Spiral pusher

A screw pusher and pusher technology, applied in the field of packaging machinery, can solve the problems of affecting the efficiency of pushing, unhygienic manual stirring, increasing labor intensity of workers, etc., and achieve the effect of high feeding efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

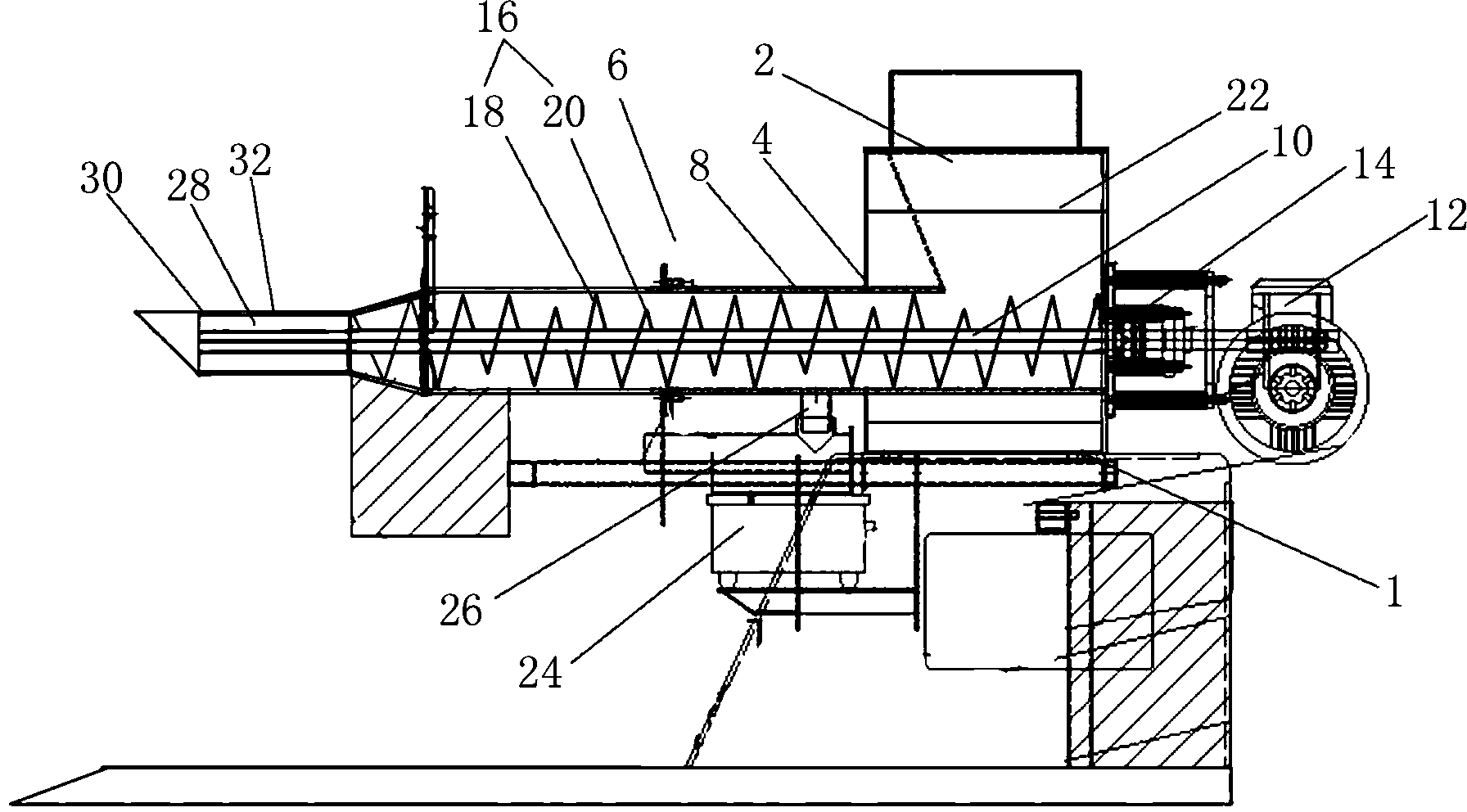

[0016] Such as figure 1 As shown, a screw pusher includes a storage bin 2 fixedly installed on a horizontal workbench 1, and an opening 4 is provided at the lower end of one side of the storage bin 2, and the setting that communicates with the interior of the storage bin 2 through the opening 4 There is a pusher 6 for pushing materials. The pusher 6 includes a hollow feeding pipe body 8, a push rod 10 which is penetrated in the feed pipe body 8 and arranged coaxially with it, and drives the push rod 10 around its own axis. The motor 12 that the line rotates, and one end that the push rod 10 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com