Internal screw quantitative feeding device

A technology of feeding device and inner screw, which is applied in explosives processing equipment, offensive equipment, explosives, etc., to improve safety and avoid bridging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

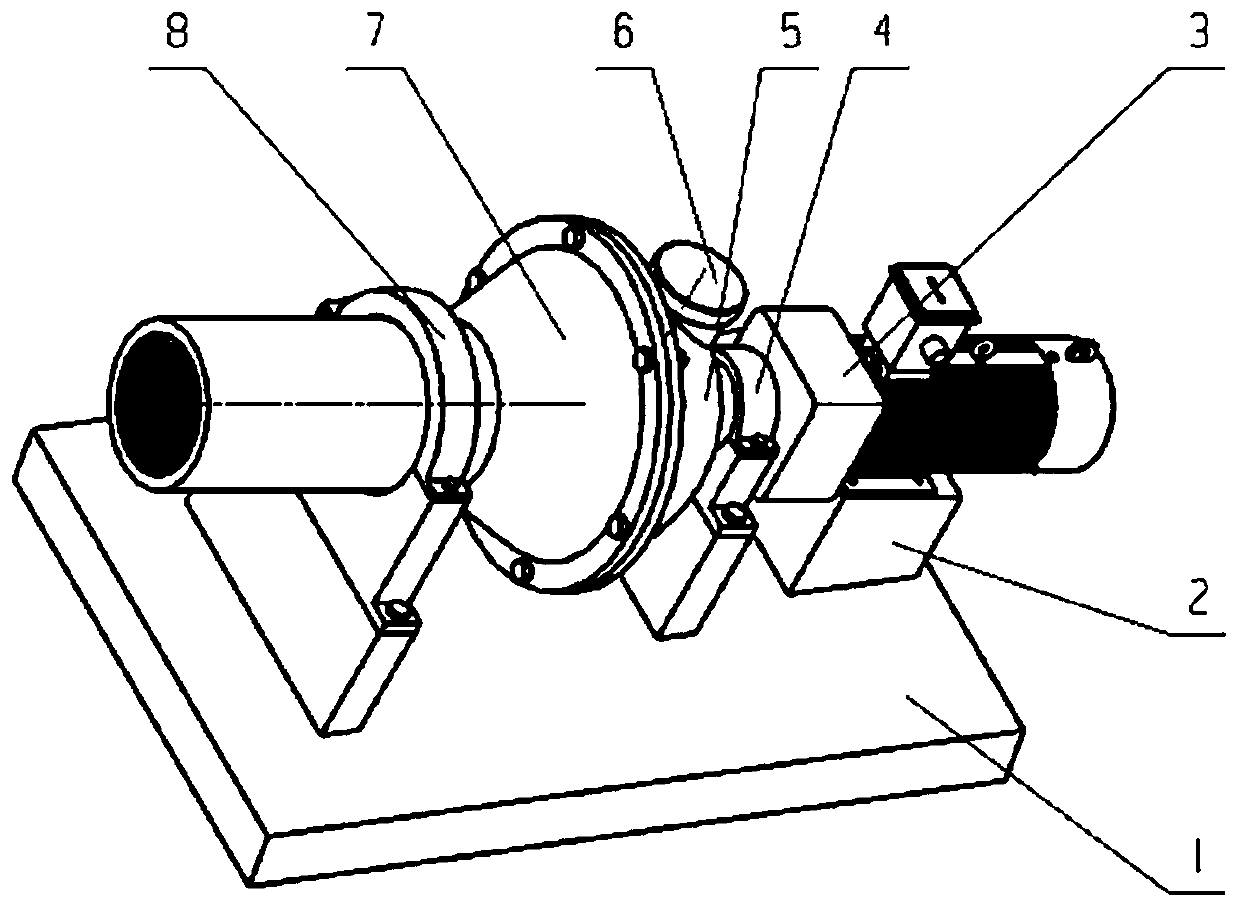

[0017] This embodiment proposes a kind of internal screw quantitative feeding device, its structure is as follows figure 1 shown. The device comprises a bracket 1, a motor mount 2, a motor and a reducer 3, a rear bearing 4, a silo 5, a silo cover 6, a barrel 7, a front bearing 8 and a baffle plate 9.

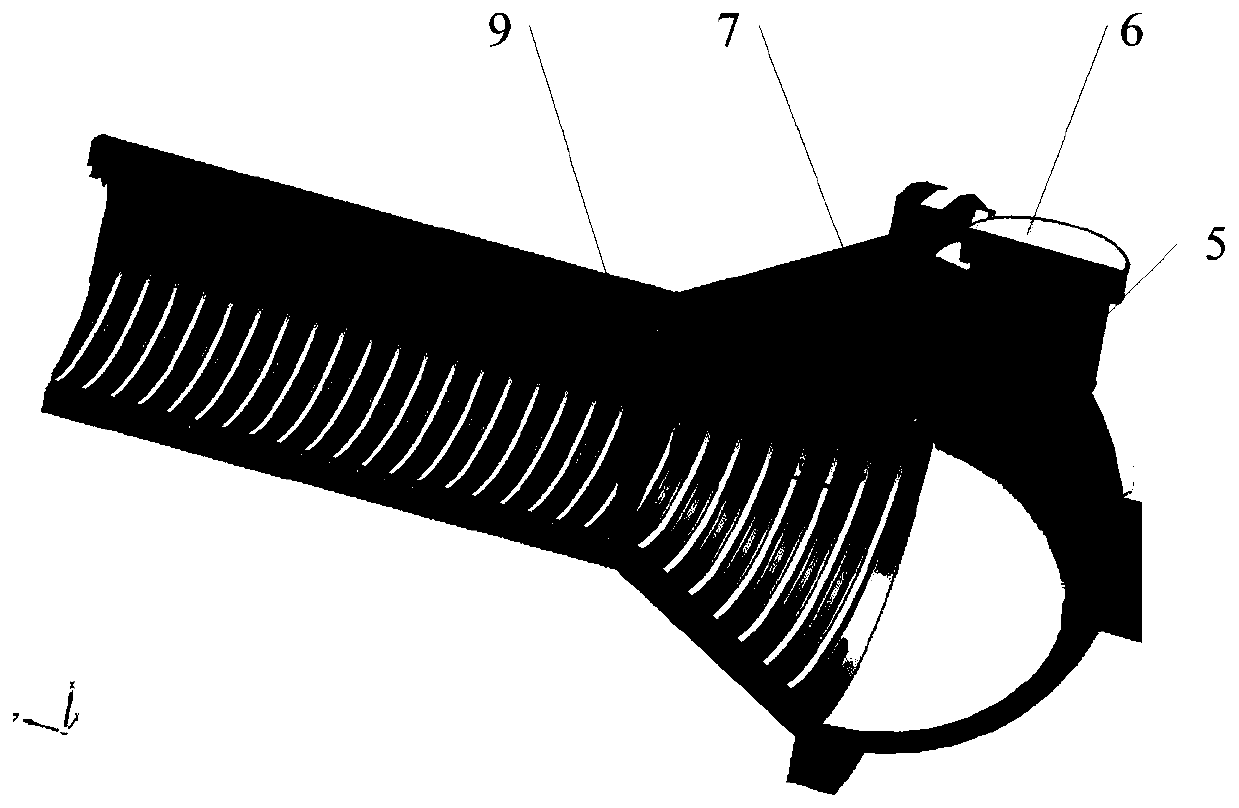

[0018] Wherein, the barrel 7 is divided into a cone section and a straight section, and the inner wall of the barrel 7 is provided with a plurality of spiral grooves. The cone section of the barrel 7 is fixedly connected with the feed bin 5 through bolts, and the feed bin 5 is installed on the support 1 through the rear bearing 4; the straight section of the feed barrel 7 is installed on the support 1 through the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com