the grid steel fiber laying layer is laid with a thickness of 2-5mm, which is arranged in the precast concrete base 2 in a parabolic shape. The midpoint of the center begins to bend, and the lowest point is 10-15mm away from the lower plane of the precast concrete matrix. The ordinary steel fiber laying layer 1 has a thickness of 5-8mm. The grid-shaped steel fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com