Manufacturing method of acrolein

A manufacturing method and technology of acrolein, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve problems such as increased equipment costs, reduce operating costs, reduce equipment costs, and reduce the number of machines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

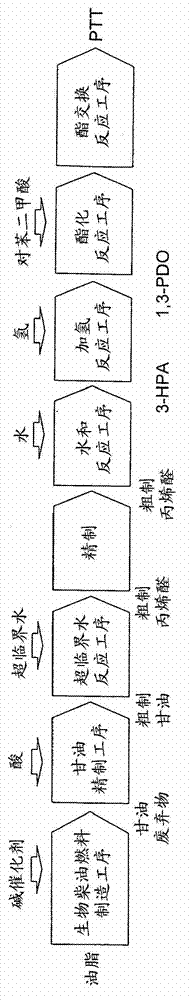

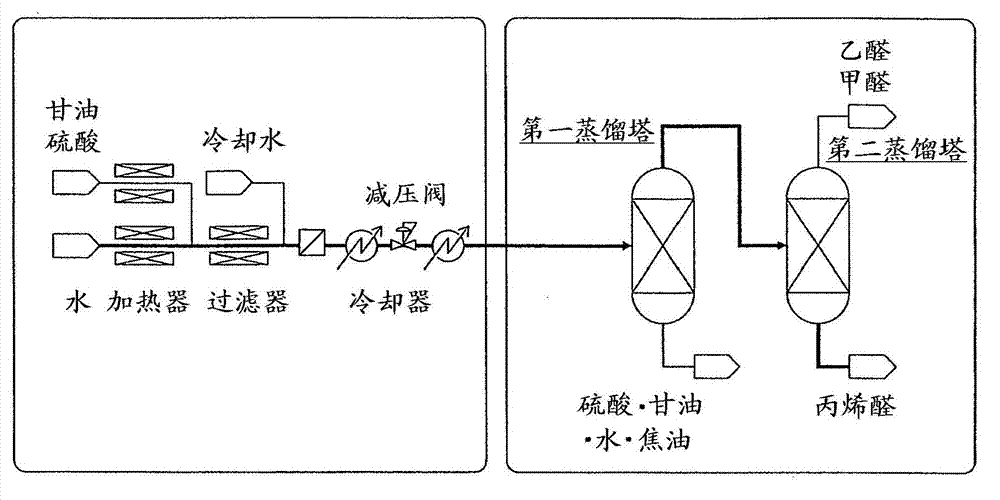

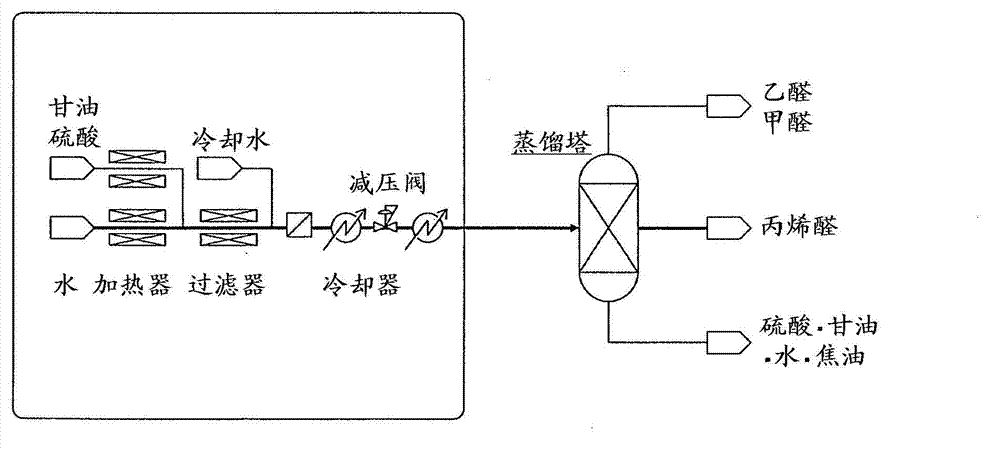

[0045] Hereinafter, the process of the present invention for synthesizing acrolein from glycerin with supercritical water and distilling and refining it will be described with reference to the drawings, but the present invention is not limited to these embodiments.

[0046] First, according to Figure 4 , the process of synthesizing acrolein from purified glycerin by supercritical water treatment will be described. The purified glycerin, concentrated sulfuric acid, and water are supplied from respective headers (refined glycerin header 120 , sulfuric acid header 121 , and water header 122 ) to the raw material tank 123 , and are adjusted to a predetermined concentration by stirring and mixing. The raw material is supplied as a liquid at 35 MPa by the raw material high-pressure pump 125 , and the temperature is raised to 250° C. by the raw material preheater 126 . In addition, the ultrapure water stored in the water tank 111 is supplied by a supercritical water high-pressure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com