Expanded perlite insulation board automatic production device

A technology of expanded perlite and production equipment, which is applied in the direction of clay preparation equipment, mixing operation control, ceramic molding machine, etc., can solve the problems of inability to realize assembly line production, low efficiency, high cost, etc., save manpower and investment, and solve the problem of material structure group, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

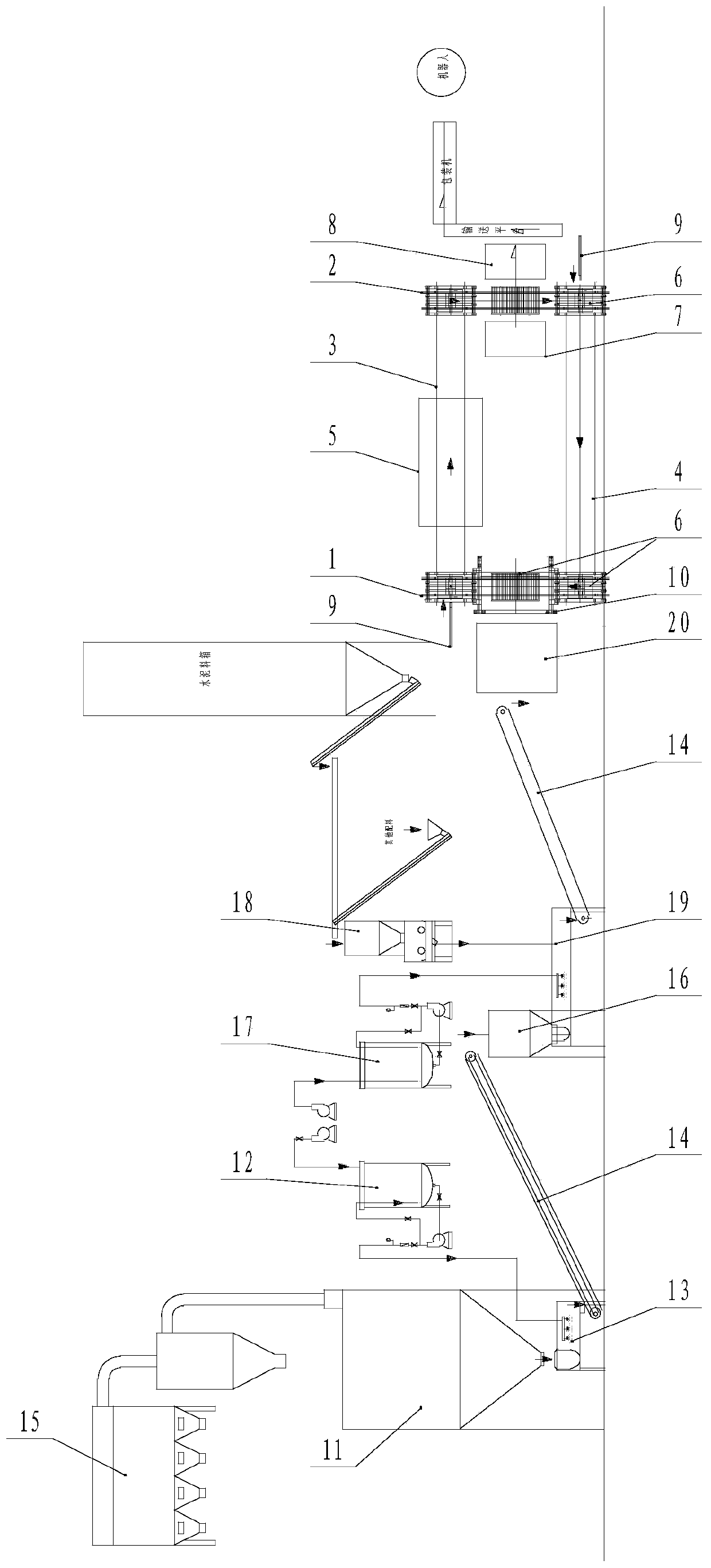

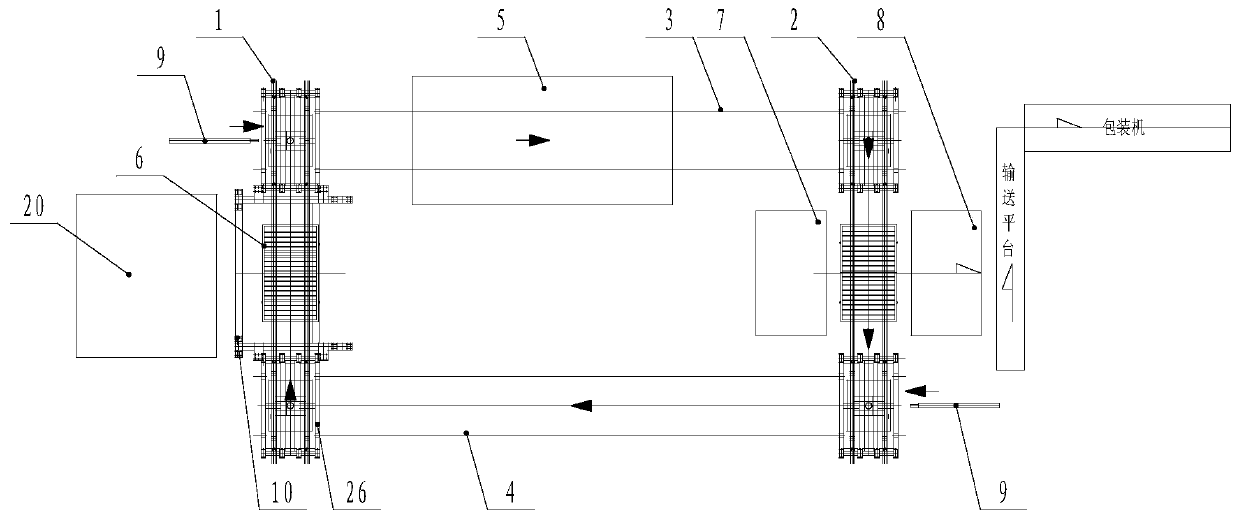

[0027] Expanded perlite insulation board automatic production device of the present invention, such as figure 1 As mentioned above, it includes a material mixing device, a pressing plate device, a drying device and a packaging platform. The material mixing device is used to mix the materials uniformly and then transported to the pressing plate device. The pressing plate device is used to press the mixed material into a heat preservation board. Dry the thermal insulation board, and the dried thermal insulation board enters the packaging platform through the conveyor for packaging. After the packed thermal insulation board is transported to the stacking robot for stacking, the forklift stacks the stacked forks to the designated place and waits for Loading and shipping sales.

[0028] The material mixing device includes a primary material mixing device and a secondary material mixing device; the primary material mixing device includes an expanded perlite material tank 11, a hot g...

Embodiment 2

[0033] This embodiment is the same as Embodiment 1 except the following features:

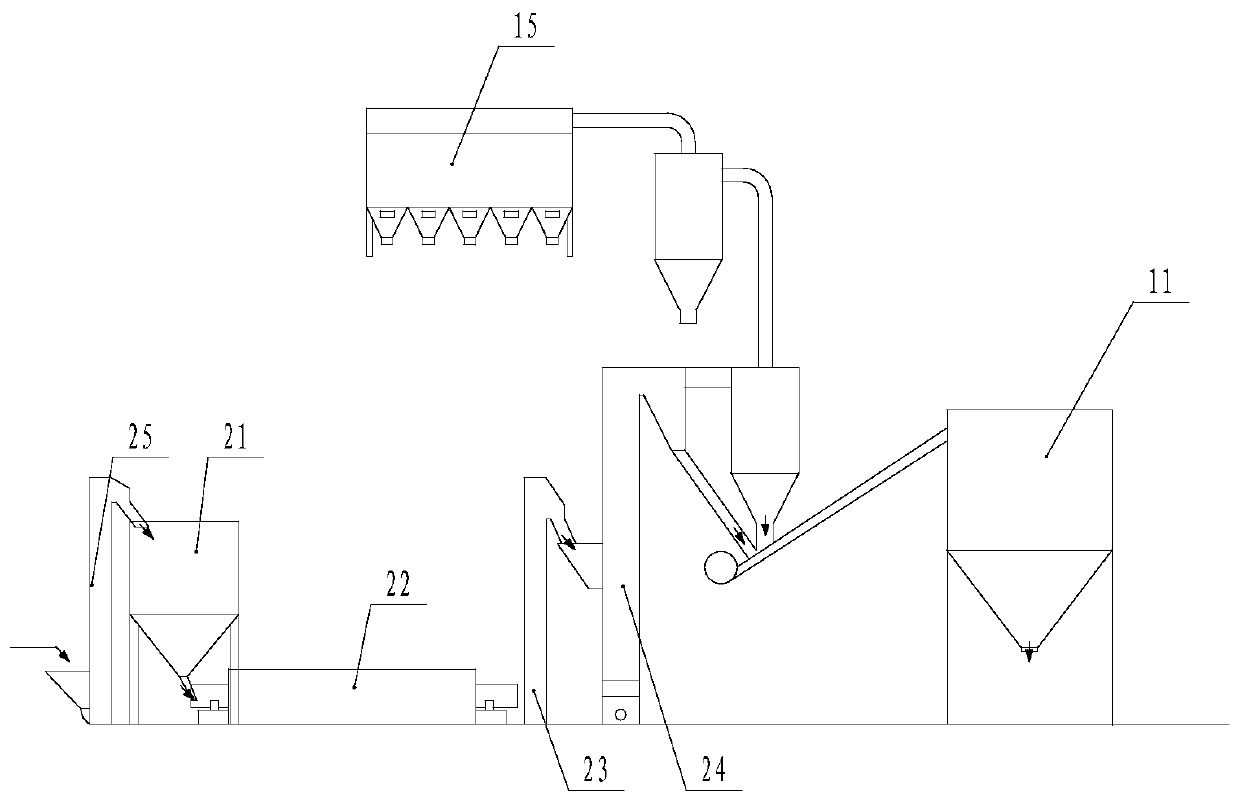

[0034] There is also expanded perlite pre-treatment equipment before the primary material mixing device, such as image 3 As shown, the pre-processing equipment includes two bucket elevators, preheating hopper 21, preheating furnace 22, puffing furnace 24 and pulse dust collector 15: the outlet of bucket elevator I25 is preheating hopper 21, preheating hopper The outlet of the heating hopper 21 is connected to the preheating furnace 22, the outlet of the preheating furnace 22 is connected to the bucket elevator II 23, the outlet of the bucket elevator II 23 is connected to the puffing furnace 24, and the outlet of the puffing furnace 24 passes through the conveying device ( Such as air blowing device) to the expanded perlite material box 11 of the primary material mixing device, and the top of the puffing furnace 24 is provided with a pulse dust collector 15 .

[0035] The drying device also i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com