Device and method for cooling high-heat-flux device by using magnetic field

A technology of heat flux density and heating device, which is used in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. and other problems, to achieve the effect of novel driving mode, large electromagnetic force and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

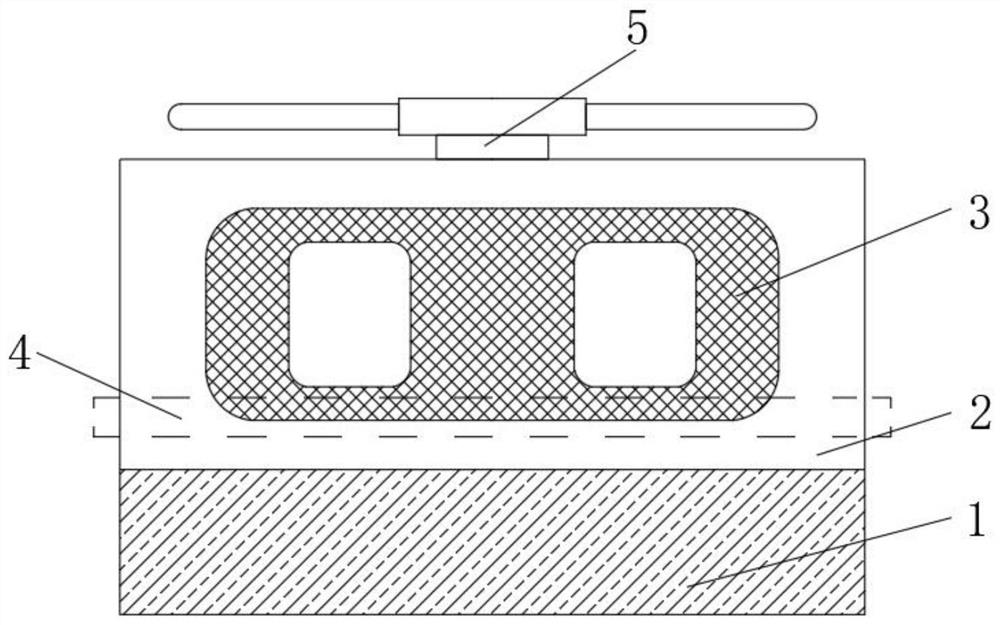

[0026] Embodiment one, by figure 1 Given, the present invention includes a heating device 1, a copper metal 2 is installed on the top of the heating device 1, a conductive fluid circuit 3 is provided on the surface of the copper metal 2, and a magnetic field coverage area 4 is provided on the surface of the copper metal 2 at the bottom of the conductive fluid circuit 3 , the top of the red copper metal 2 is equipped with a cooling fan 5.

Embodiment 2

[0027] Embodiment 2, on the basis of Embodiment 1, the material of the red copper metal 2 is a red copper block, and the arrangement of the red copper metal 2 enables it to transfer heat in the device by way of heat conduction.

Embodiment 3

[0028] Embodiment three, on the basis of embodiment one, conductive fluid circuit 3 comprises conductive fluid and liquid metal or conductive fluid and conductive metal powder, through the setting of conductive fluid circuit 3, the liquid metal that it flows such as gallium, gallium alloy, mercury , potassium-sodium alloy, etc., conductive fluid or conductive metal powder, in the high temperature zone generated by the thermal power of the device with large heat flux density and the low temperature zone generated by the rotation and cooling of the cooling fan 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com