Novel phenol-free technology for producing basic violet 5BN

An alkaline and high-tech technology, which is applied in the field of new phenol-free production of Basic Violet 5BN, can solve the problems of not being suitable for large-scale industrial production, corrosion of phenol mucosa, and material clumping, so as to solve the problem of material clumping in the process of alkalization and heating up , Increase the concentration of active oxygen and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

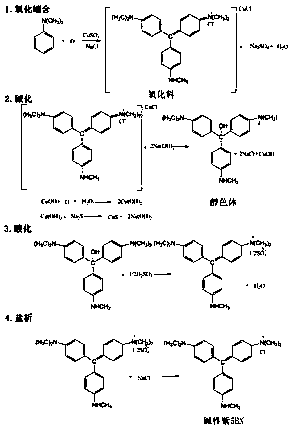

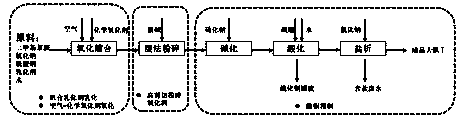

Method used

Image

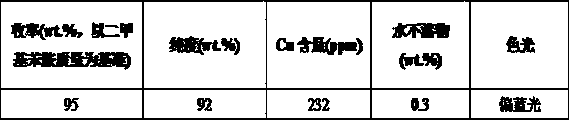

Examples

Embodiment 1

[0036] First add water, NaCl, copper sulfate pentahydrate to the oxidation pot, start the equipment and add N,N-dimethylaniline after stirring evenly, add combined emulsifier (OP-9 and dodecyltrimethylammonium chloride combined and into), stir for 2 hours until the material is in the form of a uniform emulsion, heat up to 70°C, blow in air and start to add sodium chlorate solution dropwise, the dropwise addition is completed within 4 hours, and the reaction is stopped until the color of the material is golden yellow and the pre-cooling becomes brittle. The total reaction time was close to 23h.

[0037] After the reaction is over, the oxidizing material is cooled to room temperature and put into a high-shear wet crushing kettle with liquid caustic soda (mass concentration: 30%), crushed for 4 hours until the particles are crushed without visible gold, and the powder is fine within 4 hours. The temperature is raised to 95°C (the first hour is raised to 60°C, the second hour is r...

Embodiment 2

[0041] First add water, NaCl, copper sulfate pentahydrate to the oxidation pot, start the equipment and stir evenly, add N,N-dimethylaniline, add combined emulsifier (OP-10 and cetyltrimethylammonium chloride combined and into), stir for 2 hours until the material is in the form of a uniform emulsion, heat up to 70°C, blow in air and start to add sodium chlorate solution dropwise, the dropwise addition is completed within 4 hours, and the reaction is stopped until the color of the material is golden yellow and the pre-cooling becomes brittle. The total reaction time is close to 20h.

[0042] After the reaction is over, the oxidizing material is cooled to room temperature and put into a high-shear wet crushing kettle with liquid caustic soda (mass concentration: 30%), crushed for 4 hours until the particles are crushed without visible gold, and the powder is fine within 4 hours. The temperature is raised to 95°C (the first hour is raised to 60°C, the second hour is raised to 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com