Reactive powder concrete intelligent stirring system

A mixing system and active powder technology, which are applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of inability to solve steel fiber agglomeration, and the accuracy of water adding metering system is difficult to meet the requirements, so as to solve the problem of steel fiber agglomeration. , The effect of shortening stirring time and smooth feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

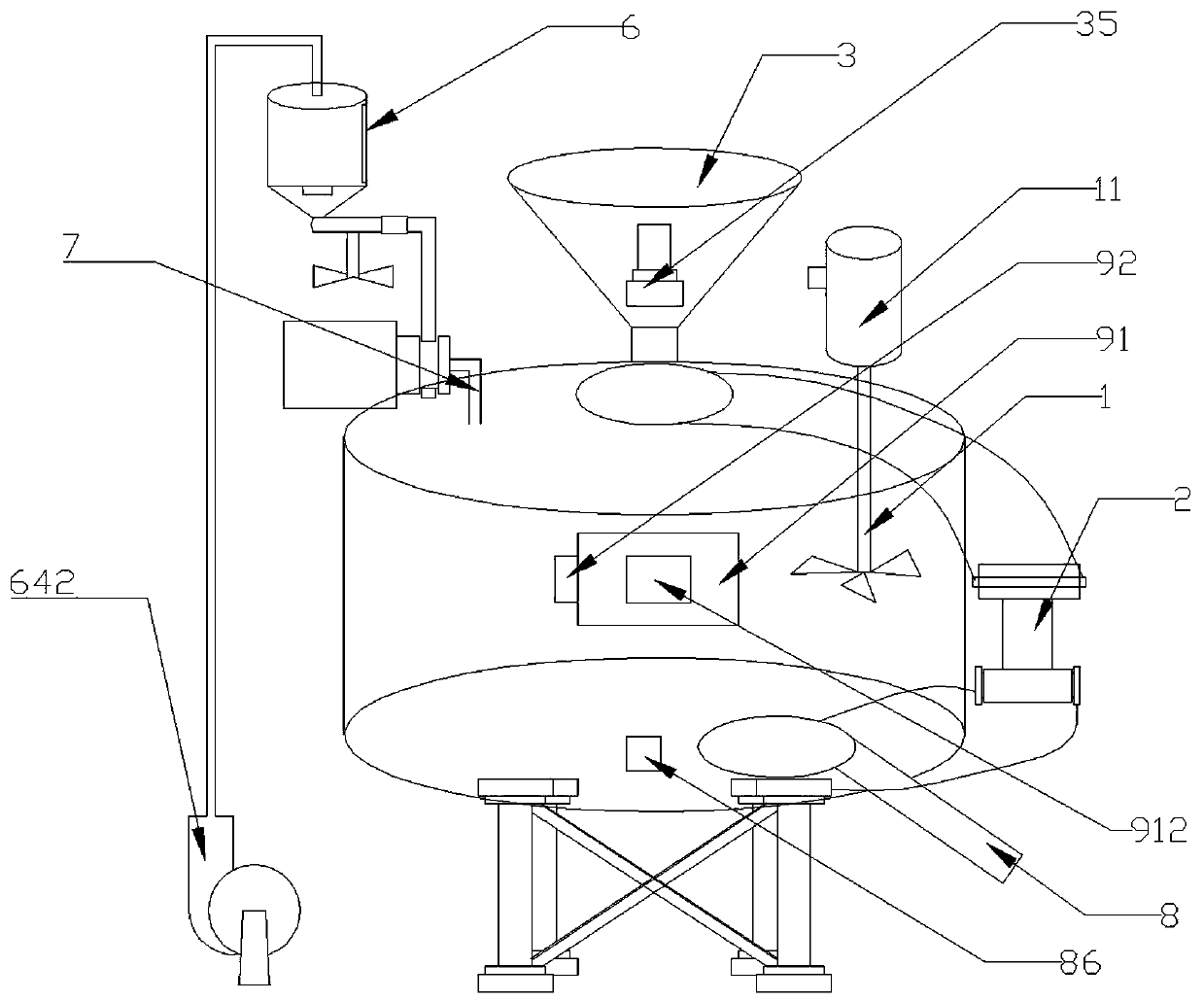

[0038] Embodiment 1, refer to Figure 1 to Figure 7 , the present invention includes a stirring mechanism 1, a stirring drum 21, a feeding mechanism 3, a spraying water adding device 7, a water adding metering system 6, a discharging system, a stirring intelligent control system, a dustproof system, and a container-type frame. The mechanism 1 is installed in the mixing drum 21, the feeding mechanism 3 is arranged on the side above the mixing drum 21, the lower end of the hopper 36 of the feeding mechanism 3 communicates with the mixing drum 21, the spraying water adding device 7 and the water adding device The metering system 6 is installed above the other side of the mixing drum 21; the discharge system is located below the mixing drum 21 and is in the symmetrical direction of the feeding mechanism 3; the mixing drum 21 is fixed in the container-type frame 4, and the stirring is intelligent The control system 9 is installed in the container frame; the dustproof system include...

Embodiment 2

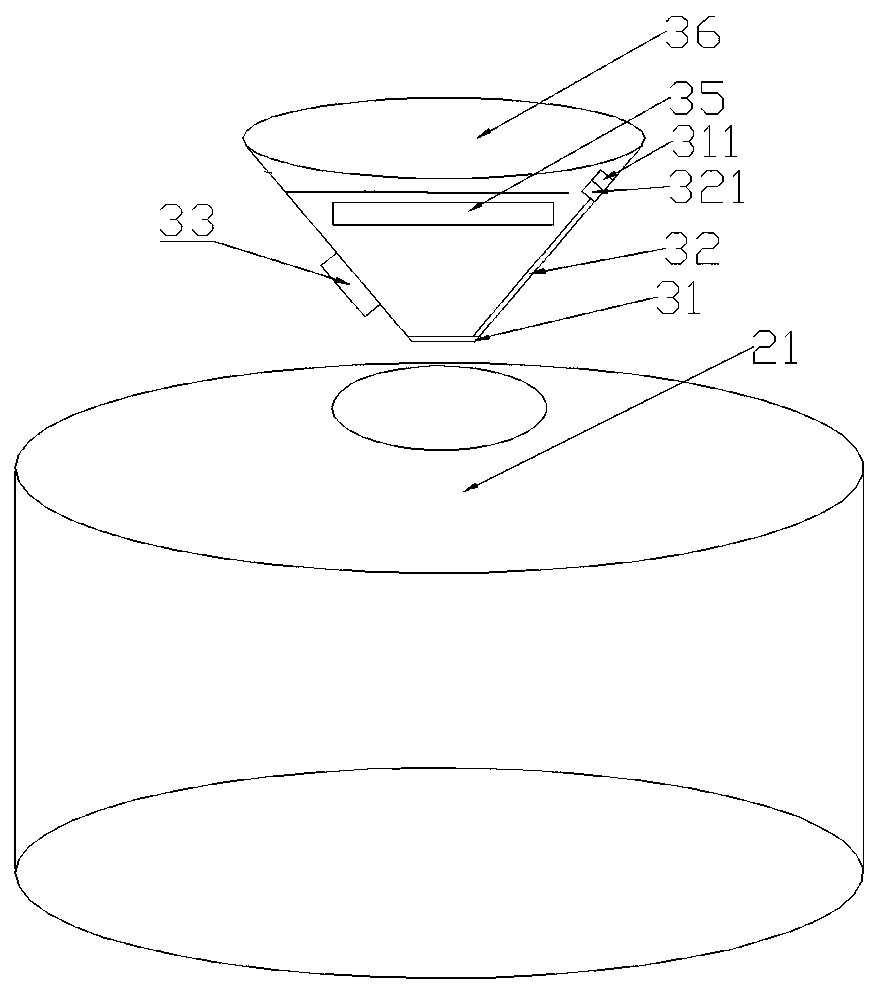

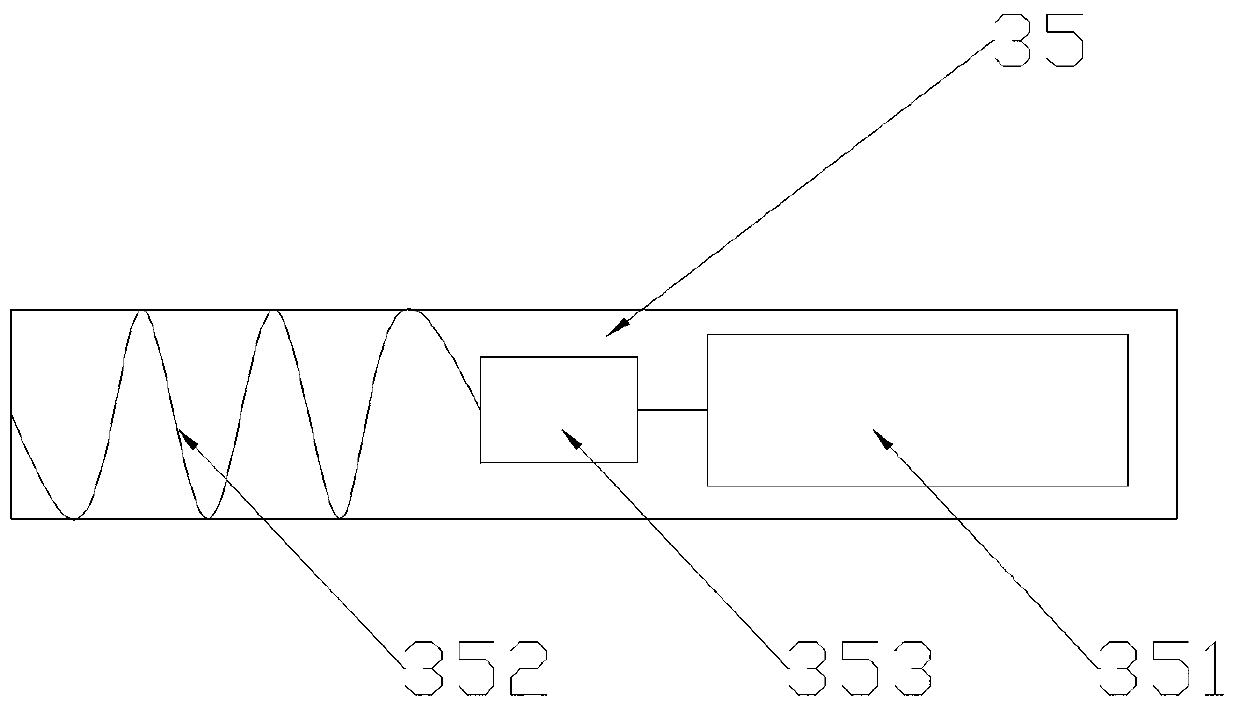

[0039] Embodiment 2, refer to Figure 1 to Figure 7 , the feeding mechanism 3 of the present invention includes a bin door 31, a bin door opening link 32, an attached vibrator 33, a self-excited eccentric vibrating rod 35, a hopper 36, and a feed door position sensor 311, wherein the bin door 31 is controlled by a bin The door opening link 32 is hoisted at the lower end of the hopper 36, the attached vibrator 33 is installed on one side of the outer wall of the hopper 36, the self-excited eccentric vibrating rod 35 is installed at the middle and lower part of the inner cavity of the hopper 36, and the feed door position sensor 311 is fixed on the The top of the door opening connecting rod 32 detects the position of the opening of the door. When stirring needs to be fed, the cylinder 321 piston rod in the door opening connecting rod 32 stretches out to open the door 31, and the attached vibrator 33 and automatic The eccentric vibrating rod 35 starts to vibrate to destroy the st...

Embodiment 3

[0040] Embodiment 3, refer to Figure 1 to Figure 7 , the mixer spraying water adding device 7 of the present invention comprises water inlet valve 71, connecting hose 72, booster pump 75, arc pipe 73, spray plate 77, metering bucket 64, replenishing water pump 642, wherein water inlet valve 71 and The metering buckets 64 are connected, and after the water inlet valve 71 is opened, the water enters the booster pump 75 through the connecting hose 72, and the pressurized high-pressure water is distributed to the spray plate 77 evenly distributed on the side of the arc tube 73 through the arc tube 73 , the high-pressure water falls into the mixing material in the form of a fine water column or mist, so that the concrete material in the mixing tank absorbs water evenly. The rest are the same as any other embodiment of the present invention or the combination of more than two embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com